Jefa Steering Systems DU-TS24-24 Service manual

Test data and installation instructions 300 Nm

transmission autopilot drive 24 volts type

DU-TSxx-24.

(version 1.4)

Test data:

Customer: …………… Test Engineer: …………..

Date: ………………… Serial number: …………..

Output torque 300 Nm: type DU-TS24-24 – 8 revolutions/minute

Motor Voltage: 24 Volts type DU-TS18-24 – 6.5 revolutions/minute

Clutch voltage: 24 Volts type DU-TS10-24 – 3 revolutions/minute

Insulation test:

Transmission drive type TS250 installation guide version 1.4 page 1 of 4

Electrical Connections: This illustration shows the minimal

components for a working autopilot

configuration. Jefa autopilot drives

work together with all mayor

autopilot electronics. The

connection of the Jefa autopilot

drive to the autopilot junction box

is quite simple. The two 1.5 mm²

red and black wires have to be

connected to the plus and minus of

the autopilot clutch line. This will

make sure that when the autopilot

user engages the autopilot on the

control screen, the clutch will

engage and allow the autopilot

motor to drive the steering system.

The two 4 mm² red and black wires

have to be connected to the

autopilot drive output connection.

autopilot control head

rudder feedback unit

autopilot junction box

fluxgate compass

clutch

output drive

output

1,5 mm2 4 mm2

to battery

drive unit

DU-TS24-18 performance table: (in combination with the 1:7 reduction box RG10-70)

rudder torque

full rudder

(KgM)

rudder torque

midships

(KgM)

power

usage

(amps)

rudder rotation

per second

(degrees/sec.)

time for

72° rudder

(sec)

0 0 0.1 3.7 19

145 73 2 3.6 20

182 364 5 3.2 23

291 582 8.5 2.9 25

Compatibility in 24 Volts:

Following table shows the maximum rudder torques at midships and full rudder that can be generated by the

Jefa 300 Nm transmission drive in combination with various autopilot junction boxes and reduction gearboxes.

As the transmission drive drives the steering system, the maximum rudder torque depends on the type of

reduction box used in the system. The hard over time (HO-time) states the time it takes the drive to travel the

full 72 degrees of rudder travel when the speed control of the pilot is set to maximum speed.

Autopilot junction

box 24 Volt

version.

Max. output

(Amp.) RG10-70

midships

(KgM)

RG10-70

full rudder

(KgM)

BRG10-67

midships

(KgM)

BRG10-67

full rudder

(KgM)

RG10-100

midships

(KgM)

RG10-100

full rudder

(KgM)

DU-TS24-24 8 revs/min 16 sec. 15 sec. 23 sec.

DU-TS18-24 6.5 revs/min 19 sec. 18 sec. 27 sec.

DU-TS10-24 4 revs/min 31 sec. 29 sec. 44 sec.

Simrad AC12 Too small, don't use in combination with this drive

Simrad AC20 20 291 582 237 449 415 830

Simrad AC40 40 fully functional, but smaller autopilot is advisable (money can be saved by choosing smaller

autopilot)

B&G h2000

ACP-2 25 291 582 237 449 415 830

Furuno Navpilot

500/511/520 25 291 582 237 449 415 830

Raymarine X10 Too small, don't use in combination with this drive

Raymarine X30 30 291 582 237 449 415 830

Fuse Protection:

To protect the autopilot drive, the rudder, and the steering system, your Jefa

transmission drive is fitted with an inline fuse. Please don’t remove this fuse

as this will invalid your warranty. The 24 volt transmission drive is fitted with a

20 Amps fuse. A spare fuse is also supplied in the installation manual bag.

The Jefa transmission drives are fitted with rubber dampers to minimise the autopilot noise level on board.

Transmission drives can be mounted on a bevel box or on a reduction gearbox.

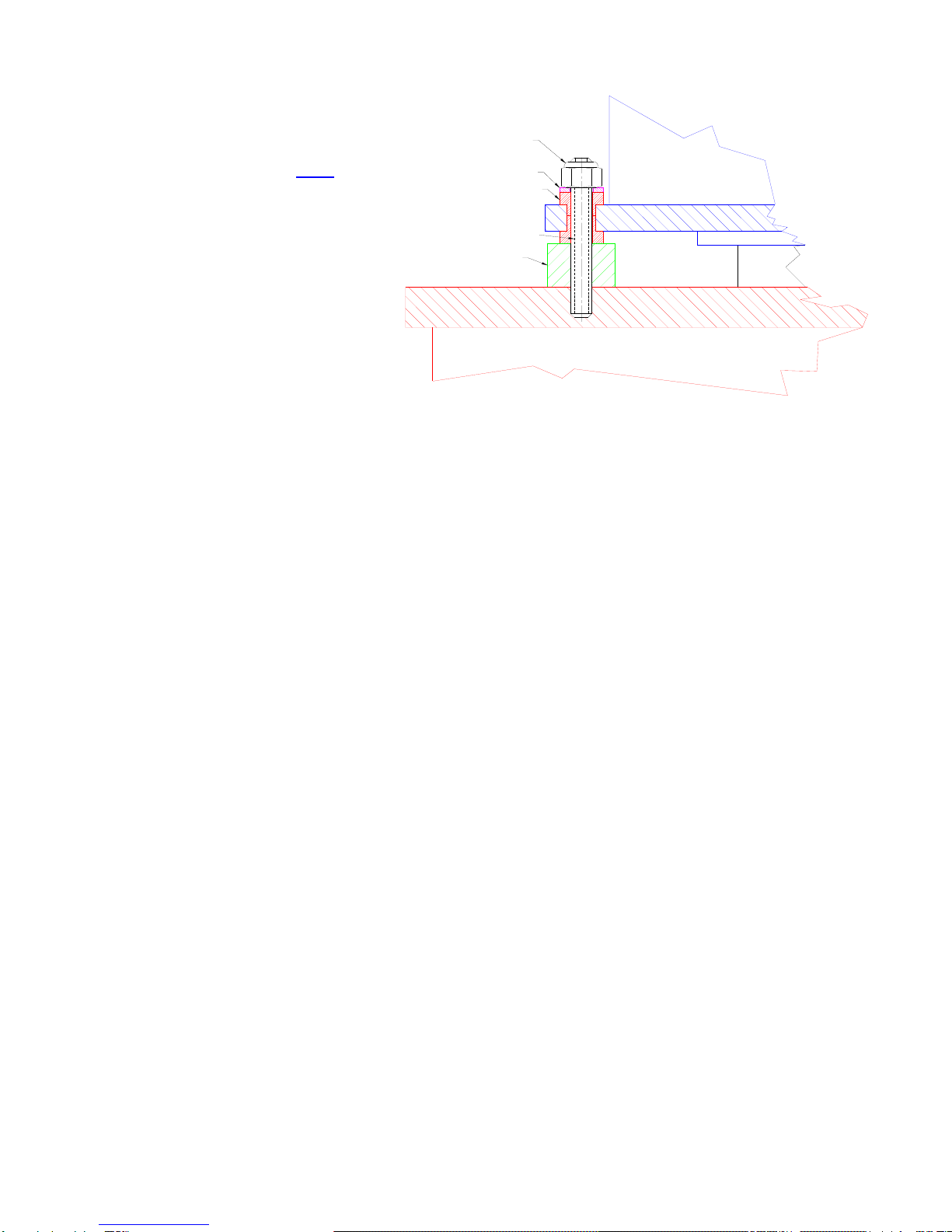

Mounting instructions for bevel box mounting:

Washer Ø8,5 x Ø16

Rubber damper transmission drive unit

bevel gearbox

Stud M8x60

M8 Nyloc nut

autopilot flange

M8 Nyloc nut

•Screw the 4 M8x60 studs into the

autopilot flange.

•Mount the 4 off M8 nyloc nuts.

Tighten well with 20Nm torque.

•Mount the drive unit.

•Mount the 4 off washers.

•Mount the 4 off nyloc nuts. Don’t

tighten too hard to prevent damage

of the rubber damper (3 Nm).

Transmission drive type TS250 installation guide version 1.4 page 2 of 4

Mounting instructions for reduction gearbox mounting:

Transmission drive type TS250 installation guide version 1.4 page 3 of 4

•Screw the 4 M8x60 studs into

the autopilot flange. Tighten

well and use loctite to lock

the thread.

of the rubber

damper (3 Nm).

est the system:

tted limiting the rudder travel to an equal travel of 36 degrees from

ghtened and will not

lete system from port to starboard making sure the rosejoints don’t hit the output lever

t lever to go “over dead centre” so it can’t return to the initial position any more, blocking the

system.

. Failing to install this fuse could mechanically overload the drive

ausing severe damage inside the drive unit.

potential damage to the structure. If motion is detected, one can rule out the drive causing the

alfunction.

aintenance:

the draglink. These balls are easy exchangeable and available for

round 10 € each from any Jefa distributor.

•Mount the 4 off delrin

Washer Ø8,5 x Ø16

Rubber damper transmission drive unit

reduction gearbox

4pcs black POM spacer

Ø25mm, hight=16mm

Stud M8x60

M8 Nyloc nut

spacers.

•Mount the drive unit.

•Mount the 4 off washers.

•Mount the 4 off nyloc nuts.

Don’t tighten too hard to

prevent damage

T

Before you can test the system, make sure following things are correct:

•Solid rudder stops should be fi

midships to port and starboard.

•Make sure all bolted parts (tiller pins, rosejoints, draglinks, tillerarm,etc) are firmly ti

come loose even when exposed to heavy vibrations. Use locktite when necessary.

•Move the comp

and tiller lever.

•Make sure the drive output lever rotates equally around 65 degrees to both sides and there is no risk for

the outpu

Connect the electronics. Make absolutely sure the autopilot is set to “reversible drive” or equivalent. Don’t use

settings like “solenoid” or “hydraulic drive” as these settings will disable the speed control of the autopilot leaving

the drive running at 100% speed or 0%, but nothing in between. Make sure the clutch voltage is set to the

correct voltage. Some brands have a default clutch voltage that has to be changed. B&G uses 9 volts as

standard, Raymarine uses 12 volts, both even on 24 volts input. This should be adjusted to the correct voltage

to guarantee a proper working of the clutch. The B&G and Raymarine course computer has to be opened for dip

switches to be changed. The Simrad pilot can be adjusted via software in the setup menu on the screen. Always

fit the delivered fuse into the power feed line

c

When the drive doesn’t react to the electronics, test the drive by bypassing it: Connect a plus and minus wire to

the battery or fuse box and first connect the clutch, one should here a click when connecting and disconnecting.

With the clutch under power, connect power for a short time to the motor cables. The system should get in

motion now. Don’t connect the cables too long as the drive will try to continue, even when the rudder stops are

reached, with

m

M

The direct drive is “greased for life”, so should no be opened. No maintenance is required except for periodic

checks of all bolted connections. As the rudder system, the steering system and the autopilot drive is exposed

to heavy vibrations (mainly by cruising on motor), all bolted connections should be yearly checked. The only

parts that could wear in time are the balls of

a

Declaration of conformity:

requirements of

e Electro Magnetic Compatibility Directive Standard contained within Standard No. 60945/A1.

…………………………. Date: 06-10-2003

Stig Jensen

For more information please visit our website www.jefa.com

I, Stig Jensen of Jefa Marine Steering ApS, Nimbusvej 2, 2670 Greve, Denmark, confirm that the Jefa 250Nm

transmission drive, when fitted in accordance with these installation instructions, will meet the

th

Signed:…………………………………

04.09.2009

Jef S

E-mail: [email protected]

a Steering Ap

Agenavej 43

26Denmark

70 GREVE

Tel: +45-46155210

Fax: +45-43695211

Transmission drive type TS250 installation guide version 1.4 page 4 of 4

This manual suits for next models

2

Table of contents