SERVICE

CLEARING BLOCKAGES

- DO NOT attempt to clear any blockage while the tractor engine is running. Sudden movement of

the tractor can cause serious injuries.

- DO NOT rely on tractor hydraulics to support the Tracaire during maintenance or repairs. A

sudden hydraulic line failure can cause the unit to drop unexpectedly causing severe injuries to

you or bystanders. ALWAYS use good quality jackstands for support.

- Tines and knives are sharp and could cut hands. ALWAYS wear leather gloves or similar hand

protection when working on or around tines or slicing knives.

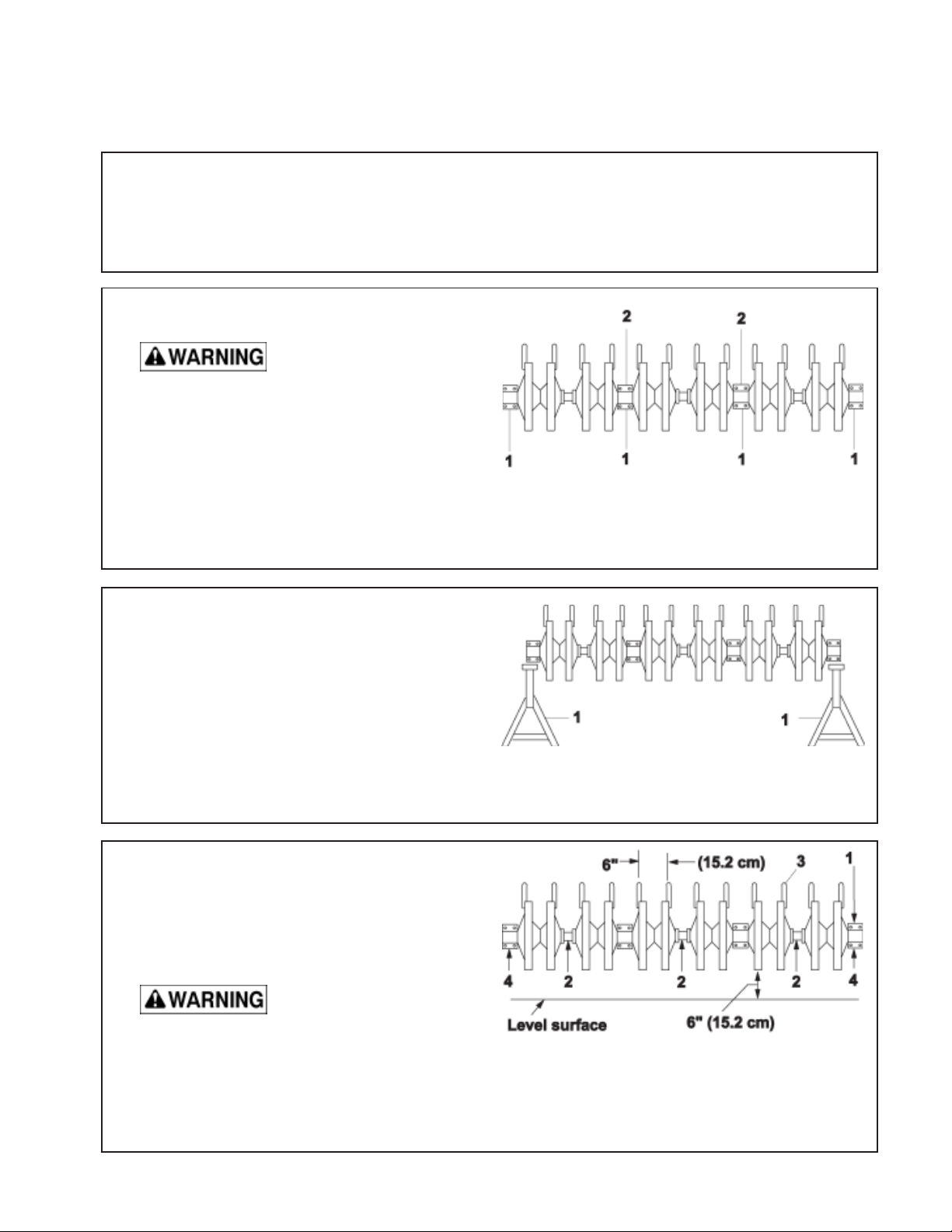

1. Using the tractor hydraulics, raise the Tracaire high enough to allow jackstands to be placed under pillow

blocks. Lower the unit down onto jackstands.

2. Shut off tractor engine.

3. Wearing good hand protection, carefully remove all built up thatch, etc. from tines or knives.

NOTE: If an object becomes wedged in the unit, it may be necessary to remove the tine guard(s) to

remove the blockage.

4. Start tractor engine, raise Tracaire and remove jackstands.

DAILY OR EXTENDED STORAGE

1. Thouroughly clean all tines inside and out when aerating is completed. A light coat of oil or rust inhibitor

inside and out , will help prevent rust and corrosion. This procedure will keep tines or knives in good

condition to insure proper coring the next time the unit is put into service.

2. Wipe off lubrication fittings before and after lubrication. Lubricate all lubrication fittings. Lubricating

before long storage periods, will help prevent moisture build-up in lubrication cavities.

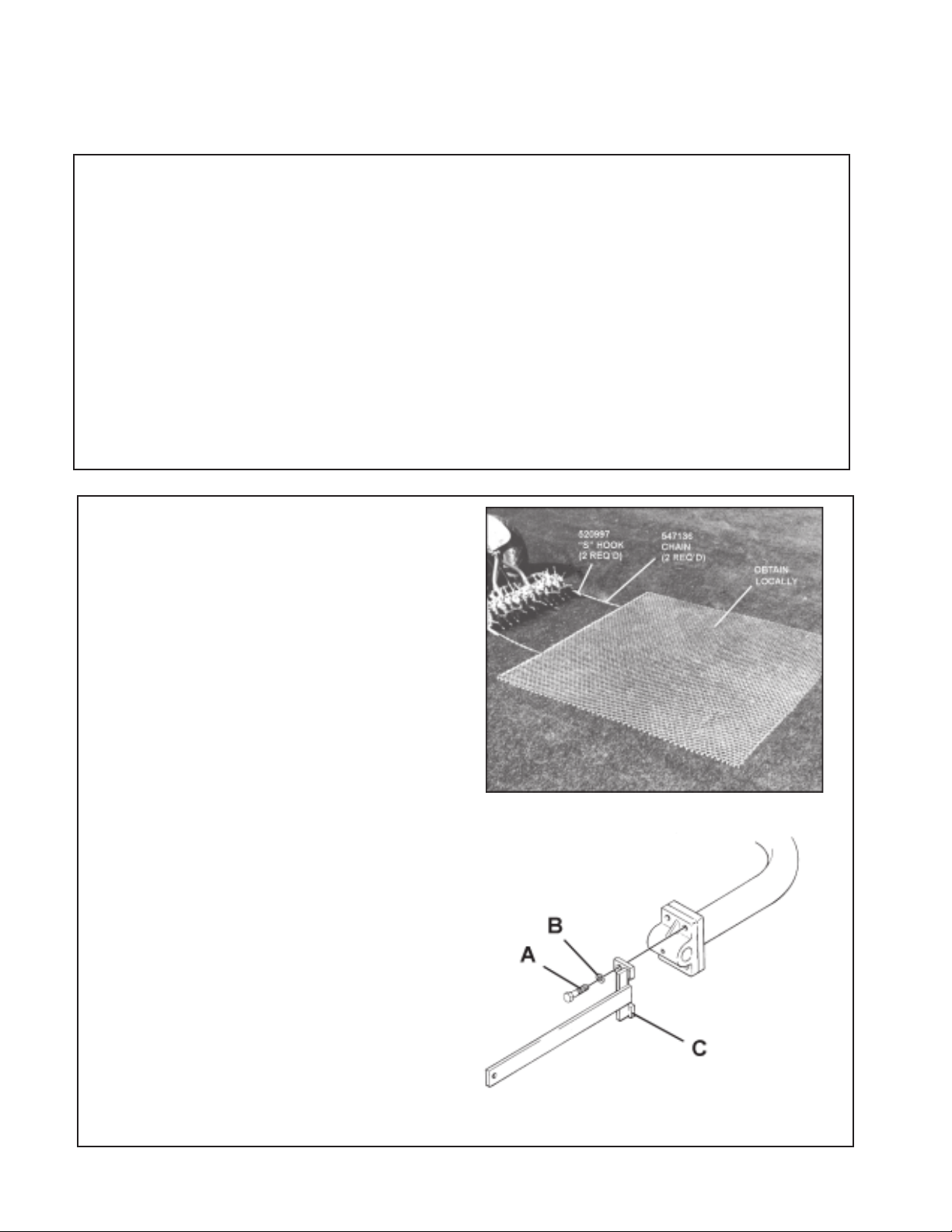

3. Place unit on rubber mats, boards or a similar type material to prevent damage to tines or knives.

LUBRICATION

NOTE: Lubricate aerating wheels after every four (4) hours of aeration.

1. Wipe off all lubrication fittings.

2. Lubricate aerating wheels with a good lithium based lubricant.

3. Wipe off lubrication fittings when finished.

NOTE: After lubricating, check to make sure tine wheel bushings are rotating on the axle and not inside

the tine wheels. If the bushings are turning inside the tine wheel, the bushing may be worn through and

the wheel may have been damaged. If the wheel is damaged it may not accept a new bushing. If the

wheel is damaged to that point, it will need to be replaced.