Shuang Ri SR258 User manual

·

Operation Manual of the Intelligent

Controller SR258

for Split Pressurized Solar Hot Water System

Please read the instruction carefully before operation!

Manual of SR258 intelligent controller

1

Contents

1. Safety information................................................................................................. 3

1.1 Installation and commissioning ............................................................................... 3

1.2 About this manual................................................................................................... 3

1.3 Liability waiver........................................................................................................ 3

1.4 Important information.............................................................................................. 4

1.5 Signal description................................................................................................... 4

1.6 Button and HMI description..................................................................................... 4

2. Overview.................................................................................................................. 5

2.1 Technical data........................................................................................................ 5

2.2 Delivery list............................................................................................................. 6

3. Installation................................................................................................................ 6

3.1 Mounting controller................................................................................................. 6

3.2 Wiring connection................................................................................................... 7

3.3 Terminal connection................................................................................................ 7

3.3.1 Electrical heating 1500W version terminal ports and wring................................... 7

3.3.1 Electrical heating 3000W version terminal ports and wring................................... 8

3.4 Connection with high efficiency pump................................................................... 10

4. System description (Standard solar system with 1 tank, 1 collector field).................11

5. Function’s parameters and options ......................................................................... 12

5.1 Overview of menu structure.................................................................................. 12

5.2 Menu operation description................................................................................... 12

5.3 Value checking..................................................................................................... 13

6. Functions operation and parameters setting (for user)............................................ 14

6.1 CLK Time setup.................................................................................................... 14

6.2 THET Timing heating............................................................................................ 14

6.3 CIRC DHWcircuit pump controlled by temperature in three time - sections / flow

switcher...................................................................................................................... 17

7. Function operation and parameter setup (engineer)................................................ 23

7.1PWD Password ..................................................................................................... 23

7.2 LOAD tank heating............................................................................................... 23

7.3 COL Collector function.......................................................................................... 26

7.4 PUMP Pump R1 control mode.............................................................................. 31

Manual of SR258 intelligent controller

2

7.5 COOL Cooling function......................................................................................... 34

7.6 AUXAuxiliary function........................................................................................... 38

7.7 MAN Manual operation......................................................................................... 42

7.8 BLPR Blocking protection..................................................................................... 43

7.9 OTDI Thermal Disinfection function ...................................................................... 43

7.10 FSFlowrate monitoring and pump dry running protection .................................. 45

7.11 UNIT C-F Switch................................................................................................. 46

7.12 RET Reset.......................................................................................................... 46

7.13 PASS Password setup........................................................................................ 47

7.14M.H Manual heating ............................................................................................ 48

7.15 Holiday function.................................................................................................. 48

8. Protection function.................................................................................................. 49

8.1 Memory function during power failure................................................................... 49

8.2 Screen protection................................................................................................. 49

8.3 Trouble checking.................................................................................................. 49

9. Quality Guarantee.................................................................................................. 50

10. Accessories.......................................................................................................... 51

Manual of SR258 intelligent controller

3

1. Safety information

1.1 Installation and commissioning

When laying wires, please ensure that no damage occurs to any of the constructional

fire safety measures presented in the building.

The controller must not be installed in rooms where easily inflammable gas mixtures are

present or may occur.

The permissible environmental conditions can’t be exceeded at the site of installation.

Before connecting the device, make sure that the energy supply matches the

specifications that the controller requires.

All devices connected to the controller must be conformed to the technical specifications

of the controller.

All operations on an open controller are only to be conducted cleared from the power

supply. All safety regulations for working on the power supply are valid.

Connecting and /or all operations that require opening the collector (e.g. changing the

fuse) are only conducted by specialists.

1.2 About this manual

This manual describes the mounting, functions and operation of a solar controller used for a

solar hot water system, for mounting of other devices of a completed solar hot water system

like solar collector, pump station and storage, please is sure to observe the appropriate

installation instructions provided by each manufacturer. Mounting, wire connecting,

commissioning and maintenance of this controller may only be performed by the trained

professional person; the professional person should be familiar with this manual and follow

the instructions contained herein.

1.3 Liability waiver

The manufacturer can’t monitor the compliance with thes e instructions or the circumstances

and methods used for installation, operation, utilization and maintenance of this controller.

Improper installation can cause damages to material and person. This is the reason why we

do not take over the responsibility and liability for losses, damages or cost that might arise

due to improper installation, operation or wrong utilization and maintenance or that occurs in

some connection with the aforementioned. Moreover we do not take over liability for patent

infringements or infringements –occurring in connection with the use of this controller on the

third parties rights. The manufacturer preserves the right to put changes to product, technical

data or installation and operation instructions without prior notice. As soon as it becomes

Manual of SR258 intelligent controller

4

evident that safe operation is no longer possible (e.g. visible damage). Please immediate

take the device out of operation. Note: ensure that the device can’t be accidentally placed

into operation.

1.4 Important information

We have carefully checked the text and pictures of this manual and provided the best of our

knowledge and ideas, however inevitable errors maybe exist. Please note that we cannot

guarantee that this manual is given in the integrity of image and text, incorrect, incomplete

and erroneous information and the resulting damage we do not take responsibility.

1.5 Signal description

Safety indication: Safety indications in the text are marked with a warning triangle.

They indicate measures which can lead to injury of person or safety risks.

►Operation steps: small triangle “►”is used to indicate operation step.

Note: Contains important information about operation or functions.

1.6 Button and HMI description

Controller is operated with the 6 buttons on the right side of the screen

“ " holiday button

“M.H” button: manual heating

“SET” button: confirm / selection

“▲” up button: increase the value

“▼” down button: reduce the value

“ESC" button return/ exit : return to previous menu

Manual of SR258 intelligent controller

5

Status description

Code

Lighting

Blinking

Exceed the maximum temperature of storage

SMX

Running of storage emergency shutdown

function

Running of collector emergency shutdown

function

CEM

+

Collector Cooling

OCCO

Tank Cooling

OSTC

System Cooling

OSYC

Start of anti-freezing function

OCFR

Running of anti-freezing function

OCFR

Collector minimum temperature

OCMI

Slow blink

2. Overview

2.1 Technical data

Inputs: 1 * PT1000 temperature sensor input

4 * NTC10K, B=3950 temperature sensor input

1 * FRT rotary vane type electronic flow meter

Outputs: 2* Electromagnetic relay(R2/R3), maximum current 1A

1* Semiconductor relay(R1), maximum current 1A

1* Electromagnetic relay(HR), maximum current 10A/15A

1 * PWM variable frequency output (on/off switchable, 0-10V)

Functions: operating hours counter, tube collector function, thermostat function, pump

speed control, external heat exchange, adjustable system parameters and optional

functions (menu-driven), balance and diagnostics

Power supply: 100…240V ~(50…60Hz)

Rated impulse voltage: 2.5KV

Housing:Plastic ABS

Mounting:Wall mounting

Operation: 6 push buttons at the front cover

Protection type: IP41

Ambient temperature: 0...40 °C

Dimensions: 187*128*46mm

Note: there are 4 inputs for NTC10K, B=3950 temperature sensor, but only 2 sensors

Manual of SR258 intelligent controller

6

are included in standard delivery list, the other two should be purchased separately by

customer if necessary.

2.2 Delivery list

SR258 1500W version

Delivery list

SR258 3000W version

Delivery list

1 * SR258 controller

1 * SR258 controller

1 * Accessory bag

1 * Accessory bag

1 * User manual

1 * User manual

1 * PT1000 temperature sensor

(φ6*50mm,cable length 1.5meter)

1 * PT1000 temperature sensor

(φ6*50mm,cable length 1.5meter)

2 * NTC10K temperature sensor

(φ6*50mm,cable length 3meter)

2 * NTC10K temperature sensor

(φ6*50mm,cable length 3meter)

1* Power cord

No power cord delivery

(please prepare 2.5mm2 wiring

directly)

3. Installation

Note: The unit must only be located in the dry interior rooms. Please separate routing

of sensor wires and mains wires. Make sure the controller as well as the system is not

exposed to strong electromagnetic fields.

3.1 Mounting controller

Follow the below steps to mount the controller on the

wall.

Unscrew the crosshead screw from the cover and

remove it along with the cover from the housing.

Mark the upper fastening point ①on the wall.

Drill and fasten the enclosed wall plug and screw

leaving the head protruding.

Hang the housing from the upper fastening point

and mark the lower fastening points ②.

Drill and insert lower wall plugs.

Fasten the housing to the wall with the lower fastening screw and tighten.

Carry out the electrical wiring in accordance with the terminal allocation

Manual of SR258 intelligent controller

7

Put the cover on the housing. Attach with the fastening screw.

3.2 Wiring connection

According to the way of installation, wire can be connected from hole A on the bottom plate

or from hole B, using a suitable tool (like knife) to cut the plastic ofA.

Note: wires must be fastened by fixing clamps on the position C.

3.3 Terminal connection

3.3.1 Electrical heating 1500W version terminal ports and wring

Note: before opening the housing! Always disconnect the controller from power

supply and obey the local electrical supply regulation.

Input ports

T1: PT1000 temperature sensor, for measuring the temperature of collector and thermal

energy calculation.

T2 ~T5: NTC10K, B=3950 temperature sensor, for measuring temperature of tank and

pipe.

PWM1: Signal ports for high efficiency pump, detailed connection see below

FRT: For rotary vane type electronic flowmeter.

Manual of SR258 intelligent controller

8

Output ports

FU1:2A/250V fuse

10A power supply Ports L, N: for power connection, L: live wire, N: zero wire,

protective wire

Output R1: Semiconductor relays (SCR), designed for pump speed control, Max.

Current: 1A

Output R2: Electromagnetic relays, designed for on/off control of pump or 3-ways

electromagnetic valve, Max. Current: 1A

Output R3: Electromagnetic relays, designed for on/off control of pump or 3-ways

electromagnetic valve, Max. Current: 1A

Output (1500W) HR: Electromagnetic relays, designed for on/off control of after

heating/thermostat function, Max. Current: 10A

1).When power supply AC230V output HR is 1500W.

2).When power supply AC110V output HR is 750W.

3.3.1 Electrical heating 3000W version terminal ports and wring

Input ports

T1: PT1000 temperature sensor, for measuring the temperature of collector and thermal

energy calculation.

T2 ~T5: NTC10K, B=3950 temperature sensor, for measuring temperature of tank and

pipe.

PWM1: Signal ports for high efficiency pump, detailed connection see below

FRT: For rotary vane type electronic flowmeter.

Output ports

15A power supply Ports L, N: for power connection, L: live wire, N: zero wire,

Manual of SR258 intelligent controller

9

protective wire

Output R1: Semiconductor relays (SCR), designed for pump speed control, Max.

Current: 1A

Output R2: Electromagnetic relays, designed for on/off control of pump or 3-ways

electromagnetic valve, Max. Current: 1A

Output R3: Electromagnetic relays, designed for on/off control of pump or 3-ways

electromagnetic valve, Max. Current: 1A

Output (3000W) HR: Electromagnetic relays, designed for on/off control of after

heating/thermostat function, Max. Current: 15A

1).When power supply AC230V output HR is 3000W.

2).When power supply AC110V output HR is 1500W.

Advice regarding the installation of temperature sensors:

Only original factory equipped Pt1000 temperature sensors are approved for using with

the controller, it is equipped with 1.5m silicon cable and suitable for all weather

conditions, the cable is temperature resistant up to 280oC, connect the temperature

sensors to the corresponding terminals with either polarity.

Only original factory equipped NTC10K,B=3950 temperature sensors are approved for

using with tank and pipe, it is equipped with 3m PVC cable, and the cable is

temperature resistant up to 105oC, connect the temperature sensors to the

corresponding terminals with either polarity.

All sensor cables carry low voltage, and to avoid inductive effects, must not be laid close

to 230 volt or 400 volt cables (minimum separation of 100mm).

If external inductive effects are existed, e.g. from heavy current cables, overhead train

cables, transformer substations, radio and television devices, amateur radio stations,

microwave devices etc., then the cables to the sensors must be adequately shielded.

Sensor cables may be extended to a maximum length of ca. 100 meter, when cable’s

length is up to 50m, and then 0.75mm2cable should be used. When cable’s length is up

to 100m, and then 1.5mm2cables should be used.

Manual of SR258 intelligent controller

10

3.4 Connection with high efficiency pump

Connecting the signal wire from the high-efficiency pump

Signal wire 1 from the high-efficiency pump is connected to GND port of controller

Signal wire 2 from the high-efficiency pump is connected to PWM port of controller

Signal wire 3 from the high-efficiency pump is not connected to the controller

Some pumps connections are available as above, for example:

Wilo Yonos PARA ST15/7.0 PWM2 M

Grundfos UPM3 SOLAR 15-75 130 CZA

Note:

1. High-efficiency pump with 0-10V signal only has 2 signal wires, connected to the

corresponding port GND, PWM1 of controller.

2. Blue wire not always represent for “GND”and brown wire not always represent for

“PWM”.

”PWM”from pump must be match for “PWM”from controller.

”GND”from pump must be match for “GND”from controller.

Manual of SR258 intelligent controller

11

4. System description (Standard solar system with 1 tank, 1 collector field)

Description:

The controller calculates the temperature difference

between collector sensor T1 and tank sensor T2. If the

difference is larger than or identical to the adjusted

switch-on temperature difference, the solar circulation

pump (R1) will be switched on and the tank will be

loaded until the switch-off temperature difference or the

maximum tank temperature is reached.

Sensor

Description

Relay

Description

T1

Temperature of collector Pt1000

R1

Solar circulation pump

T2

Temperature of tank base NTC10K

HR

Back up heating

T3

Temperature of tank upper

( selectable) NTC10K

Auxiliary function

Code

Des cription

Object sensor

Object rela ys

CI RC

DHW circulation (controlled by

temperature or flow impulse)

T4/flow switcher

(connected on T4

port)

R2

OHDP

Thermal transfer -by external radiator

R2/R3( selectable)

TIME

Timer functi on

R3

AH

Thermostat function

T2/T3/T5( selectable)

R3

Note:

Sometime, for one selected function, it needs an extra input to connect temperature sensor

or an extra output to control pump or electromagnetic valve, in the case all inputs and

outputs are in using, and then this selected function will not be triggered even when you have

activated it. Controller can distinguish it automatically and switch-off this function.

1. When one of these functions (TIME, AH) is activated, and then the other one will be

Manual of SR258 intelligent controller

12

deactivated automatically.

2. After CIRC function is activated, if OHDP function is activated also and R2 output is

selected for it, and then CIRC will be deactivated automatically.

5. Function’ s parameters and options

5.1 Overview of menu structure

5.2 Menu operation description

Access main menu

►Press “SET” button to access main menu

Manual of SR258 intelligent controller

13

►Press “▲/▼” to select menu

►Press “SET” button to enter the submenu

Access submenu

►After selecting main menu, then press “SET” button to access submenu

►Press “▲/▼” button to select submenu,

►Press “SET” button to enter the value adjust interface or selection function (select

ON/OFF)

►Press “▲/▼” to adjust value

►Press “SET” or ”ESC”to confirm the value you set

►Press “ESC” to exit the submenu

Note: Enter the menu adjustment interface, if you don’t press any button in 3 minutes,

screen will exit the adjustment and return to the main interface.

5.3 Value checking

At the normal operation mode, press “▲/▼” button, you can view the temperature of

collector and tank, pump speed(n1%), flow rate(L/M), countdown time of disinfection function,

auxiliary function. The controller operation time(DAYS),and firmware version(SW).

Note:

1. For the countdown time of disinfection, auxiliary function, you can only check them when

the function is activated in the parameter menus.

2. At the value check interface, if you don’t press any button within 3 minutes, screen will exit

the check interface and return to the main interface.

Manual of SR258 intelligent controller

14

6. Functions operation and parameters setting (for user)

6.1 CLK Time setup

Menu structure

►Press “SET” button, select CLK menu

►Press “SET” button, hour “00” blinks on the display.

►Press “▲/▼” button to adjust hour

►Press “SET” button, minute time “00” blinks on the display

►Press “▲/▼” button to adjust minute

►Press “SET” or “ESC” button to save the set value

Note: In the case power to controller is switched-off, date and time will be remembered

in controller for 36 hours.

6.2 THET Timing heating

Electrical back-up heater, gas boiler or oil boiler can be installed in the solar system to

ensure the tank’s temperature meets the required temperature, this electrical heater can be

controlled automatically by this controller, when tank temperature T3 drops below the

switch-on set point of this function, electrical heater HR is triggered to heat tank up to the

switch-off temperature, and then electrical heater HR stops working.

Note:the reference sensor T3 or T2 of this function can be selected in parameter

THTS.

It is possible to set three time sections for activating this function,

Factory default set:

The first time section: heating starts at 4:00am, stops at 5:00am, and switch on

temperature is set at 40oC, switch-off temperature is set at 50oC

The second time section: heating starts at 10:00am, stops at 10:00am

The third time section: heating starts at 17:00am, stops at 22:00am, and switch on

temperature is set at 50oC, switch-off temperature is set at 55oC

If you want to shut off one timing heating ,then you can set the turning on time and turning off

Manual of SR258 intelligent controller

15

time with a same value(for example, set second start time tA2 O at 10:00 and set the stop

time tA2 F at 10:00)

Every day three timing heating can be set, and the switch-on temperature adjustable range is

0℃~(OFF-2 oC), switch-off temperature adjustable range is (ON+2 oC) ~95 oC.

Intelligent heating mode

In the case the solar irradiation isn’t enough to heat the tank, in order to ensure the tank

temperature meets the requirement, controller will check the temperature of tank at the

specified time, if temperature doesn’t rise to the required value, and controller will trigger the

electrical heater to heat tank until its temperature rises up to the default switch-off

temperature.

Default set (not adjustable):

The first time: starts heating at 13:00 until temperature of 30 oC.

The second time: starts heating at 14:00 until temperature of 35 oC.

The third time: starts heating at 15:00 until temperature of 40 oC.

The forth time: starts heating at 16:00 until temperature of 45 oC.

The fifth time: starts heating at 17:00 until temperature of 50 oC.

Note: If customer use electrical heater as back-up, please according to the power of

electrical heater to equip corresponding safety devices like contactor and breaker with this

controller, we strongly recommend equipping with SR802 device with this controller, (SR802

detailed technical data see item 10 Accessories)

Menu structure

Main

menu

Submenu

Factory

set

Adjustable

range

Step per

adjust

Description

THET

Timing heating

THTS

S2

S2. S3

Select desired sensor for

timing heating function

(S3 for T3, S2 for T2)

SMT

ON

ON/OFF

Intelligent timing heating

Manual of SR258 intelligent controller

16

tH1O

04:00 /40℃

00:00-23:59/0 ℃

~(OFF-2℃)

0.5℃

Switch-on time and

temperature of the first

timing heating

tH1F

05:00/50℃

00:00-23:59/(ON+

2℃) ~95℃

0.5℃

Switch-off time and

temperature of the first

timing heating

t H2O

10:00/40℃

00:00-23:59/0 ℃

~(OFF-2℃)

0.5℃

Switch-on time and

temperature of the second

timing heating

tH2F

10:00/50℃

00:00-23:59/(ON+

2℃) ~95℃

0.5℃

Switch-off time and

temperature of the second

timing heating

tH3O

17:00/50℃

00:00-23:59/0 ℃

~(OFF-2℃)

0.5℃

Switch-on time and

temperature of the third

timing heating

tH3F

22:00/55℃

00:00-23:59/(ON+

2℃) ~95℃

0.5℃

Switch-off time and

temperature of the third

timing heating

Function setting:

►Press “SE T” button to access main menu, and press “▲” to select

THEH timing heating main menu.

►Press “SET” button to set parameter, select the reference sensor

of tank, “THS S2” displays on the screen.

►Press “SET” button, “S2”blinks

►Press “▲/▼” button to select desired sensor (S3 for T3, S2 for T2)

►Press “SET” or “ESC” button to save the setting.

►Press “▲” button, to access intelligent heating mode, “SMT OFF”

displays on the screen

►Press “SET” button, “OFF” blinks

►Press “▲/▼” button to activate this function.

►Press “▲” button to set start time of the first time section, “tH1O 04:00” displays on the

screen

►Press “SET” button, hour time “04” blinks

►Press “▲/▼” button to adjust hour of the switch-on time

►Press “SET” button, minute time “00” blinks

►Press “▲/▼” button to adjust minute of the switch-on time

►Press “SET” button, to set the switch on temperature, “40oC” blinks

►Press “▲/▼” button to adjust the switch-on temperature.

►Press “SET” or “ESC” button to save the setting.

Manual of SR258 intelligent controller

17

►Press “▲” button to set stop time of the first time section, “tH1F 05:00” displays on the

screen

►Press “SET” button, hour time “05” blinks

►Press “▲/▼” button to adjust hour of the switch-off time

►Press “SET” button, minute time “00” blinks

►Press “▲/▼” button to adjust minute of the switch-off time

►Press “SET” button, to set the switch off temperature, “45oC” blinks

►Press “▲/▼” button to adjust the switch-off temperature.

►Press “SET” or “ESC” button to save the setting.

►Press “▲” button to access the window of the switch-on time of the second time section,

repeat above steps to set time and temperature for the second and third time section.

When heating sign blinks on the screen, it indicates that timing-heating function is

activated.

Note:

The Sign represents whether timing heating function is on or off.

1. Within the preset time section, heating sign is lighted on the screen

2. Out of the preset time section, heating sign doesn’t display on the screen.

6.3 CIRC DHWcircuit pump controlled by temperature in three time - sections / flow

switcher

Function description:

This function is designed to get warm water quickly when customer open the stopcock. In the

case stopcock is closed, hot water pipe is also used as the circuit pipe. Two hot water circuit

supply modes are available, temperature controlled mode and flow switcher controlled mode.

For using this function, an extra circuit pump R2 or a flow switcher or a temperature sensor

(mounted on the hot water return pipe (T4)) should be installed in the system.

2 control mode of DHW circuit pump are designed in this controller: temperature control in

three time sections and flow switch control in three time sections.

Note:

1. for 2 DHW circuit pump control modes, only one mode can be selected.

2. for 2 DHW control modes, three time - sections/temperature control mode and three time -

Manual of SR258 intelligent controller

18

sections /flow switcher control mode, their parameter adjust steps of two control mode are

same.

Three time - sections/ temperature control mode (tEP)

Within the time - section (default: DHW temperature is less than 40oC, DHW circuit pump is

trigger, when temperature rises to 45oC, DHW circuit pump is stopped).

Trigger on conditions of temperature controlled DHW circuit pump (STAT):

when tank temperature (T2 or T3, T3 is prior control) is 2oC higher than the

preset switch-off temperature (CYCF) of this function, DHW pump just can

be triggered.

Default time - section set:

The first time - section: start at 05:00 and stops at 07:00a.m

The second time - section: starts at 11:00 and stops at 13:00

The third time - section: starts at 17:00 and stops at 22:00 p.m.

Note: if this sensor is necessary to be installed in the system, in order to avoid the

measure error, please ensure its position is 1.5m far to the tank.

Three time - sections/ flow switcher control mode FS

Function description:

Open the stopcock, water flows through pipe, a flow signal is felt by a flow switcher which is

mounted on the cold-water pipe and sent to the controller, and then controller will trigger the

DHW circuit pump (R2) and it pumps hot water from tank to the circuit pipe. The running time

of circuit pump is adjustable, when the preset time runs out,

pump stops.

This stopcock seems like a remote controller to control the

running of circuit pump. This operation mode is an

environment-friendly, energy-saving control solution.

Open the stopcock for a shortly time, the flow switcher which is

mounted on the cold flow pipe of tank will feel the flow signal,

and then controller will trigger the circuit pump R2, and pump

will feed hot water from tank to the pipe. Then when you re-open

the stopcock, hot water flows out immediately. Once the pump’s running time finishes, then

pump is stopped. When hot water is not used, to avoid the heat releasing through pipe due to

the running of circuit pump, controller will stop the pump after the pre-set running time. To

avoid the pump being re-triggered just after it stopped, parameter “rest time” is used for this

control.

Open the stopcock within a pre-set time - section, pump running as the default design: pump

running for every three minutes and then rest for 15minutes (the adjustable range of the

running time is 1-30 MIN and the rest time is 0-60MIN

Manual of SR258 intelligent controller

19

Note:

Installed a check valve on the inlet pipe of circuit pump to avoid the water which

is from tank mixing with water from circuit pipe.

If the stop time is set with value 0 minute, then when flow switcher feels the flow

and thus to trigger the pump, pump will run for the whole time - section. And when the

stopcock is closed, pump is stopped automatically.

Default time - section set:

The first time - section: start at 05:00 and stops at 07:00a.m

The second time - section: starts at 11:00 and stops at 13:00

The third time - section: starts at 17:00 and stops at 22:00 p.m.

Flow switch fitting:

Material of fitting: brass

House: plastic

Connection: G3/4

Reed of flow switch: Max 300V DC/1A

Note:

1. Note the flow direction indicated on the flow switch!

2. Lead the wires from flow switcher to input ports of controller, no polarity required.

3. Flow switch is not included in the delivery list of this controller, please buy it

separately.

Note:

1. Three time - sections/ flow switcher control mode, only one of two modes is available

in same time. It’s impossible activate the two modes at the same time.

2.If this sensor is necessary to be installed in the system, in order to avoid the measure

error, please ensure its position is 1.5m far to the tank

3. three time - sections/temperature control mode and three time - sections /flow switcher

control mode, their parameter adjust steps of two control mode are same

Table of contents

Other Shuang Ri Controllers manuals

Popular Controllers manuals by other brands

Asco

Asco WSDU-M Series Installation and maintenance instructions

Johnson Controls

Johnson Controls EDA-8000 Product/Technical Bulletin

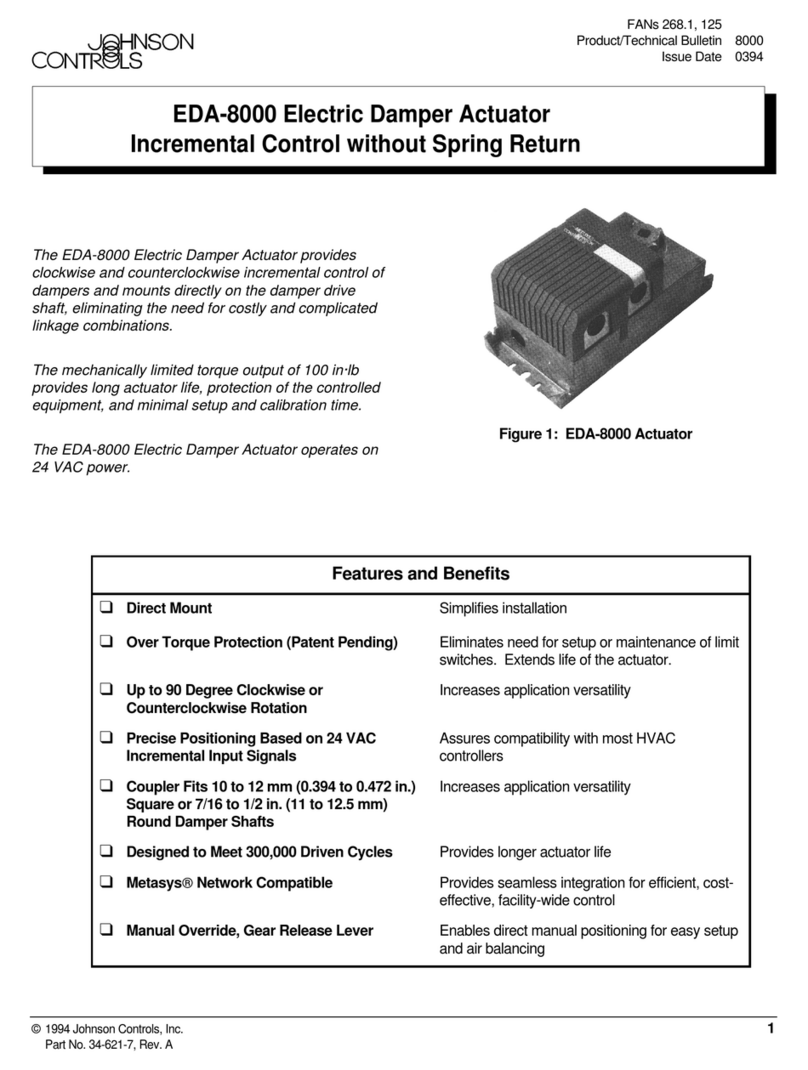

NOVAK

NOVAK ATOM ESC operating instructions

Sanyo

Sanyo VSP-9000 instruction manual

Adaptec

Adaptec GDT8546RZ - ICP Vortex RAID Controller specification

Distech Controls

Distech Controls ECL-VAVS installation guide

Berker

Berker 8536 51 00 operating instructions

Gossen MetraWatt

Gossen MetraWatt SMARTCONTROL ECS installation instructions

Oxbox

Oxbox JAYLOAM001 installation manual

Montalvo

Montalvo X-3000-ce-RW instruction manual

Bosch

Bosch FW 120 Installation and operating instructions

Trane

Trane Tracer MP580 Programming guide