jcm-tech RADIOBAND3G User manual

Popular Conference System manuals by other brands

Jabbla

Jabbla Tellus 6 operating instructions

LY International Electronics

LY International Electronics H-9500 Series Installation and operating manual

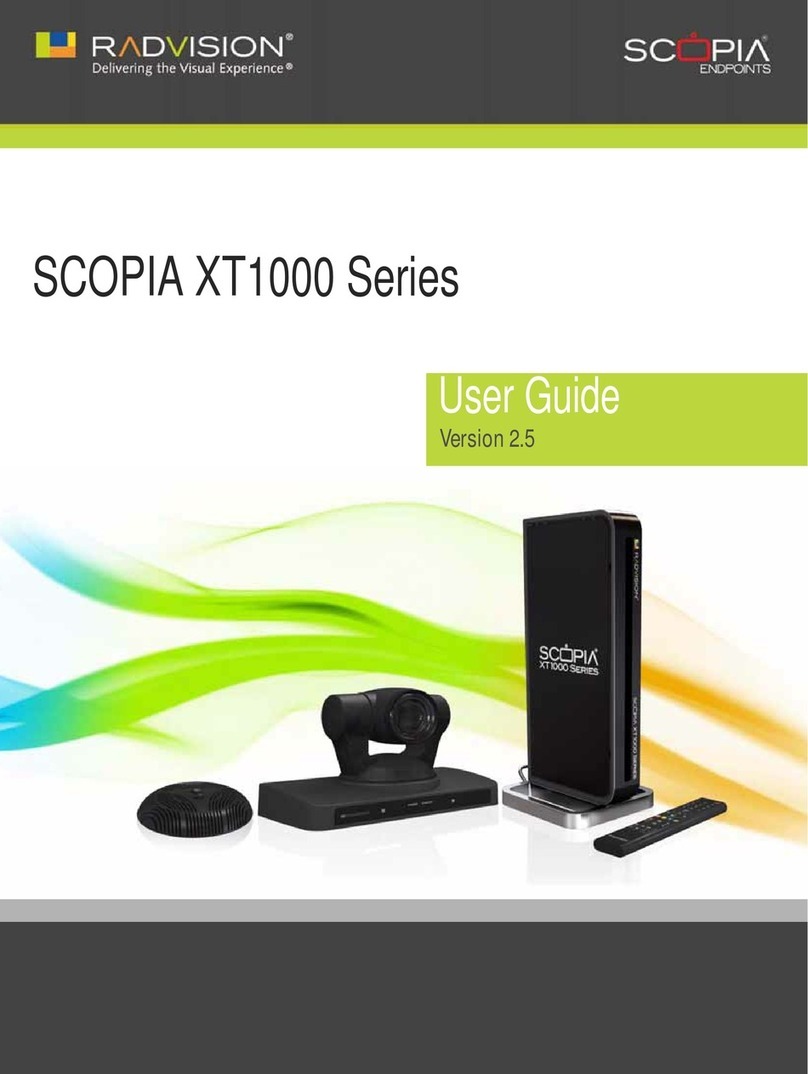

RADVision

RADVision Scopia XT1000 user guide

AT&T

AT&T MERLIN LEGEND Reference

Polycom

Polycom RealPresence Group Series setup sheet

ProSoft Technology

ProSoft Technology AN-X4-AB-DHRIO user manual

Sony

Sony PCS-I150 Operation guide

Middle Atlantic Products

Middle Atlantic Products VTC Series instruction sheet

AVT

AVT MAGIC AC1 Go Configuration guide

Prentke Romich Company

Prentke Romich Company Vanguard Plus Setting up and using

Speakerbus

Speakerbus iD 712 user guide

Trelleborg

Trelleborg SafePilot CAT PRO user guide