Fig. 22

Power

cable

Fig. 16

Template Guide

Part number 611028_A

Approved by the appropriate

electrical supply authorities.

I N H O M E

WARR ANTY

questions or warranty matters:

Sampford IXL Pty Ltd

Service Department

Phone: 1300 727 421

Fax:

1300 727 425

aftersalesser

www.ixlappliances.com.au

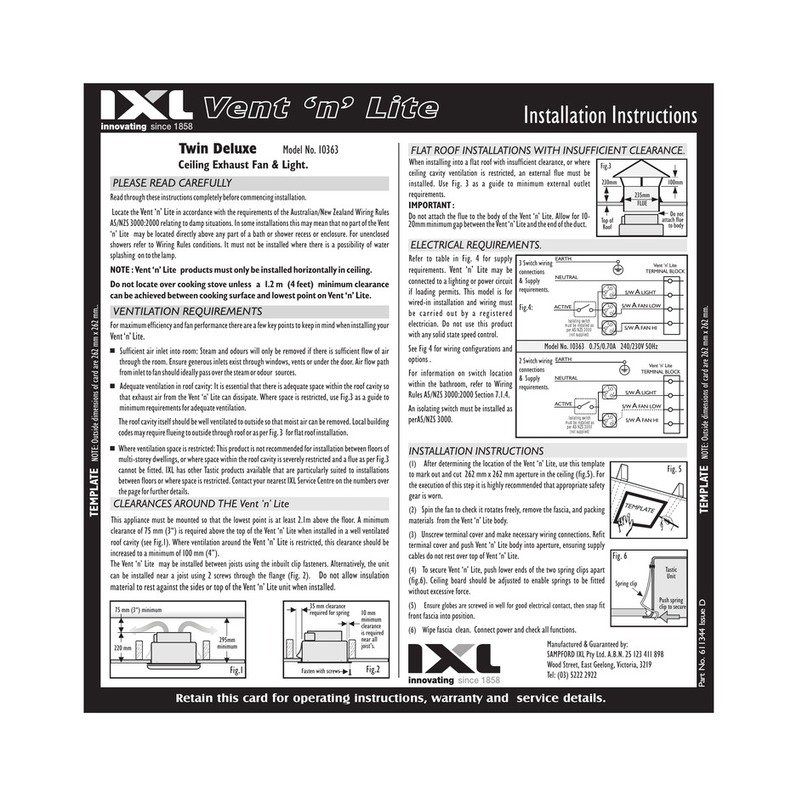

Fig. 13: Use template to mark position of module

Installation

The Neo modules may be installed between joists

using the spring clips, clearances must be maintained

as per Fig. 2b, 2c & 2d.

IMPORTANT:

cut or notched to install the appliance.

Joists, beams and rafters shall not be

Depending on your model, the modules have a weight

of 1.0 – 2.6 kg (see below). If adequate support is not

available for the modules, it may be necessary to

provide extra strengthening.

If ceiling battens have been cut to install this

then ensure that the cut ceiling battens are

adequately secured to rafters.

product

NOTE: This product must be installed by a qualified

installer. Ensure power is off to location of Tastic.

Cut out hole for Neo module

After determining the location of the Neo module,

mark out and cut aperture in ceiling using the

appropriate template. Trim the template to the outside

of the black outline.

Vent and Vent n Lite modules (models

34101, 34102, 35101 & 35102)

1.

mm dia. ducting. Determine the length of ducting

required ensuring that the length is as short as

possible. Refer to Fig’s 19-21 to attain optimum

performance.

2. Tape a length of ducting 1 m long (max) to the

blower inlet. Tape remaining length of ducting to

exit of blower.

3. Feed ducting and blower through hole in ceiling.

While feeding ducting into ceiling direct it towards

the installation position of the outlet grille. Position

blower so that the short length of ducting and

stripped wire (models 34101 & 34102) is sitting

next to the hole as per Fig. 22.

4. Make the necessary electrical connections. Refit

terminal cover.

5. Tape short length of ducting, from blower inlet, to

transition.

6. Push unit into ceiling aperture, allowing metal

springs to snap open. As the unit is raised into the

ceiling, ensure electric cable do not rest on the

unit.

7. To secure the unit in position, push lower ends of

springs apart (Fig 16.). Ceiling board thickness

should be adjusted to enable springs to be fitted

without excessive force.

8. Bring fascia up to unit and connect the earthing

wire (models 34101 & 34102). Clip fascia into the

unit. Fig 17.

9. Remove downlight mounts and fit down lights.

Connect lamp holders to downights and refit

downlight mounts (models 34101 & 34102).

10. Turn on the power at the isolating switch and

check operation of the unit.

These products have been designed to suit 150

Fig. 19: Straight ducting

Performance

Fig. 20: Gradual bends,

ducting stretched straight.

100%

Performance

Neo Light small – approx 1.0 kg

Neo Light large – approx 1.3 kg

Neo Vent n Lite - approx 1.9 kg

Neo Vent - approx 1.5 kg

Neo Heat - approx 2.6 kg

Installation Installation

Fig. 23

Fig. 21: Tightly compressed bends

Performance

100%

Fig. 17

Modules - Heat • Vent • Light

Model: 33132 Neo Light Small Silver - Hardwired

Model: 33141 Neo Light Large White - Hardwired

Model: 33142 Neo Light Large Silver - Hardwired

Model: 34101 Neo Vent n Lite White - Hardwired

Model: 34102 Neo Vent n Lite Silver - Hardwired

Model: 33131 Neo Light Small White - Hardwired

Electrical Rating: 230~240 V. 50 Hz.

Model: 35101 Neo Vent White - Hardwired

Model: 35102 Neo Vent Silver - Hardwired

Model: 36111 Neo Heat White - Hardwired

Model: 36112 Neo Heat Silver - Hardwired

Heat module (models 36111 & 36112)

IMPORTANT: Under no circumstances shall this

appliance be covered with insulating material or

similar material.

1. Unscrew terminal cover and make necessary

electrical connections. Refit terminal cover. Do

not turn on power to unit.

2. Push unit into ceiling aperture, allowing metal

springs to snap open. As the unit is raised into the

ceiling, ensure electric cable does not rest on the

unit.

3. To secure the unit in position, push lower ends of

springs apart (Fig 16.). Ceiling board thickness

should be adjusted to enable springs to be fitted

without excessive force.

4. Bring fascia up to unit and connect the earthing

wire. Clip fascia into the unit. Fig 17.

5. Using care, fit the tubular heat lamps into the

lamp holders. Be careful not to touch the glass

surface as oils from skin can shorten the life of

the glass lamp. A clean soft cloth or tissue is

recommended. Ensure that the white reflective

layer on the tubular heat lamp is on the upper side

of the lamp, ie lamp is pointing downwards.

6. Fit the glass sheets to the heat lamp reflector

bodies Fig. 18.

7. Turn on the power at the isolating switch and

check operation of the unit.

Installing the Grille

1.

wall. Feed ducting out through this hole and tape

to the Grille baseplate.

2. Feed the ducting back through the hole so that the

Grille base is against the eaves or outer wall.

3. Fix Grille base with four 6 G screws and snap ft

the Grille louvres over the Grille base as shown in

Fig. 23.

Note: A piece of fly screen can be fitted to the Grille

base prior to fitting the Grille louvre.

Cut a hole 160 mm in diameter in eaves or outer

13

2

Fig. 18

TEMPLATE MODELS: 36111 & 36112 TEMPLATE MODELS: 34101, 34102, 35101 & 35102

Cut-out size: 292mm x 332mm Cut-out size: 214mm x 332mm

Model: 33131, 33132, Neo Light Small Model: 33141, 33142, Neo Light Large

Model: 36111, 36112, Neo Heat Model: 34101, 34102, Neo Vent n Lite Model: 35101, 35102, Neo Vent

T

rim to outside of black line.

T

rim to outside of black line.

IXL Pty Ltd

Service Department

Free Call: 1300 727 421

www.ixlappliances.com.au

Model: 34101 Neo Vent n Lite White - Hardwired

Model: 34102 Neo Vent n Lite Silver - Hardwired

Model: 35101 Neo Vent White - Hardwired

Model: 35102 Neo Vent Silver - Hardwired

Model: 36111 Neo Heat White - Hardwired

Model: 36112 Neo Heat Silver - Hardwired

Electrical Rating 230 ˜ 240 V. 50 Hz