Manual 751 OB

latching mechanism is designed to make it easier to connect the two halves of the connector than to disconnect

them. The wires are held in adevice called acage-clamp which does not require that the wires be tinned,

although you may do that if you feel the need, ll^e cage-clamp will accommodate awire range of #14-#22

AWG. Strip tihe wires 1/4 inch, insert into the holes as indicated by the rear panel silkscreen, and tighten the

screws.

The Model 7510B Automatic Mixer provides +48 volt DC Phantom Power for condenser microphones.

Phantom Power gets its name from the fact tiiat the DC voltage is invisible to any BALANCED microphone

not specifically designed to use it. This includes most dynamic and ribbon microphones.. The Phantom

Power may be turned ON by the Phantom Power Switch on the Output Assembly. Turning this switch ON

supplies Phantom Power to all inputs except the auxiliary input located on the Output Assembly. Because of

the nature of the phantom circuitry it is not possible to use unbalanced connections with the Phantom Power

ON. DO NOT ATTEMPT TO USE AN UNBALANCED SOURCE WHENTHE PHANTOM POWER

SWITCH IS ON. SEVERE DAMAGE MAY OCCUR TO THE MICROPHONE (OR OTHER SOURCE

)

OR TO THE MIXER WHICH WILL NOT BE COVERED BY ANY MANUFACTURER'S WARRANTY.

Most microphones designed for Phantom Powering will operate from +48 volts, but if you have any doubts

about the use of aspecific microphone with the 7510B Mixer, consult the operating instructions for the

microphone or, if necessary, its manufacturer.

If none of your inputs require Phantom Power make sure that the Phantom Power Switch on the Output

Assembly is turned OFF.

If you wish to connect aLine level source to one of the inputs, but also need to supply Phantom Power to

condenser microphones, make sure that the source will not be damaged by application of +48 volt DC. If the

source is transformer balanced, that is fine. Otherwise you may need to install aDC blocking capacitor in

series with the input line. The capacitor should have its positive lead connected to the input terminal of the

751OB and its negative lead connected to the source. Acapacitor of 10p.F/50V minimum rating should be used

to avoid low frequency rolloff.

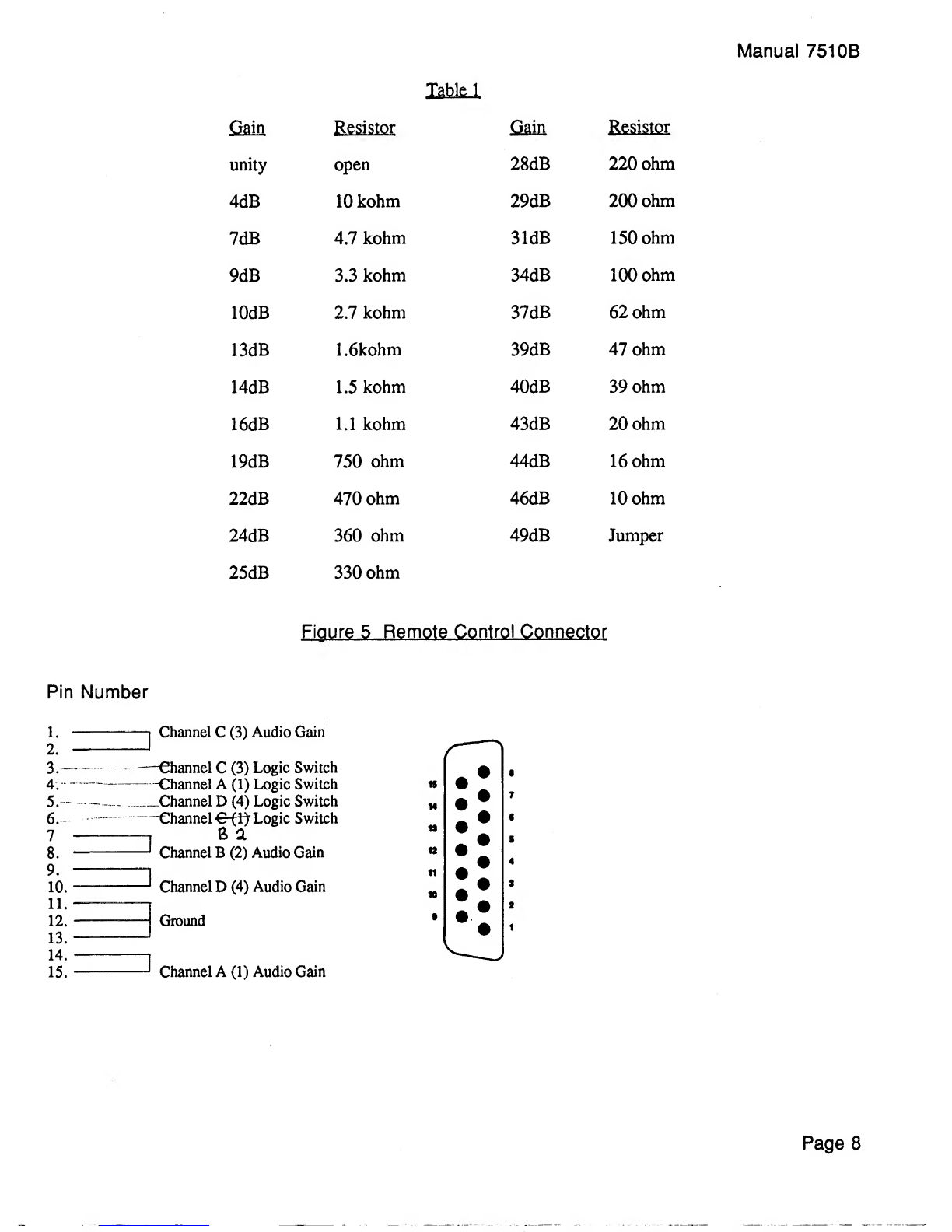

Pre-arop_Gain_Adiusl

The Input Preamp gain may be externally adjusted for optimum signal-to-noise and headroom. As shipped

from the factory the 15 pin connector on the rear panel of the Input Assembly includes four wire jumpers, one

for each of the four input channels. These jumpers, which set the gain of the input preamp at 49 dB, may be

removed and aresistor may be inserted in their place according to the values in Table 1on the next page. Use

only agood quality 1/8 or 1/4 watt carbon film or metal film resistor for best noise performance. Pin numbers

for the connectors are shown in Figure 5.

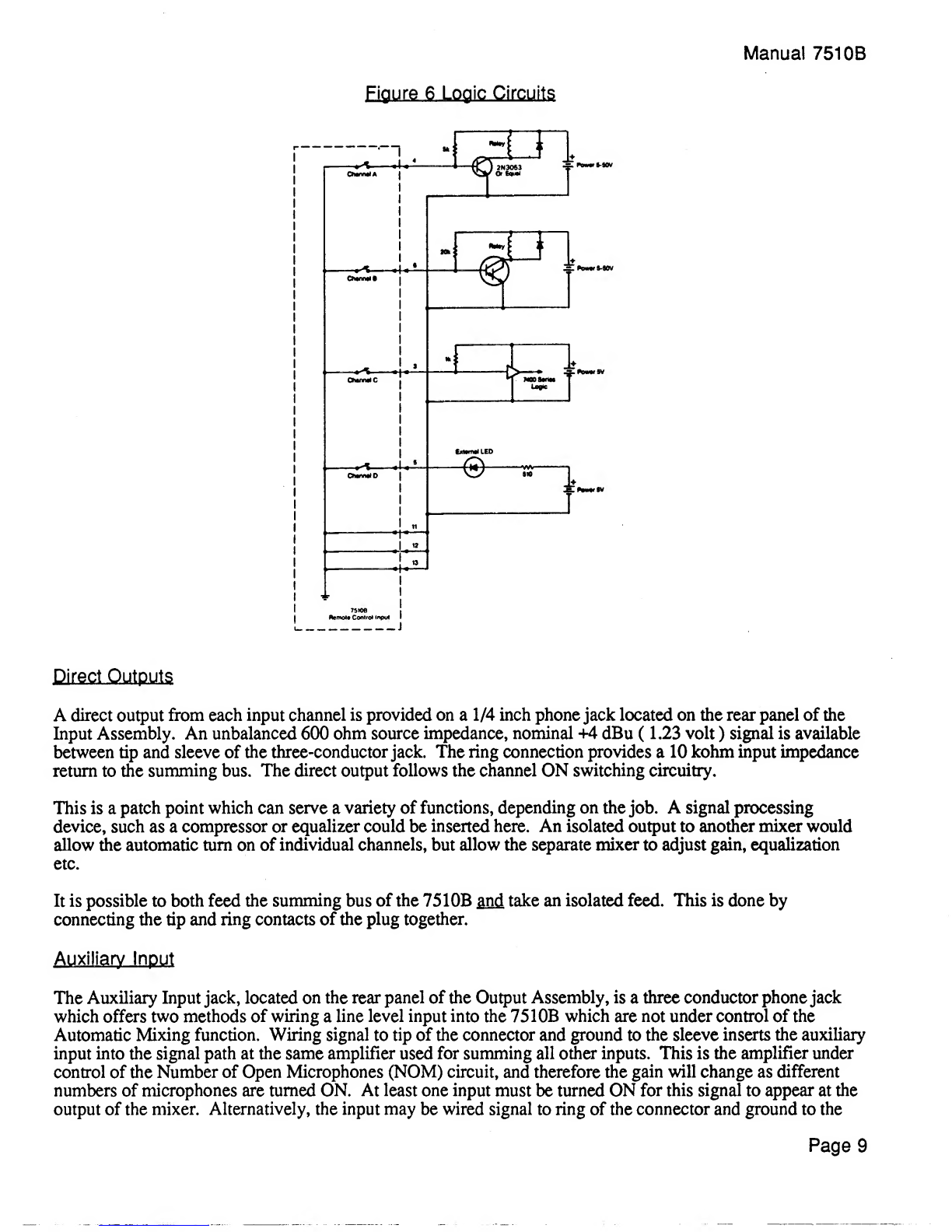

Wiring of Logic Circuits from Remote Control Connector

Figure 5shows the pin configuration for the Remote Control Connector on the rear panel of the Input

Assembly. In addition to the Preamp Gain adjustments described in the previous section, the 7510B also

provides acontact closure to ground when an input is activated. This contact closure, made through aCMOS

gate can switch ±5 volts with amaximum current of 10 milliamperes. Note that this is not avoltage source,

just acontact closure for an external source.

Figure 6shows several examples of circuits which could be used with this contact closure to activate relays,

drive Series 7400 TTL logic, LEDs, switch loudspeakers OFF to provide additional Acoustic Gain, switch

television cameras in ateleconferencing system etc.

Page 7