Assembly Manual - HD Washing just behind Eviscerator in & outside - super narrow - art.no. HD.500.BHEV.4x4

INTRODUCTION

ASSEMBLY GUIDE SYMBOLS

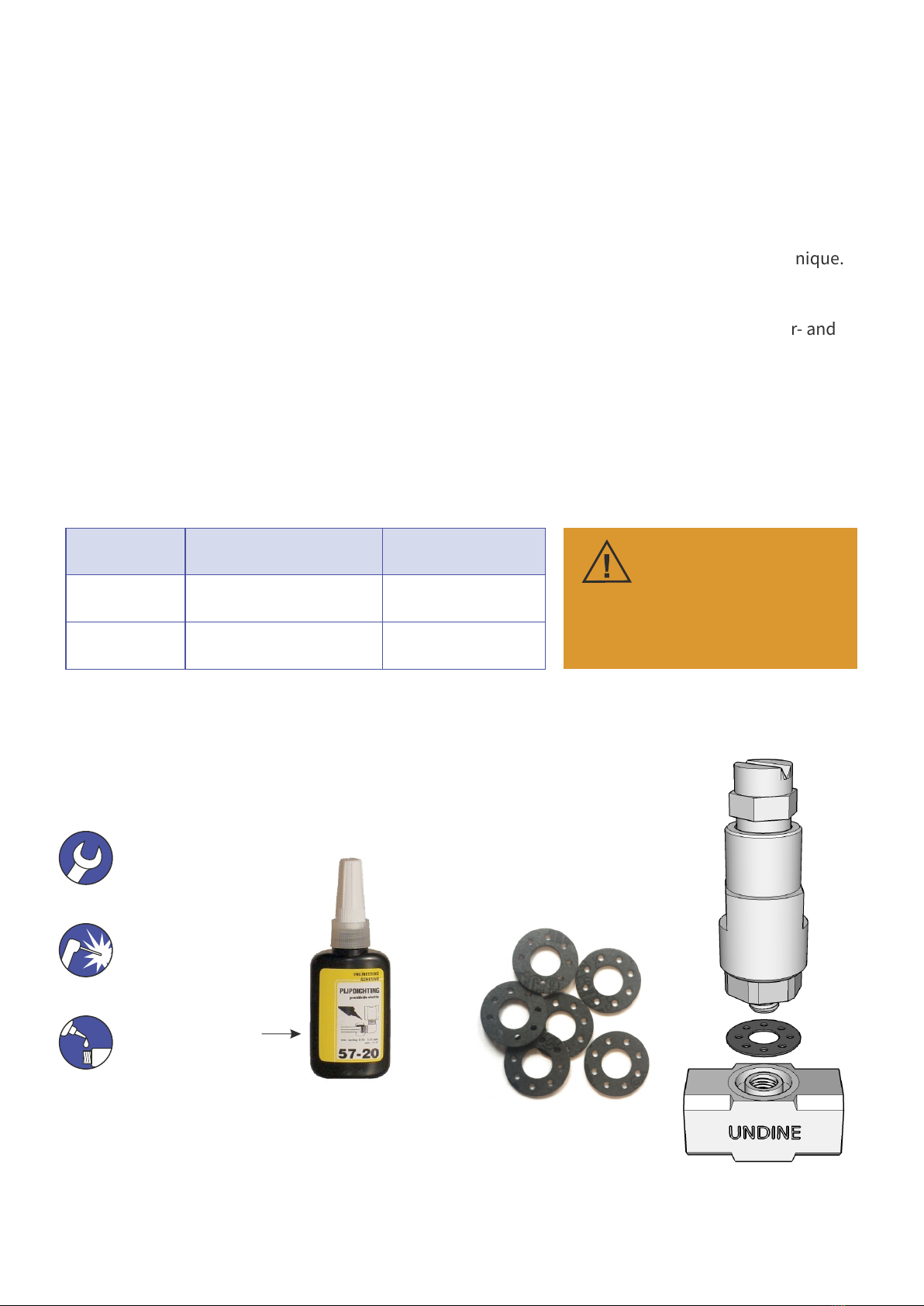

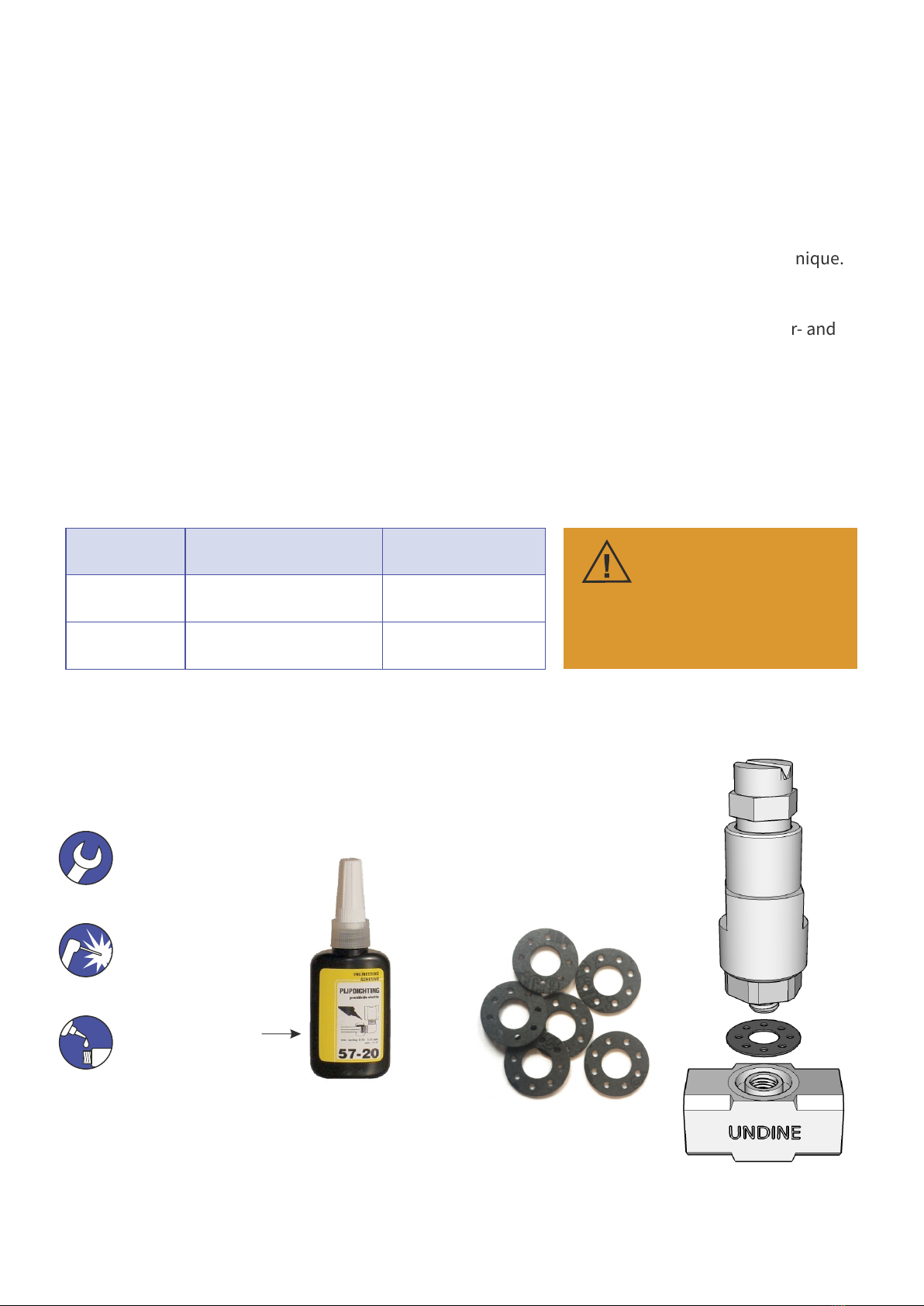

Bolt/screw

Welding

Liquid gasket

(included in package)

Spare gasket rings

for use in the UNDINE®

unit are included.

MAINTENANCE

This is the assembly manual for the:

HD Washing just behind Eviscerator in & outside - super narrow

Article No. HD.BHEV.4x4

The working principle of this equipment is based on the unique UNDINE® water/air mixing technique.

See for details of this technique our introduction movie at www.iwc-international.com

Installation must be performed by qualified technical personnel familiar with poultry slaughter- and

cleaning systems.

Start by checking all parts are available as mentioned in the part list on the next page.

SPECIFICATIONS

Consumption Pressure

Water 1.750 - 2.250 ltrs/hour 10 bar

Air 400 ltrs/min 6 - 8 bar

(actual size)

If the water- and airpressure as

advised are not applied,

the equipment may not function in

accordance with your requirements.

IMPORTANT NOTICE

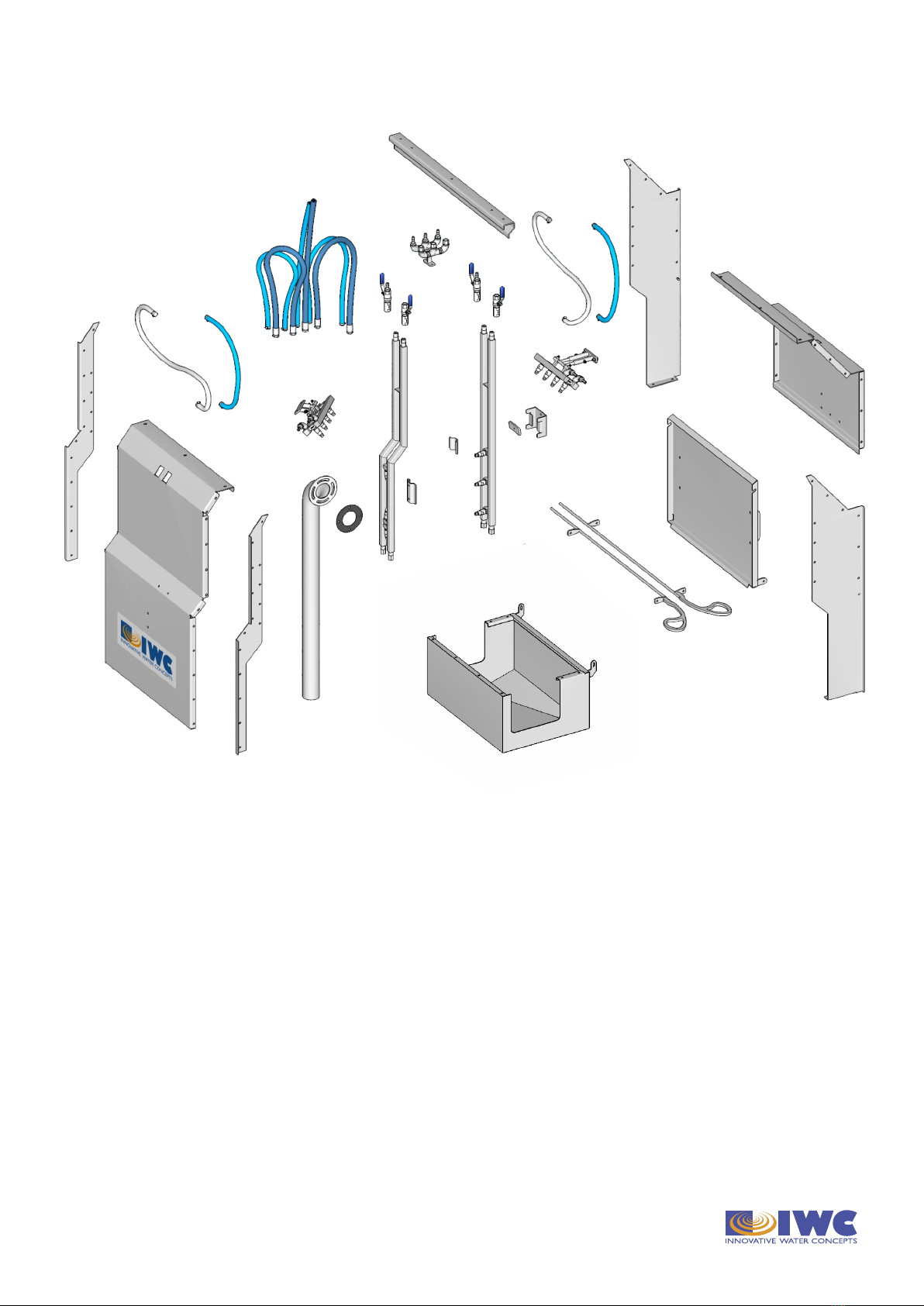

PARTS MOUNTING MATERIAL

1. G-rail

2. Le cabin cover

3. Right cabin cover

4. Back cover LHS

5. Back cover RHS

6. Front cover LHS

7. Front cover RHS

8a. Manifold LHS

8b. Mounting plate

9. Mounting bracket

10a. Manifold RHS

10b. Mounting plate

10c. Mounting plate

11. Upper manifold LHS

12. Upper manifold RHS

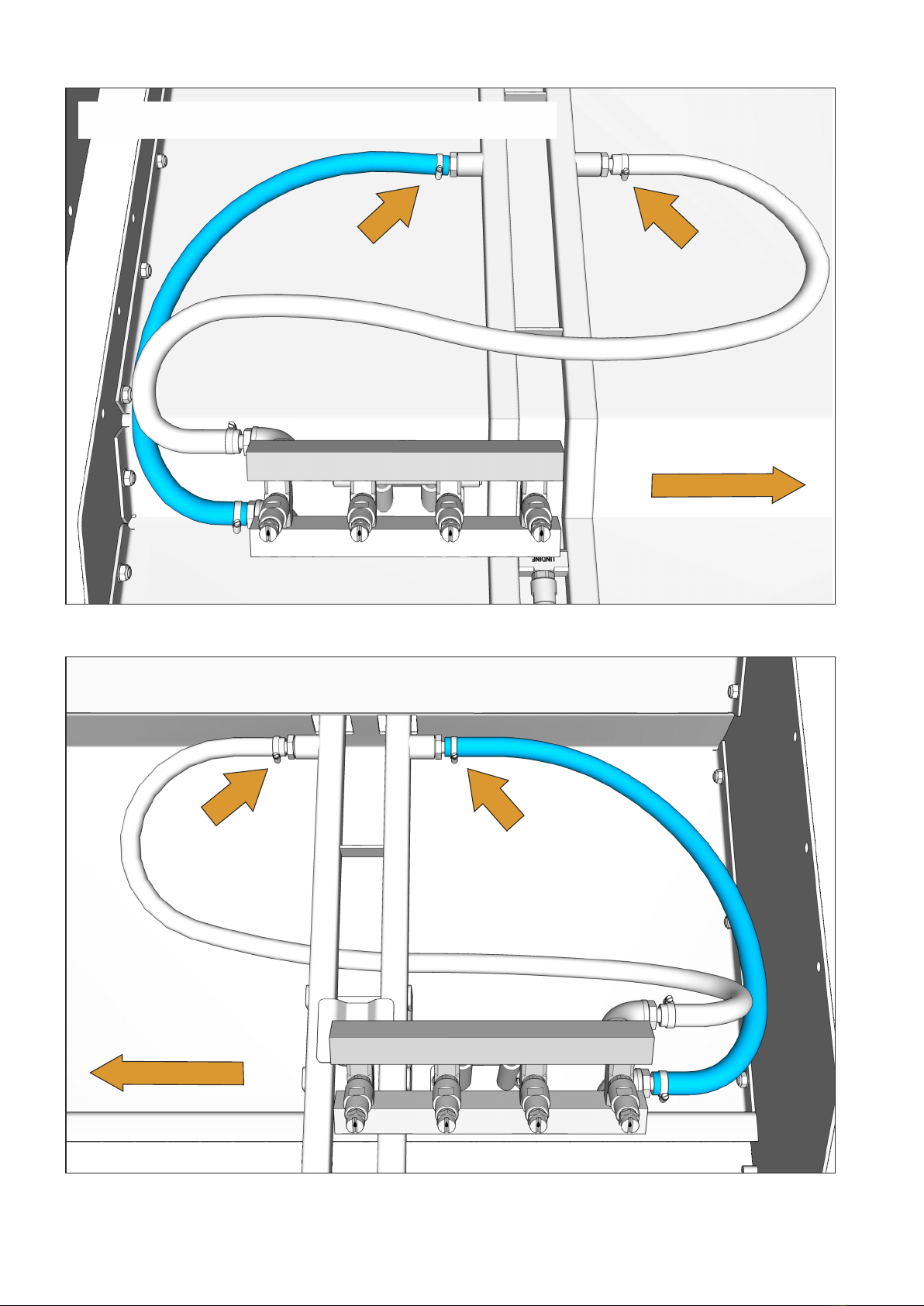

13. Inside air/water hoses LHS

14. Inside air/water hoses RHS

15. Air ball/safety valve (2x)

16. Water ball/safety valve (2x)

17. Divider manifold

18. Hose assembly

19. Guide rails (2x)

20. Drip tray

21a. Drain pipe

21b. Drain pipe gasket

22. Door

Bolt M8 x 15 34

Bolt M8 x 20 20

Bolt M8 x 30 7

Safety nut M8 58

Washer M8 119

Bolt M10 x 30 5

Nut M10 3

Safety nut M10 2

Washer M10 5

1

2

6

8a

8b

9

19

20

21a

21b

22

10a

13

14

11

15

15

16

16

12

17

18

10b

10c

7

4

5

3