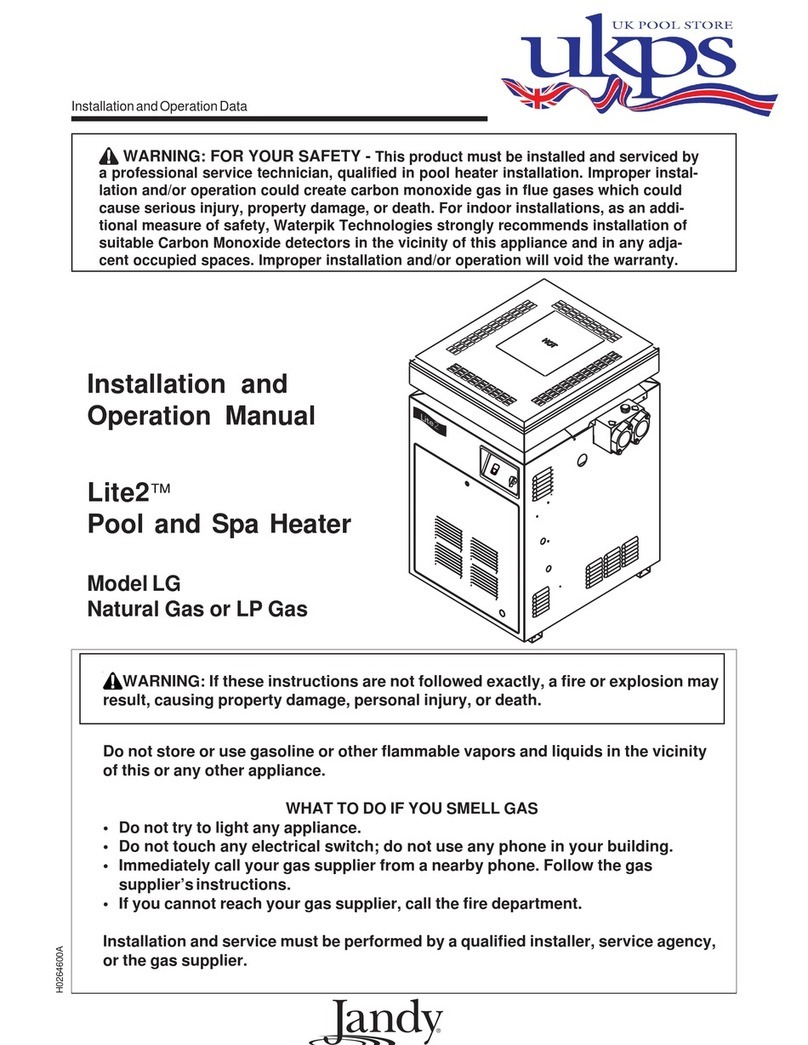

Page3LITE 2 MODEL LG POOL AND SPA HEATER

WARNING

Do not connect the heater to any external

source of electricity. The Jandy Lite 2 Model

LG heater has a built in thermoelectric

generator. It provides a completely self-

contained electrical system. Any attempt to

make electrical connections to an external

source will damage the heater, and could be

dangerous.

The heater can be installed indoors (using the

draught divertor and a suitable flue system) or out-

doors (using a flue system or with the outdoor flue

terminal assembly, which is available as an optional

extra).

Zodiac Pool Systems, Inc., specifically designs

this appliance to heat fresh water swimming pools

and spas. Do not use it as a heating boiler or general

service water heater. For special applications, consult

your Jandy dealer.

1C. Warranty

The LG heater is sold with a limited factory

warranty. A copy of the warranty is shown on the

back cover of this manual.

The warranty does not cover damage caused by

improper installation, or field modification, or to the

heat exchanger by corrosive water.

SECTION 2.

InstallationInstructions

2A. Statutory Information

It is the law that all gas appliances are to be

installed only by competent persons (e.g., members of

the Confederation of Registered Gas Installers

[CORGI]) in accordance with the Gas Safety (Instal-

lation and Use) Regulations, 1994. Failure to install

appliances correctly could lead to prosecution.

The LG heater, as supplied, has been tested and

certified by British Gas to PREN656 for use with

natural and LPG gases. LG heaters are only permit-

ted to be installed in the open air or in a room which

is separated from living rooms and provided with

appropriateventilation directlyto theoutside.

WARNING

The LG heater is certified to European

requirements for use only as a swimming pool

or spa heater. The LG heater must not be used

for any other purpose and must be installed

and serviced by a qualified professional. The

LG heater must be operated strictly in

accordance with the manufacturer's

instructions. If the LG heater is installed in a

room, adequate air supply and ventilation must

be provided and maintained. Never store any

materials within the area of the heater or

ventilationopenings.

It is important that no external control devices

(e.g., flue dampers, economizers, etc.) be directly

connected to the LG heater unless covered by these

installation and servicing instructions or otherwise

recommended in writing by Zodiac Pool Systems, Inc.

If in doubt please ask. Any direct connection of a

control device not approved by Zodiac Pool Systems,

Inc., could invalidate the British Gas certification, the

normal LG heater warranty, and could also violate

applicable gas safety regulations.

2B. General Installation Requirements

The LG heater must be installed by competent

persons (e.g., CORGI member). The LG heater must

be installed in accordance with the relevant require-

ments of the Gas Safety Regulations, current I.E.E.

Regulations, Model Water Bylaws, local Water

Authority Bylaws, and any relevant requirements of

local gas region, local authority, and relevant British

Standard Codes of Practice and Building Regulations.

Table 3 lists regulations for small and large pipe

installations.

All gas-fired products require correct installation

to assure safe operation. The requirements for heaters

includethefollowing:

1. Appropriate site location (clearances)

2. Non combustible surface

3. Sufficient combustion air and ventilation air

4. Adequate ventingof combustion products

5. Adequate waterflow

6. Properly sized gas pipe

7. Regularmaintenance

2C. Reversible Water Connections

Zodiac Pool Systems, Inc., ships the LG heater

with the water connections on the right side. It could