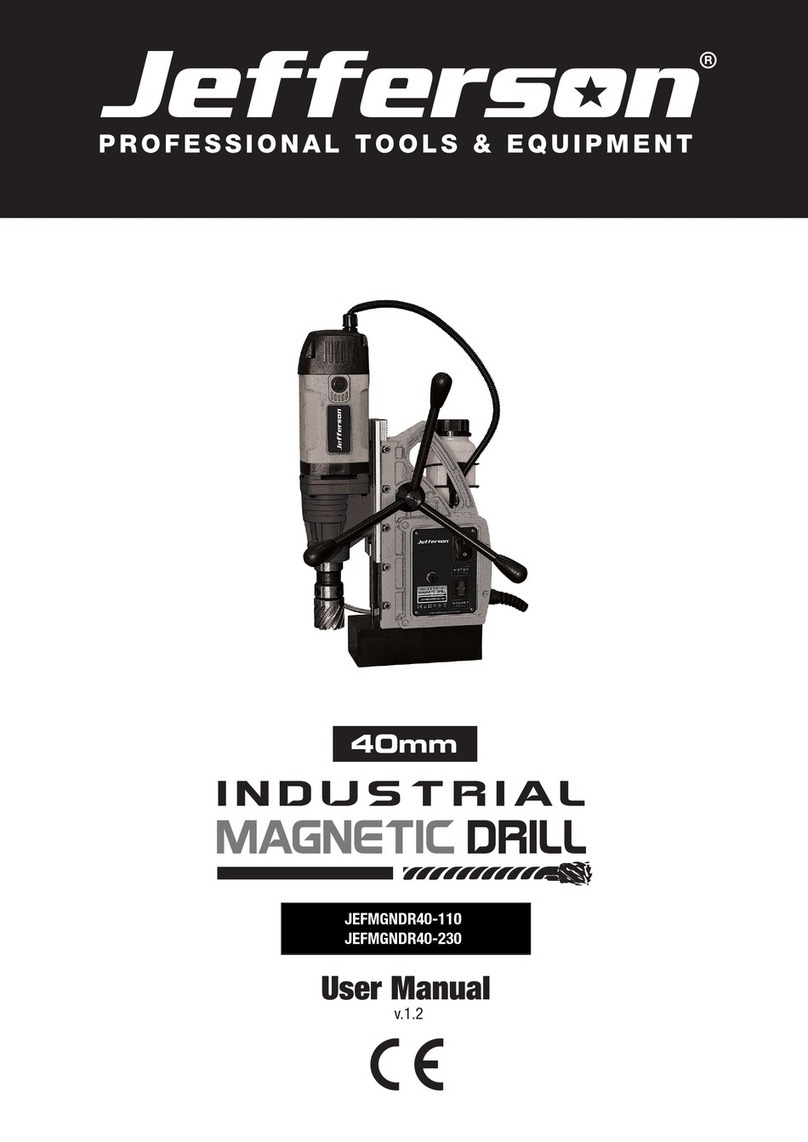

Jefferson JEFMAGDPER35-230 User manual

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 1

User Manual

v.1.1

JEFMAGDPER35-230

JEFMAGDPER35-110

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

2

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 3

CONTENTS

Introduction 4

Safety Guidelines 5

Specications 6

Operation Guide 6

Cleaning & Maintenance 7

Parts Diagram - Frame & Magnet Components 8

Parts List - Frame & Magnet Components 9

Parts Diagram - Motor Components 10

Parts List - Motor Components 11

Limited Warranty Statement 12

EC Declaration of Conformity 14

Environmental Protection 15

WEEE Waste Electrical and Electronic Equipment Statement 15

RoHS Directive 2011/65/EU 15

Important: Please read all these instructions before operating this product and save these instructions. This manual has been compiled by Jefferson Tools

and is an integrated part of the product with which it's enclosed and should be kept with it for the future reference.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure its correct and safe use.

We recommend that this manual is read before any operation or, before performing any kind of adjustment to the product and prior to any maintenance

tasks. By following all the general safety instructions contained in this manual you will help to ensure operator safety and extend the potential lifespan of the

equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort has been made

to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make modifications without prior

warning.

Note: The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance of the equipment. Some

illustrations in this Instruction Manual may show details or attachments that differ from those on your own model. Contact your nearest Jefferson Dealer if

you are unsure about any information included in this manual or require any additional information about the safe use, operation maintenance, or repair of

this equipment.

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

4

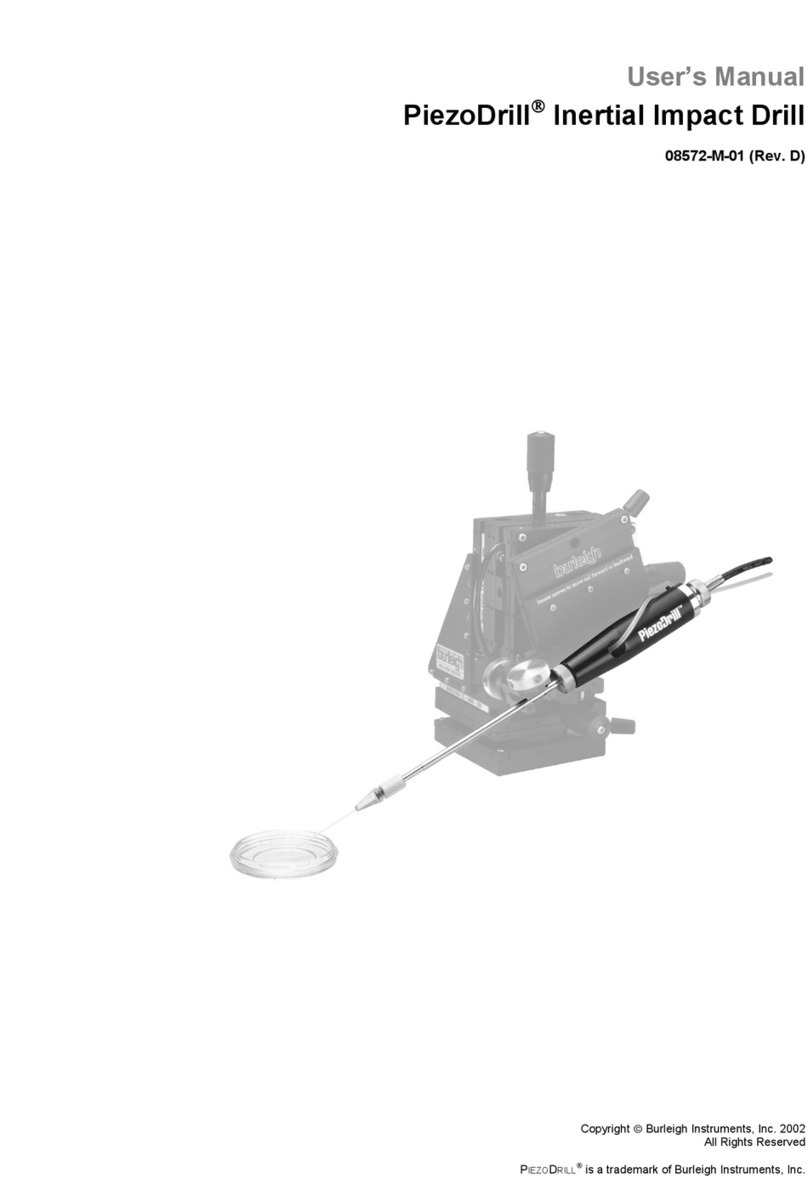

1. Introduction

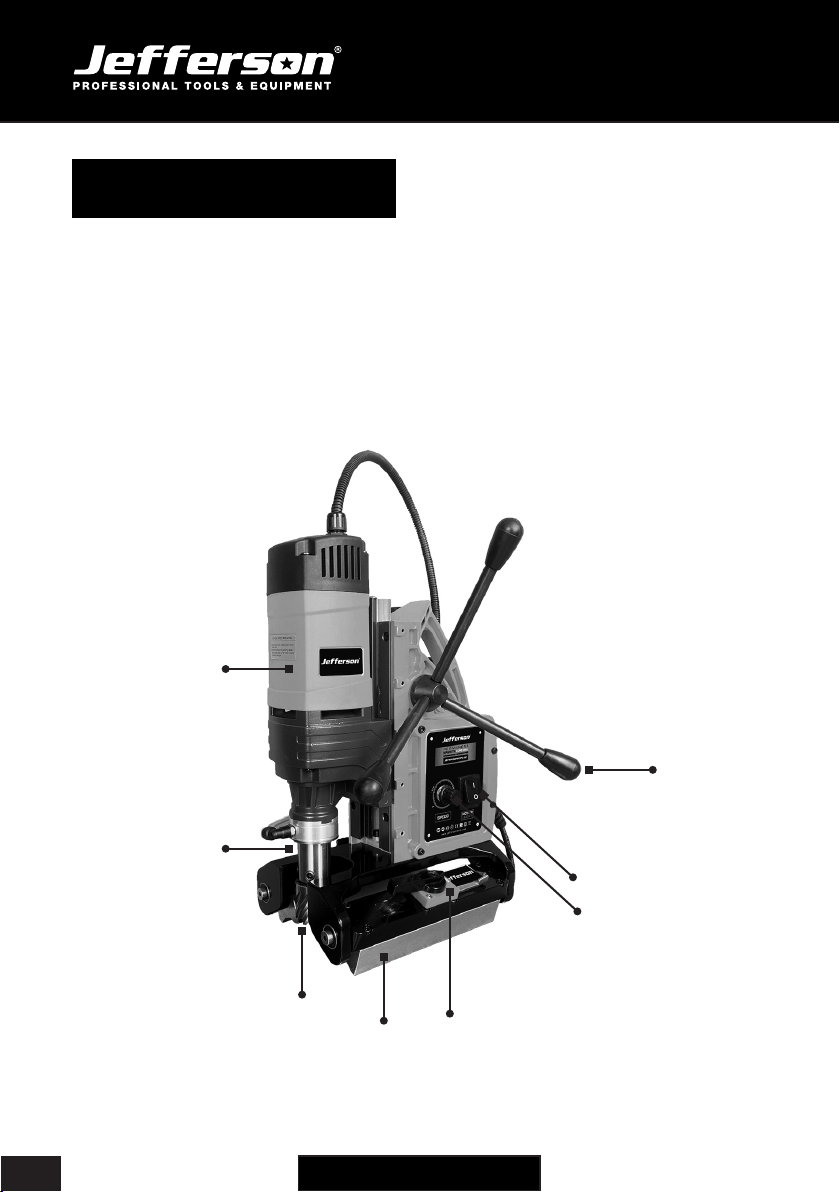

Motor Housing

Spindle

Annular Hole Cutter

(Slugger Bit) Magnet Permanent

Magnet Lock

On / Off

Speed Control

Motor Control

On / Off

Capstan

Control Handle

This magnetic drill is designed for drilling holes in steel fabrication work. It is an ideal portable

drilling solution equally suited for use in building sites or the workshop environment and can be

used to cut in horizontal, vertical and overhead positions.

This model features a permanent magnetic locking feature which ensures safe and lasting

magnetic adhesion in the event of electrical supply failure. The magnetic base can also swivel to

change the angle making it possible to fix to a variety of pipe shapes.

The magnetic drill uses an annular hole cutter (sometimes called a slugger bit) to cut clean and accurate holes

without pre-drilling or step drilling. After cutting through the steel the cutter produces a "slug" (a cylindrical

lump of steel) that falls from the centre of the cut.

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 5

2. Safety Guidelines

Important: Ensure that you have read and

understand the information contained in this

manual before operating this equipment.

This appliance is not intended for use by persons

with reduced physical, sensory or mental

capabilities. The appliance must not be operated by

children or by any persons who have not been

instructed in the correct operation.

Children and pets should be kept away from the

working environment at all times during operation.

Please read these instructions carefully and

keep in a safe location for future reference.

Ensure that the manual is passed on should

ownership of the equipment change at any

time.

Contact your nearest Jefferson Dealer for advice on

correct usage, accessories (including compatible

detergents), servicing and replacement parts.

Do not modify this equipment for any other purpose

than those originally intended buy the manufacturer.

Ensure that the product is used in

accordance with the guidelines described

in this manual. Failure to do so can result in

personal injury and may void the warranty.

Ensure that you disconnect from the power supply

before carrying out any adjustments maintenance

or servicing on this equipment.

Working Environment

Ensure that the working environment is kept clear

and uncluttered. There should be plenty of light

available for safe operation.

Do not use this equipment in wet or windy

conditions or damp or wet conditions.

Do not use this equipment in the presence of

ammable liquid or gases.

Protect against electric shock by preventing

contact with earthed or ground surfaces (e.g. pipes,

radiators, cookers and refrigerators).

Jefferson recommend using a suitable residual

current device (RCD) for electrical safety when us-

ing this equipment.

Store idle tools when not in use in a dry and secure

location, out of reach of children.

Do not force the tool during operation or use

the equipment for a larger job than which it was

designed.

Personal Protection Equipment (PPE)

Do not wear loose clothing or jewellery during

operation incase they get caught in moving parts.

Wear protective hair covering to prevent long hair

getting caught up in the tool.

Ensure that suitable safety equipment is worn

during use these include:

•Safety glasses

•Ear defenders

•Protective gloves

Wear a hard hat (if working with magnetic drill

above head height to prevent injury from ejected

slugs after cutting). Use a face or dust mask if

cutting operations create dust. Non-slip, steel

toecap footwear is recommended.

Cutters are sharp. Wear gloves when installing or

removing cutter from the arbor. Do not grab a

rotating cutter.

Keep tools sharp and clean for better and safer

performance. Do not use dull or broken cutters.

Follow safety instructions for lubricating and

changing accessories (always check compatibility

of annular cutters before use). Inspect tool cords

periodically and, if damaged, have them repaired

by a qualied electrician or an authorised

Jefferson Repair Centre.

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

6

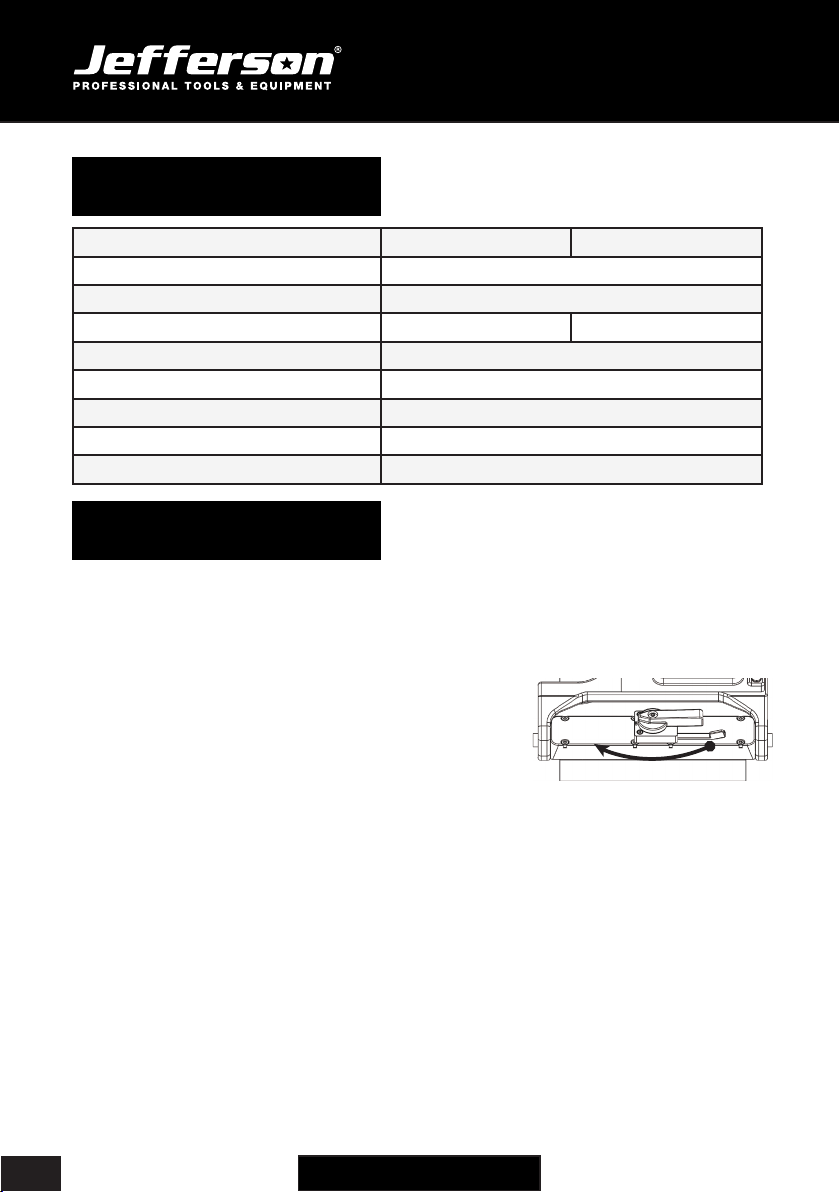

3. Specications

Model Number: JEFMAGDPER35-110 JEFMAGDPER35-230

Maximum Core Drill Diameter: 35mm

Maximum Cutting Depth: 35mm

Input Voltage / Frequency: 110V 230V

Magnetic Adhesion: 16000N

Motor Power / Speed: 1600W

No Load Speed: 700rpm

Dimensions: 34 x 25 x 43cm

Weight: 11.5kg

1. Make sure the workpiece is suitable for magnetic adhesion and that both the surface of the workpiece and

the magnetic base of the drill are clean and free of dirt, grease and debris.

2. Secure the magnetic drill to the unit to workpiece with safety chain provided.

3. Position the drill by sliding it and gently feeding the arbor so that pilot pin is in contact with the centre of the

hole you need to cut.

4. Activate the magnet by moving the Magnet Handle to the ON

position (rotate 180°).

5. Turn the Feed Handle, raising the annular cutter until the pilot pin is

above the work surface.

6. Open the cutting uid valve.

8. Make certain that the annular cutter is clear of the workpiece and turn

the motor on by pressing the motor button to the ON position.

9. Feed the cutter slowly onto the workpiece. Carefully establish a cutting

depth of about 1/16" before using the full force of the drill on the cut by turning the feed handle to lower the

arbor as required.

10. Ease up on feed pressure as the cutter starts to break through the workpiece.

11. When you have completed the cut, turn off the motor by pushing

the motor button into the STOP position.

12. Turn feed handles to raise the arbor away from the hole. This will cause the slug to fall free (if it hasn’t

already) so take care to ensure it does not fall in a way that can cause bodily harm to the operator or any other

persons in the vicinity.

13. Turn the magnet OFF by moving the Magnet Handle to the OFF position. As the magnet de-activates the

base should lift up off the work surface.

14. Disconnect the equipment from the power source.

15. Remove any chips or debris from the cutter and the magnet wearing a pair of protective working gloves

and a set of pliers to protect your hands from sharp materials.

16. Disconnect the safety chain and carefully remove the drill to complete the procedure.

4. Operation Guide

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 7

Important: The magnetic strength of the drill base is related to the thickness of the steel ,or other ferrous

metal, in the workpiece. Magnetic adhesion can also be affected by the cleanliness of the metallic surface

you are fixing to. Material that is clean and free from coatings will offer the best surface for the magnet.

Factors that can reduce the effectiveness of the magnet and safe operation of the equipment include:

•Coatings or paint layers on material

•Material less than 3/8” thick

•Workpieces with dirt, grease or debris between the magnet and the metallic surface

•Curved or uneven work surfaces (The surface of the workpiece should be flat. For pipe applications, a pipe

adapter should be used.)

•Workpieces that are smaller than the dimensions of the metallic base.

• Keep the machine, the cutter and electric cables clean from drilling debris.

• Always turn off the machine and unplug from the mains before carrying out any cleaning.

• Clean the motor by means of dry compressed air.

• Clean and grease any sliding surfaces regularly.

• Carbon brushes should be replaced after approximately 250 hours running time.

• When not in use the magnetic drilling machine should be stored securely in the transport case lying at in a

dry storage space.

Note: Excessive sparking may indicate the presence of dirt in the motor or worn out carbon brushes.

We recommend that you periodically check the brushes for wear and tear and replace them when they reach

6mm. Keep moving parts lubricated.

Maintenance, checks and repairs should only be made by qualied electricians or a Jefferson approved

technician. We recommend that the machine should be serviced after approximately 250 hours running time.

Only use genuine spare parts. A full list is available at the end of this manual. Contact your nearest

Jefferson dealer for further information.

5. Cleaning & Maintenance

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

8

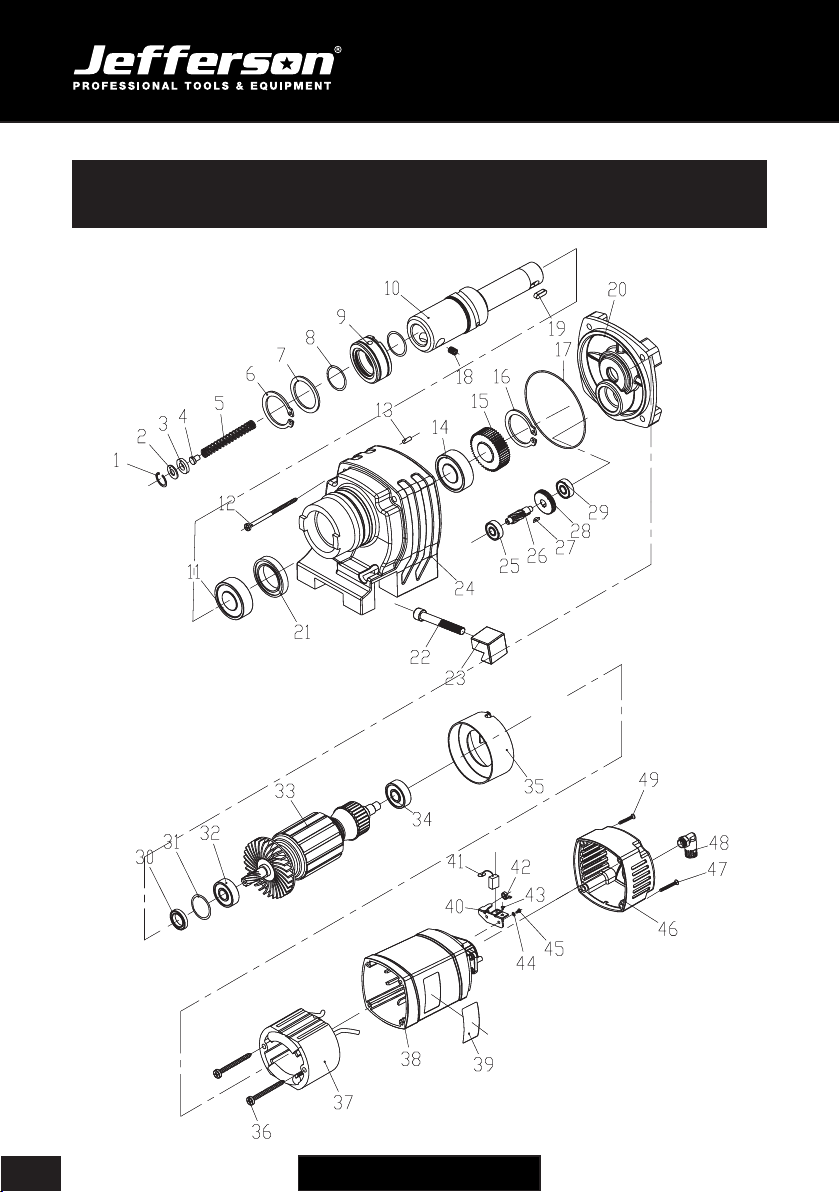

PARTS DIAGRAM - Frame & Magnet Components

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 9

PARTS LIST - Frame & Magnet Components

# Qty Description # Qty Description

11 Left Rail Track

Bar17*230"

23 1 Gear Shaft For Armature

21 40 Pressure Bar 230 24 1 Key 9*3

31 Right Rail Track Bar

17*230

25 1 Gear For Armature

41 Slide Bar 1.5*11*230 26 1 Bearing 608

51 Rack 10*16*180 27 4 Oil Seal Ø 10*16*4

62 Protection Sleeve 12 28 4 O Ring Ø 29*1.8

71 Stropper 13 29 1 Bearing Lfb6000

81 13 Frame Scy 30 1 Rotor

91 E Clamp Ring 15 31 1 Bearing 608

10 2 Stainless Washer

17*30*1

32 4 Wind Circle

11 4 Bearing 6903 33 1 Self-Tapping Screw M4*60

12 1 Circlip, Outter 18 34 1 Field

13 1 Lifting Rack 18*44*16 35 4 Motor Housing

14 1 Plain Bearing

58*26*30

36 1 Nameplate

15 1 Lift Shaft 32Hd-1 37 1 Brush Bracket

16 1 Square Key 5*14 38 4 Carbon Brush

17 3 Rocker M10*145 39 1 Carbon Brush

18 3 Plastic Handle

M10(4)

40 4 Screw M4*8

19 5 Inner Hexagon Screw

M4*10

41 2 Washer 4

20 1 Protection Sleeve 12 42 6 Self-Tapping Screw M4*12

21 1 Grounded Plate

(Magnetic Drill)

43 2 40 Sealing Sleeve

22 1 Nut M4

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

10

PARTS DIAGRAM - Motor Components

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 11

PARTS LIST - Motor Components

# Qty Description # Qty Description

11 Circlip, Inner 19 26 1 Gear Shaft For Armature

21 Gasket 9*19*2 27 1 Key 9*3

31 Plastic Gasket 28 1 Gear For Armature

41 Key For Spring

10.3*12

29 1 Bearing 608

51 Spring 120 30 1 Oil Seal Ø 10*16*4

61 Circlip, Inner 33 31 1 O Ring Ø 29*1.8

71 Ring Ø 34* Ø 40 32 1 Bearing Lfb6000

82 O Ring Ø 40*2 33 1 Rotor

91 Water Seal 34 1 Bearing 608

10 1 Spindle 35 1 Wind Circle

11 1 Bearing Jvb6904 36 2 Self-Tapping Screw M4*60

12 4 Self-Tapping Screw

M5*60

37 1 Field

13 1 Round Key 4*12 38 1 Motor Housing

14 1 Bearing 6904 39 1 Nameplate

15 1 Gear 40 2 Brush Bracket

16 1 Circlip, Outter 20 41 2 Carbon Brush

17 1 O Ring Ø 73*2 42 2 Carbon Brush

18 1 Hex Socket Flat Top

Thread M10*15

43 4 Screw M4*8

19 1 Pin 6*10 44 4 Washer 4

20 1 Gear Cover 35Pm 45 4 Self-Tapping Screw M4*12

21 1 Oil Seal Ø 20*32*7 46 1 40 Sealing Sleeve

22 1 M8*45 Screw 47 2 Self-Tapping Screw M5*40

23 1 Dovetail Groove Iron 48 1 Hose Connection

24 1 Gear Box 49 2 M5*35 Self-Tapping Screw

25 1 Bearing 608

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

12

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in

workmanship or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or

components of this product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations, improper

care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end

user, then the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• JEFMAGDPER35-230 • JEFMAGDPER35-110 - PERMANENT MAGNETIC CORE DRILL

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or

the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the

need to provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment

is not covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs

incurred.

These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under

this warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused

by the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with

respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for

possible wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 13

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson

dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and

submit it to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised

Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with

a copy of the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to

equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of

purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and

in need of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented

must have been used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally

within 7 working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour

plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the

problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back

to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon

receipt of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available

Jefferson will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made

without guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage

suffered from the use of this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data

or suggestions infringes any patent. Jefferson Tools® reserve the right to change product specifications and warranty statements without

further notification. All images are for illustration purposes only.

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com

14

EC DECLARATION OF CONFORMITY

We, Tundra Industrial, as the authorised European Community representative of the manufacturer, declare that

the following equipment conforms to the requirements of the following Directives:

Directive: Description:

2014/30/EU (as amended) Electromagnetic Compatibility

2006/42/EC (as amended) Machinery Directive

2014/35/EU (as amended) Low Voltage Directive

2011/65/EU (as amended) RoHS Directive

Equipment Category: Magnetic Drill

Model Number: JEFMAGDPER35-230 • JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 14 August 2018

Name and address of

manufacturer or authorised

representative:

Jefferson Tools, Herons Way, Chester

Business Park, Chester, United

Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

JEFMAGDPER35-230 •JEFMAGDPER35-110

PERMANENT MAGNETIC CORE DRILL

www.jeffersontools.com 15

WEEE Waste Electrical and Electronic Equipment Statement

Information on Disposal for Users of Waste Electrical & Electronic Equipment

This symbol on the product(s) and / or accompanying documents means that used electrical and electronic products

should not be mixed with general household waste. For proper treatment, recovery and recycling, please take this

product(s) to designated collection points where it will be accepted free of charge.

For private households:

Dispose of this product at the end of its working life and in compliance with the EU Directive on Waste Electrical and Electronic

Equipment (WEEE). Contact your local solid waste authority for recycling information for this equipment.

Disposing of this product correctly will help save valuable resources and prevent any potential negative effects on human health and the

environment, which could otherwise arise from inappropriate waste handling.

Please contact your local authority for further details of your nearest designated collection point.

Penalties may be applicable for incorrect disposal of this waste, in accordance with you national legislation.

For business users in the European Union:

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union:

This symbol is only valid in the European Union. If you wish to discard this product please contact your local authorities or dealer and ask

for the correct method of disposal.

We hereby declare that this equipment has been tested and found to be compliant to RoHS Directive 2011/65/EU of the European

Parliament and the Council from 08/06/2011 on restriction of the use of certain hazardous substances in electrical and electronic

appliances.

Determination of levels of regulated substances in electrotechnical products, elements of Cadmium (Cd), Lead (Pb), Mercury (Hg),

Chromium (Cr) and Bromine (Br) contents were measured by XRF Spectroscopy and chemical conrmation test for RoHS restricted

substances.

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and

packaging should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the

environment. When the product becomes completely unserviceable, reaches the end of its working life and requires

disposal, drain off any uids (if applicable) into approved containers and dispose of the product and the uids according

to local regulations.

RoHS Directive 2011/65/EU - COMPLIANCY

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

www.jeffersontools.com

This manual suits for next models

1

Table of contents

Other Jefferson Drill manuals

Jefferson

Jefferson JEFPDB0350 User manual

Jefferson

Jefferson JEFMGNDR40-110 User manual

Jefferson

Jefferson JEFMAGD42HD/110 User manual

Jefferson

Jefferson JEFPDB0550 User manual

Jefferson

Jefferson JEFMAGDAUT35-230 User manual

Jefferson

Jefferson JEFPDB1100 User manual

Jefferson

Jefferson JEFPDB1500 User manual