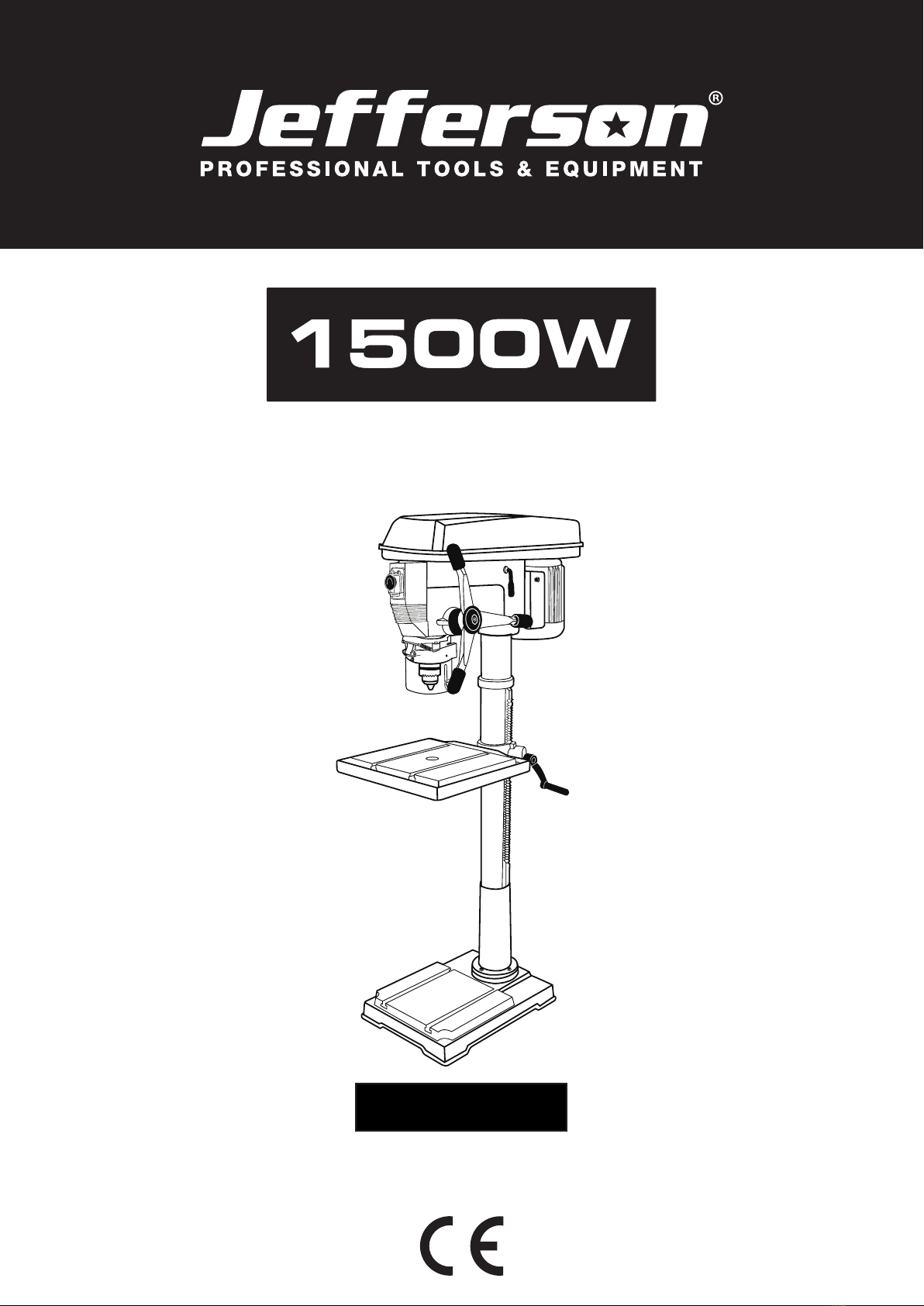

Jefferson JEFPDB1500 User manual

User Manual

v.1.1

JEFPDB1500

Pillar Drill

230V ~ 50Hz

2

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Contents:

About This Document: 2

Introduction 2

Specications 3

Safety Information 3

Parts Identication 5

Unpacking & Working Environment 5

Assembly Instructions 6

Settings & Adjustments 7

Using Straight Shank Drill Bits 7

Using Morse Taper Drill Bits 7

Pre-Setting The Drilling Depth Bench Type 8

Adjusting Speed Settings 8

Operation Guide 8

Drilling 9

Maintenance 9

Troubleshooting 10

Circuit Diagram 11

Parts Lists & Diagram 12

Environmental Protection 16

WEEE Waste Electrical and Electronic Equipment Statement 16

RoHS Directive 2011/65/EU 16

EC Declaration of Conformity 17

Limited Warranty Statement 18

About This Document:

This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed and should be kept with it for

future reference. Please read all of the information supplied in this User Manual before operating this product.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure its correct and

safe use. We recommend that you read the information supplied before carrying out any maintenance or repair. By following all the general safety

instructions contained in this manual you will help to ensure operator safety and extend the potential life span of the equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst every effort

has been made to ensure accuracy of information contained in this manual our policy of continuous improvement determines the right to make

modifications without prior warning.

The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance of the equipment. Some

illustrations in this Instruction Manual may show details or attachments that differ from those on your own model. Contact your nearest Jefferson

Dealer if you are unsure about any information included in this manual or require any additional information about the safe use, operation

maintenance, or repair of this equipment.

Introduction:

This equipment has been designed for drilling large or small holes in metal, wood, plastic, etc.

Before attempting to use this product, please read this manual thoroughly and follow the instructions carefully. In doing so you will ensure the

safety of yourself and that of others around you and will help to ensure long and reliable service from the equipment.

3

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

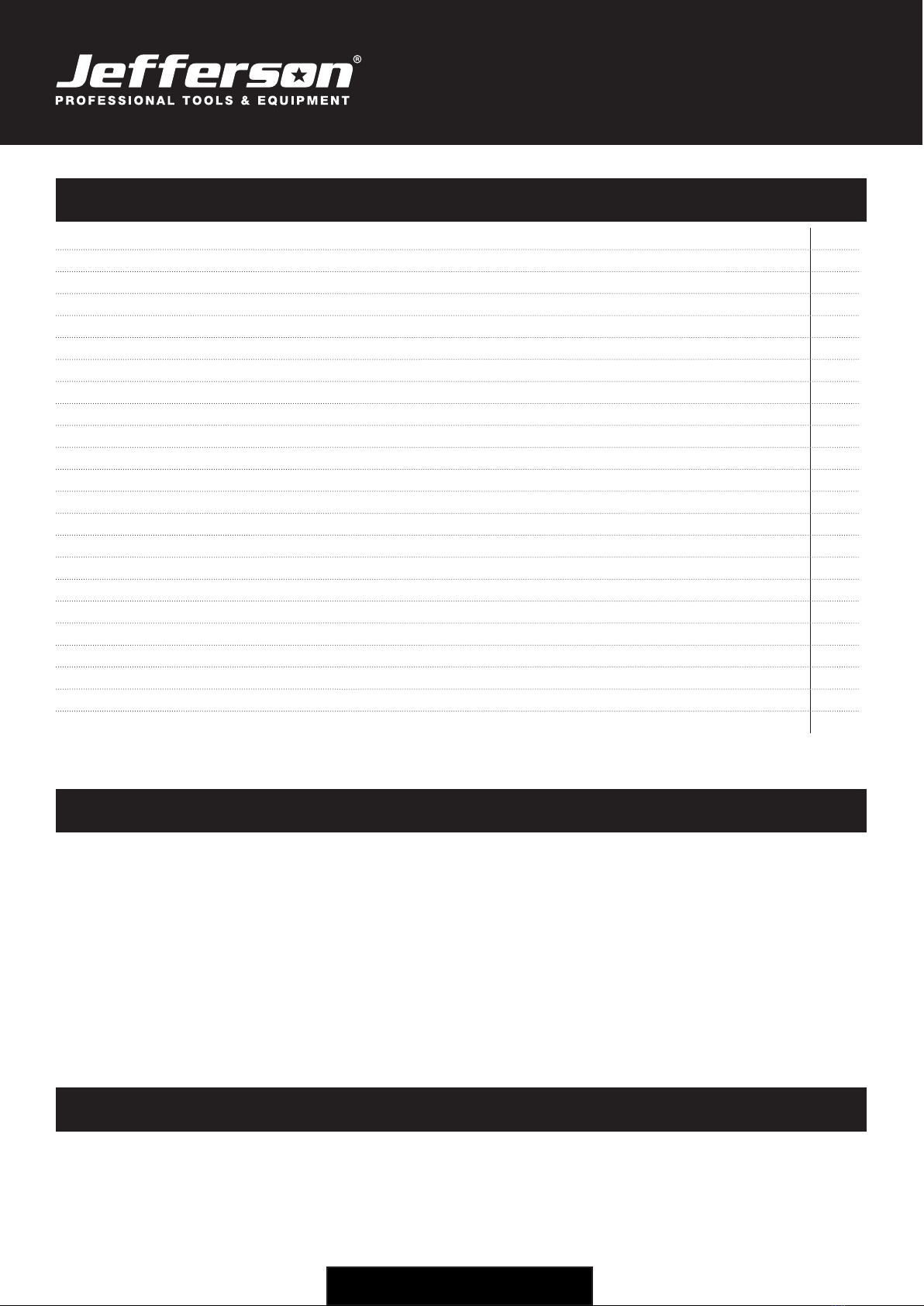

Specifications:

AMax Drilling Diameter 32mm (1/1-4”)

Motor Power 1500W

Chuck Capacity 5-20mm

Input Voltage - Frequency 230V - 50Hz

BSpindle Travel 120mm

Number of Speeds 12

Speed 50Hz 150-2450R.P.M.

CSpindle Taper MT4

DMax. distance from spindle axis to surface of column 255mm

EMax. distance from spindle end to surface of table 745mm

FMax. distance from spindle end to surface of base 1205mm

Swing 510mm

Table Size 420X480mm

Base Size 575X425mm

GColumn Diameter 92mm

HHeight 1710mm

NW/GW 125/130kg

Safety Information:

Warning: this symbol is used throughout the instructions whenever there is a risk of personal injury. Ensure that these warnings are

read and understood at all times. When using electric tools, basic safety precautions should always be followed to reduce the risk of

fire, electric shock and personal injury: You should not operate this machine unless you are thoroughly familiar with drilling machines

and drilling techniques. If there is any doubt whatsoever you should consult a qualified person.

Please read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire

and/or serious injury. Store this instruction manual in a safe place for future reference.

General Safety

• Always ensure that air can circulate around the machine and that the air vents are unobstructed.

• Always keep work area clean & tidy. Cluttered work areas and benches increase the risk of accidents and injury.

• Never over-reach. Maintain a balanced footing at all times.

• Never use or store this equipment in a wet/damp environment or expose to rain.

• Keep untrained personal, children and pets away from the work area.

• Never operate a machine when under the inuence of alcohol, drugs or medication.

• Always ensure the workplace is well lit. Ensure that lighting is placed so that you will not be working in your own shadow.

• Do not use tools in the presence of ammable liquids or gasses.

• Stay alert at all times, watch what you are doing, use common sense and do not operate the tool when you are tired.

4

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Safety Information: (continued)

Equipment Safety

• Always keep guards in place and in clean, working order. A guard or other part that is damaged should be properly repaired or replaced using

Jefferson approved parts.

• Don’t force the machine or use it for purposes other than it was designed for. Do not modify the equipment to improve performance or ex-

ceed the specied rated speed.

• Remove any adjusting keys or wrenches before using the equipment.

• Always disconnect the machine from the power supply before carrying out any servicing or changing accessories.

• Check the alignment and condition of all moving parts before use. Do not use if any parts are damaged or worn.

• Never remove the cover panel unless the machine is disconnected from the power supply, and never use the machine with the cover panels

removed.

• Guard against electric shock. Avoid body contact with earthed or grounded surfaces.

• This equipment is designed for use in dry, indoor working environments with suitable ventillation.

• Avoid accidental starting by making sure the power switch is off before plugging in the power cable.

• Never operate the machine until it is completely assembled and you have read and understood this entire manual.

• Always use clamps or a drill vice bolted to the table, to hold the work. The workpiece should never be held with bare hands.

• Always shut off the power & remove the drill bit before leaving the machine. Never leave the drill unattended whilst it is running.

• Always use the correct drilling speeds for the drill size and the type of material being drilled.

• Always remove and store the drill bits when you have nished working with the equipment.

• Never attempt to drill into a workpiece that does not have a at surface unless a suitable support is used.

• Always stop the drill before removing workpieces, work supports or swarf from the table.

• Keep drills sharp and clean for best and safest performance.

• Adjust the table or depth stop where necessary to avoid drilling into the table surface.

• Always be sure that the drill bit is securely locked in the chuck.

• Never assemble or set up any work on the table while the drill is running.

• Always ensure the table lock is tight before starting the drill.

• Keep the handles dry, clean and free from oil and grease.

• Always keep hands and ngers away from the drill bit when the equipment is connected to the power supply.

• Do not operate the equipment if you are tired or under the inuence of alcohol, drugs or medicine.

• Keep children and animals away from the equipment and work area at all times.

Dust generated from certain materials can be hazardous to your health. Always operate the drill in a well-ventilated area. Use a dust

collection system if possible. Use a dust mask or other suitable respiratory protection as required. The use of any accessory or

attachment other than one recommended in this instruction manual may present a risk of personal injury.

Protective Clothing

• Always wear the appropriate clothing and personal protection equipment

• Non-slip footwear and safety boots is recommended.

• Wear a protective hair covering or tie back long hair.

• Always wear safety glasses and ear protection.

• Wear a face mask if drilling into any material which produces dust.

• Do not operate this equipment using loose clothing or other jewellery may get caught in moving parts.

Electrical Safety

• Ensure that you check the equipment thoroughly to ensure it is safe and t for purpose before each use. It is important that you inspect all

plugs, sockets, power cables and electrical ttings for wear and damage and repair or replace any defective components. The risk of electric

shock can be minimised by the correct use of the appropriate electrical safety devices.

• We recommend that you t a Residual Current Circuit Breaker (RCCB) in the main distribution board and that a Residual Current Device

(RCD) is used when operating this equipment.

• The Electricity at Work Act 1989 includes legislation that places legal implications on employers to ensure the safety of electrical devices

in the workplace. The regulations dictate that all portable equipment must be inspected regularly and tested to ensure that it is safe for use.

'Portable equipment' means any electrical item that can be moved and this is often referred to as Portable Appliance Testing (PAT). PAT

testing should be carried out regularly on this equipment by trained, authorised personnel, as required by the legislation.

The Health and Safety at Work Act 1974 states that it is the responsibility of the owner of electrical appliances to ensure that both the

equipment and working environments are maintained to ensure safe operation at all times.

• Check that all equipment cables are secure, correctly insulated, free from damage, and protected against short circuit and overload before

connecting to the power supply. Do not use worn or damaged cables, plugs, sockets or other ttings.

• Ensure that the power supply matches voltage requirements specied on the equipment and that the plug is wired correctly and tted with

the correct fuse. If the electrical fuse blows, ensure it is replaced by an identical type of fuse with the same rating. maintaining, cleaning,

replacing or checking any parts.

• Ensure the power cable is kept away from heat, oil and sharp edges.

• Always disconnect the equipment from the power source before servicing, inspecting, adjusting or changing accessories.

5

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

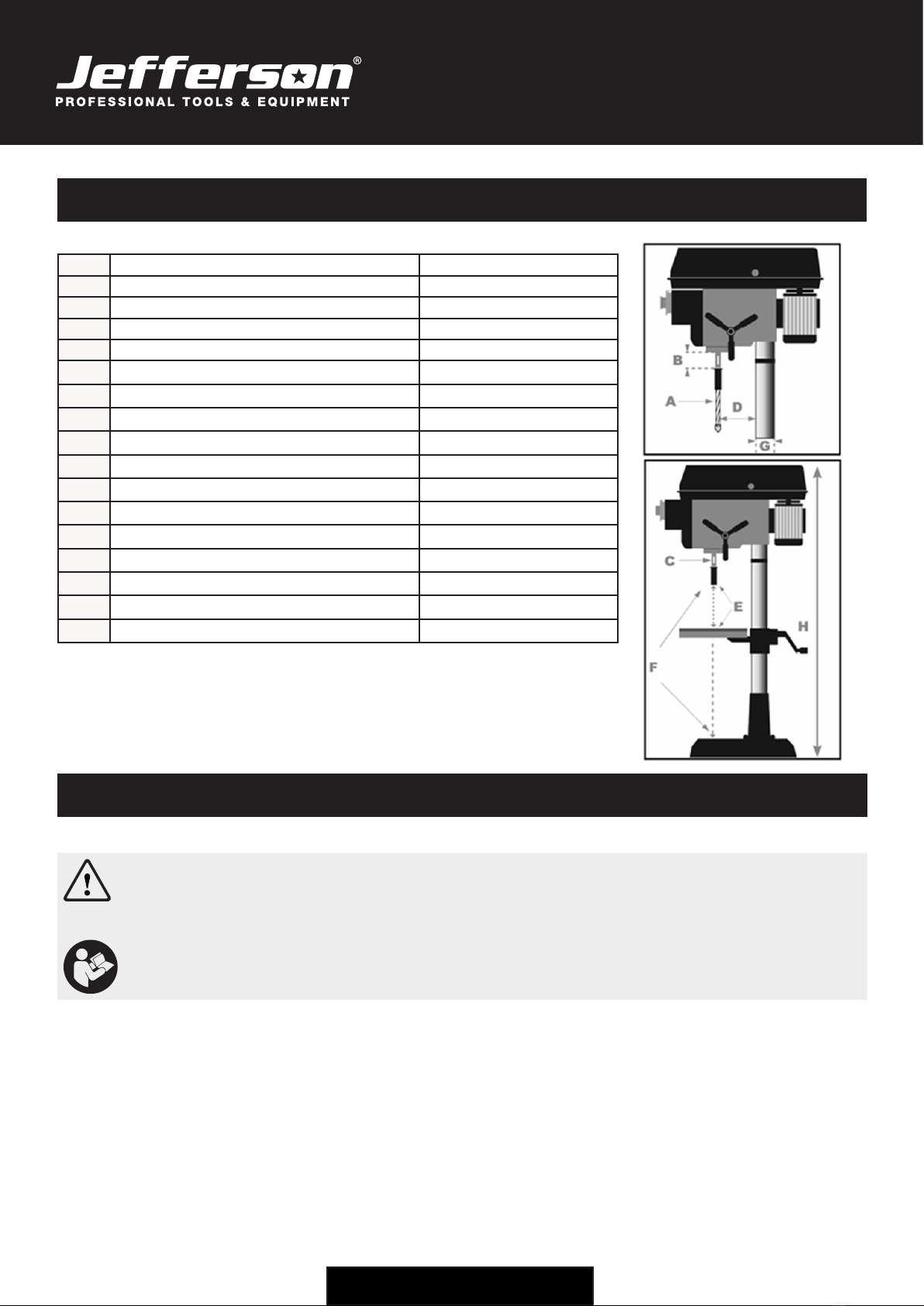

Parts Identification

1Pully Cover

2Motor

3Switch

4Chuck Guard

5Chuck

6Feed Handle

7Table

8Table Holder

9Belt Tension Lock Knob

10 Column Support

11 Base

12 Main Housing

13 Column

14 Bolts

15 Depth Stop Lock Knob

16 Table Lock

17 Table Adjustment Handle

18 Rack Collar

19 Rack

Unpacking & Working Environment

The equipment is delivered with the components shown above. After unpacking, check the parts against this list and check for any damage aused

during transit. If any damage is found contact your Jefferson Dealer and arrange a replacement.

Do not discard the packaging until the machine is assembled. The packaging consists of cardboard and appropriately marked materials which can

be sent to a suitable re-cycling centre.

To protect the machine parts from moisture, a protective coating of light machine oil will have been applied to the outside surfaces. Remove any

excess with a paper towel.

Take care when lifting the heavy head assembly. Before use, the machine must be mounted, and securely bolted, to a strong, heavy workbench, of

sufcient height that you will be standing upright when working.

Ensure the work place is adequately lit, and that you will not be working in your own shadow.

Always ensure the bench drill is disconnected from the power supply during assembly, setup, adjustment and servicing. Never leave

the equipment running while unattended.

6

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

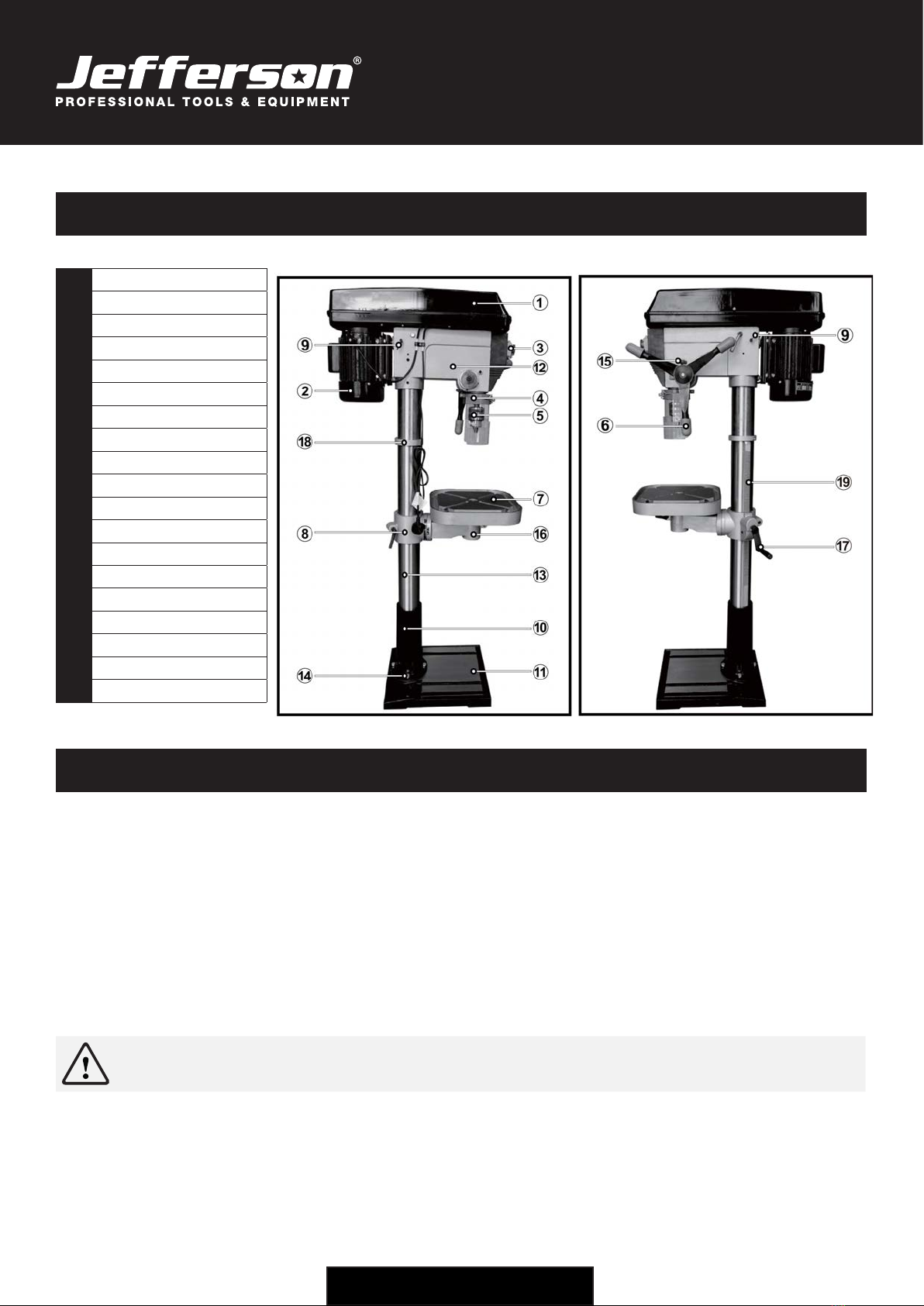

Assembly Instructions

Base & Column

1. Carefully remove contents from the packing box.

2. Select a rm, level surface on which to assemble the bench drill.

3. Select the base (Fig.1) and align the column support over the large

hole (Fig.2).

4. Align the holes in the column support with those in the base and

secure in place using the bolts and washers. (Fig.5).

5. Use a spanner to securely tighten all bolts (Fig.3). We recommend

mounting the base to stable surface for proper support.

6. Slide the column into the column support (Fig.4).

7. Secure in place with 2 grub screws using the hex key (Fig.5).

Rack & Table

1. Fix the rack on the table support as shown (Fig.6).

2. Assemble the support and rack onto the column, ensuring the rack is

positioned on the right side of the column (when viewing the product

from the front) (Fig.7).

3. Slide the rack all the way down until it locates into the lower column

support (Fig.8).

4. Slide the collar, tapered side facing down, over the column until it

locates the rack.

5. Tighten the grub screw on upper collar (Fig.9).

6. Fix table adjustment handle on the support (Fig.10).

7. Assemble table onto table support, tighten in place with table lock

(Fig.11).

Main Housing

1. Lift the main housing and slide it down onto the column as far as it will

go (Fig.12).

2. Ensure the spindle aligns with the table and base before securing the

housing.

3. To secure in position tighten the grub screws on the left and right hand

sides of the housing (Fig.13).

4. To t the feed wheel handles, screw them into feed wheel hub (Fig.14).

5. For some cast iron feed handle, tighten the 3 grub screws to wheel hub

(Fig.15) then x the plastic case on cast iron feed handle as shown

(Fig.16).

Chuck & Arbor

1. Before any assembly, ensure the chuck jaws are wound all the way up

(inside the chuck) to prevent them from damage (Fig.17).

2. Tighten Philip's head screws of the chuck guard to quill shaft (Fig.18).

3. Fit the tapered arbor end into the chuck by hand, using reasonable

force (Fig. 19).

5. Once it is located a rm tap on the underside of the chuck with a soft

hammer is required to secure it. The chuck & arbor are installed

correctly if they cannot be pulley out with hand force (Fig. 21).

Fig.1 Fig.2

Fig.3 Fig.4

Fig.5 Fig.6

Fig.7 Fig.8

Fig.9 Fig.10

Fig.11 Fig.12

Fig.13 Fig.14

Fig.15 Fig.16

7

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

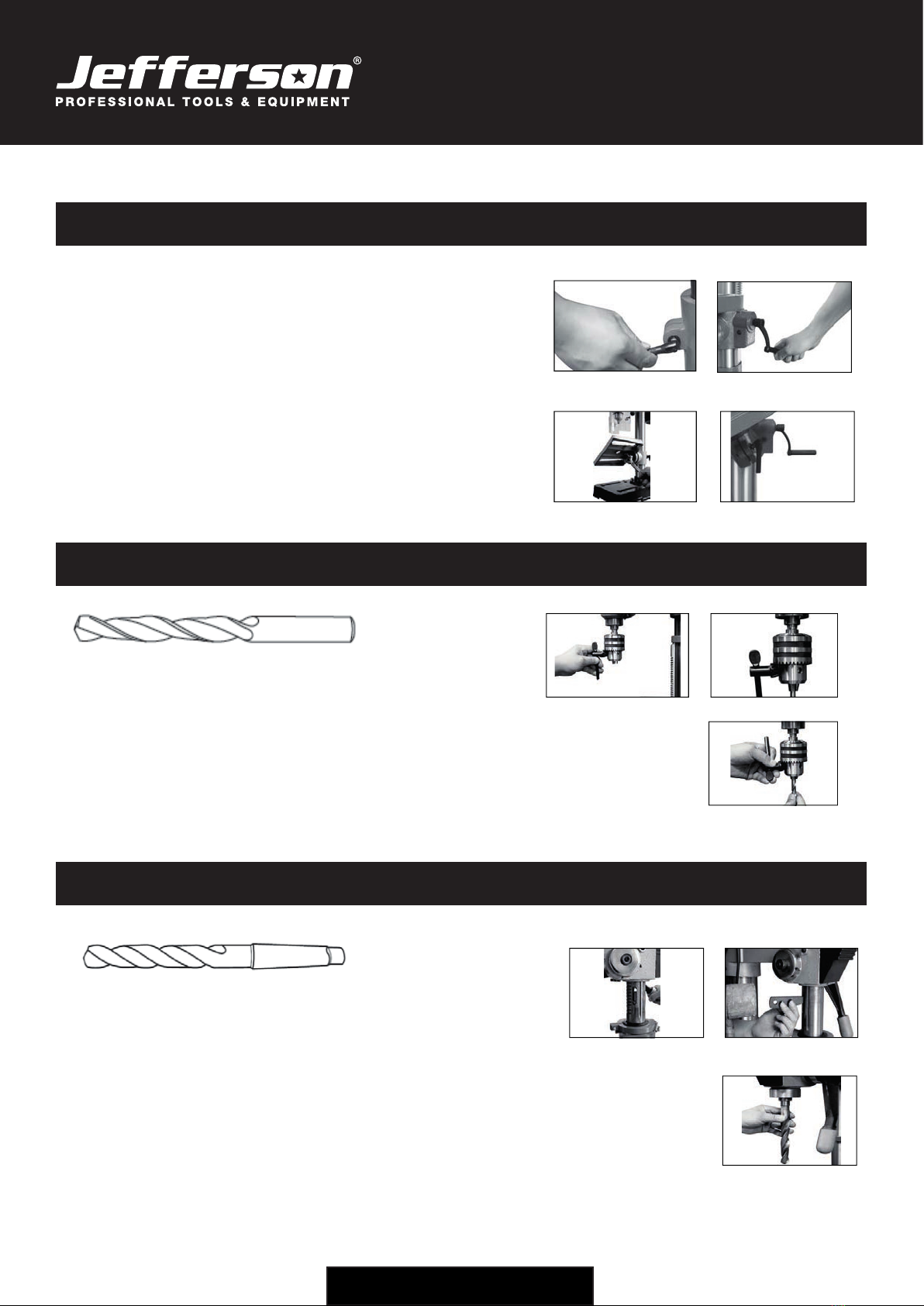

Settings & Adjustments

Table Height Adjustment

1. Loosen the table support lock (Fig. 22).

2. Rotate the table adjustment handle to set the desired table height and

tighten the table rock to secure the table in position (Fig. 23).

Table Bevel Adjustment

1. The bevel angel is adjusted by loosening the bolt that is located

underneath table support with a spanner (Fig. 24).

2. After tilting the working table (Fig. 25). to appropriate position,

re-tighten the bolt to secure its position.

Caution: When the table is angled/tilted, ensure the workpiece is clamped

to the table.

Using Straight Shank Drill Bits

1. Using the chuck key, loosen the jaws of the chuck by rotating in an

anti-clockwise direction (Fig. 26).

2. Insert the drill bit into the chuck (Fig.27).

3. While holding the drill bit in one hand rotate the top collar of the chuck

in a clockwise direction. Insert the chuck key into 1 of the 3 rotating

holes and tighten until the drill bit is secure (Fig. 28).

Using Straight Shank Drill Bits

1. To use Morse taper bits, remove chuck and arbor.

2. Turn arbor until the tang aligns with the slot in the quill (Fig. 29).

3. Insert the drill key into the slot and tap rmly with a metal hammer

until it is released (ensure the chuck jaws are wound all the way up to

prevent any damage (Fig. 30).

3. Place tapper bit into the spindle hole, twisting and pushing upward until

the bit is snug (Fig. 31).

4. Place block of wood on the table and raise up table until the tapered

bit is rmly into the spindle.

Fig.22 Fig.23

Fig.24 Fig.25

Fig.26 Fig.27

Fig.28

Fig.29 Fig.30

Fig.31

8

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Pre-Setting The Drilling Depth

To set the depth of the hole, adjust the depth stop as follows:

• Loosen depth stop lock knob by turning in an anti-clockwise

direction see (Fig.32.1)

• Rotate the to the desired depth, then tighten the half-wing

bolt (Fig.32.2)

To hold the spindle (and bit) at a desired depth:

• Loosen depth stop lock knob, turn feed wheel handle to lowest point

(Fig.32.3).

Rotate depth scale to desired depth and re-tighten the depth stop lock

knob. workpiece is clamped to the table.

Adjusting Speed Settings

You can change the drill press speed by adjusting the belt on the pulley

system. Refer to the chart inside the pulley cover for the various speed

congurations available for your model.

• Release the belt tension locking knobs located on either side of the

main housing (Fig.33.1).

• Once the tension is released, the belt tension handle can be used to

move the motor pulley closer to the idler pulley (Fig.33.2).

• The belt is removed by lifting it over the lip of the pulley while rotating

the pulley simultaneously (Fig.33.3).

• After re-adjustng the belts, use the belt tension handle to move the

motor pulley further away from the idler pulley. When the desired

positon is achieved use the locking knobs to secure the pulleys in

place (Fig.33.4).

• Proper belt tension is achieved when the measured deection (by

pushing in the centre of the belt) is approx. 5mm (Fig.33.5).

Operation Guide

Turning the Equipment On And Off

Note: The pulley cover must be closed to operate the drill.

• Turn the bench vice on by pressing the green button on the switch as

shown (Fig.34).

• Switch the bench vice off by pressing the red button on the switch.

(Fig.35).

• Secure your workpiece to the table if possible (for example use a vice

or a set of clamps).

Fig.32.1 Fig.32.2

Fig.32.3

Fig.33.1 Fig.33.2

Fig.33.3 Fig.33.4

Fig.33.5

Fig.35

Fig.34

9

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Drilling

1. Ensure the bench drill is switched off and disconnected from the power supply.

2. Loosen the jaws of the chuck with the chuck key by turning in an anti-clockwise direction and insert the selected drill bit into the as far as it

will go.

3. Insert the chuck key into 1 of the 3 locating holes and tighten until the drill bit is secure.

4. Select your drilling depth and secure the depth stop lock knob in position.

5. Turn the bench drill on by pressing the green button on the switch (Fig.34).

6. Adjust the table to your desired position.

7. Slowly rotate the feed wheel handles to bring the drill bit down towards the table and into your workpiece.

After drilling a hole, release the feed wheel handles slowly to return the chuck to its original position.

8. Continue the operation until the task is completed.

9. When your work is complete, switch the bench drill off by pressing the red button on the switch.

Maintenance

For maximum performance, it is essential that the bench drill is properly maintained. Always inspect it before use. Any damage should be re-

paired, and faults xed immediately. Always remove the plug from the power supply before carrying out any adjustment, servicing or maintenance

on this equipment. Contact your nearest Jefferson Dealer if any faults or damage is found.

Monthly Maintenance

1. Check tightness of mounting bolts, and head and column securing set screws.

2. Check the drive belt for wear, and replace if frayed or damaged.

3. Blow out with compressed air, or vacuum clean out, any dust that may have accumulated in the motor fan vents.

4. Apply a thin coat of wax paste or light oil to the table and column, for lubrication, and to help prevent corrosion.

5. If the mains lead is damaged in any way, it should be replaced immediately.

Lubrication

• All bearings are packed with grease at the factory and require no further lubrication.

• Occasionally, lubricate the quill shaft assembly and rack with light oil if required.

After Use

• Remove all swarf from the machine and thoroughly clean all surfaces.

• Components should be kept dry, with machined surfaces lightly oiled.

• Always remove drill bits, and store in a safe place.

Parts & Servicing

For Jefferson approved replacement parts contact your

nearest dealer or contact Jefferson tools

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

10

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

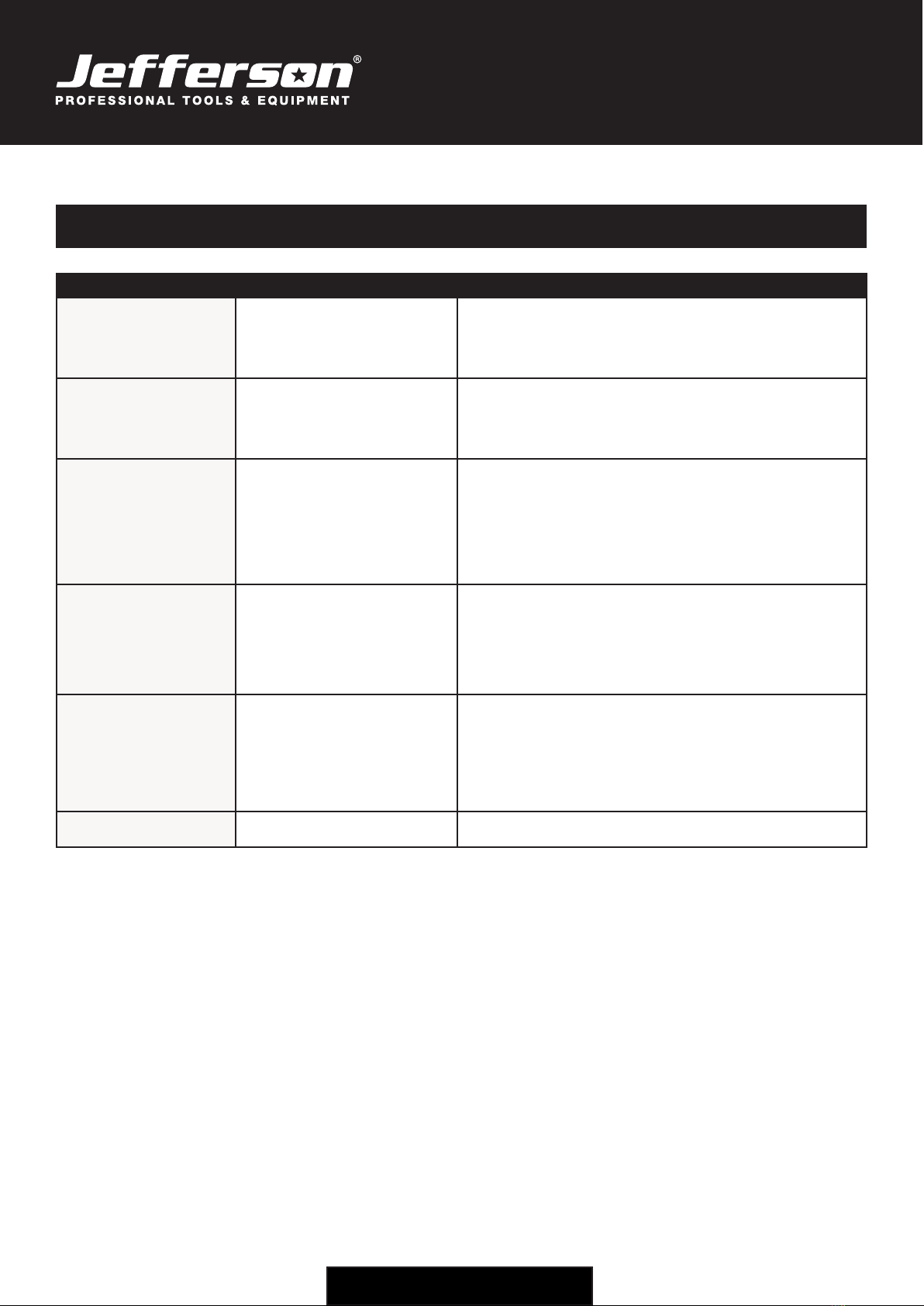

Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

Noisy operation

(under load)

a. Incorrect belt tension

b. Dry spindle

c. Loose pulley

d. Loose belt

e. Worn bearing

a. Adjust tension

b. Remove spindle and quill assembly and lubricate

c. Tighten pulley

d. Adjust belt tension

e. Replace bearing

Excessive drill wobble a. Loose chuck

b. Worn spindle or bearing

c. Worn chuck

d. Bent drill bit

a. Tighten the chuck by pressing it down on to a block of wood against

the table

b. Replace the spindle shaft or bearing

c. Replace the chuck

d. Renew the drill bit

Motor wont start a. Power supply

b. Motor connection

c. Switch connection

d. Faulty switch.

e. Motor windings burned

f. Pulley cover not closed

g. Micro switch on cover is

not operating correctly

a. Check power cord/fuse.

b. Check motor connections.

c. Check switch connections.

d. Replace switch.

e. Replace motor.

f. Close pulley cover.

g. Check operation of micro switch, and renew /

adjust as necessary.

Drill binds in the

workpiece

a. Excessive feed pressure

b. Loose belt

c. Loose drill

d. Incorrect bit speed

e. Drill angles incorrect

for type of material

a. Apply less pressure

b. Check belt tension

c. Tighten drill with key

d. Adjust the drill speed reasonably

e. Consult a technical manual dealing with materials, drills and cutting

angles, and sharpen drill

accordingly.

Drill bit burns or smokes a. Incorrect speed

b. Swarf is not discharging

c. Dull drill or not proper

clearance for material

d. Needs coolant

e. Excessive feed pressure

a. Adjust drill speed accordingly

b. Clean drill

c. Check sharpness & taper

d. Use coolant whilst drilling

e. Apply less pressure

Table is difcut to raise a. Needs lubrication

b. Table lock tightened

a. Lubricate with light oil

b. Loosen clamp

11

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

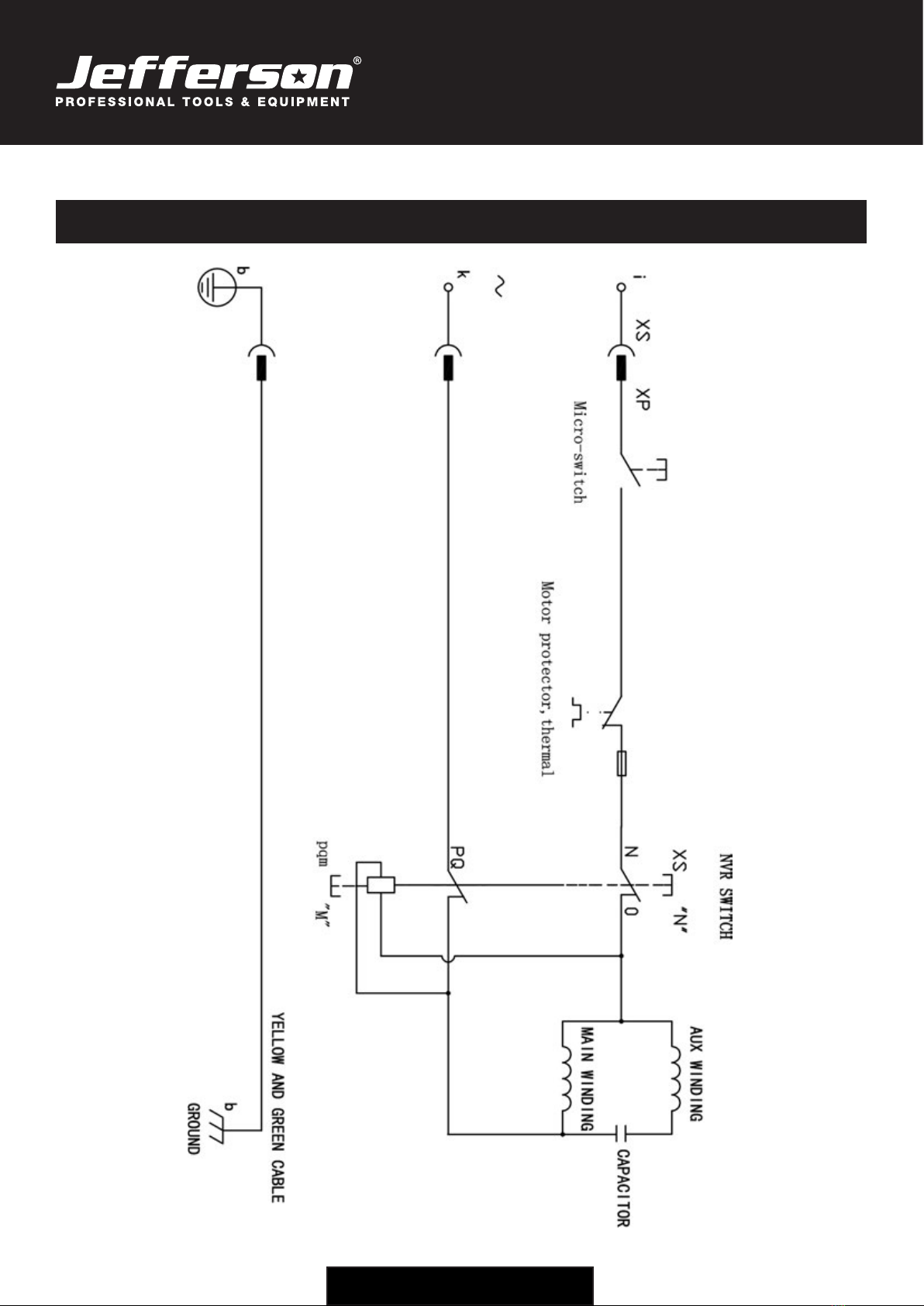

Circuit Diagram

12

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

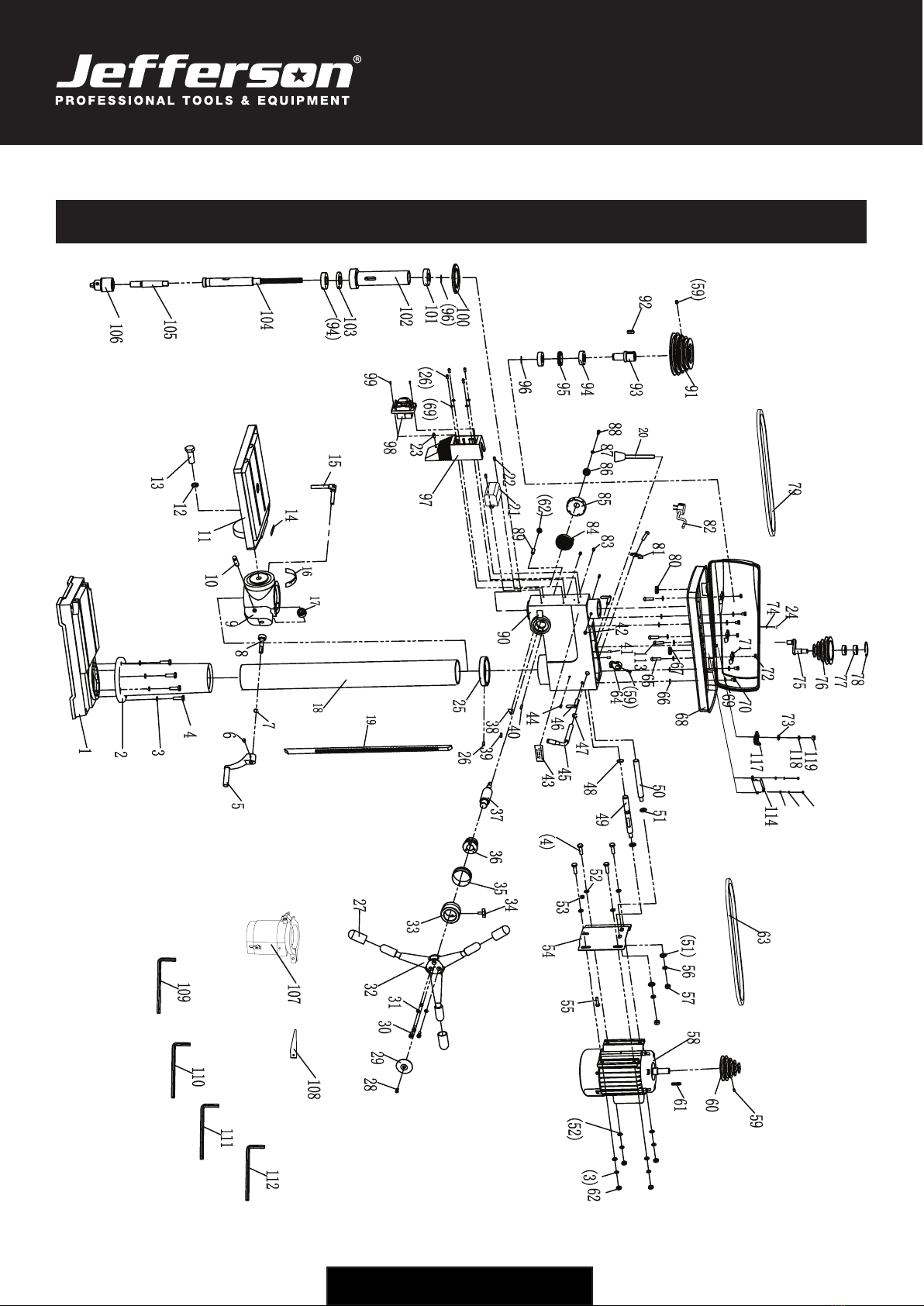

115

116

(72)

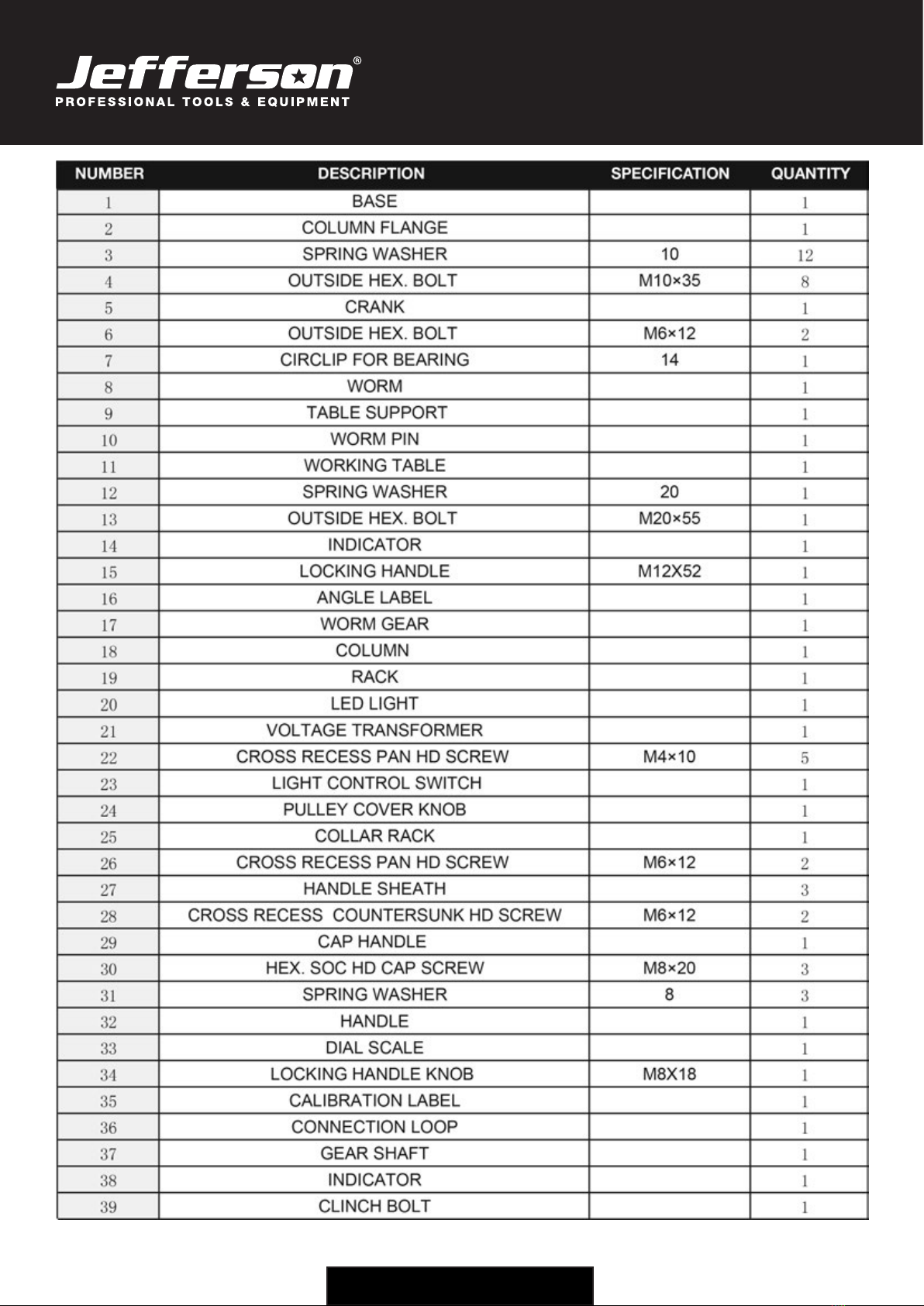

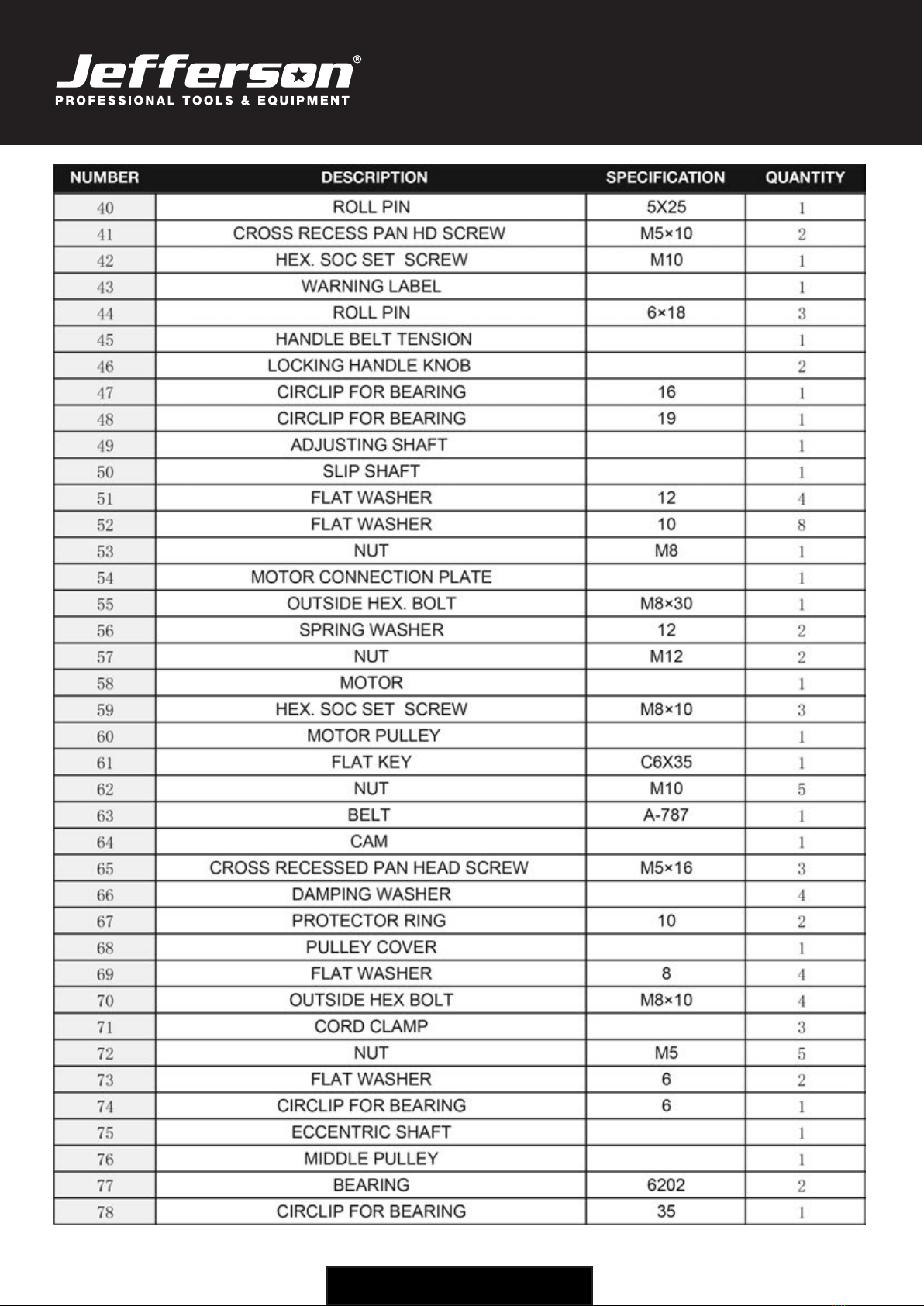

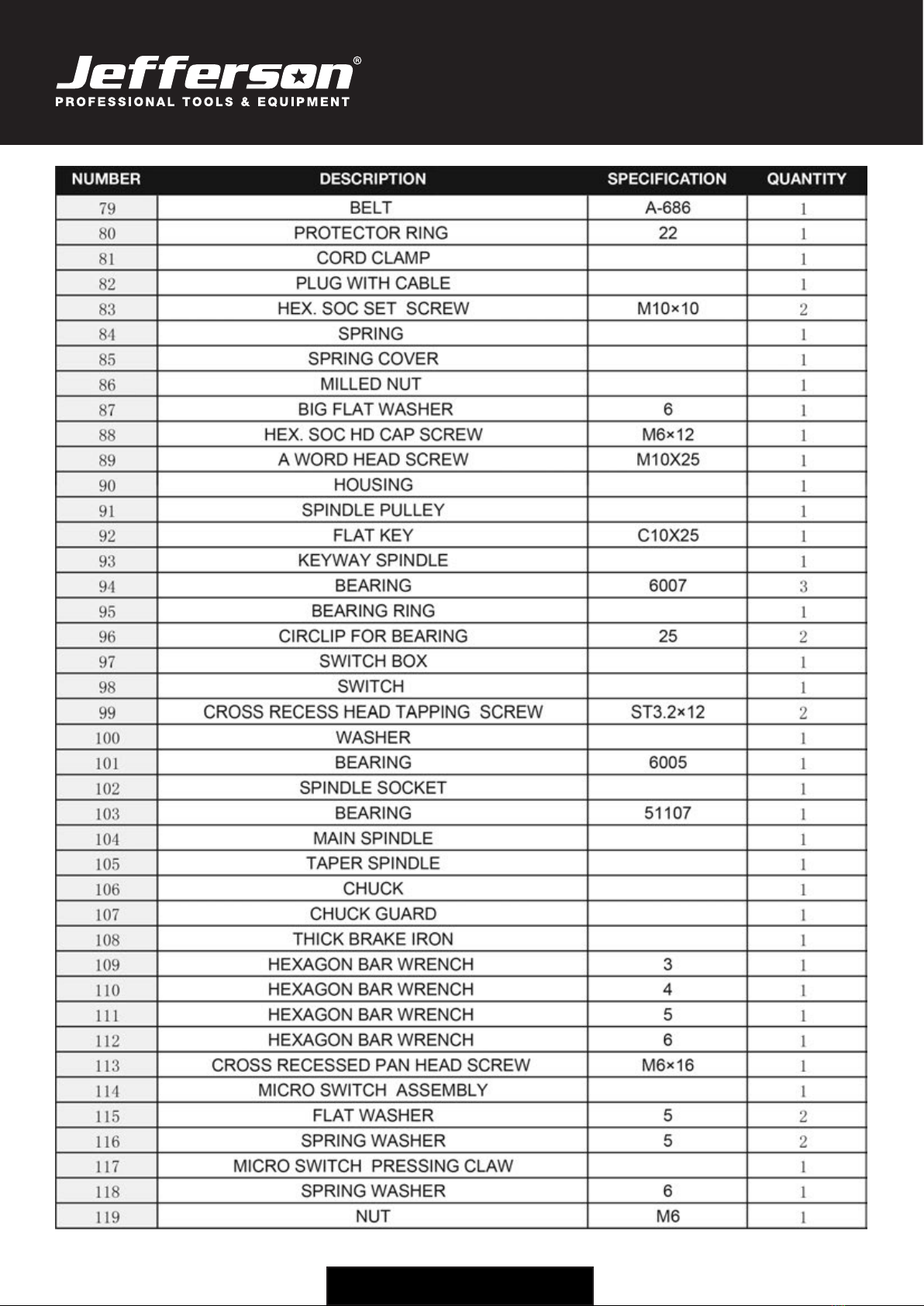

Parts List & Diagram

13

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

14

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

15

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

16

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Environmental Protection

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and requires disposal, drain off any

uids (if applicable) into approved containers and dispose of the product and the uids according to local regulations.

WEEE Waste Electrical and Electronic Equipment Statement

Information on Disposal for Users of Waste Electrical & Electronic Equipment

This symbol on the product(s) and / or accompanying documents means that used electrical and electronic products should

not be mixed with general household waste. For proper treatment, recovery and recycling, please take this product(s) to

designated collection points where it will be accepted free of charge.

For private households:

Dispose of this product at the end of its working life and in compliance with the EU Directive on Waste Electrical and Electronic

Equipment (WEEE). Contact your local solid waste authority for recycling information for this equipment.

Disposing of this product correctly will help save valuable resources and prevent any potential negative effects on human health and the

environment, which could otherwise arise from inappropriate waste handling.

Please contact your local authority for further details of your nearest designated collection point.

Penalties may be applicable for incorrect disposal of this waste, in accordance with you national legislation.

For business users in the European Union:

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union:

This symbol is only valid in the European Union. If you wish to discard this product please contact your local authorities or dealer and ask for the

correct method of disposal.

RoHS Directive 2011/65/EU

We hereby declare that this equipment has been tested and found to be compliant to RoHS Directive 2011/65/EU of the

European Parliament and the Council from 08/06/2011 on restriction of the use of certain hazardous substances in electrical

and electronic appliances.

2011/65/EU

RoHS

17

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

EC Declaration of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

Directive: Description:

2014/30/EU (as amended) Electromagnetic Compatibility

2006/42/EC (as amended) Machinery Directive

2014/35/EU (as amended) Low Voltage Directive

2011/65/EU (as amended) RoHS Directive

Equipment Category: Bench Drill / Pillar Drill / Drill Press

EU Member State United Kingdom

Product Name/Model: JEFPDB1500 - 1500W Pilllar Drill

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 19 August 2019

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United Kingdom,

CH4 9QR

Telephone: +44 (0)1244 646 048 Fax: +44 (0)1244 241 191

Email: [email protected]

18

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Limited Warranty Statement

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, air compressor service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty

periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

• All Jefferson Bench & Pillar Drills

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the remain-

ing duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address: www.jeffersontools.com/warranty

and completing the online form. Online warranty registration is recommended as it eliminates the need to provide proof of purchase should a war-

ranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an author-

ized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and transpor-

tation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not covered

under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

* Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this war-

ranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by the

defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its prod-

ucts. Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved. Jefferson is not responsible

for cable wear due to exing and abrasion. The end user is responsible for routine inspection of cables for possible wear and to correct any issues

prior to cable failure.

19

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

nal determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specication plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of the

original proof of

purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during transit. Any claims against a

third party courier will be dealt with under the terms & conditions of their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus return

carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identied as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for

completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to warranty@jef-

fersontools.com

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for illustra-

tion purposes only.

20

USER MANUAL v1.1

JEFPDB1500

1500W Pillar Drill • 230V ~50Hz

www.jeffersontools.com

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of re,

electric shock or personal injury.

www.jeffersontools.com

Table of contents

Other Jefferson Drill manuals

Jefferson

Jefferson JEFMAGDPER35-230 User manual

Jefferson

Jefferson JEFMAGDAUT35-230 User manual

Jefferson

Jefferson JEFPDB0350 User manual

Jefferson

Jefferson JEFMAGD42HD/110 User manual

Jefferson

Jefferson JEFPDB1100 User manual

Jefferson

Jefferson JEFPDB0550 User manual

Jefferson

Jefferson JEFMGNDR40-110 User manual

Popular Drill manuals by other brands

Parkside

Parkside PBH 1050 A1 Operation and safety notes

EINHELL

EINHELL LE-BM 1010 operating instructions

Micromat

Micromat 1575 user manual

Parkside

Parkside PABH 20-Li B2 instructions

Bosch

Bosch 06019G010A Original instructions

Harbor Freight Tools

Harbor Freight Tools EarthquakeXT EQ38XT-20V owner's manual