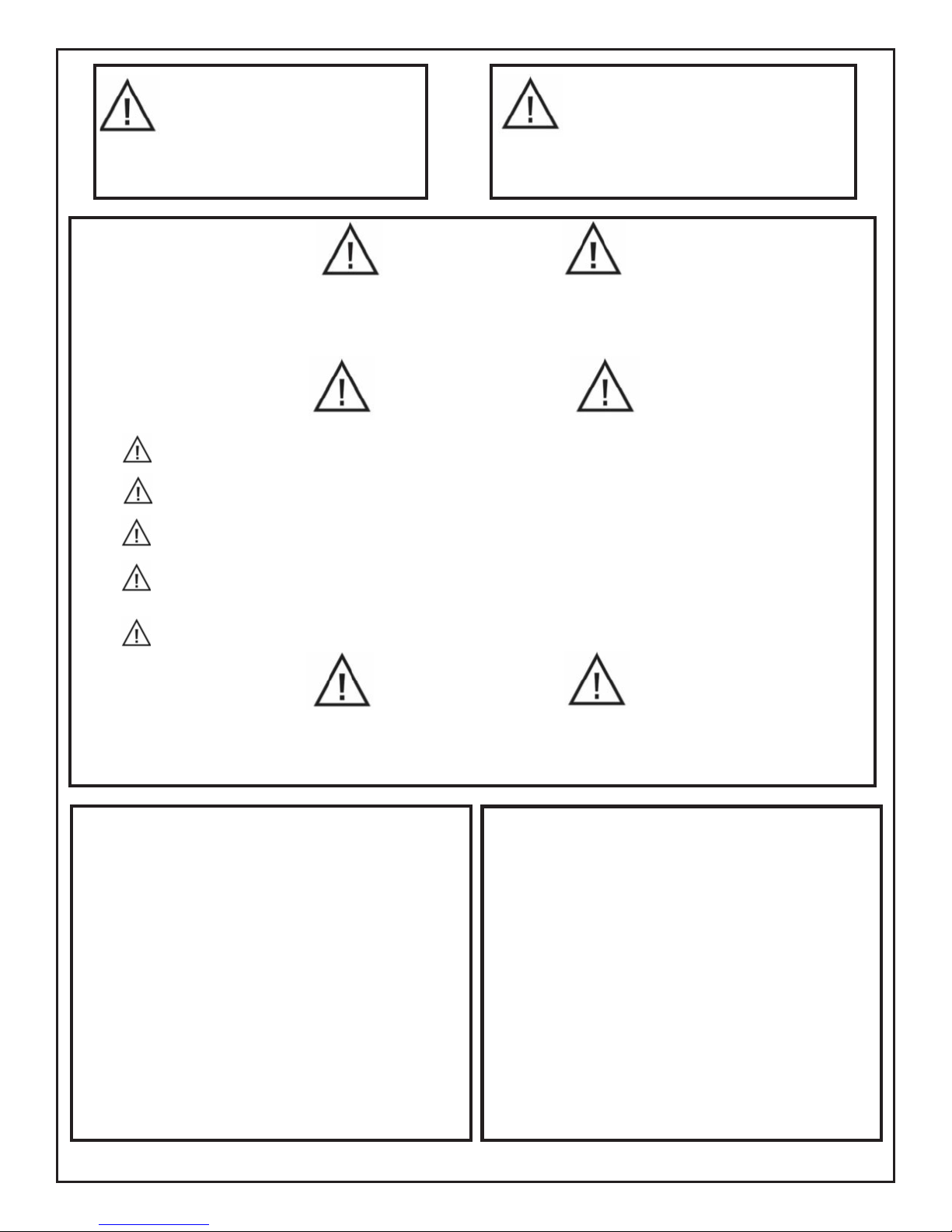

1FAN AND LIMIT CONTROL

The fan limit control turns the fan on

and off. It works off of temperature

and also provides a high temperature

safety limit.

2

3

4

5

6

7

8

9

SECONDARY HEAT EXCHANGER

More heat exchanger surface means

less heat up the Chimney. Made of 10

gauge steel rectangular tubes, which

the heat produced by the furnace,

passes through, before entering the

chimney.

EASY ACCESS CLEAN OUTS

The two clean out plates on the front

of the furnace allow easy access to

clean the Secondary Heat Exchanger

tubes. Keeping the inside of your fur-

nace clean insures high efficiency and

helps prevent creosote fires.

PICTURE FRAME FRONT

The front and back of the furnace is

built of 10 gauge steel and painted

with high temperature black paint. The

22 gauge painted side panels are de-

signed to slide onto the flanged steel

for easy installation.

LARGE LOADING FIRE DOOR

WITH POSITIVE DOOR LOCK

This 13” x 13” opening allows for easy

loading and larger diameter split logs.

The positive door lock ensures that

smoke and heat will not escape from

the furnace.

The round cast iron spinner disc

allows secondary air over the flame. It

helps burn smoke and unburned

gases that leave the flame, thereby

increasing efficiency.

FORCED DRAFT INDUCER

BLOWER

This furnace operates on a forced

draft principle. When the thermostat is

calling for heat, the draft blower will

turn on to get the fire burning. Draft

blower air disc must be open.

HONEYWELL TRANSFORMER /

RELAY

These Honeywell Transformers are the

industry standard and made for heating

systems. This 24V control circuit step-

down transformer is designed to power

any 24V control system, including ther-

mostats and relays.

EASY ACCESS ASH PAN

Designed to allow for easy removal of

ashes. Pulls out of furnace, equipped

with additional cross bar handle for

easy ash disposal.

HIGH TEMPERATURE FIREBRICK

1-1/4 thick Hi-Temperature firebrick

surrounds the wood/coal fire. The

Super Jack features 90 pounds of fire-

brick. This firebrick not only protects

the steel from the extreme combustion

temperature in the firebox, but it also

retains a substantial amount of heat

after the wood/coal fire burns down.

HEAVY CAST IRON GRATE

It is imperative that 80 percent of the

air for combustion enter the firebox

from below a wood/coal grate to insure

an efficient and clean burning fire. This

grate is made of heavy cast iron that

can endure the temperatures of wood

and coal fires.

Furnace Features - SJ125

10