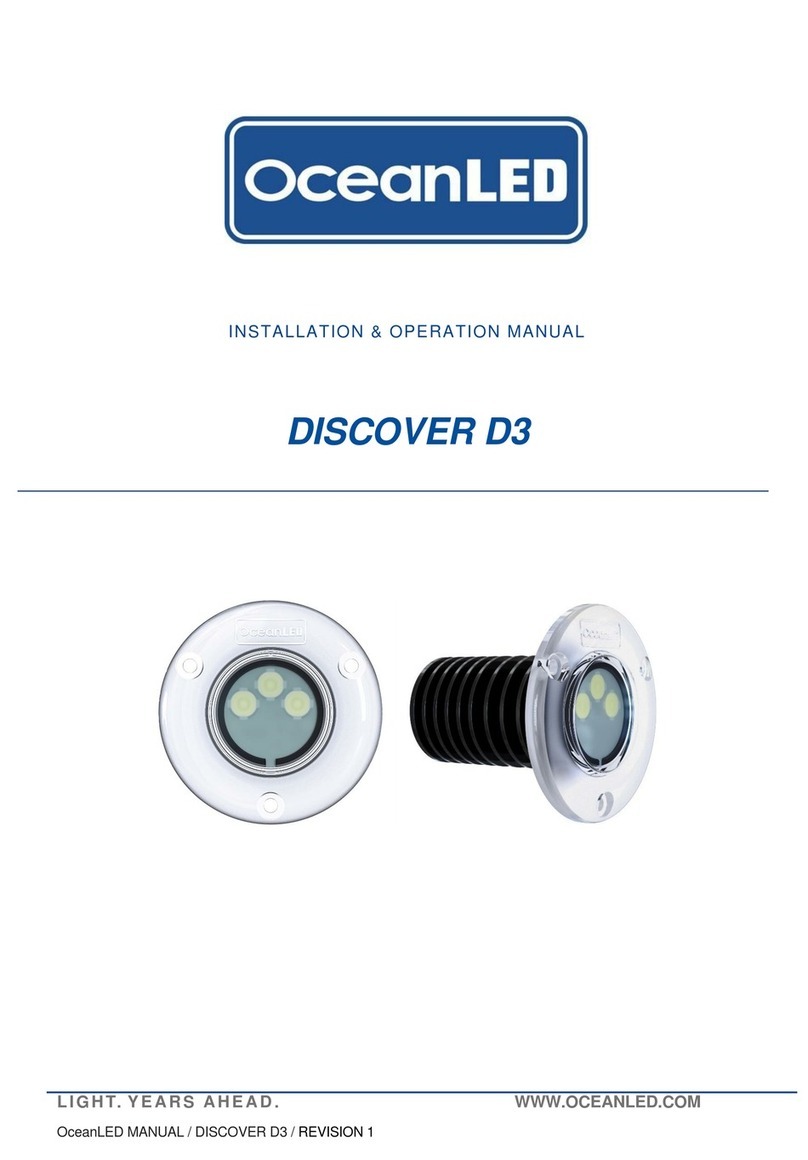

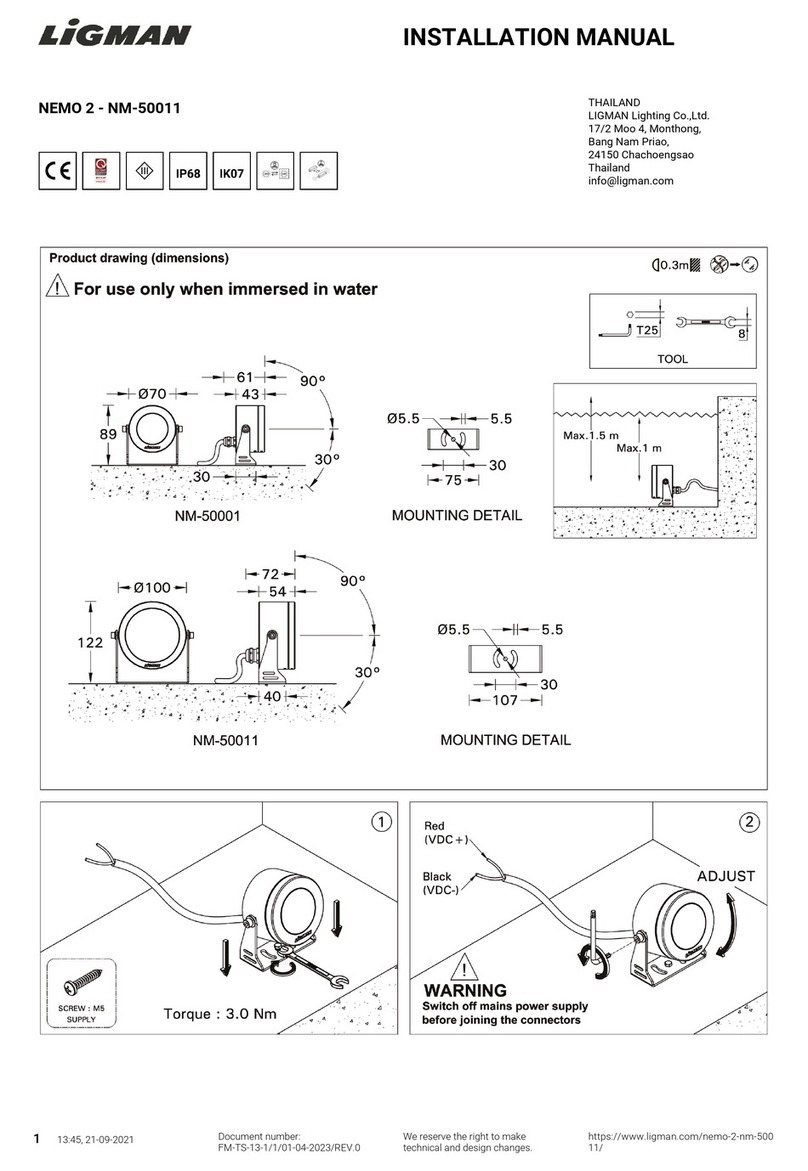

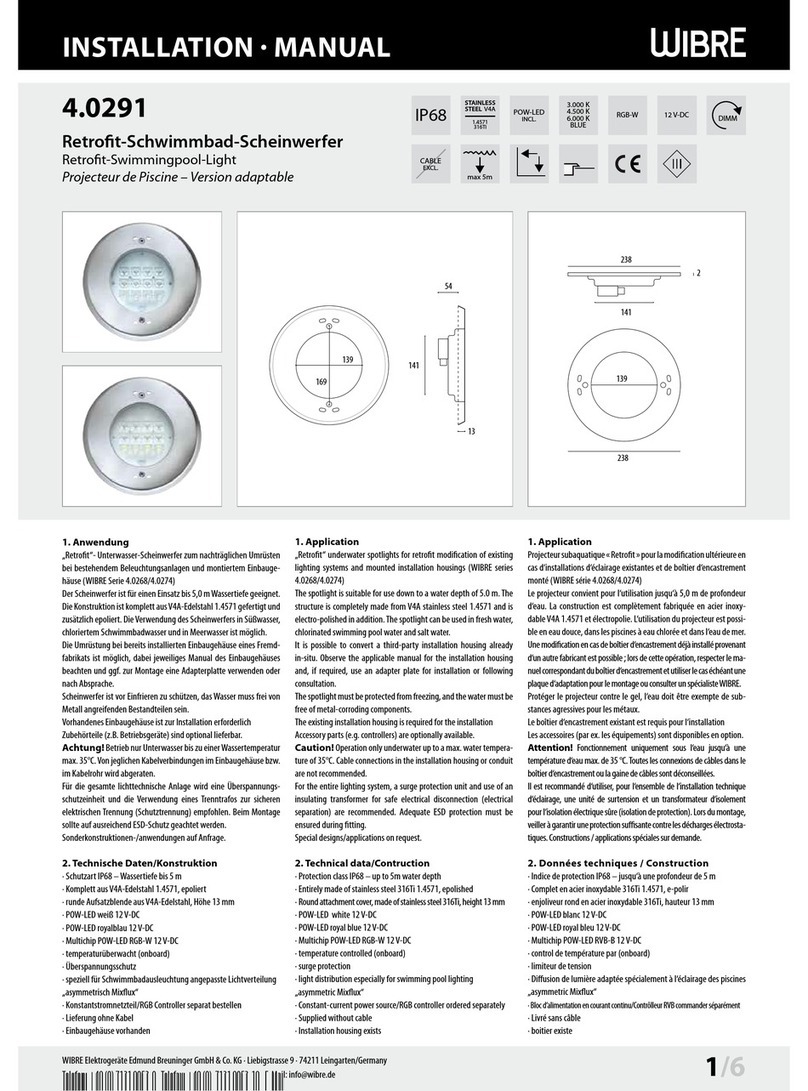

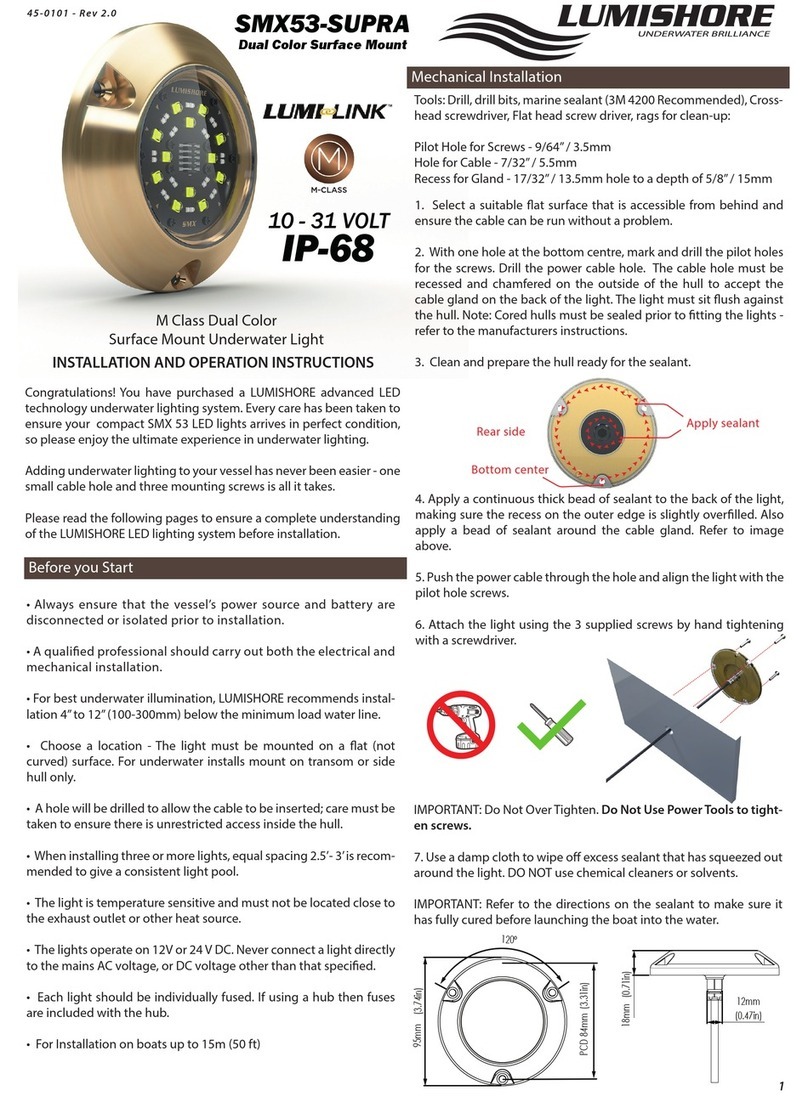

Installation:

This light should be installed at minimum 250-300mm (10-12”) below the light load water line with approximately a 20° down angle

by qualified/approved personnel using proper tools, welding procedures and materials. An access area of at least 75mm (3”)

should be left behind the light for servicing and general ventilation.

After selecting a location, cut an appropriate sized hole through the vessel hull. Note: Hole size will be defined by the specific weld-

in Front Flange (18) that came with the light. Caution! Check that no electrical wiring, fuel lines, oil lines, water lines etc., pass

near or through the intended hole location. Note: In order to allow proper heat dissipation from the installed lights it is important

to ensure that any hull insulation/cladding is not in contact with the thru hull or light body. It is recommended that a minimum of

30mm (1.2”) of clear space should be surrounding the fixture to allow for adequate cooling.

Place the supplied Front Flange (18) into said hole and following common ship building practices, permanently weld-in place. Note:

Leave the factory installed block-off disk and protective cap on the supplied Front Flange (18) until final light assembly.

Final light assembly - Remove Front Flange (18) block-off disk, protective cap and clean all surfaces. Install two Glass Gaskets (5)

(one gasket on either side of glass) Glass (4), Glass Retaining Ring (3) and six fasteners (13) tightened in a criss-cross pattern to 9

Nm (7 ft/lbs) using a 5mm allen wrench. Screw Connecting Ring (2) with attached Main Body (1) onto Front Flange (18) and

tighten to 40 Nm (30 ft/lbs). Note: Apply anti-seize compound to Connecting Ring (2) threads. Upon making proper electrical

connections (see driver box manual), connect Receptacle (16) to plug (17). Note: Upon completing light installation, it is highly

recommended that the Front Flange (18) be coated with antifouling paint.

Serviceable Parts:

This light is fully serviceable and all parts are replaceable. Please contact our technical support staff to discuss your individual

needs.

For Glass (4) replacement, disconnect Receptacle (16) from Plug (17), remove Connecting Ring (2) with attached Main Body (1),

remove six fasteners (13), Glass Retaining Ring (3) and Glass Gaskets (5). Upon thoroughly cleaning all surfaces, reverse said

procedure to assemble the new Glass (4) and Glass Gaskets (5). Note: Tighten all six fasteners (13) in a criss-cross pattern to 9

Nm (7 ft/lbs) using a 5mm allen wrench. Caution! Never attempt to remove/replace Glass (4) while vessel is in the

water.

MODELS B15_12A41-12G32L, 120/230VAC (STEEL)

MODELS B15_10A41-12G32L, 120/230VAC (ALUMINUM)

BALLOON PART DESCRIPTION

1 14323 MAIN BODY / COFFERDAM

2 14002 CONNECTING RING

3 14004 GLASS RETAINING RING

4 14007 GLASS

5 14008 GLASS GASKET

6 14009 CONNECTING RING GASKET

7 14310 LED ARRAY

8 14321 THERMOSWITCH

9 14305 CABLE STRAIN RELIEF

10 14306 ELECTRICAL CABLE

11 14015 M6 x 1.0 x 14LG SST SHCS

12 14320 SILICONE LENS

13 14319 LENSE HOLDER

14 14322 M7 x 0.7 x 8LG SST PPHS

15 14307 M3 x 0.5 x 5LG SST PPHS

16 14316 RECEPTACLE ASSEMBLY, 2-WAY

17 14317 PLUG ASSEMBLY, 2-WAY

18 N/A CALL TECHNICAL SUPPORT FOR

APPROPRIATE FRONT FLANGE

SV14 LED Light

Underwater Lights USA, LLC Underwater Lights Europe Sarl

3406 S.W. 26th Terrace, C 6/7 16, rue Rouaze

Fort Lauderdale, FL 33312 USA 06400 Cannes, France

Phone: 1-954-760-4447 Phone: 33-(0)-4-97-21-02-96

Fax: 1-954-525-3261 Fax: 33-(0)-4-97-21-10-96

Internet: www.seavision.com Internet: www.seavision.com

Email: sales@seavision.com DOC:022412-4 Email: sales@seavisioneurope.com

STEEL/ALUMINUM