CONTENTS

WHAT TO DO WHEN .................................................................................................................................1 - 3

SERVICE ACCESS

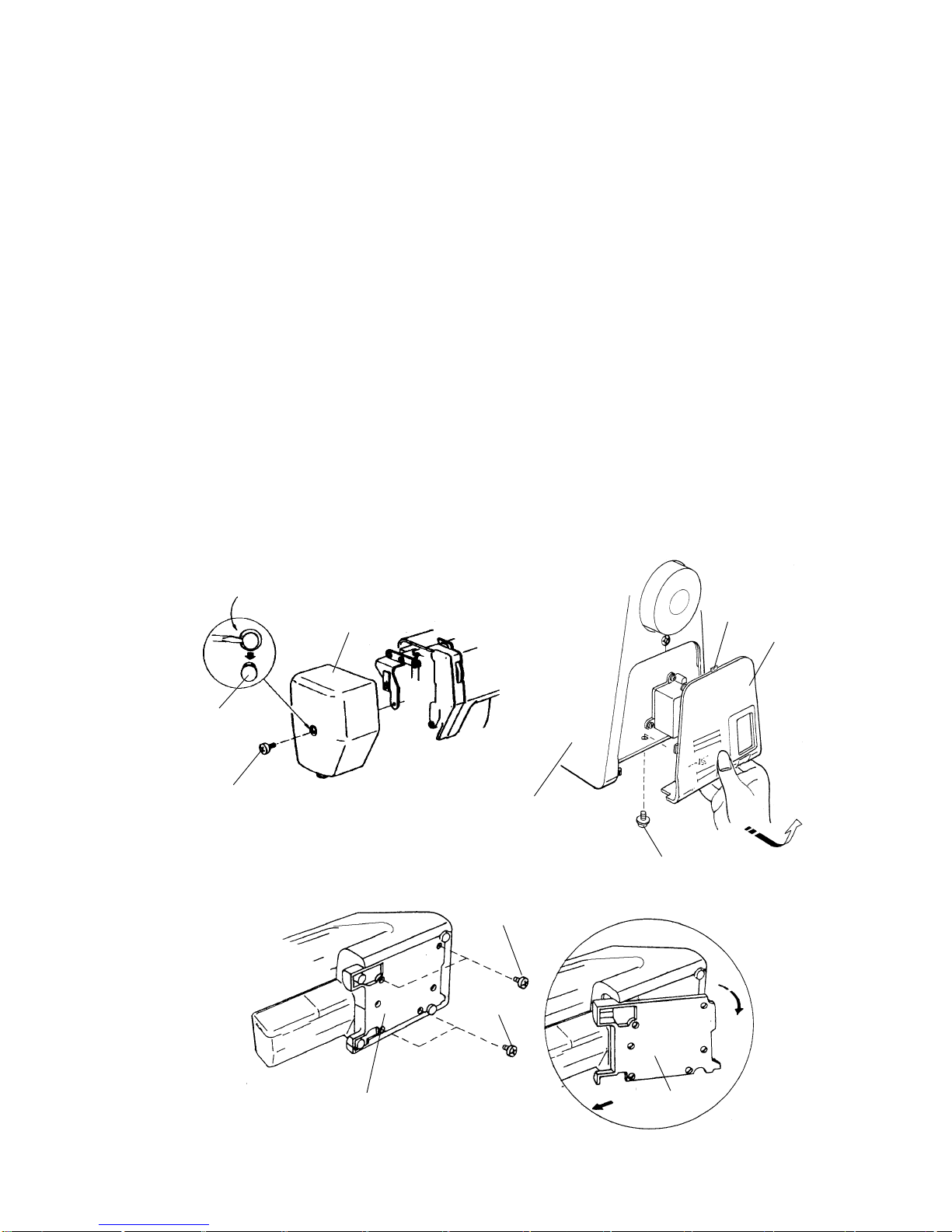

FACE PLATE ........................................................................................................................................4

BELT COVER ....................................................................................................................................... 4

BED BASE PLATE ...............................................................................................................................4

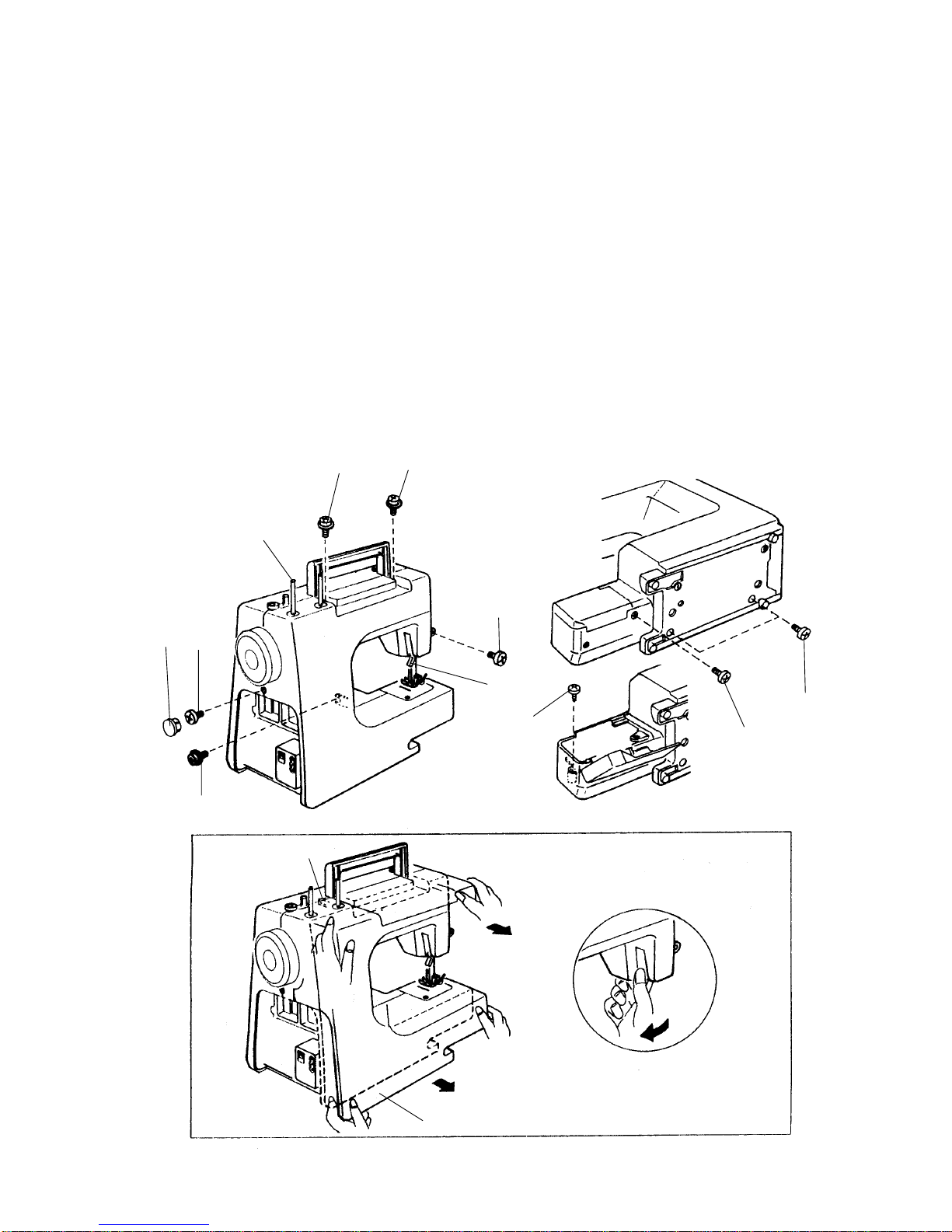

FRONT COVER ...................................................................................................................................5

REAR COVER......................................................................................................................................6

MECHANICAL ADJUSTMENT

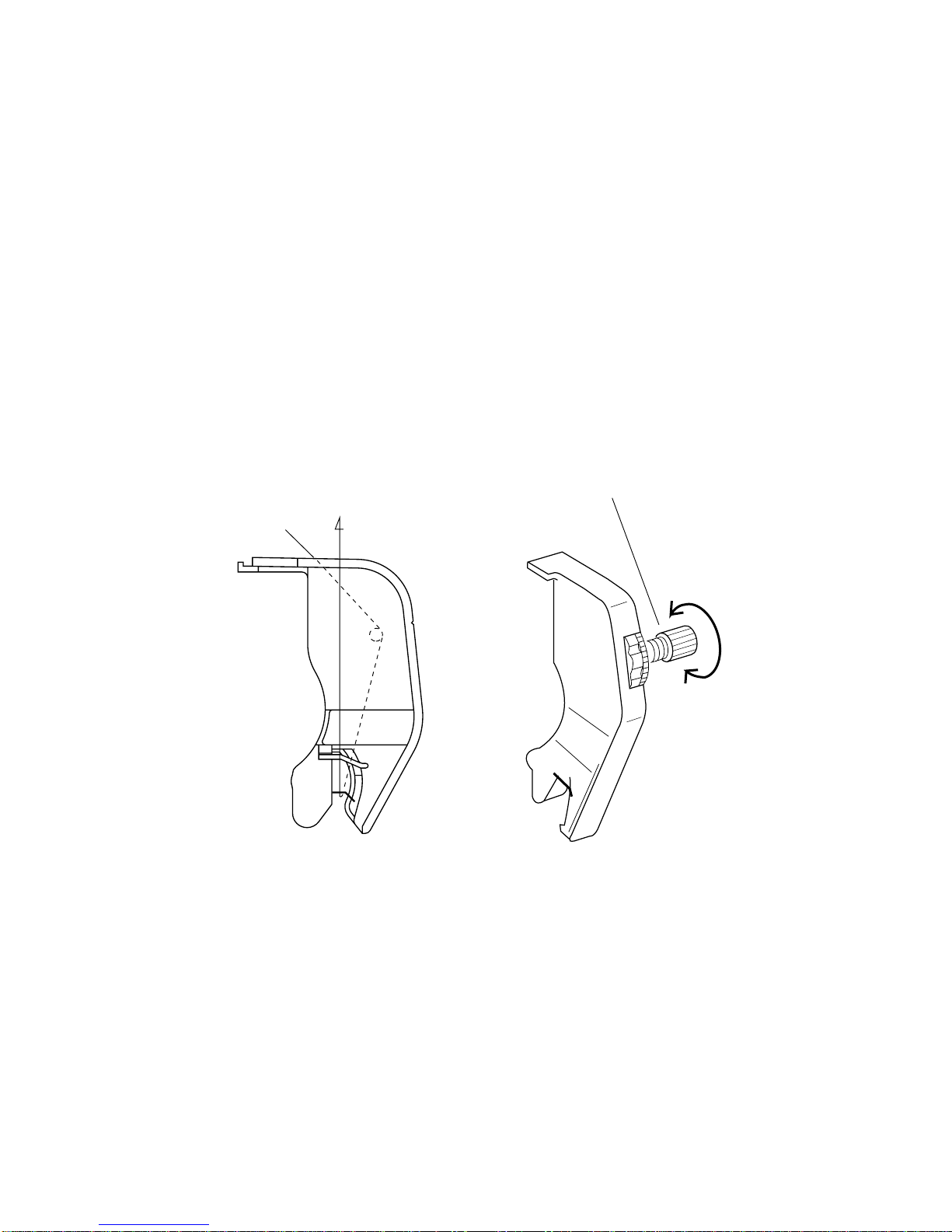

UPPER THREAD TENSION DIAL........................................................................................................ 7

BOBBIN THREAD TENSION ............................................................................................................... 8

PRESSER BAR HEIGHT AND ALIGNMENT.......................................................................................9

NEEDLE SWING................................................................................................................................ 10

NEEDLE DROP.................................................................................................................................. 11

HEIGHT OF FEED DOG .................................................................................................................... 12

CLEARANCE BETWEEN NEEDLE AND HOOK (NO.1) ................................................................... 13

CLEARANCE BETWEEN NEEDLE AND HOOK (NO.2) ................................................................... 14

NEEDLE BAR HEIGHT ...................................................................................................................... 15

HOOK TIMING ................................................................................................................................... 16

FEED BALANCE ON STRETCH STITCH.......................................................................................... 17

BUTTOHOLE FEED BALANCE ......................................................................................................... 18

BARTACK FEED OF BUTTONHOLE ................................................................................................. 19

DISENGAGEMENT OF CAM FOLLOWER (NO.1) ............................................................................ 20

NEEDLE MOVEMENT FOR STRAIGHT STITCH.........................................................................21-22

BUTTONHOLE FUNCTION ............................................................................................................... 23

MOTOR BELT TENSION .................................................................................................................... 24

WIRING......................................................................................................................................................... 25