Jefferson JEFPDB0350 User manual

www.jeffersontools.com

FEATURES

User Manual

v.1.1

JEFPDB0350

JEFPDB0350

350W

BENCH

DRILL

Fitted with a heavy duty motor, capable of drilling into

wood, plastics, ceramics and many metals.

Small footprint area for workshop or portable

enough to take to the job.

Manufactured with a steel pillar, with rigid cast iron

head, table, and base to accurate holes.

Smooth and balanced performance

even at high speeds.

Predrilled base holes for mounting onto

a bench or work stand.

Slotted table allows for mounting clamps

and vises for effective work holding.

Fitted with a table height adjustment control

Supplied with a telescopic chuck guard and

a front mounted.

NVR switch for added convenience and safety.

Drilling capacity Ø13mm

Motor power 350W

Chuck capacity 1.5-13mm

Spindle Taper B16

Speeds (50Hz) 620~2620 RPM

Swing 210mm

Spindle travel 50mm

Column diameter Ø46mm

Table size 160 x 160mm

Throat depth 105mm

Height 580mm

SPECIFICATION

IMPORTANT: Please read all of the safety and operatng instructons

carefully before using this product. Please pay particular

attention to all sections of these instructions that display

warning symbols and notices.

IMPORTANT!

……………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………………………………

………………………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………

…………………………………………………………………………………………………………………………………………

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

1. Features and specication

2. Safety information

3. Maintenance

4. Parts identication

5. Unpacking

6. Assembly

7. Operation

8. Exploded diagram

9. Parts list

10. Troubleshooting

11. Declaration of conformity

12. Warranty statement

1

4

6

7

8

8

13

14

15

16

17

18

CONTENT

Please read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury. Store this instruction

manual in a safe place for future reference.

WARNING:

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

1. SAFETY

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOL USE

When using any type of power tool there are steps that should be taken to make sure that you, as the user, remain safe.

Common sense and a respect for the tool will help reduce the risk of injury.

1.1 Read the instruction manual fully. Do not attempt any operation until you have read and understood this manual. Most important you must

know how to safely start and stop this machine, especially in an emergency.

1.2 Keep the work area tidy and clean. Attempting to clear clutter from around the machine during use will reduce your concentration. Mess on

the oor creates a trip hazard. Any liquid spilt on the oor could result in you slipping.

1.3 Find a suitable location. If the machine is bench mounted; the location should provide good natural light or articial lighting as a replacement.

Avoid damp and dust locations as it will have a negative effect on the machine’s performance. If the machine is portable; do not expose the

tool to rain. In all cases do not operate power tools near any ammable materials.

1.4 Beware of electric shock. Avoid contact with earthed surfaces; because they can conduct electricity if there is an electrical fault with the

power tool. Always protect the power cable and route it away from danger.

1.5 Keep bystanders away. Children, onlookers and passers by must be restricted from entering the work area for their own protection. The

barrier must extend a suitable distance from the tool user.

1.6 Unplug and house all power tools that are not in use. A power tool should never be left unattended while connected to the power supply.

They must be housed in a suitable location, away locked up and from children.

1.7 Do not overload or misuse the tool. All tools are designed for a purpose and are limited to what they are capable of doing. Do not attempt to

use a power tool (or adapt it in any way) for an application it is not designed for. Select a tool appropriate for the size of the job. Overloading

a tool will result in tool failure and user injury: This covers the use of accessories.

1.8 Dress properly. Loose clothing, long hair and jewellery are all dangerous because they can become entangled in moving machinery: This can

also result in parts of body being pulled into the machine.

1.9 Clothing should be close tted, with any long hair tied back, jewellery and neck ties removed.

Footwear must be fully enclosed and have a nonslip sole.

1.10 Wear personal protective equipment (PPE). Dust, noise, vibration and swarf can all be dangerous if not suitably protected against. If the work

involving the power tool creates dust or fumes; wear a dust mask. Vibration to the hand, caused by operating some tools for longer periods

must be protected against. Wear vibration reducing gloves and allow long breaks between uses. Protect against dust and swarf by wearing

approved safety goggles or a face shield. These are some of the more common hazards and preventions; however, always nd out what

hazards are associated with the machine/work process and wear the most suitable protective equipment available.

1.11 Do not breathe contaminated air. If the work creates dust or fumes; connect the machine (if possible) to an extraction system either locally or

remotely. Working outdoors can also help if possible.

1.12 Move the machine as instructed. If the machine is hand held, do not carry it by the power supply cable. If the product is heavy; employ a

second or third person to help move it safely or use a mechanical device. Always refer to the instructions for the correct method.

1.13 Do not overreach. Extending your body too far can result in a loss of balance and you falling. This could be from a height or onto a machine

and will result in injury.

1.14 Maintain your tools correctly. A well maintained tool will do the job safely. Replace any damaged or missing parts immediately with original

parts from the manufacturer. As applicable; keep blades sharp; moving parts clean, oiled or greased; handles clean;

and emergency devices working.

1.15 Wait for the machine to stop. Unless the machine is tted with a safety brake; some parts may continue to move due to momentum. Wait for

all parts to stop; then unplug it from the power supply before making any adjustments, carrying out maintenance operations

or just nishing using the tool.

1.16 Remove and check setting tools. Some machinery requires the use of additional tools or keys to set, load or adjust the power tool. Before

starting the power tool always check to make certain they have been removed and are safely away from the machine.

1.17 Prevent unintentional starting. Before plugging any machine in to the power supply, make sure the switch is in the OFF position. If the

machine is portable; do not hold the machine near the switch and take care when putting the machine down;

that nothing can operate the switch.

1.18 Carefully select an extension lead. Some machines are not suitable for use with extension leads. If the tool is designed for use outdoors; use

an extension lead also suitable for that environment. When using an extended lead, select one capable of handling the current (amps) drawn

by the machine in use. Fully extend the lead regardless of the distance between the power supply and the tool. Excess current

(amps) and a coiled extension lead will both cause the cable to heat up and can result in re.

1.19 Concentrate and stay alert. Distractions are likely to cause an accident. Never operate a power tool if you are under the inuence of drugs

(prescription or otherwise), including alcohol or if you are feeling tired. Being disorientated will result in an accident.

1.20 Have this tool repaired by a qualied person. This tool is designed to conrm to the relevant international and local standards and as such

should be maintained and repaired by someone qualied; using only original parts supplied by the manufacturer:

This will ensure the tool remains safe to use.

SPECIFIC SAFETY INSTRUCT/ON FOR BENCH DRILLS

MECHANICAL HAZARDS:

1.21 Crushing

When setting/changing a tool or maintaining the machine avoid crushing injuries sustained between xed and

moving elements of the machine.

1.22 Cutting or Severing

At all times the workpiece shall be clamped as manual support will lead to injury.

1.23 Entanglement

Switch off the machine for maintenance, workpiece loading/unloading, swarf/chip removal, cutting/lubrication uid application as contact

with rotating spindle or tool will cause entanglement and possibly lead to injury and entrapment.

1.24 Impact

Ensure the workpiece is securely clamped at all times to avoid sudden movement (rotation) or ejection causing injury.

Ensure any special tools associated with tool exchange, i.e. chuck key are removed prior to attempting to start the machine.

1.25 Stabbing, Cutting or Puncture Wounds

Take care when handling the tools and avoid contact with swarf and burrs created during drilling as they are extremely sharp.

ELECTRICAL HAZARDS:

1.26 Hearing Loss

Wear ear defenders during operation to avoid damage to hearing, however ensure this does not interfere with

speech communications or audible warnings.

MATERIAL HAZARDS:

1.27 Contact and Inhalation

Wear personal protective equipment to avoid contact from harmful uids, gases or dust thrown or created during the drilling process.

1.28 Fire or Explosion

Do not drill or drill in the vicinity of ammable or combustible materials.

LOCATION:

1.29 Posture

Ensure when mounting the machine that the chosen location does not lead to unhealthy posture or repetitive strain during normal operation.

1.30 Lighting

Adequate lighting must be provided to ensure no operations are light impaired possibly leading to injury.

1.31 Reach

Do not reach over or around the machine at any time.

UNEXPECTED START-UP:

1.32 Remove the plug

Remove the plug from the socket before carrying out adjustment, servicing or maintenance.

ERRORS OF FITTING:

1.33 Tools

Ensure a suitable tool for the job in hand is securely and correctly tted prior to starting the machine.

Guards shall be tted and in place at all times.

STABILITY:

1.34 Toppling

The drill shall be securely bolted down to a suitable and level surface to prevent the machine from overturning leading to injury.

1.35 Slipping

Ensure the area is clean of any residue cutting/lubration uid and other materials which may lead to a slip, trip or other such hazard.

CONNECTION TO THE POWER SUPPLY

Make sure the power supply information on the machine’s rating plate are compatible with the power supply you intend to connect it to.

The Drill comes supplied with a UK standard 3 pin plug tted. It is designed for connection to a domestic power supply rated at 230V AC.

Because it is constructed mostly of metal parts, it is a Class 1 machine; meaning, it must have an earth connection in the power supply. This is to

prevent electrocution in the event of a failure. Apart from replacing the fuse in the plug, no other electrical work is recommended on this drill.

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

2. MAINTENANCE

2.1 Read this manual carefully.Learn the machine applications and limitations,as well as the specic potential hazards peculiar to it.

2. 2 ALWAYS keep guards in place and in working order. A guard or other part that is damaged should be properly repaired or replaced by an

authorized serv ice centre, unless otherwise indicated in this instruction manual.

2. 3 Remove any adjusting keys or wrenches before starting. Form the habit of checking to ensure that keys, wrenches and tools

are removed from the machine.

2.4 Don’t force the machine and use the correct tool. It will do the job better and safer, at the rate for which it was intended.

2.5 ALWAYS disconnect the machine from the power supply before carrying out any servicing or changing of accessories.

2.6 Before further use of the tool, it should be carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting or other condition that may affect its operation.

2.7 Have defective switches repaired by an authorized service centre. Do not use a tool if the switch does not turn it on and off.

2.8 ALWAYS check for any damage or any condition that could affect the operation of the machine. Damaged parts should be properly repaired.

2.9 NEVER remove the cover panel unless the machine is disconnected from the power supply, and never use the machine

with cover panels removed.

2.10 Have your tool repaired by a qualied person. This tool complies with the relevant safety rules. Repairs should only be carried out by

qualied persons using original spare parts, otherwise this may result in considerable danger to the user.

2.11 NEVER use this product for any other purpose than that described in this booklet.

2.12 NEVER abuse the power cable by yanking the cable to disconnect it from the socket. Keep the cable away from heat, oil or sharp edges.

2.13 Guard against electric shock. Avoid body contact with earthed or grounded surfaces.

2.14 If the tool should be used outdoors, use only extension cables intended for outdoor use and marked accordingly.

2.15 Avoid accidental starting by making sure the power switch is off before plugging in the power cable.

MONTHLY MAINTENANCE (IF IN REGULAR USE)

2.16 Check tightness of mounting bolts, and head and column securing set screws.

2.17 Check the drive belt for wear, and replace if frayed or damaged.

2.18 Blow out with compressed air, or vacuum clean out, any dust that may have accumulated in the motor fan vents.

2.19 Apply a thin coat of wax paste or light oil to the table and column, for lubrication, and to help prevent corrosion.

2.20 If the mains lead is damaged in any way, it should be replaced immediately.

LUBRICATION

All bearings are packed with grease at the factory and require no further lubrication.

Occasionally, lubricate the quill shaft assembly and rack with light oil if required.

Fig.44 Fig.45

AFTER USE

Remove all swarf from the machine and thoroughly clean all surfaces. Components should be kept dry, with machined surfaces lightly oiled.

Always remove drill bits, and store in a safe place.

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

3. PARTS IDENTIFICATION

1

2

3

4

5

8

9

15

6

19

1 Pulley cover 11 Base

2 Motor 12 Main housing

3 Switch 13 Column

4 Chuck guard 14 Bolts

5 Chuck 15 Depth stop lock knob

6 Feed handle 16 Table lock

7 Table 17 Table adjustment handle

8 Table holder 18 Rack collar

9 Belt tension lock knob 19 Rack

10 Column support

12

16

7

18

13

10

11

14

6

17

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

4. UNPACKING

5.1 Carefully remove the drill from the packaging and examine it for any sign of damage that may have happened during shipping. Lay the

contents out and check them against the parts shown below. If any part is damaged or missing; please contact the Jefferson Helpline (the

telephone number appears on the Title page) and do not attempt to use the lathe.

5.2 The packaging material should be retained at least during the guarantee period: in case the machine needs to be returned for repair.

5.3 Warning! Some of the packaging materials used may be harmful to children. Do not leave any of these materials in the reach of children.

5.4 If any of the packaging is to be thrown away, make sure they are disposed of correctly; according to local regulations.

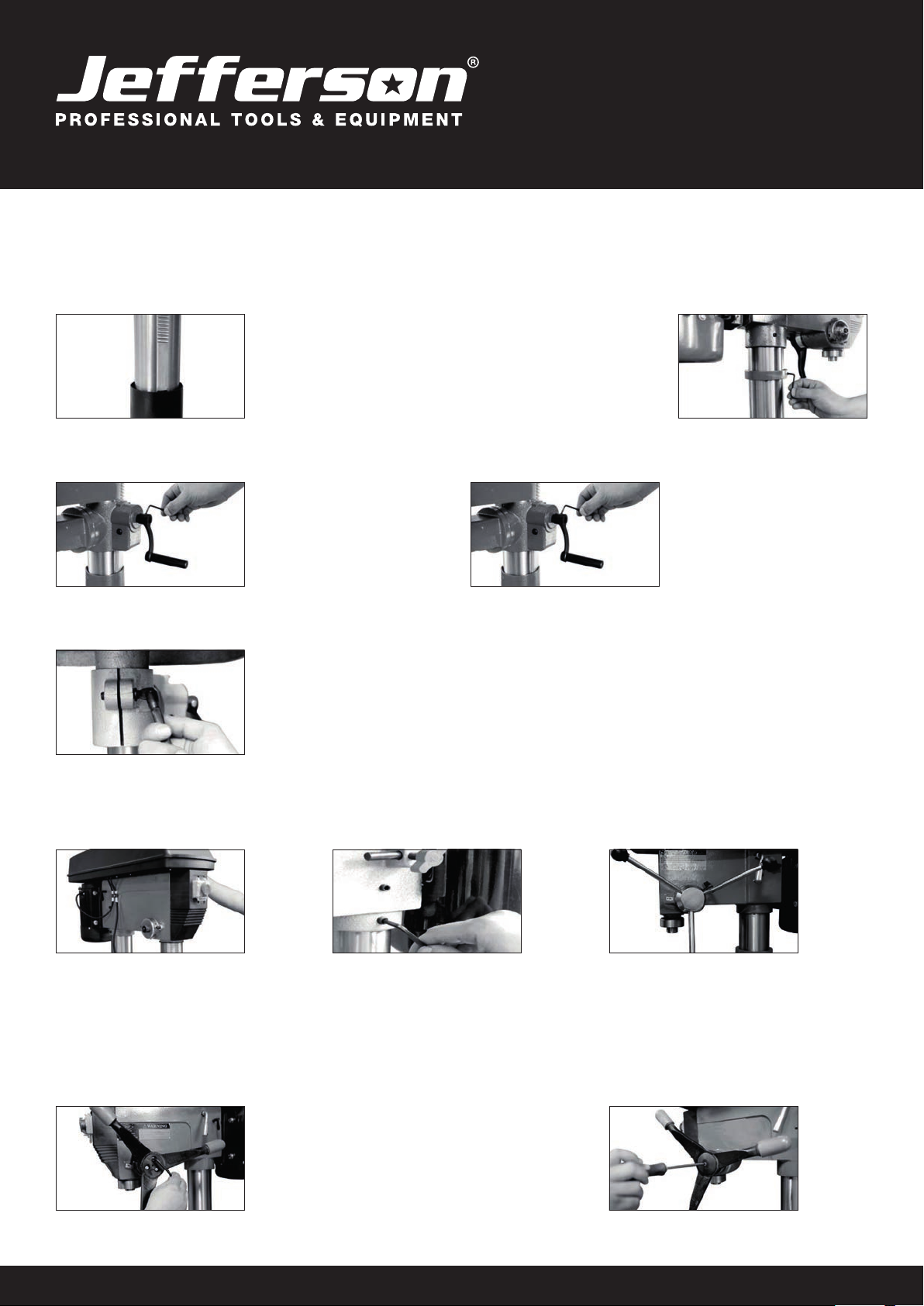

5. ASSEMBLY

BASE & COLUMN

Select the base (Fig. 1) and align the column support over the large hole (Fig. 2).

Align the holes in the column support with those in the base and secure in place using the bolts and washers.

Using a spanner securely lighten all bots (Fig. 3).

We recommend mounting the base to stable surface for proper support. Slide the column into the column support (Fig.4).

Fig.1 Fig.2 Fig.3 Fig.4

Secure in place with 2 grub screws using the hex key (Fig. 5).

Fig.5

RACK & TABLE

2. Assemble the support and

rack onto the column, ensuring

the rack is positioned on the right

side of the column (when viewing

the product from the front)

(Fig. 7).

Fig.6 Fig.7

1. Install the rack into the table

support as shown (Fig. 6).

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

6. ASSEMBLY

MAIN HOUSING

RACK & TABLE (Continued)

Fig.8 Fig.9

3. Slide the rack all the way down until it locates into the lower column

support(Fig. 8). Slide the collar, tapered side facing down, over the

column until it locates the rack.

Tighten the grub screw on upper collar (Fig.9).

Fig.10 Fig.10

4. Fix table adjustment handle on

the support (Fig. 10).

4. Fix table adjustment handle on

the support (Fig. 10).

Fig.10

5. Assemble table onto table

support, tighten in place with

table lock (Fig. 11).

1. Lift the main housing and slide

it down onto the column as far as

it will go (Fig. 12). Before securing

the housing, ensure the spindle

aligns with the table and base.

3. To t the feed wheel handles,

screw them into feed wheel hub

(Fig. 14).

2. To secure in position tighten

the grub screws on the left and

right hand sides of the housing

(Fig. 13).

4. For some cast iron feed

handle, lighten the 3 grub screws

to wheel hub (Fig.15) then x the

plastic case on cast iron feed

handle as shown Fig. 16.

Fig.12 Fig.13 Fig.14

Fig.15 Fig.16

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

7. ASSEMBLY

CHUCK & ARBOR

Fig.17 Fig.18

1. Before any assembly, ensure the

chuck jaws are wound all the way up

(inside the chuck) to prevent them

from damage (Fig. 17).

Fig.19

Fig.20

3. Fit the tapered arbor end into the chuck by

hand, using reasonable fore (Fig. 19).

4. The arbor can then be

inserted into the quill,

twisting the arbor as you

insert, aligning the tang

into the slot. It should t

in with little resistance

(Fig. 20). Fig.21

5. Once it is located a rm tap

on the underside of the chuck

with a soft hammer is required

to secure it. The chuck & arbor

are installed correctly if they

cannot be pulley out with hand

force (Fig. 21).

2. Tighten Philip’s head screws

of the chuck guard to quill shaft

(Fig. 18).

TABLE HEIGHT & ADJUSTMENT

Fig.22

1. Loosen the table

support lock (Fig. 22).

Fig.23

2. Rotate the table

adjustment handle to set

the desired table height

and tighten the table rock

to secure the table in

position (Fig. 23).

TABLE BEVEL ADJUSTMENT

Fig.24

1. The bevel angel is

adjusted by loosening

the bolt that is located

underneath table support

with a spanner (Fig. 24).

Fig.25

2. After tilting the

working table (Fig. 25)

to appropriate position,

re-tighten the bolt to

secure its position.

When the table is angled/tilted,

ensure the workpiece is clamped

to the table.

CAUTION:

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

8. ASSEMBLY

INSTALLING STRAIGHT SHANK DRILL BITS

Fig.26 Fig.27

1. Using the chuck key, loosen the

jaws of the chuck by rotating in an

anti-clockwise direction (Fig. 26).

Fig.28

3. Whilst holding the drill bit in one hand rotate

the top collar of the chuck in a clockwise

direction. Insert the chuck key into 1 of the

3 rotating holes and tighten until drill bit is

secure (Fig. 28).

2. Insert the drill bit into the chuck

(Fig.27)

MORSE TAPER DRILL BITS

Fig.29 Fig.30

To use Morse taper bits, remove

chuck and arbor.

1. Turn arbor until the tang aligns

with the slot in the quill (Fig. 29) .

Fig.31

3. Place tapper bit into the spindle hole,

twisting and pushing upward until bit is sung

(Fig. 31).

4. Place block of wood on the table and raise

up table until the tapered bit is.

2. 2. Insert the drill key into the

slot and tap rmly with a metal

hammer until it releases. (Ensure

the chuck jaws are wound all the

way up to prevent damage

(Fig. 30).

PRE-SETTING THE DRILLING DEPTH

BENCH TYPE

To set the depth of the hole, adjust the depth stop as follows:

1. Lower the chuck with the power OFF, until the drill bit touches the surface

of the workpiece, and hold in that position.

2. Spin down the adjuster nut so that the gap between its underside and top of bracket is the

depth of the hole required. Screw down the lock nut and lock it against the adjuster nut.

Fig.32

The drill is now set to drill holes to your pre-determined depth from that particular start point. i.e. Providing the surface of your workpiece is

at and level, you may drill a series of holes, each to the same depth. The scale and pointer can be used when drilling individual holes.

Lower the chuck until the drill bit touches the work, set the pointer against a point on the scale, and proceed to drill to the required depth,

using the scale.

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

9. ASSEMBLY

FLOOR TYPE

Fig.33 Fig.34

To stop spindle (and bit) at a desired depth:

1. Loosen depth stop lock knob by turning in an anti-clockwise direction (Fig. 33).

2. Rotate depth scale to the desired depth, then tighten half wing bolt (Fig. 34).

To hold the spindle (and bit) at a desired depth:

1. Loosen depth stop lock knob, turn feed wheel handle to lowest point (Fig.35).

2. Rotate depth scale to desired depth and re-tighten depth stop lock knob. This will hold assembly stationery at desired depth.

Fig.35

CHANGING THE SPEED

Fig.36

Before changing the speeds, ensure the machine is switched OFF, and disconnected from the power supply.

1. Open the pulley cover.

2. Slacken off the belt tension locking knob, to relieve any tension on the drive belt.

3. Consult the chart inside the pulley cover, and position the belt on the pulley’s according to the spindle speed required.

4. When the belt has been correctly positioned, re-tension by levering the motor away from the head. Lever the motor, with its bracket, away from

the head, so that tension is applied to the Fig.36 belt. Tension is correct when the belt deects by approx. ½”at its centre, when using

reasonable thumb pressure. Lock the motor in this position using the locking knob.

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

10. OPERATION

TURNING ON AND OFF

Fig.42

Note: The pulley cover must be closed to operate the drill press.

1. Switch the drill press On by pressing the green(I)button on the switch (Fig.42-43).

2. Switch the drill press Off by pressing the red(O)button on the sw itch.

3. Secure your workpiece to the table if possible,use a vice or clamps.

DRILLING

1. Ensure the drill press is switched off and disconnected from the power supply.

2. Loosen the jaws of the chuck with the chuck key by turning in an anti-clockwise direction and

insert the selected drill bit into the as far as it will go.

3. Insert the chuck key into 1 of the 3 locating holes and tighten until drill bit is secure.

4. Select your drilling depth and secure the depth stop lock knob in position.

5. Adjust the table to your desired position.

6. Slowly rotate the feed wheel handles to bring the drill bit down towards the table and into your workpiece. After drilling a hole, release the feed

wheel handles slowly to return the chuck to its original position.

7. Continue the operation until the task is completed. When completed, switch the drill press Off by pressing the red (O) button on the switch.

Fig.43

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

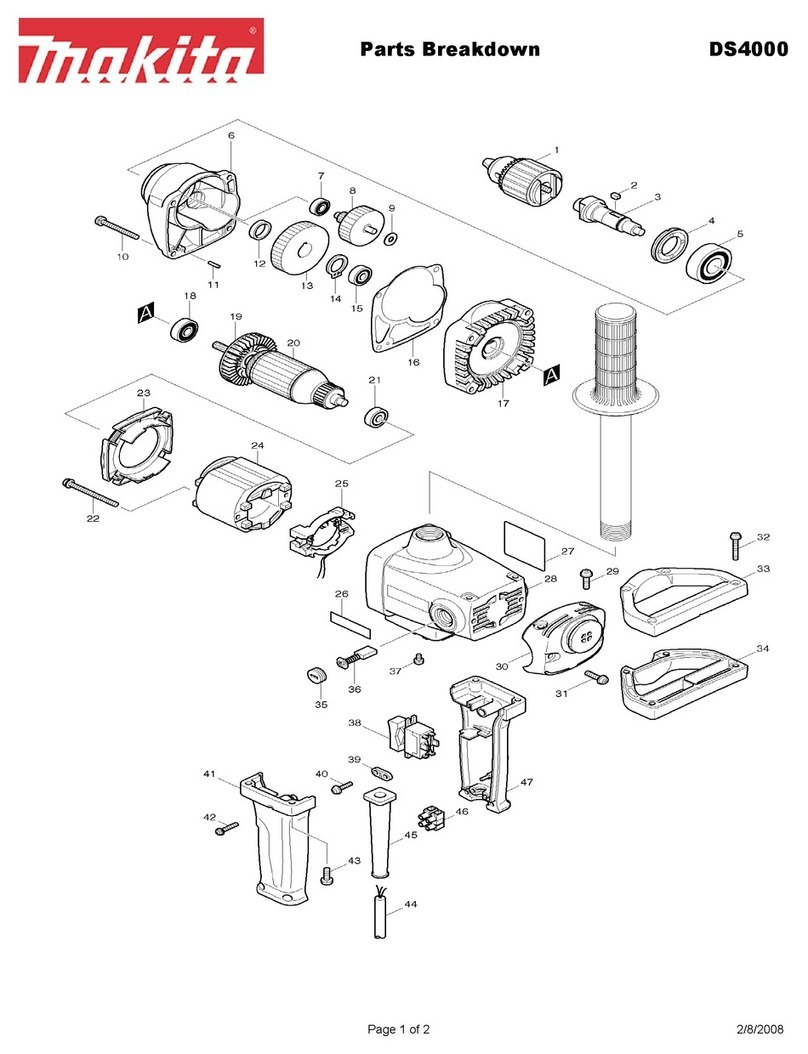

11. EXPLODED DIAGRAM OF BENCH PRESS

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

11. PARTS LISTING FOR BENCH PRESS

1BASE 40 NUT

2COLUMN FLANGE 41 SPRING WASHER

3FLAT WASHER 42 MICRO SWITCH PRESSING CLAW

4SPRING WASHER 43 HEX. SOC SET SCREW

5OUTSIDE HEX. BOLT 44 MOTOR PULLEY

6OUTSIDE HEX. BOLT 45 CIRCLIP FOR HOLE

7SPRING WASHER 46 BEARING

8WORKING TABLE 47 KEYWAY SPINDLE

9TABLE SUPPORT 48 CIRCLIP FOR BEARING

10 ANGLE LABEL 49 SPINDLE PULLEY

11 LOCKING HANDLE 50 BELT

12 COLUMN 51 PLUG WITH CABLE

13 HANDLE TIP 52 NUT

14 HANDLE 53 SPRING COVER

15 GEAR SHAFT 54 SPRING

16 NUT 55 SCREW

17 A WORD HEAD SCREW 56 CIRCLIP FOR BEARING

18 HOUSING 57 CROSS RECESS HEAD TAPPING SCREW

19 HEX. SOC SET SCREW 58 SWITCH

20 WING KNOB 59 CALIBRATION LABEL

21 MOTOR SPRING 60 CROSS RECESSED PAN HEAD SCREW

22 MOTOR PUSH ROB 61 SWITCH BOX

23 WASHER 62 CROSS RECESSED PAN HEAD SCREW

24 MOTOR 63 GROUNDED PARTS

25 OUTSIDE HEX. BOLT 64 TOOTH LOCK WASHER

26 DAMPING WASHER 65 INDICATOR

27 CROSS RECESS PAN HD SCREW 66 NUT

28 FLAT WASHER 67 LIMITED BOLT

29 CROSS RECESS PAN HD SCREW 68 BEARING

30 FLAT WASHER 69 WASHER

31 PROTECTOR RING 70 SPINDLE SOCKET

32 CORD CLAMP 71 CIRCLIP FOR BEARING

33 NUT 72 CHUCK GUARD

34 CROSS RECESSED PAN HEAD SCREW 73 MAIN SPINDLE

35 PULLEY COVER ASSEMBLY 74 CHUCK

36 ROLL PIN 75 HEXAGON BAR WRENCH

37 PROTECTOR RING 76 HEXAGON BAR WRENCH

38 MICRO SWITCH 77 SPRING WASHER

39 FLAT WASHER

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

TROUBLE SHOOTING

PROBLEM PROBABLE CAUSE REMEDY

Machine will not start. 1. Fuse

2. Other

1. Replace/ reset time delay fuse or circuit

breaker.

2. Return to an authorised service agent for

diagnosis.

Noisy operation (under load). a. Incorrect belt tension.

b. Dry spindle.

c. Loose pulley.

d. Loose belt.

e. Worn bearing.

a. Adjust tension.

b. Remove spindle and quill

assembly and lubricate.

c. Tighten pulley.

d. Adjust belt tension.

e. Replace bearing.

Bit burns or smokes. 1. Incorrect belt tension.

2. Swaft not coming out of hole.

3. Blunt bit.

4. Feeding too slow.

5. Not lubricated.

1. Change speed.

2. Retract bit frequency to clear swaft.

3. Sharpen or replace bit.

4. Feed fast enough to allow drill to cut.

5. Lubricate bit.

Excessive drill run-out or wobble. 1. Bent bit.

2. Worn spindle bearings.

3. Bit not properly installed in chuck.

4. Chuck not properly installed.

1. Use a straight bit.

2. Return to an authorised service agent.

3. Install bit centrally.

4. Ret chuck properly.

Drill binds for workpiece. 1. Workpiece pinching bit or

excessive feed pressure.

2. Improper belt tension.

1. Support or re-clamp workpiece.

2. Adjust tension.

For your safety always turn the main switch on the machine “off”

and remove the plug from the power supply before carrying out any

maintence or trouble shooting.

WARNING:

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

EC Declaration of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

Directive: Description:

2014/30/EU (as amended) Electromagnetic compatibility

2006/42/EC (as amended) Machinery directive

2011/65/EC (as amended) Restriction of Hazardous Substance

Directive (RoHS)

Equipment Category: Bench Drill / Pillar Drill / Drill Press

Product Name/Model: JEFPDB0350

Notified Body: TÜV SÜD Product Service GmbH Zertifizierstellen

Ridlerstraße 65

80339 MÜNCHEN

Country : Germany

http://www.tuev-sued.de/ps

Notified Body Number: 0123

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 31 January 2018

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park,

Chester, United Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

Jefferson Professional Tools & Equipment, or hereafter “Jefferson” warrants its

customers that its products will be free of defects in workmanship or material. Jefferson

shall, upon suitable notication, correct any defects, by repair or replacement, of any

parts or components of this product that are determined by Jefferson to be faulty

or defective. This warranty is void if the equipment has been subjected to improper

installation, storage, alteration, abnormal operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during

the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer.

If proof of purchase is unavailable from the end user, then the date of purchase will be

deemed

to be 3 months after the initial sale to the distributor.

1 Year

• Jefferson 350W Bench Drill [JEFPDB0350].

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment

will be subject to a minimum of 90 days cover or the remaining duration of the warranty

period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using

the following address: www.jeffersontools.com/warranty and completing the online

form.

Online warranty registration is recommended as it eliminates the need to provide proof

of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the

defect will be corrected by repair or replacement at an authorized Jefferson dealer or

repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready

for collection. Jefferson will arrange collection and transportation of any equipment

returned under warranty. Upon inspection of the equipment, if no defect can be found

or the equipment is not covered under the terms of the Jefferson warranty, the customer

will be liable for any labour and return transportation costs incurred. These costs will be

agreed with the customer before the machine is returned.

NOTE: * Jefferson reserve the right to void any warranty for damages identified as being

caused through misuse *

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised

technicians or engineers. Jefferson’s liability under this warranty will not exceed the

cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of

business or hire of substitute equipment etc.) caused by the defect or the time involved

to correct the defect. This written warranty is the only express warranty provided by

Jefferson with respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for

the equipment involved.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment:

(Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where final

determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns

form. You can complete the form online and submit it to us directly or download the

form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax,

together with details of your nearest authorised Jefferson repair centre. On receipt

of this form Jefferson will arrange to collect the equipment from you at the earliest

convenience.

Step 2 - Returning the Equipment

It is the customer’s responsibility to ensure that the equipment is appropriately and

securely packaged for collection, together with a copy of the original proof of purchase.

Please note that Jefferson cannot assume any responsibility for any damage incurred

to equipment during transit. Any claims against a third party courier will be dealt with

under the terms & conditions of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a

copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it

will be determined if the equipment is defective and in need of repair and any repairs

needed are covered by the warranty policy. In order to qualify for warranty cover all

equipment presented must have been used, serviced and maintained as instructed in

the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and

return delivery will be sent to the customer (normally within 7 working days). Note: If the

repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1

hour labour time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the

equipment is identified as the cause of the problem, a minimum of 1 hour labour at £30

per hour plus carriage costs will be required before the equipment will be despatched

back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment

back to the customer within 7 working days upon receipt of the equipment at an

authorised Jefferson Repair centre (subject to part availability). Where parts are not

immediately available Jefferson will contact you with a revised date for completion of

the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call:

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but

all recommendations or suggestions are made without guarantee. Since the conditions

of use are beyond their control, Jefferson Tools® disclaim any liability for loss or

damage suffered from the use of this data or suggestions. Furthermore, no liability is

accepted if use of any product in accordance with this data or suggestions infringes any

patent. Jefferson Tools® reserve the right to change product specifications and warranty

statements without further notification. All images are for illustration purposes only.

LIMITED WARRANTY STATEMENT

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

NOTES

www.jeffersontools.com

User Manual

v.1.1

JEFPDB0350

JEFPDB0350

350W

BENCH

DRILL

Table of contents

Other Jefferson Drill manuals

Jefferson

Jefferson JEFMGNDR40-110 User manual

Jefferson

Jefferson JEFMAGDPER35-230 User manual

Jefferson

Jefferson JEFPDB1500 User manual

Jefferson

Jefferson JEFPDB1100 User manual

Jefferson

Jefferson JEFPDB0550 User manual

Jefferson

Jefferson JEFMAGD42HD/110 User manual

Jefferson

Jefferson JEFMAGDAUT35-230 User manual