KREMLIN Page 2 Manual : 573.049.112

Dear customer,

We thank you very much for purchasing our extrusion pump model 12.22. You are the owner of

one of the most reliable pumping system available on the market.

Special care has been taken during all designing and manufacturing process to make sure your

investment will provide full satisfaction.

To get the best result, safe and efficient operation of your equipment, we advise you to read and

make yourself familiar with this instruction and service manual. Indeed, the non compliance with

instructions and precautions stated in this manual could reduce the equipment working life, result

in operating trouble and create unsafe conditions.

1. EC DECLARATION OF CONFORMITY

The manufacturer : KREMLIN REXSON with assets of 6 720 000 euros

Head office : 150, avenue de Stalingrad – 93 245 - STAINS CEDEX - FRANCE

Tel. 33 (0)1 49 40 25 25 - Fax : 33 (0)1 48 26 07 16

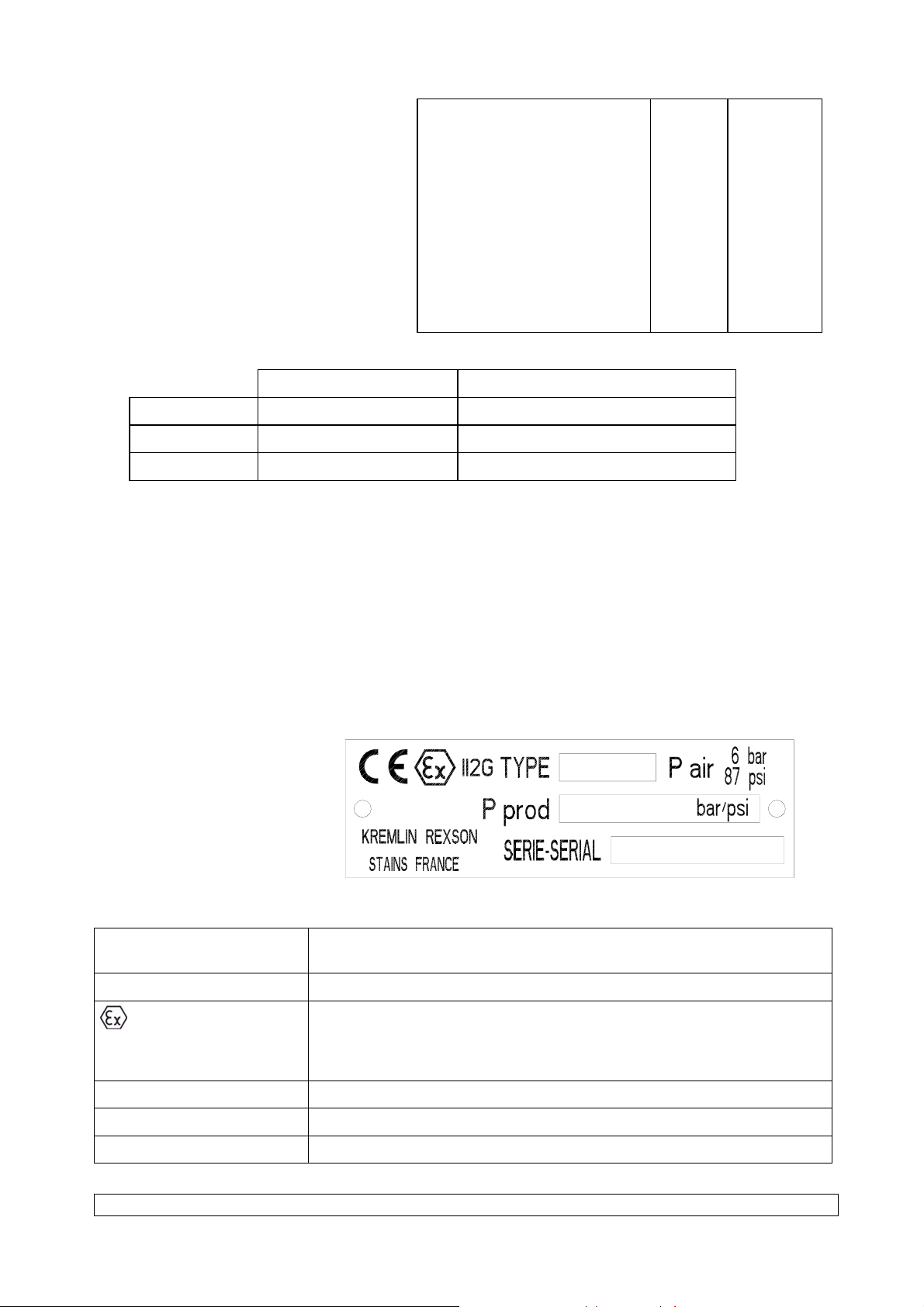

Herewith declares that : Pneumatic pump

Is in conformity with the provisions of :

CE - Machinery Directive (Directive 98/37/EC) as amended and with national implementing legislation.

Ex - ATEX Directive (Directive 94/9/EC) : II 2 G (group II, class 2, gas).

Established in Stains, on march 1st 2003,

Daniel TRAGUS

President

2. GENERAL SAFETY INSTRUCTIONS

WARNING : Any misuse of the equipment or accessories can damage them, result in serious

body injury, fire or explosion hazard and reduce the equipment working life. Read,

understand and comply with the safety instructions hereafter.

The personnel involved in operating and servicing this equipment must be aware of all safety

requirements stated in this manual. The workshop supervisor must be certain that the personnel has

perfectly understood the safety instructions and complies with them.

Read all instruction manuals as well as the tags of the equipments before operating the equipment.

Refer to local safety instructions and comply with them.

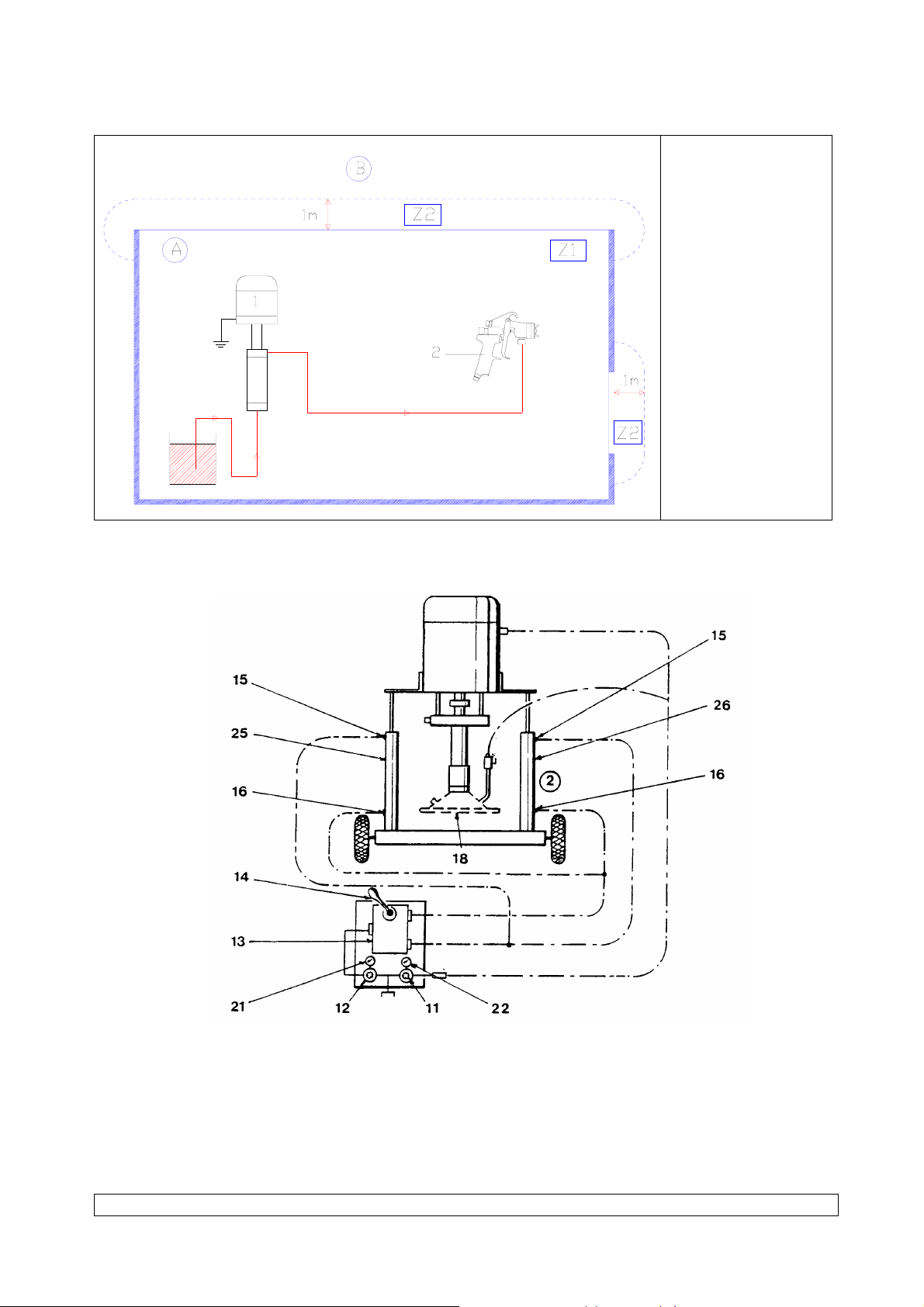

INSTALLATION REQUIREMENTS

ÂGround the equipment.

Use the equipment only in a well-ventilated area to prevent from serious body injuries, fire and

explosion hazards. Do not smoke in the spray area.

Never stock paints and solvents in the spray area. Always close the pots and the tins.

Always keep the spray area clean and free from debris (solvent, rags,…).

Read paint and solvent manufacturer's technical instructions.

Spraying of some materials may result in hazardous working conditions. To protect the operator,

respirator mask, hand cream and glasses are required (Refer to chapter "Safety equipment" of

KREMLIN selection guide).