J.E. Adams 8670-5WB User manual

8670-5WB Manual – 10/2006 2

TABLE OF CONTENTS

•Product Information…………………………………… 3

•Specifications…………………………………………… 4

•Installation……………………………………………… 5-10

oRequirements…….…………………………… 5

oInstallation Directions..………………………. 6

oFigure 1: Hose Reel Base Footprint.…………. 7

oFigure 2: Mounting and Routing Detail………..8

oFigure 3: Electrical Installation Detail…………9

oFigure 4: Cabinet and Base Dimensions……….10

•Timer setup……………………………………………… 11-15

oSSAC Setup…………………………………... 11

oIDX Setup…………………………………….. 12

oInfitec Setup………………………………….. 13

oTimer Settings Chart…………………………. 14

oTypical Timer Settings………………………. . 15

•Programming the Remote Start System…………………16

•Maintenance……………………………………………... 17

•Parts Breakdown………………………………………... 18-20

o8670-5WB…………………….……………… 18

o8778A-1………………………..……………... 19

o22002-51A……………………………………. 20

•Schematics……………………………………………….. 21

oS8670-5WB………………………...…………. 21

•Troubleshooting…………………………………………. 22

8670-5WB Manual – 10/2006 3

PRODUCT INFORMATION

Please take a moment to fill out the information below in order to aid us with any future sales or service inquiries. Model

number and serial number information can be found on the serial tag located inside the control box and/or on the lower

exterior of the can. Key number can be found on the tag that comes attached to the keys. There may be more than one key

number depending on unit.

Please keep this information with your records.

MODEL#:_________________________________________

SERIAL#:_________________________________________

KEY NUMBER(S):_________________________________

DATE PURCHASED:_______________________________

DISTRIBUTOR:___________________________________

J.E. Adams Industries

1025 63rd Ave. S.W.

Cedar Rapids, IA 52404

1-800-553-8861

www.jeadams.com

8670-5WB Manual – 10/2006 4

SPECIFICATIONS

DeVILBISS COMPRESSOR

•20 AMP SERVICE REQUIRED

•120 VAC, 60Hz, 14 AMPS

•1.5 HORSEPOWER

•ONE CYLINDER

•ONE STAGE OIL-LESS

SCFM @ PSI :

6 @ 0

5 @ 20

4.1 @ 40

3.1 @ 90

2.9 @ 100

2.1 @ 125 (MAX PSI)

TEMPERATURE RANGE:

-10 DEGREES F TO 100 DEGREES F.

MOTOR:

•1.5 HP, 1725 RPM

•CAPACITOR START

•NEMA 56 FRAME

•AUTOMATIC THERMAL

OVERLOAD.

NO LUBRICATION REQUIRED ON MOTOR OR COMPRESSOR.

8670-5WB Manual – 10/2006 5

INSTALLATION REQUIREMENTS

!IMPORTANT!

TO ENSURE PROPER FUNCTIONALITY AND ADHERANCE TO BOTH LOCAL AND NATIONAL ELECTRIC

CODES, IT IS RECOMMENDED THAT SERVICE BE INSTALLED BY A LICENCED ELECTRICIAN EXPERIENCED

IN COMMERCIAL APPLICATIONS. INADEQUATE POWER AND WIRING MAY CAUSE THE UNIT TO PERFORM

ERRATICALLY, BLOW FUSES AND TIME INCORRECTLY.

GENERAL MECHANICAL:

•ALL DIMENSIONS IN DRAWINGS ARE IN INCHES.

•MOUNTING STUD SIZE 3/8” X 16 UNC X 1”.

•4” MINIMUM CONCRETE REQUIRED AROUND MOUNTING STUD.

•18” MINIMUM PAD RECOMMENDED FOR BUMPER CLEARANCE.

FOR GASOLINE DISPENSING LOCATIONS:

•A MINIMUM 18” HIGH PAD ABOVE THE DRIVEWAY.

•20 FOOT HORIZONTAL CLEARANCE FROM THE EXTERIOR ENCLOSURE OF ANY

GASOLINE DISPENSING PUMP.

ELECTRICAL SERVICE:

•Dedicated service required

o120V single phase

o20 amp service

o60Hz cycle

•Minimum service wire size:

oLess than 100ft run: 12Ga

o100ft – 200ft run: 10Ga

8670-5WB Manual – 10/2006 6

INSTALLATION

IT IS HIGHLY RECOMMENDED THAT THIS UNIT BE INSTALLED BY A LICENSED

ELECTRICIAN to ensure all local and national electrical codes are adhered to.

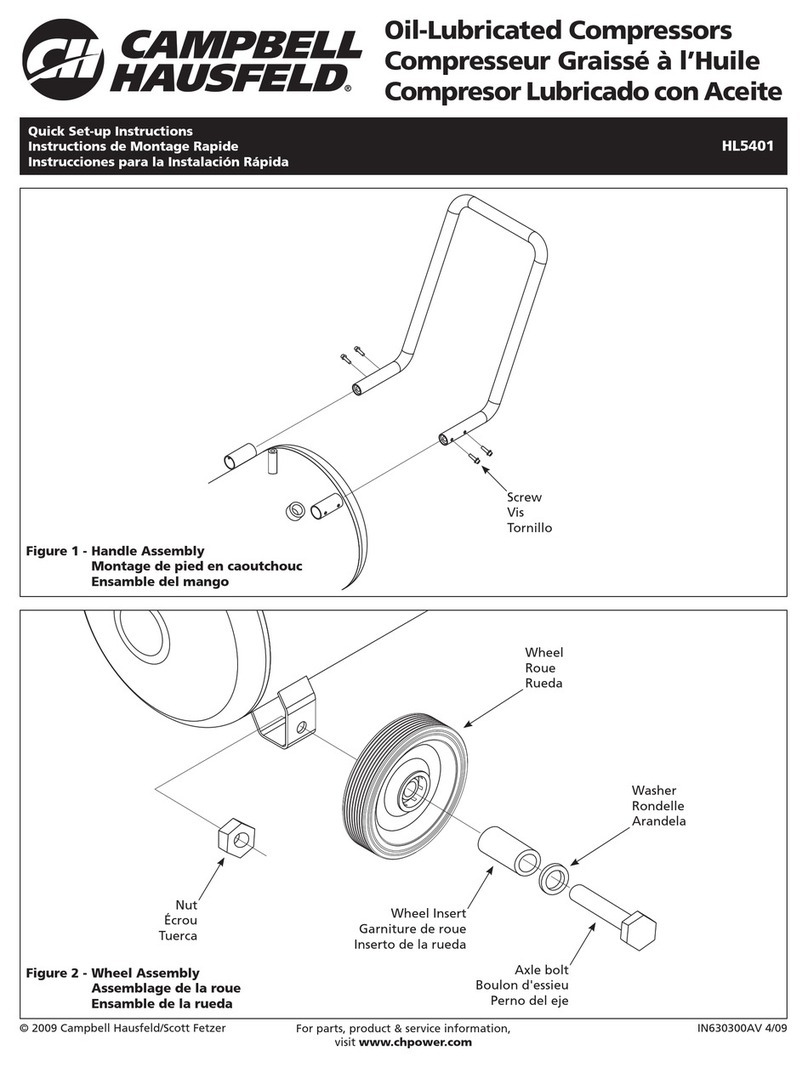

1. This unit is designed to be used with the J.E. Adams 6025 hose reel base.

2. Using the 6025 footprint dimensions shown in Figure 1, locate and install mounting studs.

3. Secure hose reel base to mounting studs securely. DO NOT install the cover at this time.

4. Mount cabinet to base securely as shown in Figure 2, using only the four 5/16-18 X ½” bolts.

DO NOT install the ¼-20 X ½” bolts at this time.

5. Using Figures 2 & 3, install electrical and water services to the unit and run air and water lines to

the inputs of their respective hose reels. Air line should run between the output of the unloader

valve and the input of the air reel.

6. Set timer to desired time and coin settings (pages 11-15).

7. Apply power to the unit and verify proper operation.

8. Install hose reel cover using ¼-20 X ½” bolts to secure in place as shown in Figure 2.

8670-5WB Manual – 10/2006 7

Figure 1: Installation footprint for 6025 hose reel base

8670-5WB Manual – 10/2006 8

Figure 2: Mounting and routing detail

8670-5WB Manual – 10/2006 9

Figure 3: Electrical installation detail

8670-5WB Manual – 10/2006 10

Figure 4: Cabinet and hose reel base dimensions

8670-5WB Manual – 10/2006 11

Figure 5: SSAC timer setup

Figure 5 shows an SSAC timer set for 1 coin to start and 3.8 minutes per

coin for a total run time of 3.8 minutes (3 minutes and 48 seconds).

TIMER SETUP – SSAC TIMERS

Note: “AE” and “AN” model SSAC timers are accumulating timers.

During use, timing can be extended proportionately by adding more

coins.

The SSAC timer has two adjustable settings: Time per coin (in minutes)

and number of coins to start.

Time per coin:

Time per coin is the amount of time the unit will run per coin inserted

and can be set from 0.1 minutes (6 seconds) to 12.7 minutes (12 minutes

and 42 seconds) in increments of 6 seconds by turning on the correct

switches until their values equal the desired time.Refer to Tables 1 and 2

(pages 14-15) for standard timer and coin settings. For custom settings,

follow the steps below:

1. Figure the total time your vac will run (in minutes) and divide that

number by the number of coins to start. This is your time per coin.

Round up or down to the nearest tenth of a minute.

2. Subtract the largest value switch (initially 6.4) from your time per

coin.

a. If the resulting number is zero, move the switch to the “on”

position and set all remaining un-set switches in the “off”

position. Your timer is now set.

b. If the resulting number is positive, move the switch into the

“on” position. Using the resulting number as your new time

per coin, repeat step 2 with the next largest switch value.

c. If the resulting number is negative, set the switch in the

“off” position and repeat step 2 using the next largest switch

value.

Coins to start:

Coins to start is the amount of coins needed to activate the timer and can

be set from one to seven coins in increments of one coin. Refer to Table

1 (page 14) for switch settings.

8670-5WB Manual – 10/2006 12

Figure 6: IDX timer setup

Figure 6 shows an IDX timer set for 3 coins to start and 60 seconds per coin

for a total run time of 3 minutes.

TIMER SETUP – IDX TIMERS

Note: IDX timers are accumulating timers. During use, timing can be

extended proportionately by adding more coins.

The IDX timer has two adjustable settings: Time per coin (in seconds)

and number of coins to start.

Time per coin:

Time per coin is the amount of time the unit will run per coin inserted

and can be set from 2 seconds to 510 seconds (8.5 minutes) in increments

of 2 seconds by turning on the correct switches until their values equal the

desired time.Refer to Tables 1 and 2 (pages 14-15) for standard timer

and coin settings (Note: IDX timers do not have 1 second or 512 second

switches. When configuring timer using Table 1, ignore settings for

switches 1 and 512). For custom settings, follow the steps below:

1. Figure the total time your vac will run (in seconds) and divide that

number by the number of coins to start. This is your time per coin.

Round up or down to the nearest even number.

2. Subtract the largest value switch (initially 256) from your time per

coin.

a. If the resulting number is zero, move the switch to the “on”

position and set all remaining un-set switches in the “off”

position. Your timer is now set.

b. If the resulting number is positive, move the switch into the

“on” position. Using the resulting number as your new time

per coin, repeat step 2 with the next largest switch value.

c. If the resulting number is negative, set the switch in the “off”

position and repeat step 2 using the next largest switch value.

Coins to start:

Coins to start is the amount of coins needed to activate the timer and can

be set from one to seven coins in increments of one coin. Refer to Table

1 (page 14) for switch settings.

8670-5WB Manual – 10/2006 13

Figure 7: Infitec timer setup

Figure 7 shows an Infitec timer set for 2 coins to start and a total run time of

240 seconds (4 minutes).

TIMER SETUP – INFITEC TIMERS

The Infitec timer has two adjustable settings: Total run time (in seconds)

and number of coins to start.

Total run time:

Total run time is the amount of time the unit will run once activated and

can be set from 1 second to 1023 seconds (17 minutes and 3 seconds) in

increments of 1 second by turning on the correct switches until their

values equal the desired time.Refer to Tables 1 and 2 (pages 14-15) for

standard timer and coin settings. For custom settings, follow the steps

below:

1. Figure the total time your vac will run (in seconds). This is your

total run time. Round up or down as desired.

2. Subtract the largest value switch (initially 512) from your total run

time.

a. If the resulting number is zero, move the switch to the “on”

position and set all remaining un-set switches in the “off”

position. Your timer is now set.

b. If the resulting number is positive, move the switch into the

“on” position. Using the resulting number as your new time

per coin, repeat step 2 with the next largest switch value.

c. If the resulting number is negative, set the switch in the

“off” position and repeat step 2 using the next largest switch

value.

Coins to start:

Coins to start is the amount of coins needed to activate the timer and

can be set from one to 15 coins in increments of one coin. Refer to Table

1 (page 14) for switch settings.

8670-5WB Manual – 10/2006 14

5

10

15

20

25

30

35

40

45

50

55

60 (1 min)

70

80

90

100

110

120 (2 min)

130

140

150

160

170

180 (3 min)

190

200

210

220

230

240 (4 min)

250

260

270

280

290

300 (5 min)

1xxxxxx

2xx xx xxxxxxxxxxxxxx

4x xx x x xxx xx xx xx xx xx x

8xx xx xx x x xx x x xx x x xx x

16 xxx xxx xx x x xx xx xx x

32 xxxxxx xxx xxxx xxx xx

64 xxxxxx xxxxxx

128 xxxxxxxxxxxxx

256 xxxxx

512

0.1 (6sec)

0.2 (12 sec)

0.3 (18 sec)

0.4 (24 sec)

0.5 (30 sec)

0.6 (36 sec)

0.7 (42 sec)

0.8 (48 sec)

0.9 (54 sec)

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

9.5

10.0

0.1 xxxxxxxxxxxxxxxxxx

0.2 xx xx xx xx xx xx xx xx xx

0.4 xxxx xxxx x x x xx x x xx

0.8 xxxxxxxx xx xx x x xx

1.6 xxxxxxx xxx xxxx

3.2 xxxxxx x

6.4 xxxxxxxx

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1xxxxxxxx

2xx xx xx xx

4xxxx xxxx

8xxxxxxxx

All Timers

Coin Switches

Coins to Start

SSAC Timers

Timer Switches

Time Per Coin (In minutes)

Infitec Timers: Total Run Time (In Seconds)

Infitec and IDX Timers

Timer Switches

IDX Timers: Time Per Coin (In Seconds)

Table 1: Timer Settings Chart

Note: “X” indicates a switch in the “on” position

8670-5WB Manual – 10/2006 15

Amount to

Start Total Run

Time Switches in "On"

Position Amount to

Start Total Run

Time Switches in "On"

Position Amount to

Start Total Run

Time Switches in "On"

Position

25¢ 2 MIN 8, 16, 32, 64 25¢ 2 MIN 0.4, 1.6 25¢ 2 MIN 8, 16, 32, 64

25¢ 2-1/2 MIN 2, 4, 16, 128 25¢ 2-1/2 MIN 0.1, 0.8, 1.6 25¢ 2-1/2 MIN 2, 4, 16, 128

25¢ 3 MIN 4, 16, 32, 128 25¢ 3 MIN 0.2, 0.4, 0.8, 1.6 25¢ 3 MIN 4, 16, 32, 128

25¢ 3-1/2 MIN 2, 16, 64, 128 25¢ 3-1/2 MIN 0.1, 0.2, 3.2 25¢ 3-1/2 MIN 2, 16, 64, 128

25¢ 4 MIN 16, 32, 64, 128 25¢ 4 MIN 0.8, 3.2 25¢ 4 MIN 16, 32, 64, 128

25¢ 4-1/2 MIN 2, 4, 8 , 256 25¢ 4-1/2 MIN 0.1, 0.4, 0.8, 3.2 25¢ 4-1/2 MIN 2, 4, 8, 256

25¢ 5 MIN 4, 8, 32, 256 25¢ 5 MIN 0.2, 1.6, 3.2 25¢ 5 MIN 4, 8, 32, 256

25¢ 5-1/2 MIN 2, 8, 64, 256 25¢ 5-1/2 MIN 0.1, 0.2, 0.4, 1.6, 3.2 25¢ 5-1/2 MIN 2, 8, 64, 256

50¢ 2 MIN 4, 8, 16, 32 50¢ 2 MIN 0.2, 0.8 50¢ 2 MIN 8, 16, 32, 64

50¢ 2-1/2 MIN 4, 8, 64 50¢ 2-1/2 MIN *50¢ 2-1/2 MIN 2, 4, 16, 128

50¢ 3 MIN 2, 8, 16, 64 50¢ 3 MIN 0.1, 0.2, 0.4, 0.8 50¢ 3 MIN 4, 16, 32, 128

50¢ 3-1/2 MIN 2, 8, 32, 64 50¢ 3-1/2 MIN *50¢ 3-1/2 MIN 2, 16, 64, 128

50¢ 4 MIN 8, 16, 32, 64 50¢ 4 MIN 0.4, 1.6 50¢ 4 MIN 16, 32, 64, 128

50¢ 4-1/2 MIN 8, 128 50¢ 4-1/2 MIN *50¢ 4-1/2 MIN 2, 4, 8, 256

50¢ 5 MIN 2, 4, 16, 128 50¢ 5 MIN 0.1, 0.8, 1.6 50¢ 5 MIN 4, 8, 32, 256

50¢ 5-1/2 MIN 2, 4, 32, 128 50¢ 5-1/2 MIN *50¢ 5-1/2 MIN 2, 8, 64, 256

75¢ 2 MIN 8, 32 75¢ 2 MIN *75¢ 2 MIN 8, 16, 32, 64

75¢ 2-1/2 MIN 2, 16, 32 75¢ 2-1/2 MIN *75¢ 2-1/2 MIN 2, 4, 16, 128

75¢ 3 MIN 4, 8, 16, 32 75¢ 3 MIN 0.2, 0.8 75¢ 3 MIN 4, 16, 32, 128

75¢ 3-1/2 MIN 2, 4, 64 75¢ 3-1/2 MIN *75¢ 3-1/2 MIN 2, 16, 64, 128

75¢ 4 MIN 16, 64 75¢ 4 MIN *75¢ 4 MIN 16, 32, 64, 128

75¢ 4-1/2 MIN 2, 8, 16, 64 75¢ 4-1/2 MIN *75¢ 4-1/2 MIN 2, 4, 8, 256

75¢ 5 MIN 4, 32, 64 75¢ 5 MIN *75¢ 5 MIN 4, 8, 32, 256

75¢ 5-1/2 MIN 2, 4, 8, 32, 64 75¢ 5-1/2 MIN *75¢ 5-1/2 MIN 2, 8, 64, 256

$1.00 2 MIN 2, 4, 8, 16 $1.00 2 MIN 0.1, 0.4 $1.00 2 MIN 8, 16, 32, 64

$1.00 2-1/2 MIN 2, 4, 32 $1.00 2-1/2 MIN *$1.00 2-1/2 MIN 2, 4, 16, 128

$1.00 3 MIN 4, 8, 32 $1.00 3 MIN *$1.00 3 MIN 4, 16, 32, 128

$1.00 3-1/2 MIN 2, 4, 16, 32 $1.00 3-1/2 MIN *$1.00 3-1/2 MIN 2, 16, 64, 128

$1.00 4 MIN 4, 8, 16, 32 $1.00 4 MIN 0.2, 0.8 $1.00 4 MIN 16, 32, 64, 128

$1.00 4-1/2 MIN 4, 64 $1.00 4-1/2 MIN *$1.00 4-1/2 MIN 2, 4, 8, 256

$1.00 5 MIN 4, 8, 64 $1.00 5 MIN *$1.00 5 MIN 4, 8, 32, 256

$1.00 5-1/2 MIN 4, 16, 64 $1.00 5-1/2 MIN *$1.00 5-1/2 MIN 2, 8, 64, 256

IDX TIMER SETTINGS SSAC TIMER SETTINGS INFITEC TIMER SETTINGS

Table 2: Typical Timer Settings

Note: “*” denotes a configuration that is not possible with this timer. See Table 2 for the closest approximation to this time.

8670-5WB Manual – 10/2006 16

PROGRAMMING THE REMOTE START SYSTEM

Note: The remote start system will need to be re-programmed each time the unit is powered up.

1. Remove cover from signal receiver by pressing in at the center of each of the two lengthwise

sides.

2. Locate the covered Learn Code Button and LED indicator at the top of the circuit board. They

will be located directly beneath the upper tab holding the circuit board in place.

3. Press and release the Learn Code Button. LED indicator will blink at a rate of two times per

second.

4. Press the Transmitter Button once. The indicator light should now be on continuously.

5. Press the same Transmitter Button again. The indicator light should now turn off. The remote

start system should now be programmed. Note: You must perform steps 3-5 within 30 seconds.

If the LED indicator begins to blink rapidly (about 4 times per second) you must repeat steps

3-5.

6. Test the system to verify proper operation.

7. Replace cover, making sure antenna is hanging straight down outside the cover.

8670-5WB Manual – 10/2006 17

MAINTENANCE

•Check air and water hoses and attachments periodically for signs of wear or

damage and replace them as needed.

•Check door gaskets periodically for signs of wear or damage and replace them as

needed.

•Water solenoid may need to be disassembled and cleaned periodically to prevent

sticking. To disassemble, remove nut on top of valve and remove coil cover and

coil. Then using a flat head screwdriver, remove the piston housing. Clean out any

debris on the piston and in the piston housing and reassemble the valve.

•Clean the outside portion of the cabinet with a stainless steel polish. DO NOT use

any abrasive cleaners, steel wool or any kind of brush to clean the exterior. Doing

so could possibly scratch or damage the finish of the cabinet.

•Mild soap and water may be used to clean the decals. DO NOT use any harsh or

abrasive cleaners or the decal surface may be damaged.

8670-5WB Manual – 10/2006 18

8670-5WB Manual – 10/2006 19

8670-5WB Manual – 10/2006 20

Table of contents

Popular Compressor manuals by other brands

Sealey

Sealey AUTO SERVICE AK3844 instructions

Emerson

Emerson Copeland Stream 4MF-13X user manual

vidaXL

vidaXL Airgoo Operating and safety instructions

LEYBOLD

LEYBOLD RW 6000-1 operating instructions

Ingersoll-Rand

Ingersoll-Rand 9/235 HA IR Operating and maintenance manual

Profroid

Profroid QUIETOR GQH-GQL operating instructions

Drawmer

Drawmer 1968 MKII Operator's manual

Parkside

Parkside PKZ 180 C3 Translation of the original instructions

Gude

Gude 225/08/24 Translation of the original instructions

Sherwin-Williams

Sherwin-Williams GTS-ProCart 283-584 owner's manual

Schneider Airsystems

Schneider Airsystems UGL MAS Assembly instructions

EKOM

EKOM DK50 2V S Instructions for use and service manual