Contents

IMPORTANT INSTRUCTION ....................................................... 1

Safety Instructions ........................................................................ 2

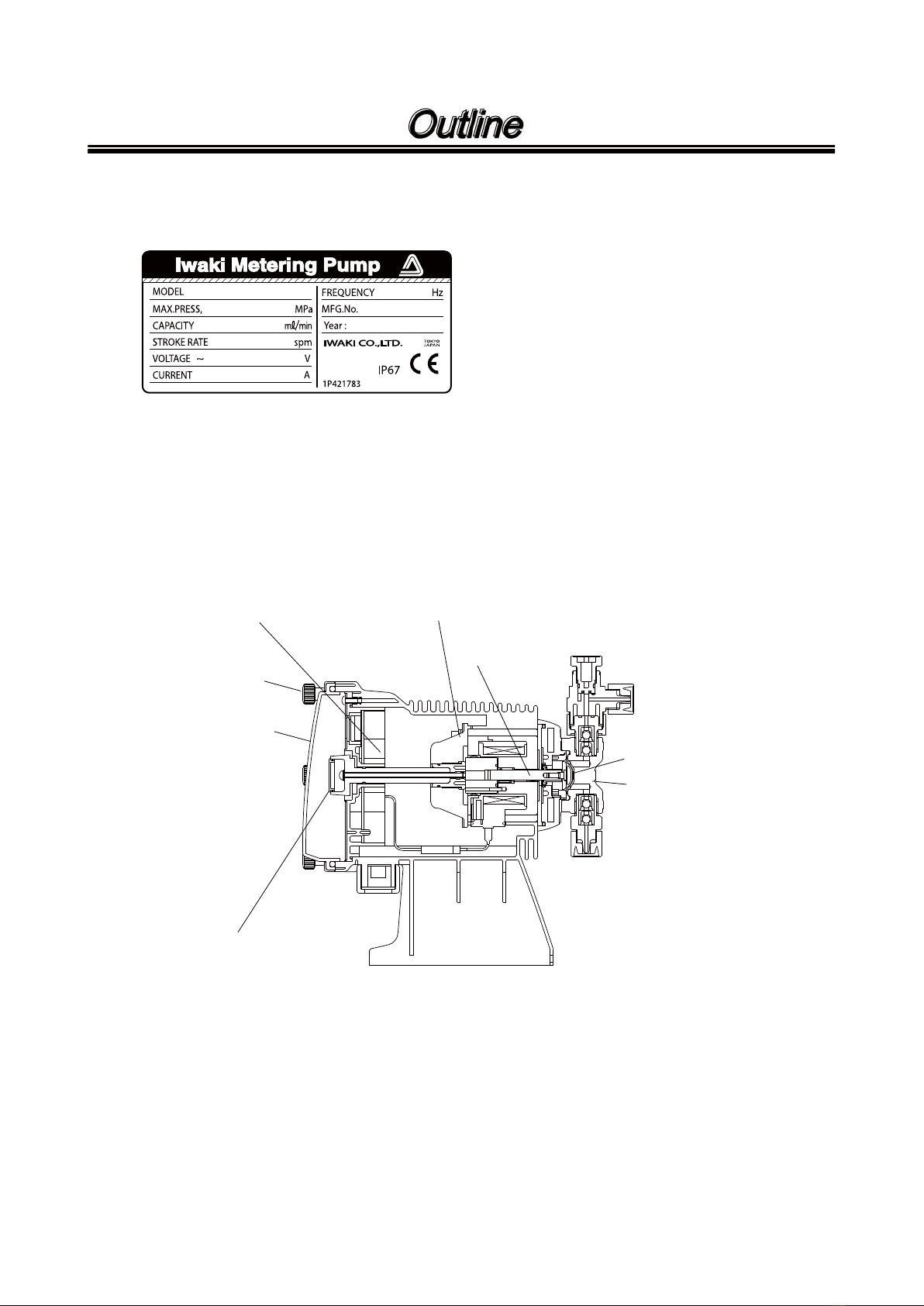

Outline........................................................................................ 5

1. Unpacking & Inspection ............................ 6

2.OperationPrinciple

................................... 6

3. Identification Codes

.................................. 7

4.Features

................................................... 8

5.MainParts

................................................ 8

6.Specifications

........................................... 9

7.OperatingFunction

.................................. 11

8.STOPFunction

....................................... 11

Installation .................................................................................. 12

1. Before Use

.............................................. 13

2.NotesonOperation................................. 13

3. Installation

.............................................. 14

4.Dimensions

............................................. 15

5. Piping

..................................................... 18

6.ElectricalWiring

...................................... 19

Operation ................................................................................... 21

1. Bleeding

.................................................. 22

2. Flow rate Adjustment .............................. 24

3.Operation

................................................ 25

4. Waterproof cover Mounting

..................... 29

Maintenance ............................................................................... 30

1. Troubleshooting

...................................... 31

2. Maintenance & Inspection ....................... 32

3. Wear Parts

............................................. 33

4. Disassembly & Assembly ........................ 34

5. Exploded View ........................................ 38

6. Accessories

............................................ 42

This instruction manual should be kept on hand by the end user for quick reference. It is

recommended that each user, after reading the instruction manual thoroughly, place it in a

position close to the pump system and where it may be easily accessed by any user at any

time whenever necessary.

Thank you for selecting the electromagnetic metering pump EK series. This instruction

manual deals with “Safety Section” “Product outline” “Installation Section” “Operation

Section” and “Maintenance Section”.

Please read through this manual carefully to ensure the optimum performance, safety and

service of the EK series.