Page 5

ENGLISH

Jandy®Pro Series, WaterColors RGBW LED Lights |Installation Manual

Section 3. Installing Jandy

Pro Series Light

Fixture during New

Construction

WARNING

Risk of Electrical Shock or Electrocution.

This underwater light must be installed by a licensed

or certified electrician or a qualified pool serviceman

in accordance with the National Electrical Code and

all applicable local codes and ordinances. Improper

installation will create an electrical hazard, which could

result in death or serious injury to pool or spa users,

installers or others due to electrical shock, and may

also cause damage to property.

Always disconnect the power to the color light at the

circuit breaker before installing or servicing the light.

Failure to do so could result in death or serious injury

to serviceman, pool or spa users or others due to

electrical shock.

3.1 Preparing the Light Fixture for

Installation

NOTE The electrician must complete preparatory steps

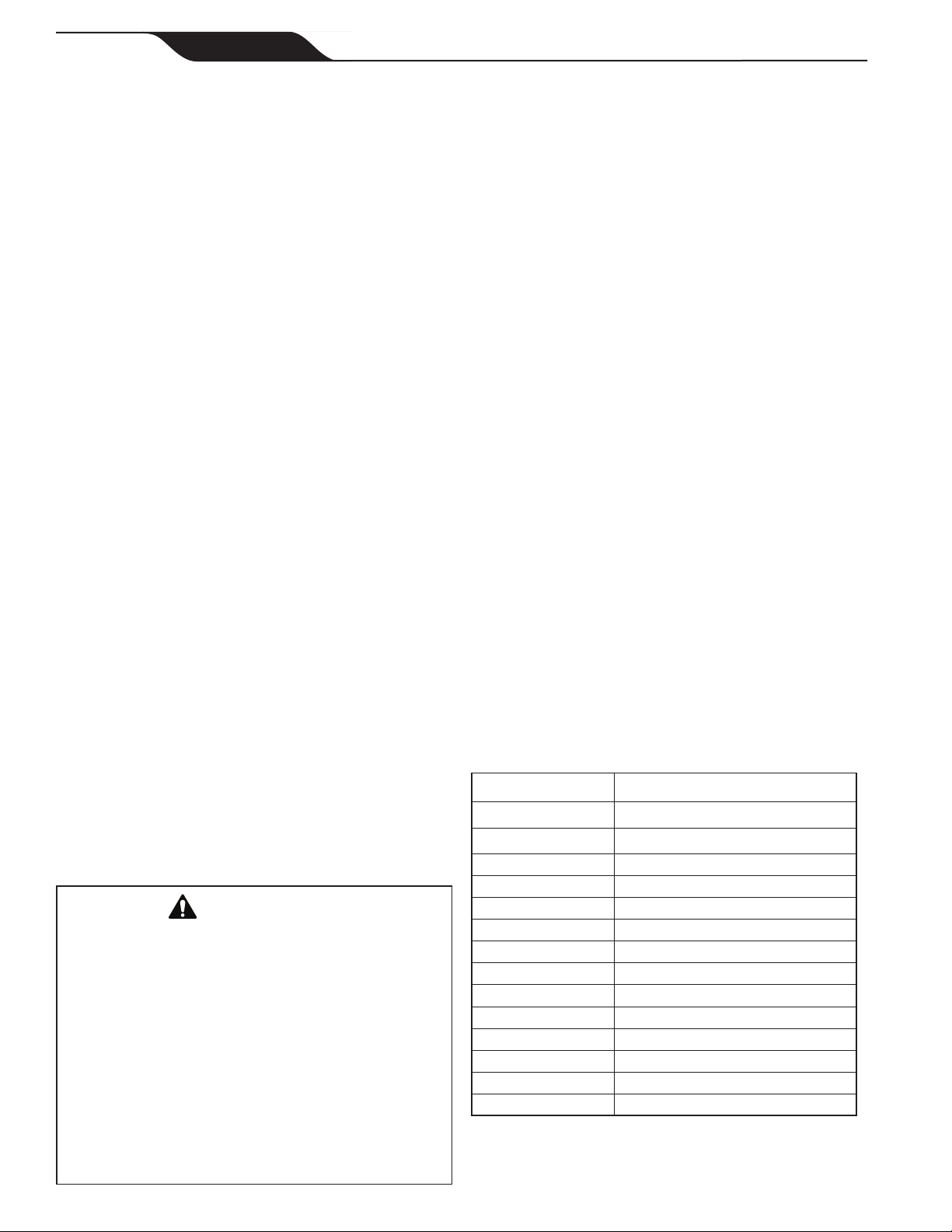

before light fixture is installed. See Figure 1.

Ensure that the pool meets the requirements of the

current National Electrical Code®and all local codes

and ordinances. A licensed or certied electrician must

install the electrical system to meet or exceed those

requirements before the underwater light is installed.

Some of the requirements of the National Electrical

Code, which the pool electrical systems must meet, are as

follows:

WARNING

To minimize risk of Electrical shock or electrocution,

which could result in injury or death, for supply

connection of low-voltage lights use only an isolating

low voltage power supply, evaluated and listed by a

Nationally Recognized Testing Laboratory (NRTL) for

swimming pool use.

1. The lighting circuit must have a Ground Fault

Circuit Interrupter (GFCI) for 120 volt models,

and must have an appropriately rated circuit

breaker.

2. The junction box (or, for 12 volt models, the low

voltage transformer) must be located at least eight

(8) inches above water level, at least four (4)

inches above ground level, and at least four (4)

feet from the edge of the pool. See Figure 1.

3. The light xture and all metal items within ve

(5) feet of the pool must be properly electrically

bonded to a reliable point of grounding.

4. The wet niche must be properly installed so that

the top edge of the underwater light’s lens is at

least 18 inches below the surface of the water in

the pool. See Figure 1.

5. The wet niche must be properly electrically

bonded and grounded via the No. 8 AWG ground

connector located at the rear of the niche. See

Figure 1.

NOTE To be certain that the pool’s electrical system meets

all applicable requirements, the electrician should also

consult the local building department.

Use only approved wet niches (see following note) to

ensure a safe and proper installation.

NOTE Jandy Pro Series lights are ETL listed (ETL report/

file 3141154CHI) for installation with only the following

manufacturer’s wet niche fixtures:

Large Niche Model Numbers:

Jandy Pro Series: PLNICLRG, PLNICVFLRG,

WT000002, SSNICLRG1R, SSNICLRG1S

Pentair: 620004, 78210200 thru 700,

78210401, 79206700

Hayward DuraNiche: SP0600U

Sta-Rite: 05161-2352 thru 2369, 05163-2395

thru 2396

Small Niche Model Numbers:

Jandy Pro Series: PLNICSM, SSNICSM,

Pentair: 78241100, 78242200, 78242300

78243100 thru 300, 78244100 thru 300,

79206600

Hayward DuraNiche: SP0601U

Sta-Rite: 05166-1017 thru 1034, 05167-1035

thru 1037

Pentair®and Sta-Rite®are registered trademarks of Pentair, Inc.

Hayward®is a registered trademark and DuraNiche™is a trademark of

Hayward Pool Products, Inc.

4" min.

48"

min.

8" min. Junction Box or Low

Voltage Transformer, to the

max water level of the pool.

18" min. to top of Lens.

11.50"

Concrete must be cut

back around Niche to

allow for a compacted

plaster seal.

Coil 4 ft. of light cable

around Fixture.

#8 AWG Ground

Connector bonding

is located at rear

of niche.

Rigid

Conduit

To GFCI, Circuit

Breaker and

Power Source.

16”