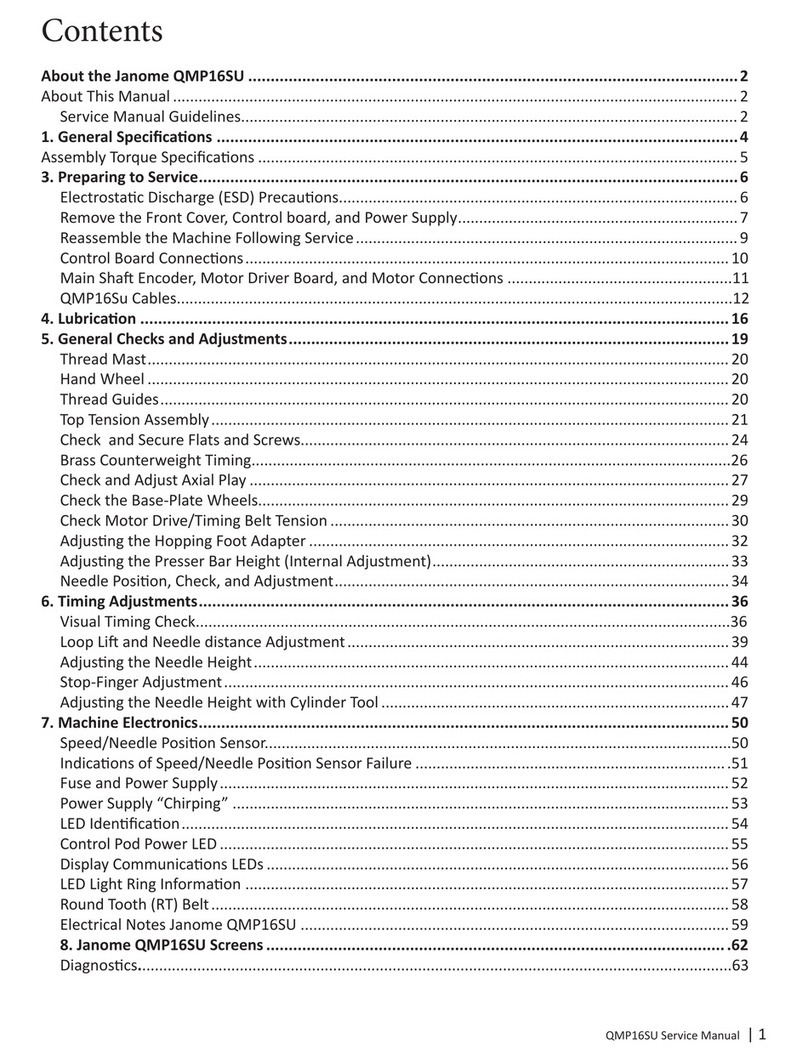

CONTENTS

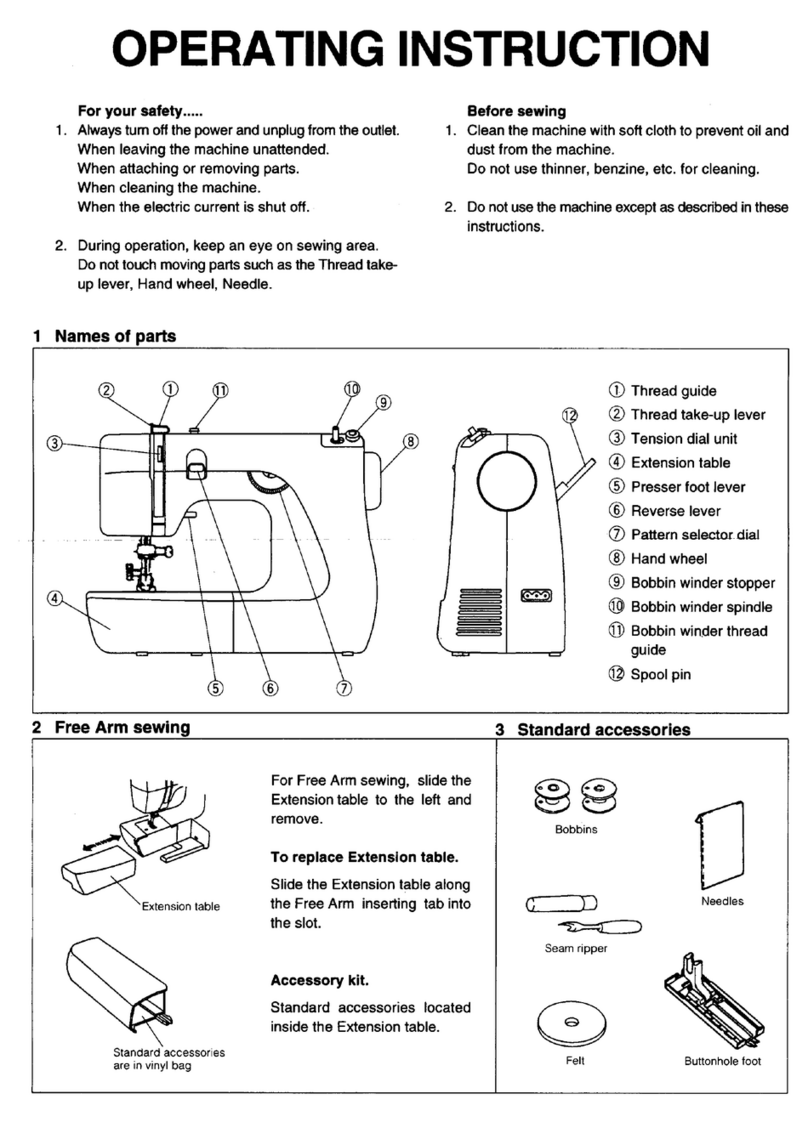

LOCATE AND IDENTIFY THE PARTS ............................................................................................................... 1

WINDING THE BOBBIN .................................................................................................................................... 2

THREADING THE MACHINE ............................................................................................................................ 3

CONNECTOR DIAGRAM .................................................................................................................................. 4

GENERAL TROUBLE SHOOTING PROCEDURE ............................................................................................ 5

WHAT TO DO WHEN ......................................................................................................................................6-8

SELF-DIAGNOSTIC TESTS .........................................................................................................................9-11

SERVICE ACCESS

FACE COVER ................................................................................................................................... 12

TOP COVER ..................................................................................................................................... 12

BELT COVER.................................................................................................................................... 13

BASE PLATE .................................................................................................................................... 14

BED COVER ..................................................................................................................................... 14

FRONT COVER ................................................................................................................................ 15

REAR COVER .................................................................................................................................. 16

FREE ARM COVER.......................................................................................................................... 17

MECHANICAL ADJUSTMENT

NEEDLE DROP POSITION .............................................................................................................. 18

NEEDLE BAR HEIGHT .................................................................................................................... 19

NEEDLE TO HOOK TIMING ............................................................................................................. 20

CLEARANCE BETWEEN NEEDLE AND HOOK ............................................................................. 21

BACKLASH (BETWEEN LOWER SHAFT GEAR AND HOOK GEAR) ....................................................

22

FEED DOG HEIGHT ........................................................................................................................ 23

ZIGZAG SYNCHRONIZATION ......................................................................................................... 24

TENSION RELEASE MECHANISM ................................................................................................. 25

STRETCH STITCH FEED BALANCE ADJUSTMENT ..................................................................... 26

NEEDLE THREAD TENSION ........................................................................................................... 27

BUTTONHOLE LEVER..................................................................................................................... 28

PRESSER FOOT HEIGHT AND ALIGNMENT ................................................................................ 29

PART REMOVAL AND REPLACEMENT

NEEDLE THREAD TENSION UNIT ................................................................................................. 30

THREADER PLATE .......................................................................................................................... 31

REPLACING THE PRINTED CIRCUIT BOARD “A” .............................................................................................. 32

REPLACING THE PRINTED CIRCUIT BOARD “F” .............................................................................................. 33

REPLACING SLIDE VOLUME .............................................................................................................................. 34

REPLACING DC MOTOR AND ADJUSTING MOTOR BELT TENSION ............................................................... 35

REPLACING THE FUSES .................................................................................................................................... 36

REPLACING MACHINE SOCKET (UNIT) ............................................................................................................ 37

REPLACING TRANSFORMER ............................................................................................................................. 38

REPLACING THE ZIGZAG WIDTH MOTOR ........................................................................................................ 39

REPLACING THE FEED STITCH MOTOR ........................................................................................................... 40

ADJUSTING THE BOBBIN WINDER SWITCH .................................................................................................... 41

OILING .......................................................................................................................................................... 42

................................. 43-61

PARTS LIST ...................................................................................................................