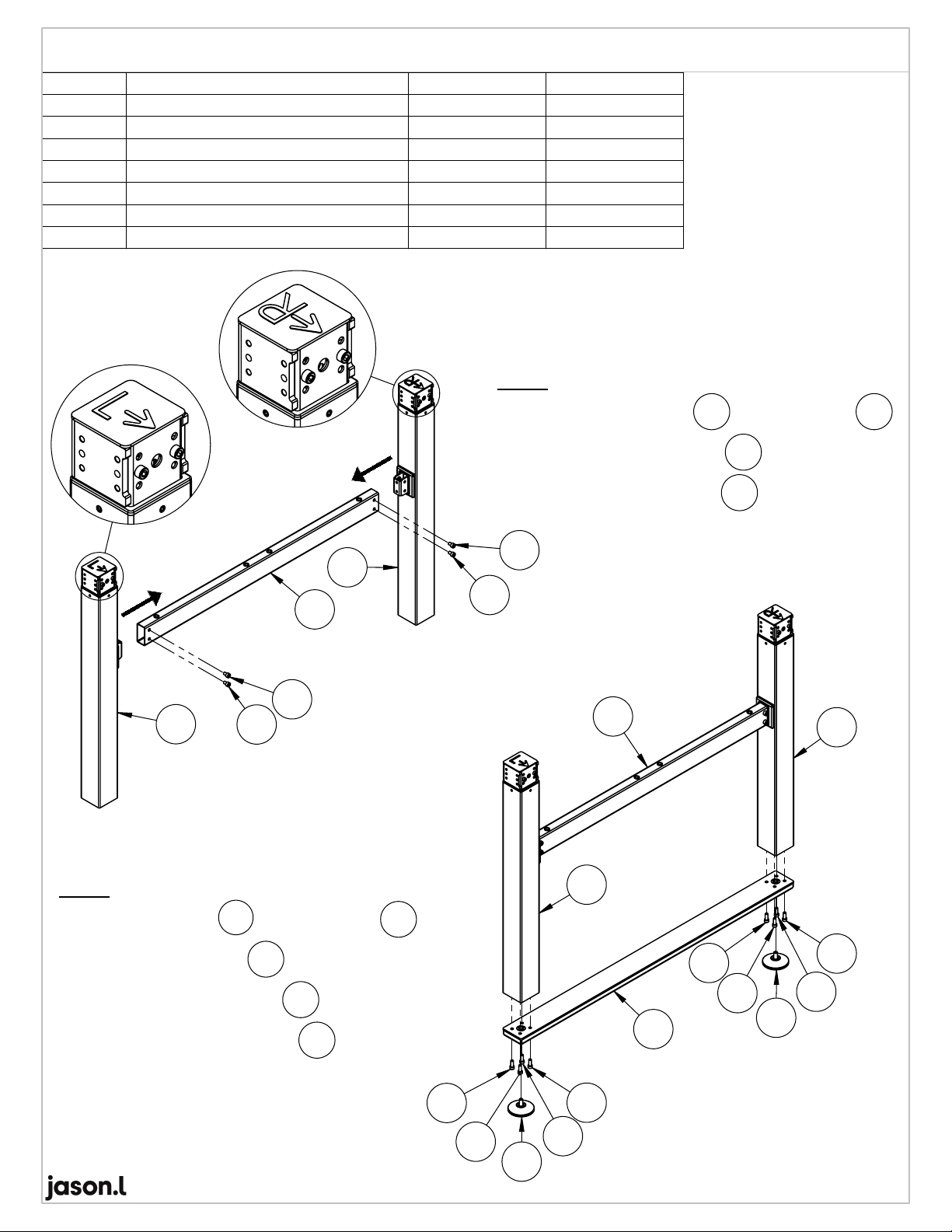

Notes:

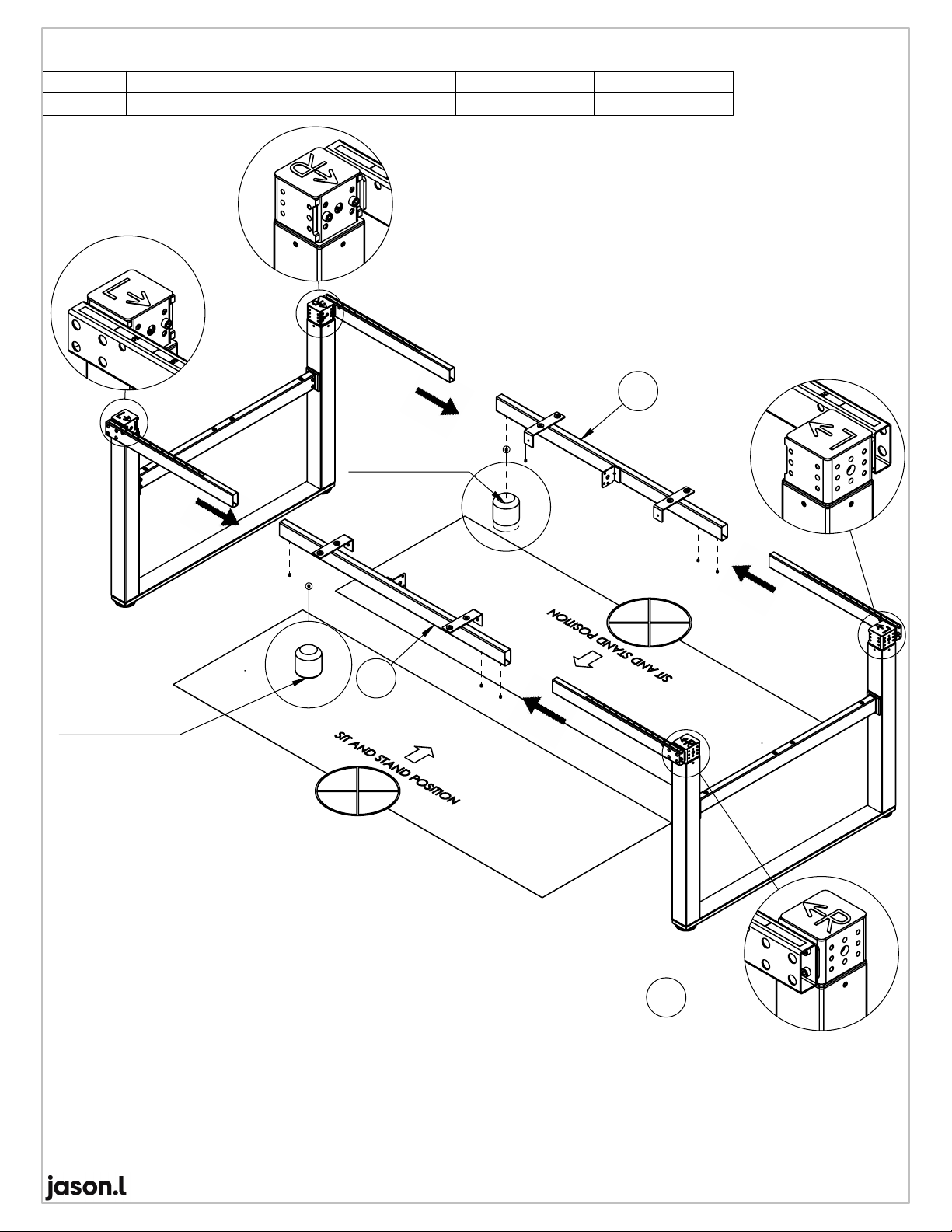

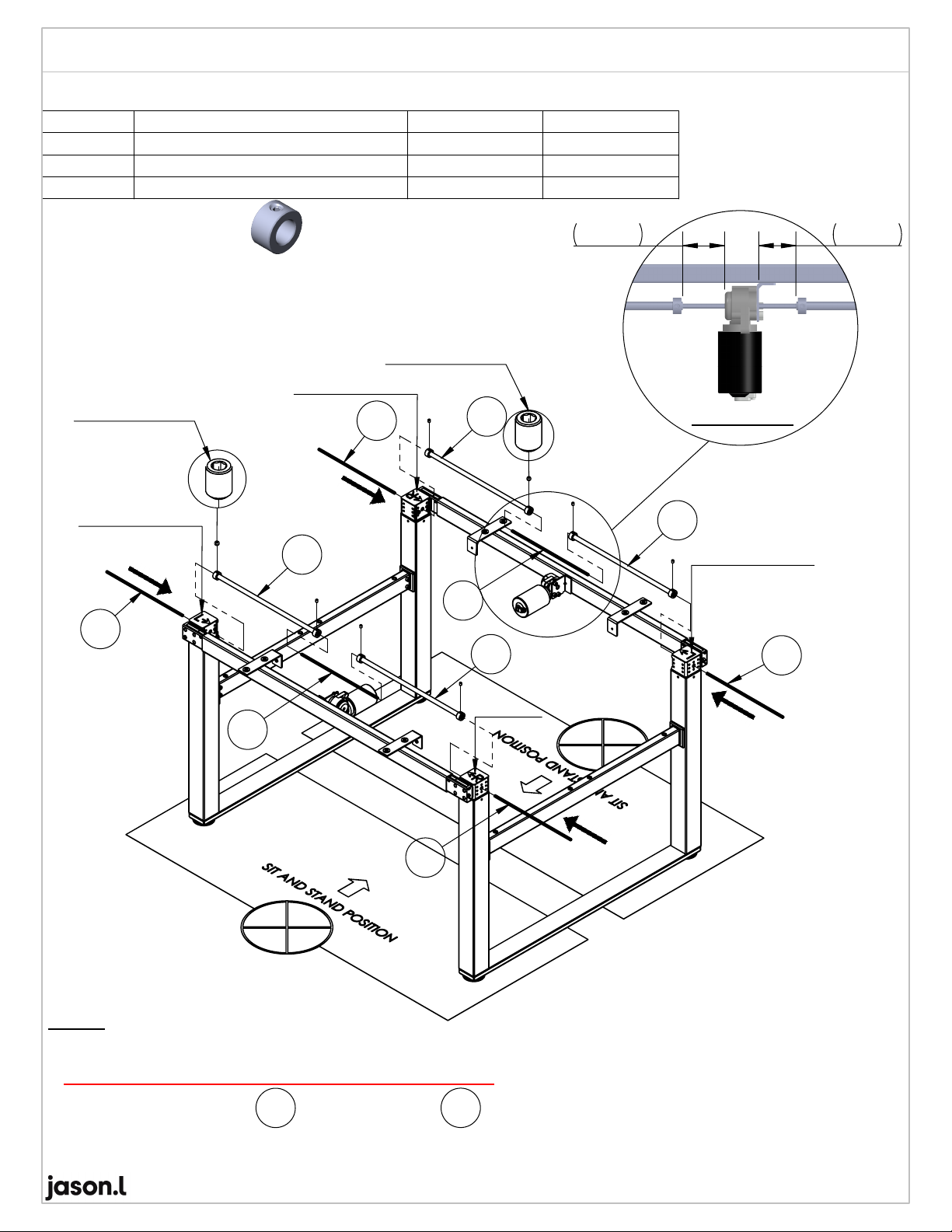

1.Before Insert Hex Shaft, make sure

Left Stand & Right Stand are at lowest position.

Please see attachment caution ! (Refer Pg.8/14)

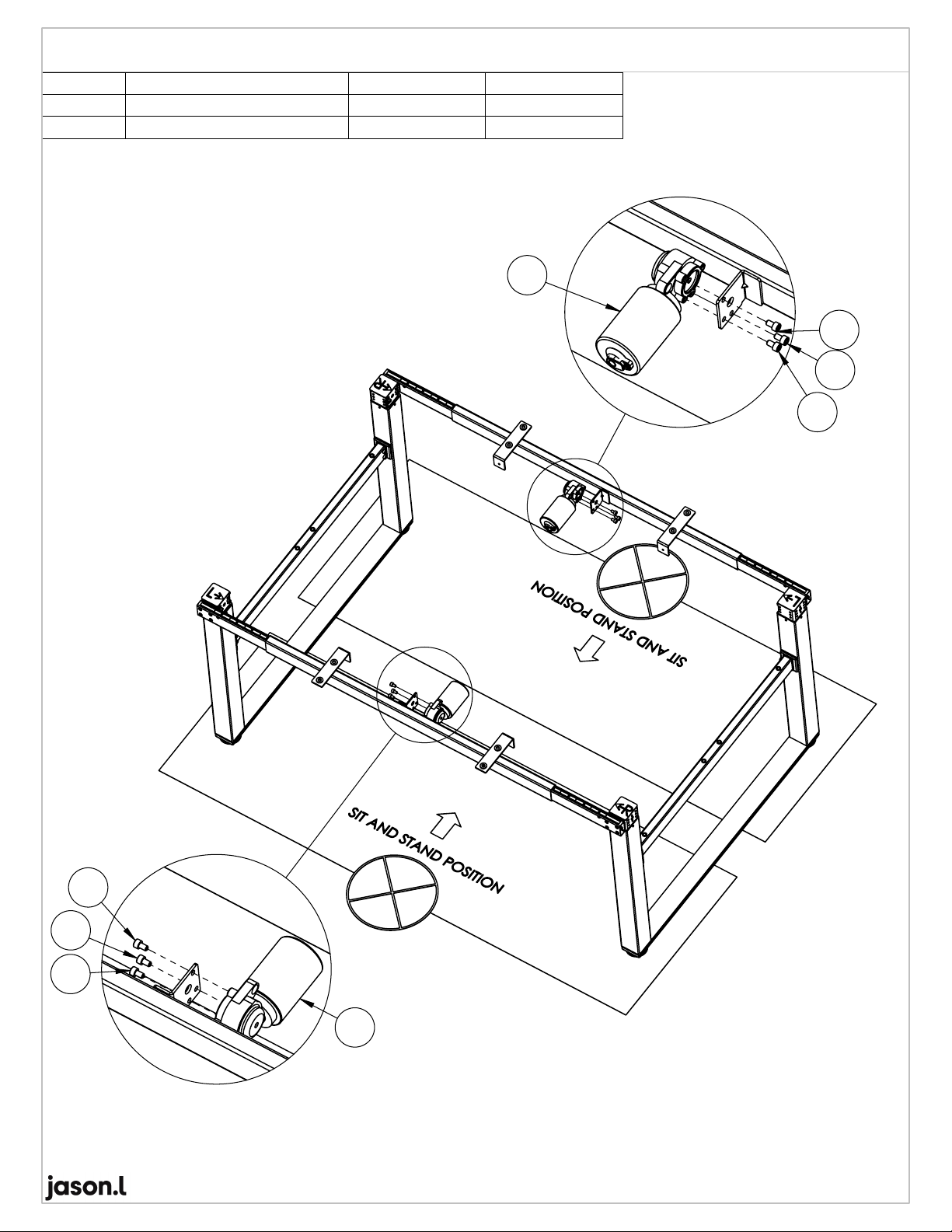

2. After insert Hex Shaft

12

and Axle Drive

09 ,

align according as per Figure No.1 dimension.

3. Locking Set Screw M6(x4)

11

09

11

PRESS DOWN

PRESS DOWN

PRESS DOWN

PRESS

DOWN

11

11

12

09

12

09

09

Set Screw M6

(X4)

Set Screw M6

(X4)

CF

50~60 50~60

Figure No.1

V1.0 Pg.5/14

For Length 115cm

Remarks; Lock Bush

Item No. 09 (Axle Drive L400mm)

Lock Bush (X4) dismantle from

Item No. 10 (Axle Drive L550mm )

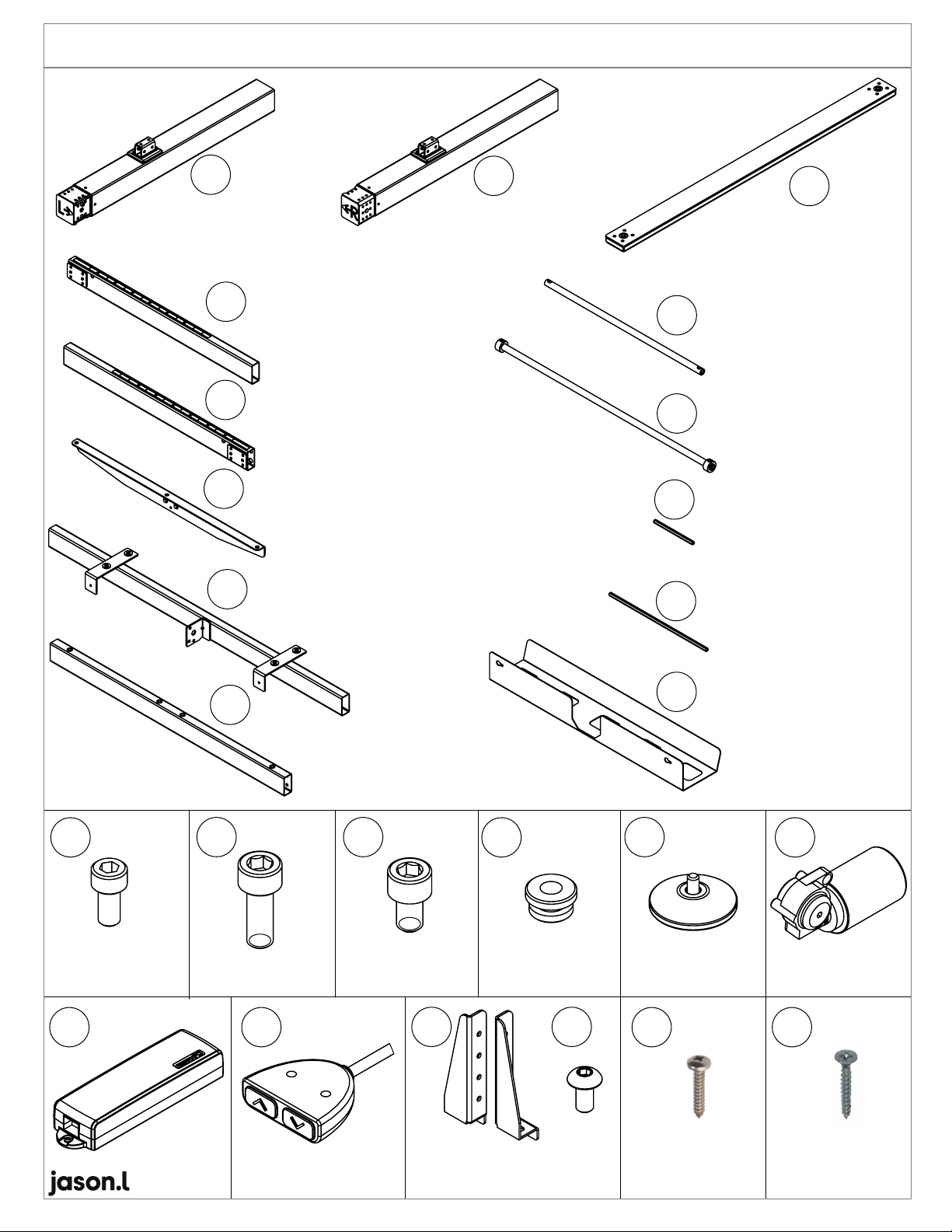

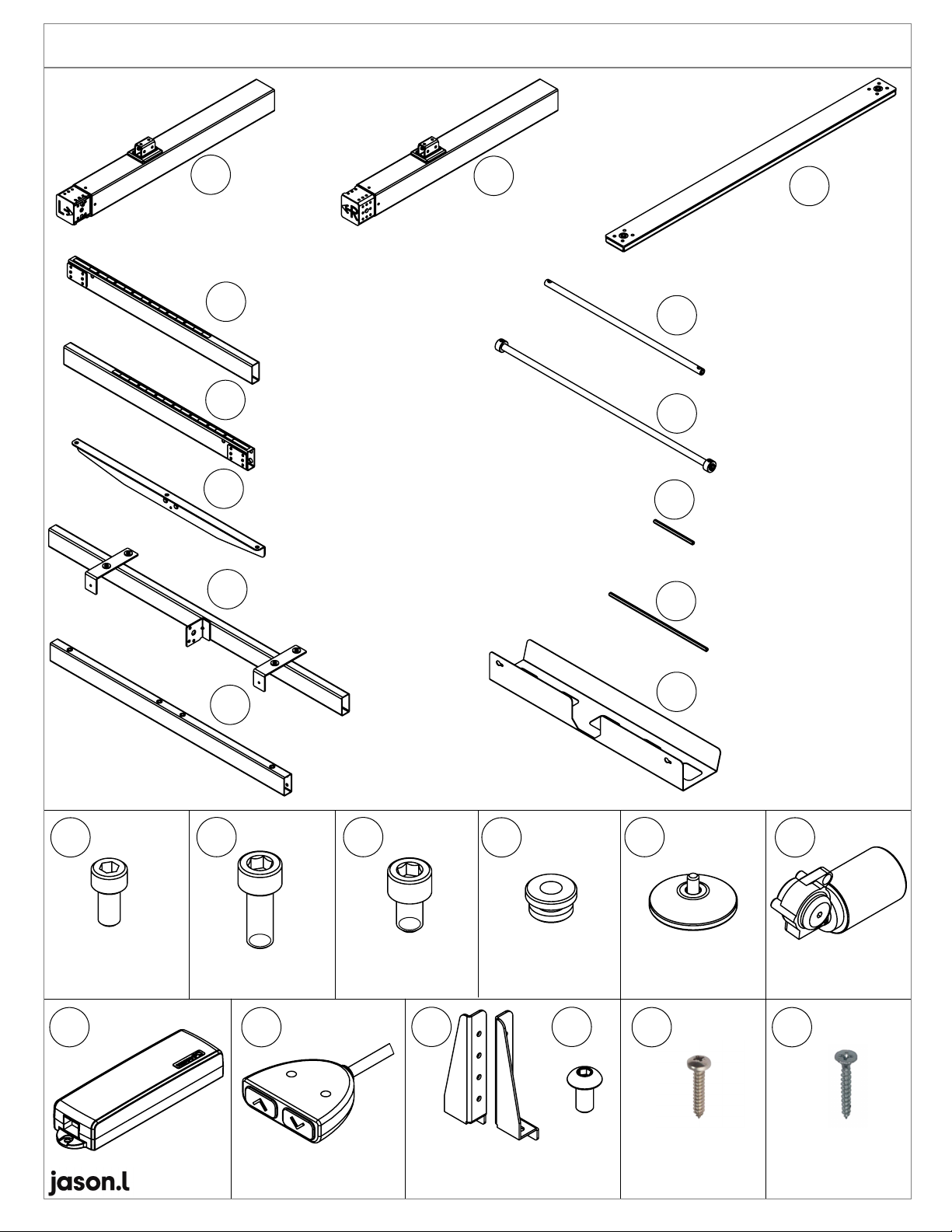

ITEM NO.

DESCRIPTION

QTY.BOX NO.1

QTY.BOX NO.2

09

Axle Drive L400mm

2 2

11

Hex Shaft L100mm

2 2

12

Hex Shaft L250mm

1 1

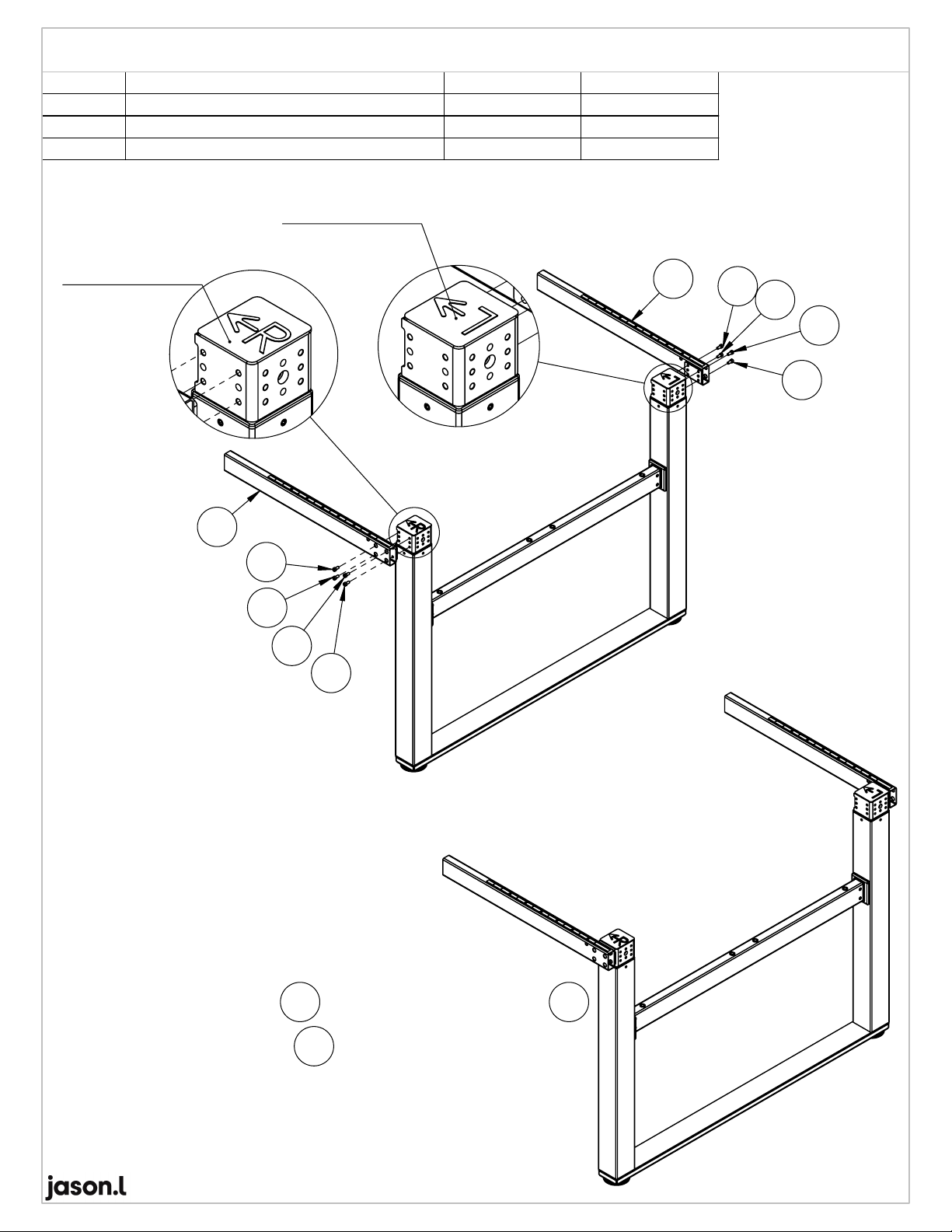

Assembly Instruction: Install Axle Drive And Hex Shaft