INDEX

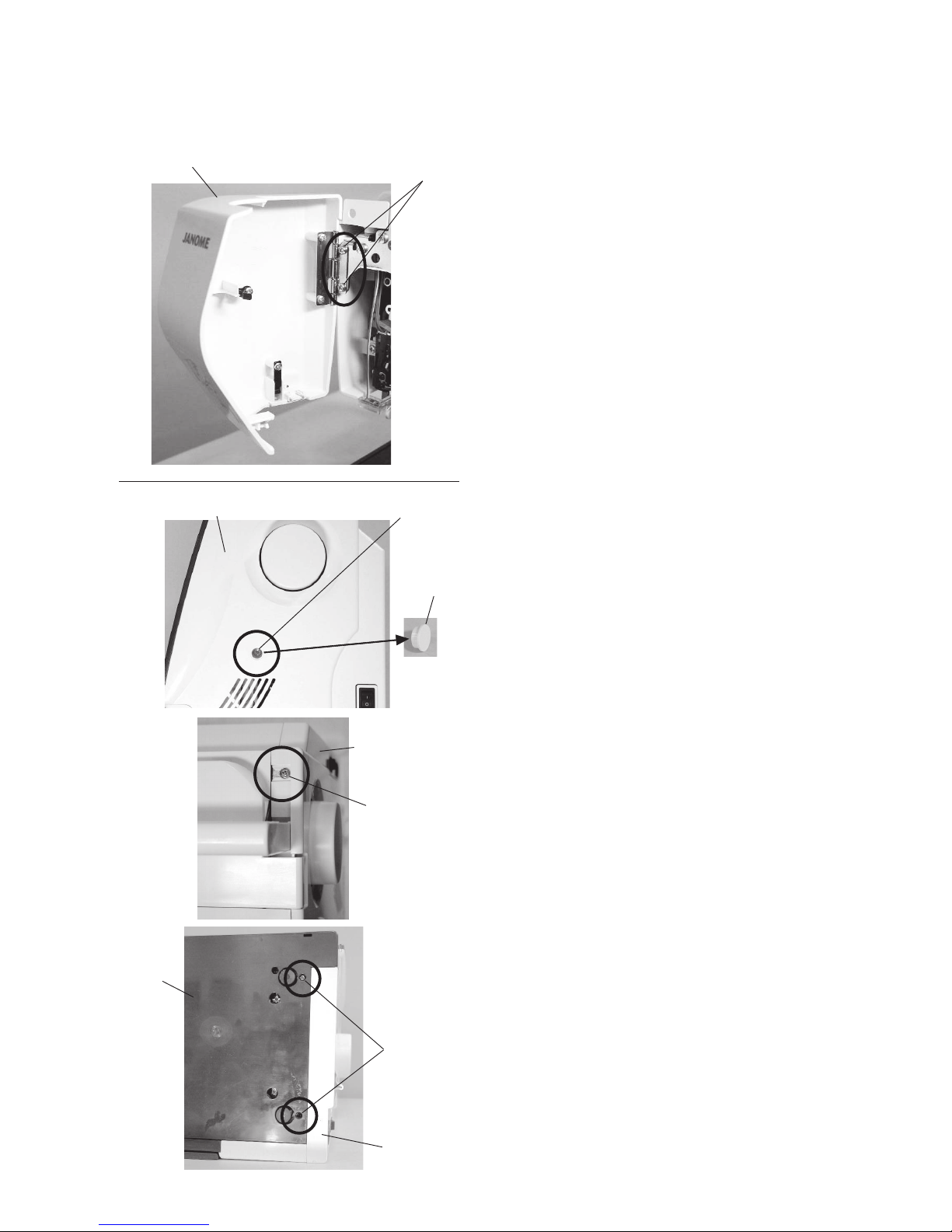

CHANGING EXTERNAL PARTS

Face cover...........................................................................................................................................1

Belt cover ............................................................................................................................................1

Top cover.............................................................................................................................................2

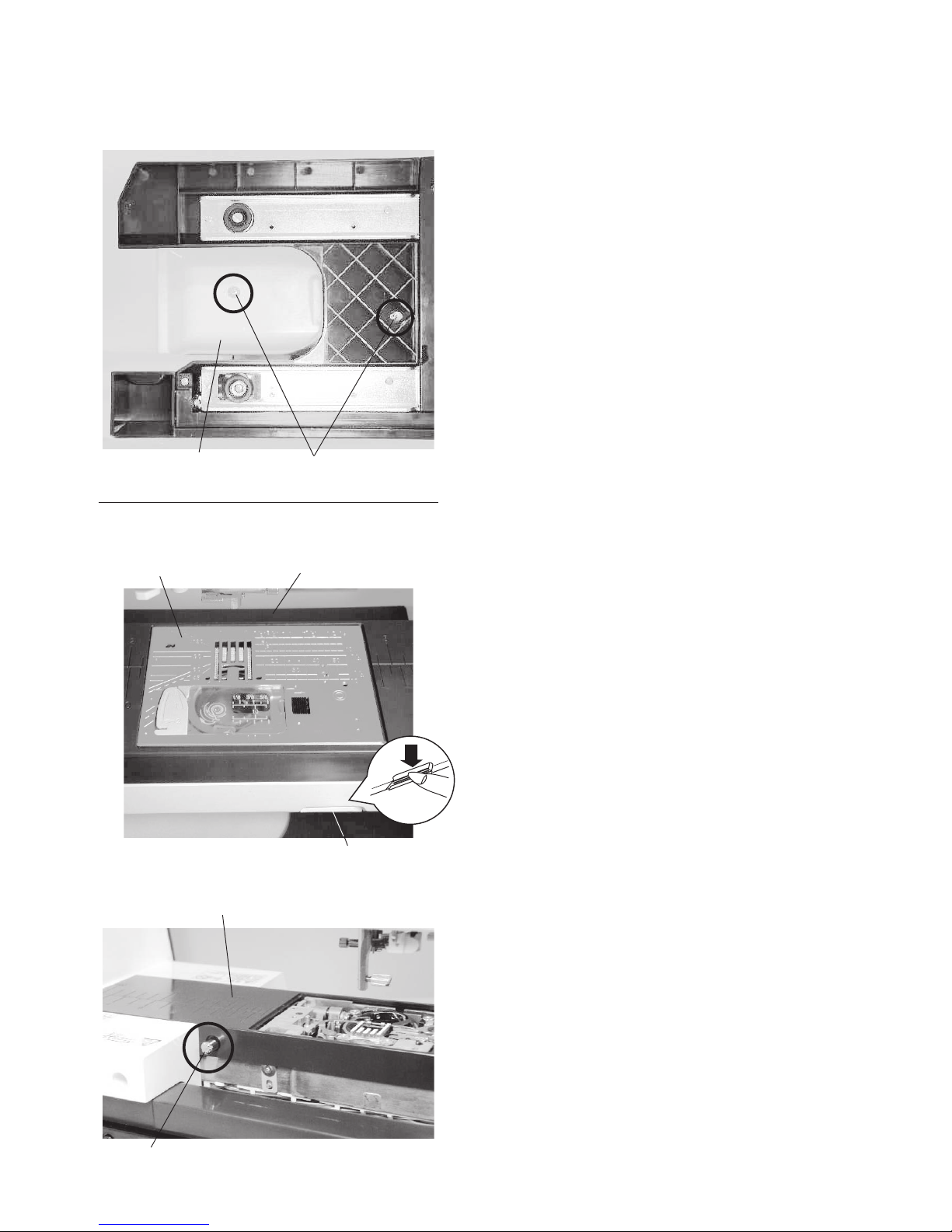

Base plate ...........................................................................................................................................3

Base cover ..........................................................................................................................................3

Bed cover ............................................................................................................................................4

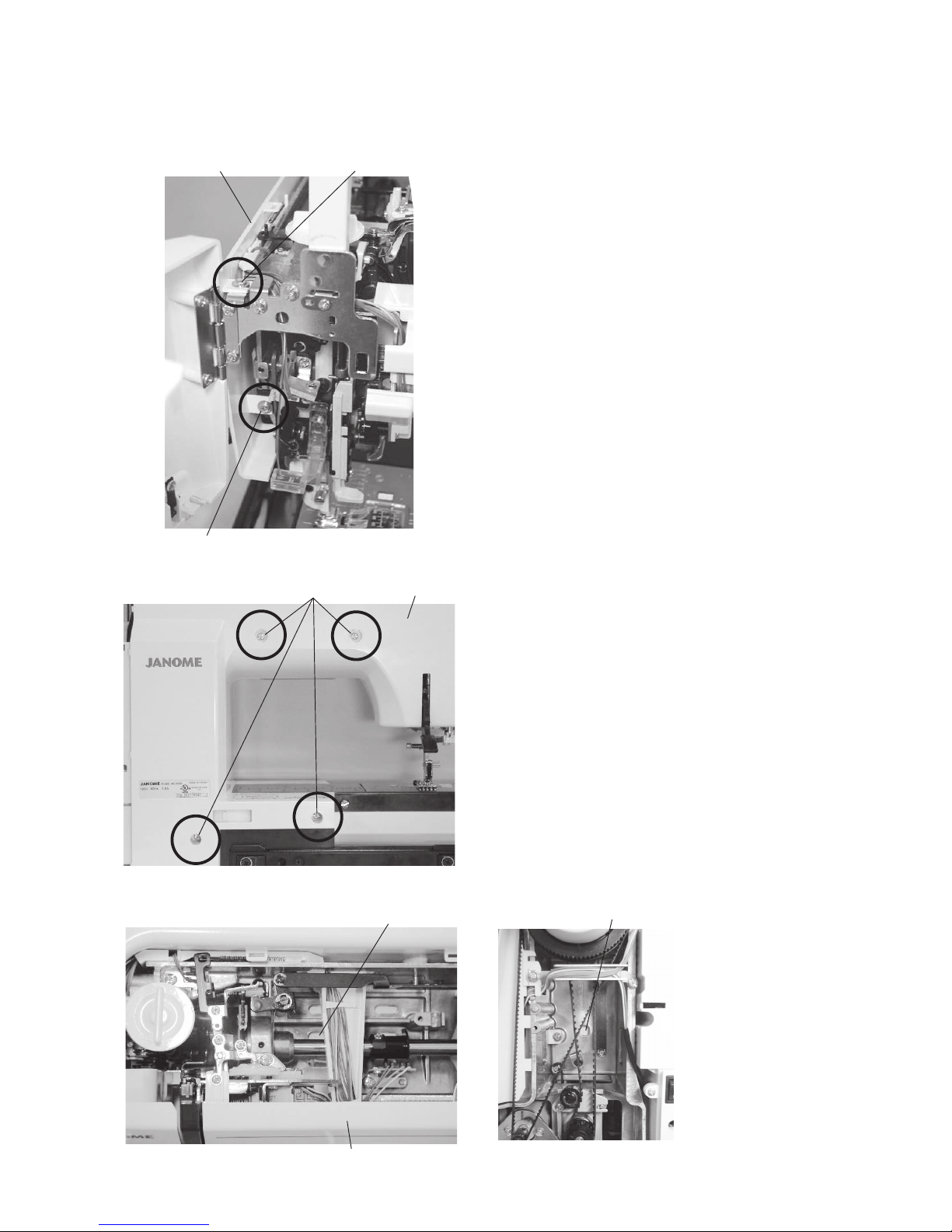

Free arm cover................................................................................................................................ 4-5

Front cover ..........................................................................................................................................6

Rear cover...........................................................................................................................................7

REPLACING ELECTRONIC COMPONENTS

Printed circuit board A.........................................................................................................................8

Printed circuit board F.........................................................................................................................9

Printed circuit board B (USB board)....................................................................................................9

Switching power supply unit..............................................................................................................10

Driving motor.....................................................................................................................................11

Thread tension unit ...........................................................................................................................12

MECHANICAL ADJUSTMENT

Feed dog height ................................................................................................................................13

Clearance between needle and tip of the rotary hook ................................................................ 14-15

Backlash between hook drive gear and lower shaft gear..................................................................16

Needle drop position .........................................................................................................................17

Hook timing .......................................................................................................................................18

Needle bar height..............................................................................................................................19

Upper shaft shield plate position.......................................................................................................20

Upper thread tension.........................................................................................................................21

Tension release mechanism..............................................................................................................22

Needle threader plate........................................................................................................................23

Thread drawing lever.........................................................................................................................24

Buttonhole lever adjustment..............................................................................................................25

Presser bar lifter switch position .......................................................................................................26

Embroidery foot height......................................................................................................................27

Embroidery foot detecting sensor adjustment...................................................................................28

Presser foot lifter switch adjustment..................................................................................................29

Knee lifter..........................................................................................................................................30

Thread cutter.....................................................................................................................................31

Remaining bobbin threader sensor...................................................................................................32

Needle plate sensor .................................................................................................................... 33-34

Bobbin winder ...................................................................................................................................35

Stretch stitch feed balance................................................................................................................36

Y-carriage play adjustment................................................................................................................37

Adjusting X and Y sensors (simple adjustment)................................................................................38

Cloth guide start position ..................................................................................................................39