DIGISPENSE 3020 CONTROLLER MODULE Page 3-2

7 April, 2011 IVEK Corp. P03L011B

Table Of Contents - Cont.

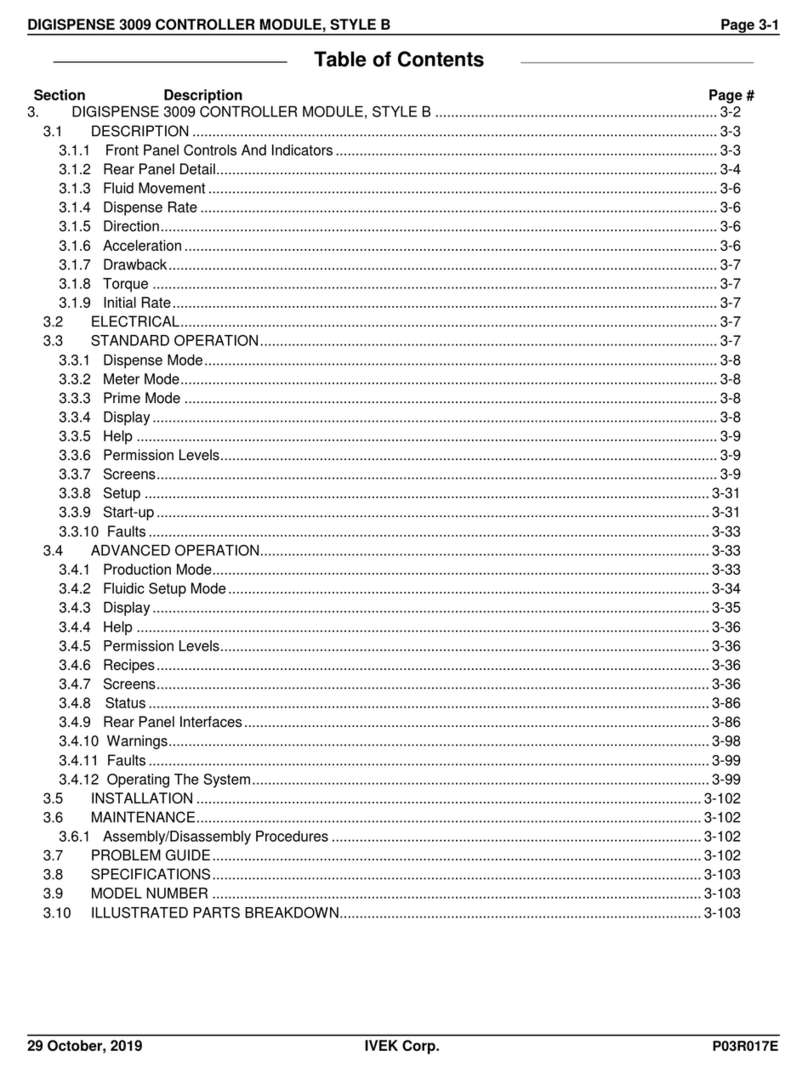

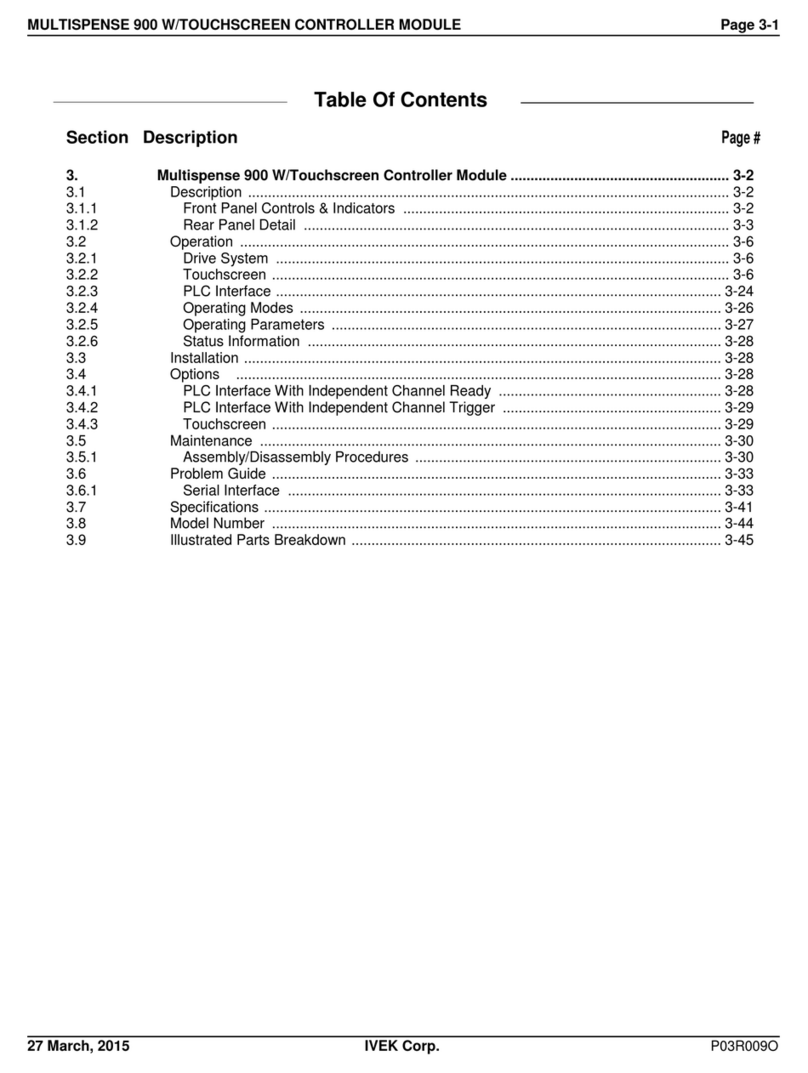

Section Description

Page #

3.2.10 Faults .................................................................................................................... 3-35

3.3 Advanced Operation .............................................................................................3-35

3.3.1 Production Mode ...............................................................................................3-35

3.3.1.1 Dispense Mode ..............................................................................................3-36

3.3.1.2 Dispense Minimum Chamber Volume................................................................3-36

3.3.1.3 Dispense Multichamber ...................................................................................3-36

3.3.1.4 Meter.............................................................................................................3-36

3.3.1.5 Meter Multichamber ........................................................................................3-37

3.3.1.6 Extra Production Mode Settings........................................................................3-37

3.3.2 Fluidic Setup Mode............................................................................................3-38

3.3.2.1 Prime Mode ...................................................................................................3-38

3.3.2.2 Bubble Clear Mode .........................................................................................3-38

3.3.2.3 Agitate Mode..................................................................................................3-39

3.3.3 Port Parking (PARK PORT) ................................................................................3-39

3.3.4 Display.............................................................................................................3-39

3.3.5 Help.................................................................................................................3-40

3.3.6 Permission Levels..............................................................................................3-40

3.3.7 Recipes............................................................................................................3-40

3.3.8 Screens............................................................................................................3-40

3.3.8.1 Power Up Screen............................................................................................3-43

3.3.8.2 Prime Screen.................................................................................................3-45

3.3.8.3 Bubble Clear Screen.......................................................................................3-47

3.3.8.4 Agitate Screen................................................................................................3-49

3.3.8.5 Dispense Screen ............................................................................................3-51

3.3.8.6 Dispense Mult Screen .....................................................................................3-53

3.3.8.7 Dispense MCV Screen ....................................................................................3-55

3.3.8.8 Meter Screen .................................................................................................3-57

3.3.8.9 Meter Mult Screen...........................................................................................3-59

3.3.8.10 Setup A Screen ..............................................................................................3-61

3.3.8.11 Setup B Screen ..............................................................................................3-63

3.3.8.12 Setup C Screen..............................................................................................3-65

3.3.8.13 Drawback Screen ...........................................................................................3-67

3.3.8.14 Auto Trig Screen.............................................................................................3-69

3.3.8.15 Prod Dwells Screen.........................................................................................3-71

3.3.8.16 Encoder Screen..............................................................................................3-73

3.3.8.17 System Info Screen.........................................................................................3-75

3.3.8.18 Select New Value and Enter New Value Screens................................................3-77

3.3.8.19 Change Permission Screen..............................................................................3-79

3.3.8.20 Change Password and Enter New Password Screens.........................................3-81

3.3.8.21 Contrast Adjust Screen....................................................................................3-83

3.3.8.22 Recipe Screen................................................................................................3-85

3.3.7.23 Warning Recipe Exists Screen .........................................................................3-85

3.3.8.24 Clear Totalizer Screen.....................................................................................3-87

3.3.8.25 Reset Parameter Warning Screen.....................................................................3-87

3.3.8.26 Fault Screen...................................................................................................3-89

3.3.8.27 I/O Test Screen..............................................................................................3-91

3.3.9 Status...............................................................................................................3-93

3.3.10 Rear Panel Interfaces.........................................................................................3-93

3.3.10.1 CC TRIG Terminal Strip...................................................................................3-93

3.3.10.2 AUX OUT Terminal Strip..................................................................................3-93