What to do when......................................................................................................... 1-2

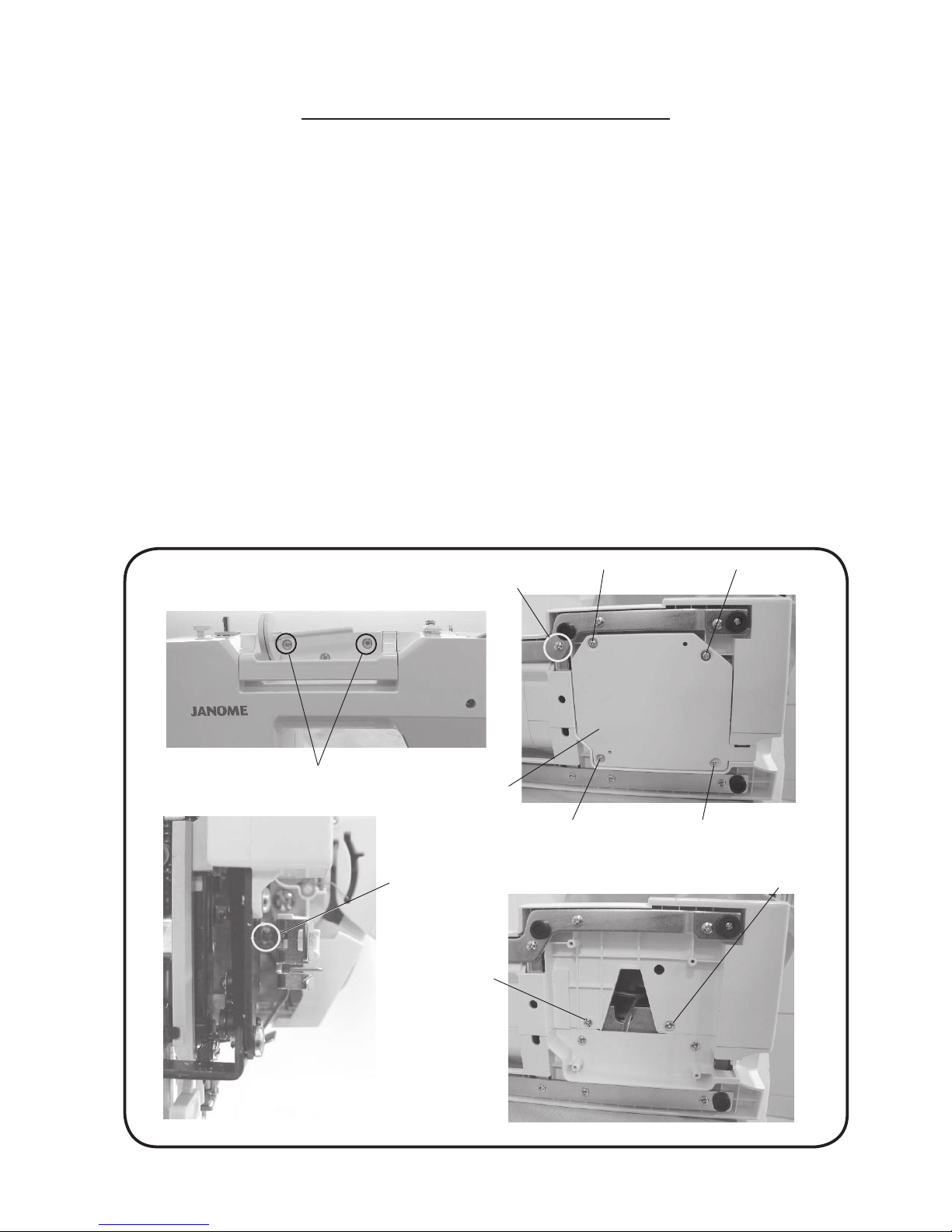

Changing External Parts (1) (Face Cover) .................................................................... 3

Changing External Parts (2) (Free-arm Cover).............................................................. 4

Changing External Parts (3-1) (Front Cover)................................................................. 5

Changing External Parts (3-2) (Front Cover)................................................................. 6

Changing External Parts (4) (Rear Cover) .................................................................... 7

Presser Bar Height ........................................................................................................ 8

Needle Drop Position..................................................................................................... 9

Adjustment of Hook Timing.......................................................................................... 10

Adjustment of Needle Bar Height ................................................................................ 11

Clearance between Needle and Tip of Hook Rotary ................................................... 12

Feed Dog Height ......................................................................................................... 13

Feed Dog Adjustment.................................................................................................. 14

Top Tension.................................................................................................................. 15

Circuit Board A connection.......................................................................................... 16

Self-diagnostic Test ................................................................................................ 17-22

To Display the Version of the Program......................................................................... 22

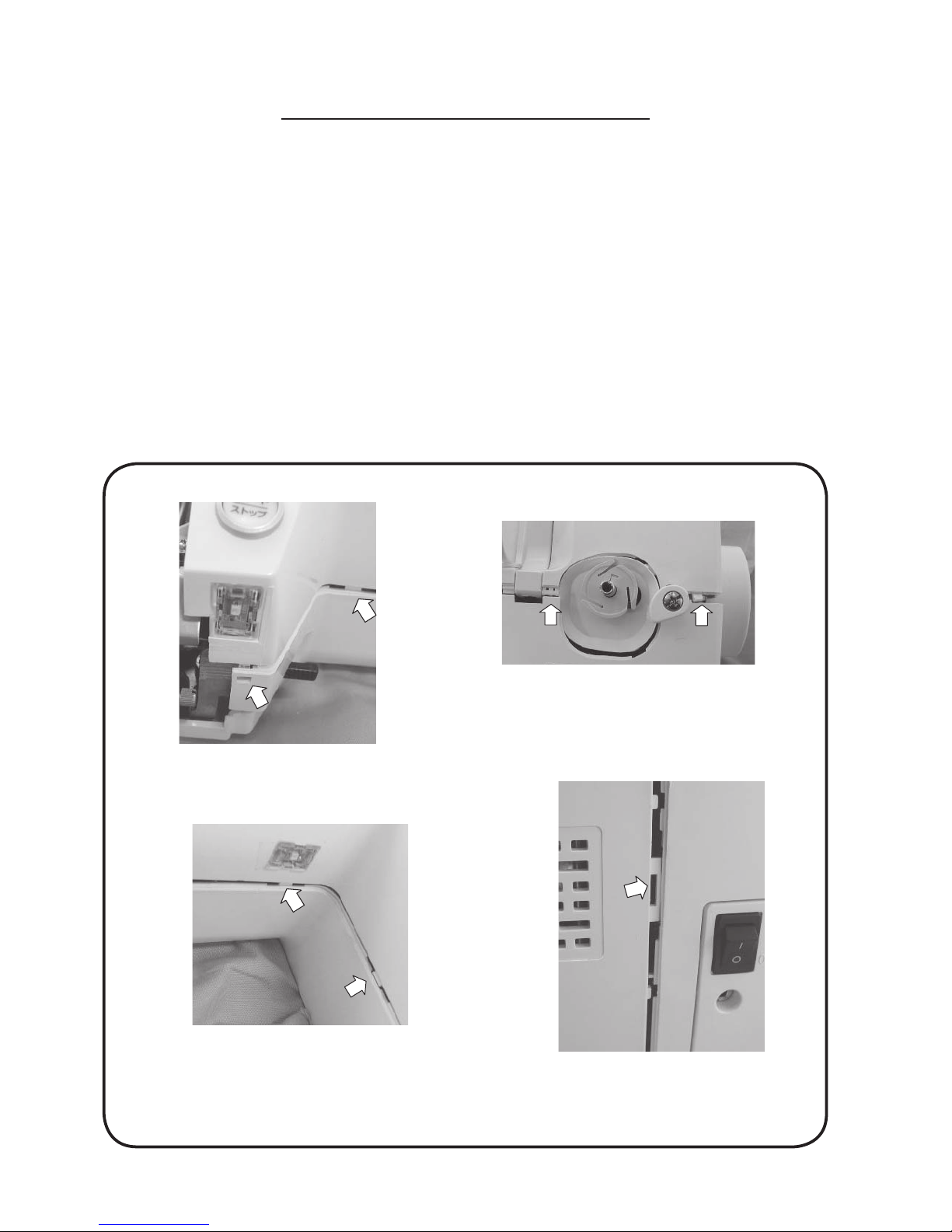

Replacing the Circuit Board A ..................................................................................... 23

Replacing the Circuit Board F, F2, L1, L2 and Speed Control Slider........................... 24

Replacing the Driving Motor ........................................................................................ 25

Replacing the Switching Regulator unit....................................................................... 26

Adjustment of Buttonhole Lever Position..................................................................... 27

Adjustment of Needle Threader Plate.......................................................................... 28

Replacing thte Bobbin Thread Holder/Cutter unit ........................................................ 29

Cleaning area of Thread Cutter and Lower Shaft Gear ............................................... 30

INDEX