INDEX

What to do when.............................................................................................................................. 1 to 3

CHANGING EXTERNAL PARTS

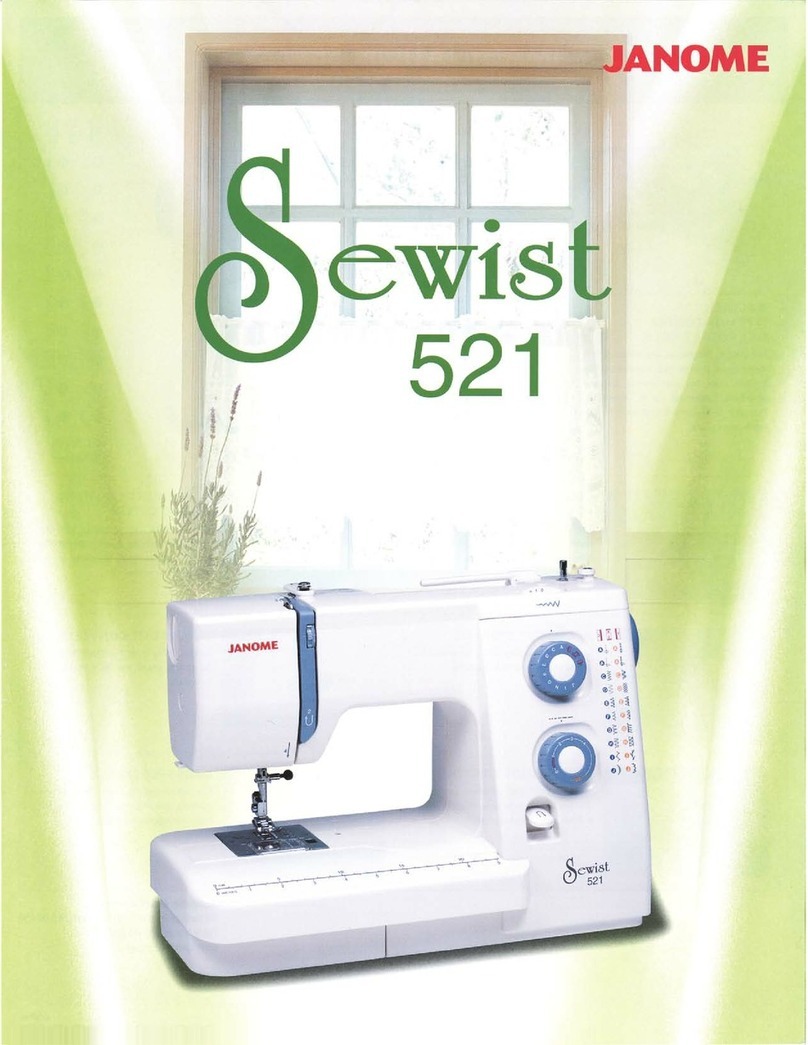

FACE COVER .........................................................................................................................................4

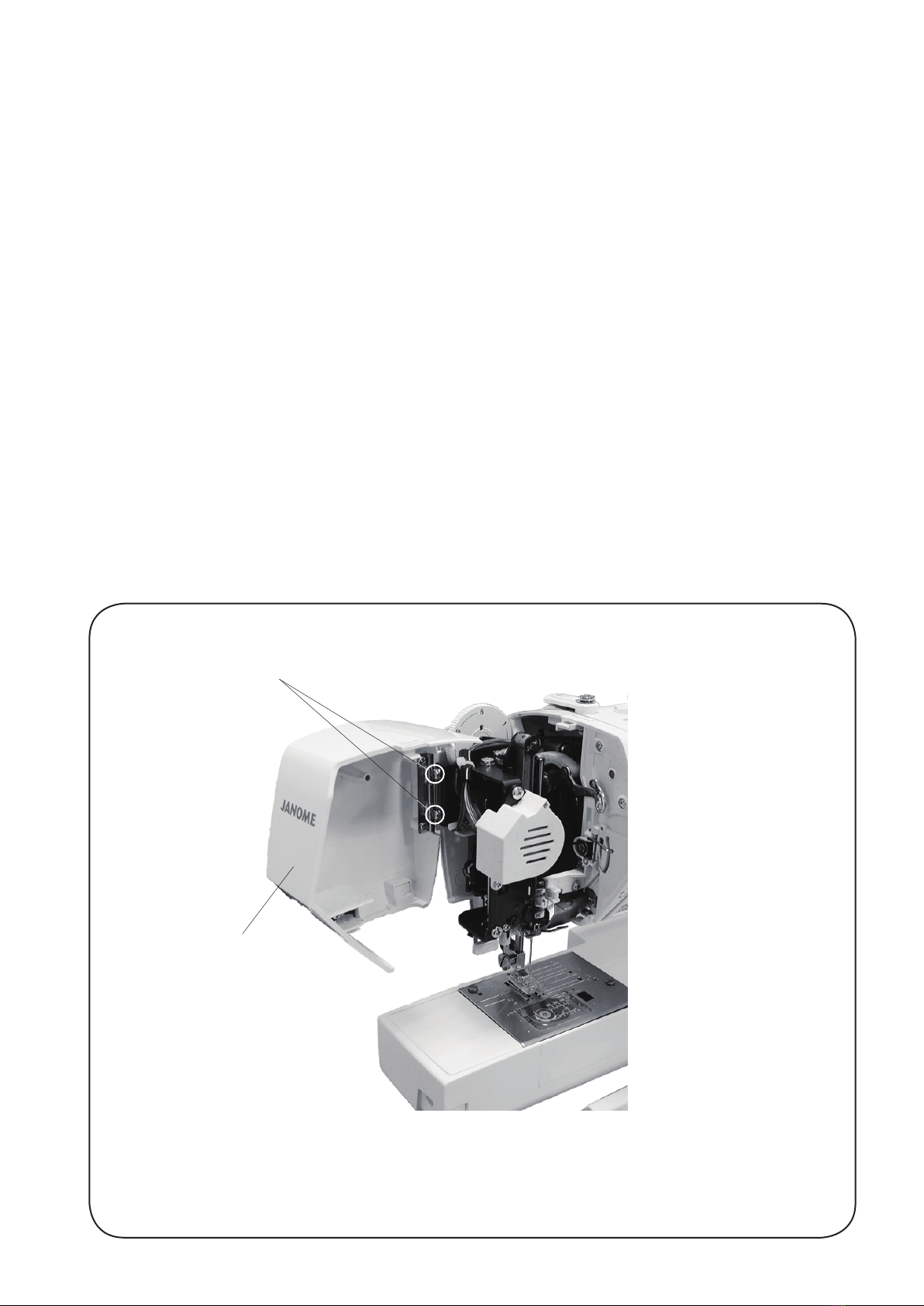

FREE ARM COVER ...............................................................................................................................5

FRONT COVER ...............................................................................................................................6 to 7

REAR COVER.........................................................................................................................................8

MECHANICAL ADJUSTMENT

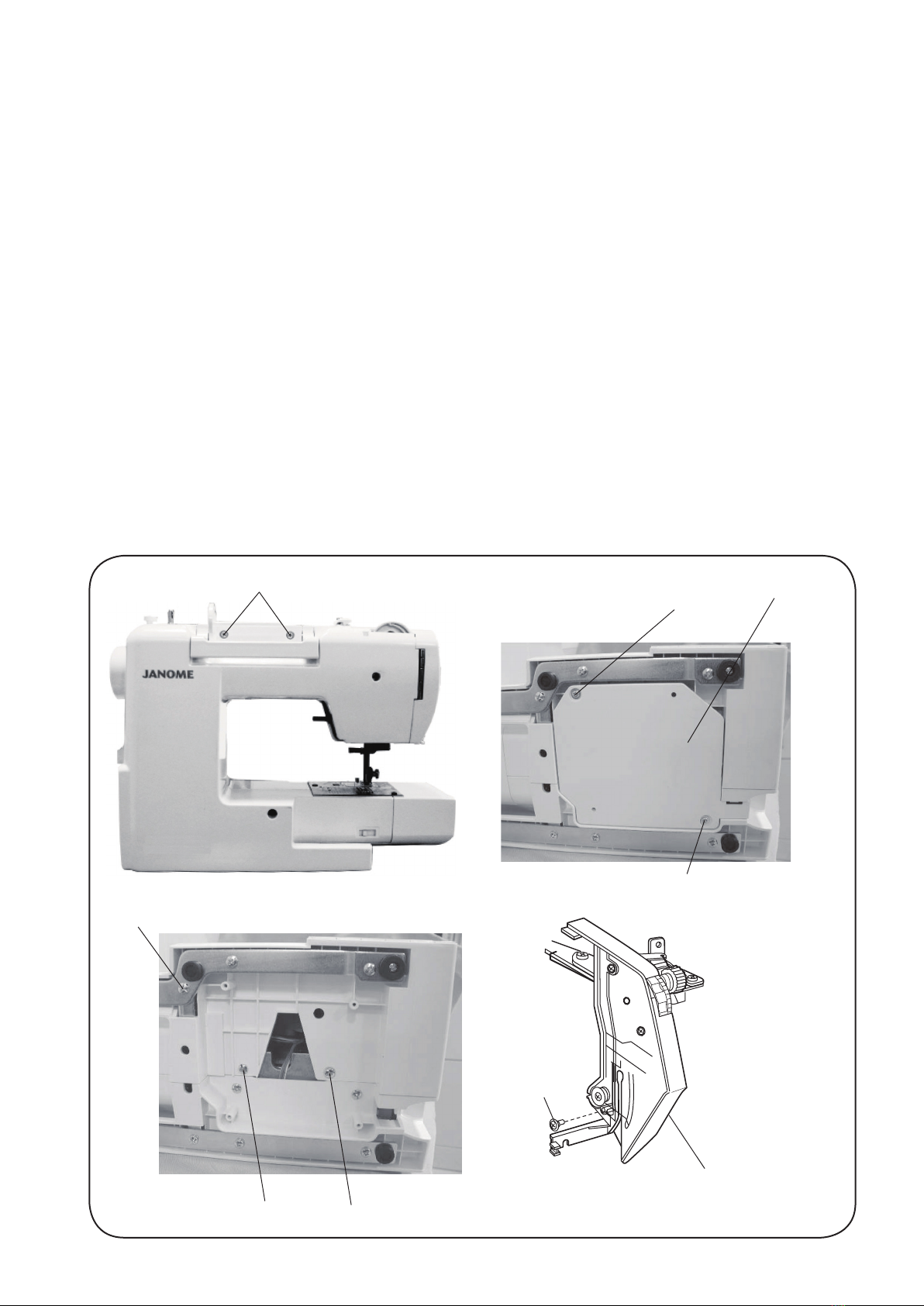

PRESSER BAR HEIGHT ........................................................................................................................9

NEEDLE DROP POSITION...................................................................................................................10

ADJUSTMENT OF HOOK TIMING .......................................................................................................11

ADJUSTMENT OF NEEDLE BAR HEIGHT..........................................................................................12

CLEARANCE BETWEEN NEEDLE AND TIP OF THE ROTARY HOOK ..............................................13

FEED DOG HEIGHT .............................................................................................................................14

FEED DOG ADJUSTMENT...................................................................................................................15

TOP TENSION ......................................................................................................................................16

STRETCH STITCH FEED BALANCE ...................................................................................................17

ADJUSTING BUTTONHOLE LEVER POSITION..................................................................................18

REPLACING AND ADJUSTING THE PRESSER FOOT LIFTER SWITCH UNIT.................................19

REPLACING AND ADJUSTING THE KNEE LIFTER WIRE UNIT...............................................20 to 21

REPLACING AND ADJUSTING THE NEEDLE THREADER HOLDER.......................................22 to 23

THREAD CUTTER ................................................................................................................................24

SELF-DIAGNOSTIC TEST

SELF-DIAGNOSTIC TEST...........................................................................................................25 to 30

TO DISPLAY THE VERSION OF THE PROGRAM...............................................................................30

REPLACING THE ELECTRONIC COMPONENTS

PRINTED CIRCUIT BOARD A CONNECTION .....................................................................................31

PRINTED CIRCUIT BOARD A ..............................................................................................................32

DRIVING MOTOR .................................................................................................................................33

SWITCHING REGULATOR UNIT..........................................................................................................34

CLEANING AREA OF THREAD CUTTER AND LOWER SHAFT GEAR..............................................35

KEY POSITION ADJUSTMENT ............................................................................................................36

TOUCH PANEL KEY POSITION ADJUSTMENT GUIDE PRINTED

THE ILLUSTRATION (ACTUAL SIZE) .............................................................................................37

PARTS LIST.................................................................................................................................38 to 53