2

TABLE OF CONTENTS

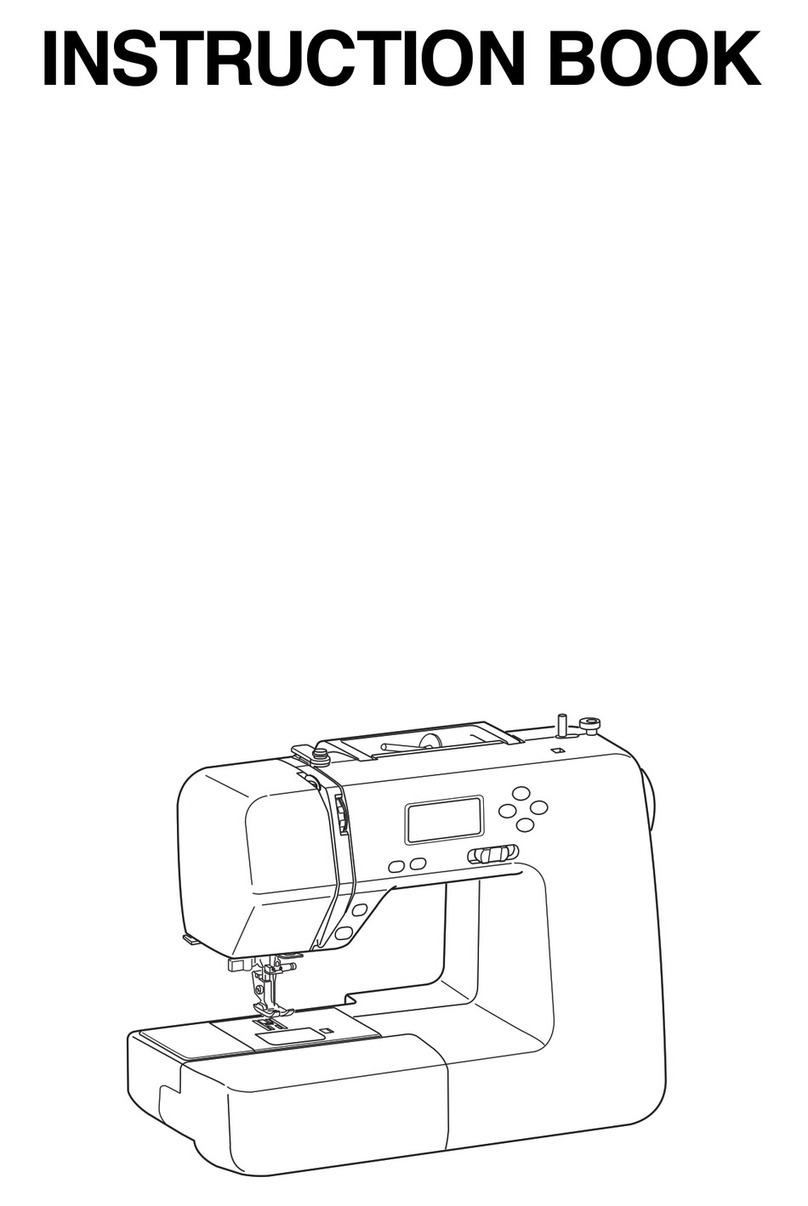

ESSENTIAL PARTS

Names of Parts............................................................... 3

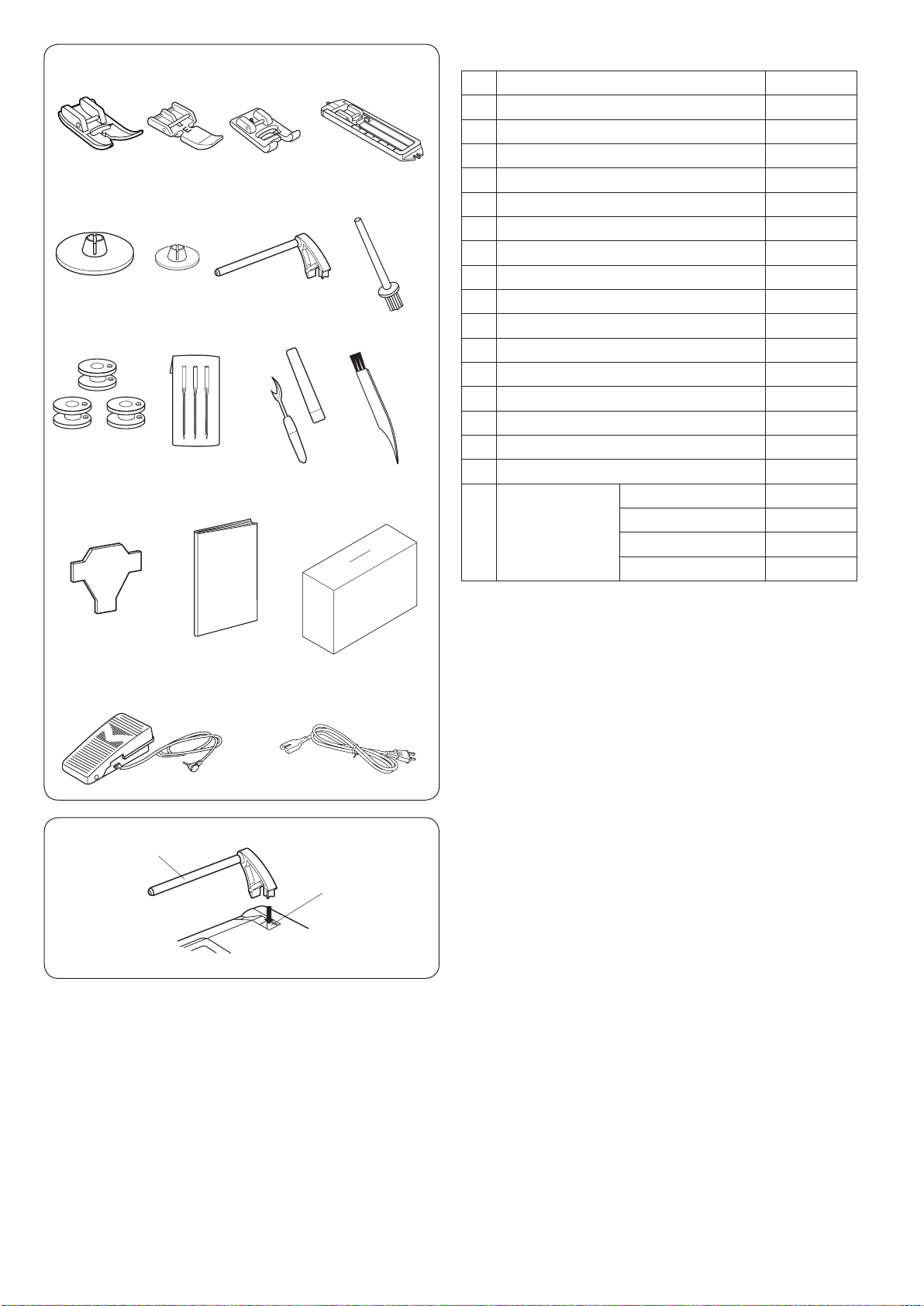

Standard Accessories .................................................... 4

Setting the Spool Pin...................................................... 4

GETTING READY TO SEW

Connecting the Power Supply........................................ 5

Using the foot control ................................................... 5

Before Using Your Sewing Machine............................. 5

Operating Instructions: ................................................. 5

Foot control .................................................................... 6

Extension Table.............................................................. 6

Free-arm Sewing............................................................ 6

Machine Operating Buttons............................................ 7

Reverse button ............................................................. 7

Auto-lock button ........................................................... 7

Needle up/down button ................................................ 7

LCD Display.................................................................... 8

Function Keys................................................................. 8

Mode key...................................................................... 8

Value set key ................................................................ 8

Selecting Stitch Patterns ................................................ 8

(1) Pattern selection mode ........................................... 8

(2) Stitch width adjustment mode ................................ 8

(3) Stitch length adjustment mode................................ 8

Presser Foot Lifter.......................................................... 9

Changing the Presser Foot ............................................ 9

Removing and Attaching the Foot Holder ...................... 9

Adjusting the Needle Thread Tension .......................... 10

Straight stitch balanced tension ................................. 10

Zigzag stitch balanced tension....................................11

Dropping or Raising the Feed Dog............................... 12

Changing the Needle.................................................... 12

Fabric, Thread and Needle Chart................................. 13

Setting the Spool of Thread ......................................... 14

Setting the spool ........................................................ 14

Extra spool pin ........................................................... 14

Bobbin Winding ............................................................ 14

Removing the bobbin ................................................. 14

Winding the bobbin .................................................... 15

Bobbin winding with the extra spool pin..................... 15

Inserting the bobbin...................................................... 16

Threading the Machine................................................. 17

Built-in Needle Threader .............................................. 18

Drawing up the Bobbin Thread .................................... 19

BASIC SEWING

Straight Stitch Sewing .................................................. 20

Starting to Sew........................................................... 20

Securing Seams ......................................................... 20

Cutting Threads.......................................................... 20

Changing Sewing Direction........................................ 20

Using Seam Guides ................................................... 21

Turning Square Corners ............................................. 21

Altering the Needle Drop Position .............................. 22

Altering the Stitch Length ........................................... 22

Variety of Straight Stitches ........................................... 23

Lock-a-matic Stitch..................................................... 23

Locking Stitch............................................................. 23

Triple Stretch Stitch .................................................... 23

Stretch Stitch .............................................................. 24

Zigzag Stitch................................................................. 25

Altering the stitch width .............................................. 25

Altering the stitch length ............................................ 25

Variety of Overcasting Stitches .................................... 26

Overcasting with Zigzag Stitch................................... 26

Multiple Zigzag Stitch ................................................. 26

Overedge Stitch.......................................................... 26

Knit Stitch ................................................................... 27

Overlock Stitch ........................................................... 27

Memory Buttonhole.................................................28-30

Altering the buttonhole width...................................... 30

Altering the buttonhole density................................... 30

Corded Buttonhole ....................................................... 31

Zipper Sewing .........................................................32-34

Blind Hemming............................................................. 35

Button Sewing .............................................................. 36

Attaching Elastic........................................................... 36

Gathering...................................................................... 37

DECORATIVE STITCHES

Patchwork..................................................................... 38

Shell Tuck ..................................................................... 38

Applique ....................................................................... 39

Fringing......................................................................... 40

Drawn Work.................................................................. 40

Fagoting........................................................................ 41

Scallop Stitch................................................................ 41

Smocking...................................................................... 42

Satin Stitches ............................................................... 42

Decorative Stitches ...................................................... 43

CARE OF YOUR MACHINE

Cleaning the Hook Race and Feed Dog ...................... 44

Installing the Bobbin Holder ......................................... 44

Correcting Deformed Stitch Patterns ........................... 45

Problems and Warning Signals .................................... 45

Troubleshooting............................................................ 46

Stitch Chart................................................................... 47