IWAKI EH-E User manual

Other IWAKI Water Pump manuals

IWAKI

IWAKI FW-H Series User manual

IWAKI

IWAKI IX-C150 TC/TE R User manual

IWAKI

IWAKI MDM Series User manual

IWAKI

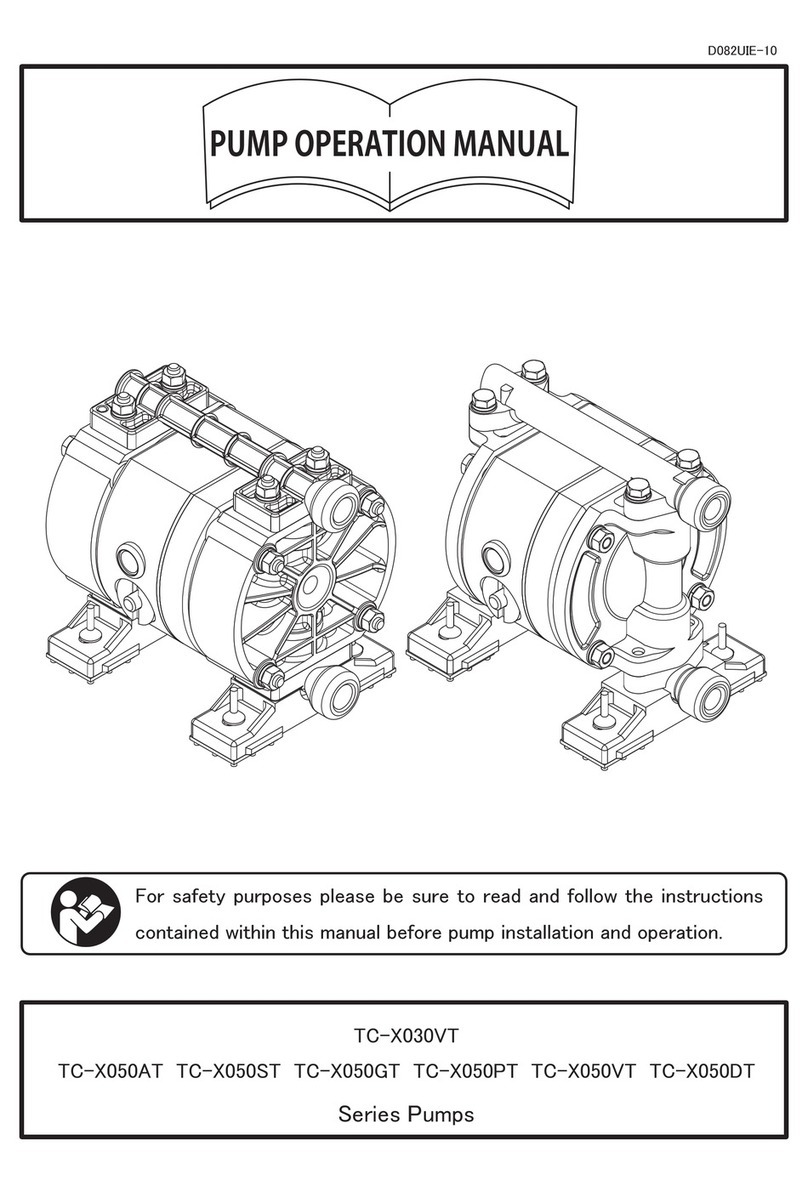

IWAKI TC-X030VT Series User manual

IWAKI

IWAKI MDW Series User manual

IWAKI

IWAKI TC-X030V User manual

IWAKI

IWAKI MDM 50 User manual

IWAKI

IWAKI MX-70 User manual

IWAKI

IWAKI MDG-M2 User manual

IWAKI

IWAKI LK-F Series User manual

IWAKI

IWAKI EW Series User manual

IWAKI

IWAKI TC-X102P Series User manual

IWAKI

IWAKI EK Series User manual

IWAKI

IWAKI APN-05-W User manual

IWAKI

IWAKI EJ-B09 User manual

IWAKI

IWAKI IX-C060 S6 R-TB User manual

IWAKI

IWAKI MDK Series User manual

IWAKI

IWAKI EWN-B31 VC User manual

IWAKI

IWAKI APN-30GD3-W User manual

IWAKI

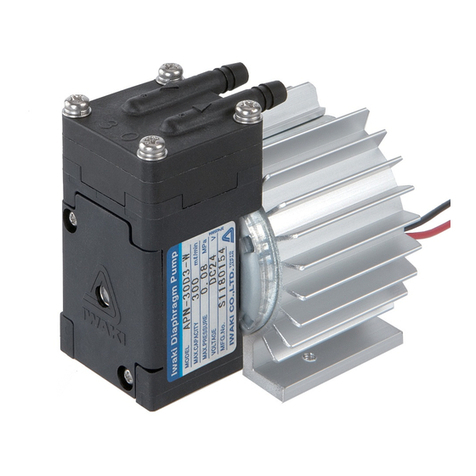

IWAKI APN-P60-W User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual