Jefferson JEFLADMPAS03 User manual

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com 1

FEATURES

• Lightweight anti-corrosive aluminium frame with strong

double aluminium rivet construction

• Advanced auto-locking technology locks securely and safely

into multiple positions

• Spring loaded J locks for quick and easy working height

adjustment

• Easily converts between Telescopic Ladder, Extension Ladder

and Stairway Ladder

• Anti-slip feet and rung threads

• Smooth glide wheels to aid transportation

• EN 131 Class - Duty Rating: 115kg / Maximum Load: 150kg

• Available in 3 Tread, 4 Tread, 5 Tread & 6 Tread sizes

Model Number: JEFLADMPAS03 JEFLADMPAS04 JEFLADMPAS05 JEFLADMPAS06

Number Of Treads: 3 4 5 6

Feet Width (A): 52cm 58cm 66cm 72.5cm

Tread Height (B) 28cm 28cm 28cm 28cm

Section Width (C) 30cm 30cm 30cm 30cm

Closed Height (D): 99cm 127cm 156cm 183cm

Open Height Stepladder 'A' Frame (E): 148cm 200cm 254cm 304cm

Extended Working Height (F): 186cm 240cm 293cm 347cm

Fully Extended Height (G): 304cm 424cm 536cm 648cm

Fully Extended Working Height (H) 294cm 402cm 509cm 617cm

Weight: 11.9kg 14.9kg 19.9kg 21.9kg

Duty Rating: 115kg 115kg 115kg 115kg

Maximum Static Weight: 150kg 150kg 150kg 150kg

Important: Please read and

understand all safety instructions

before use. Failure to follow these

instructions may result in serious

injury or death. Jefferson Tools

assumes no liability for damage or

injury that may result from failing

to follow all instructions correctly.

Read and familiarise yourself with

all the safety labels on the ladder

before use.

SPECIFICATIONS

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com

2

SAFETY GUIDELINES

General Safety

Jefferson Multipurpose Ladders have a maximum static load of 150kg and a duty rating of 115kg.

Ensure that the total weight of the user, tools and materials do not exceed this recommended working load guideline.

• Inspect the ladder for safety before each use.

• If you nd signs of damage, have it repaired before using it.

• Never use the ladder with missing, worn or damaged parts.

• Do not use the ladder if it has been exposed to excessive heat or corrosive agents (such as acids or alkalis).

• Regularly inspect the ladder feet and replace them when they show signs of wear.

• Always keep the ladder clean of all foreign materials and clean it after each use.

• Check moving parts regularly and lubricate them when necessary.

• Avoid getting lubricant on the rungs or side rail, as this may cause a slip hazard.

Placement & Setup

• Place the feet of the ladder on rm, level ground to ensure that they are fully supported to prevent any movement.

• Never place anything on or under the ladder to gain height or use unstable means to adjust for uneven surfaces.

• Do not use the ladder in front of unlocked doors, or anywhere you may be hit by moving people or objects.

• If you need to use the ladder on a slippery surface, secure it to prevent it from sliding before you climb it. The use of ladders on drop cloths

may present a sliding hazard.

• Do not force the hinges in or out using any tools. Doing so may cause permanent damage to the hinge mechanism.

• If there is pressure on the hinge lock pins, they may not open properly. Relieve the pressure by moving one half of the ladder back and forth

until the hinge locks move with minimal force.

• Where applicable, ensure that the hinge locks are securely engaged before climbing your ladder.

• Make sure each lock tab is fully engaged into the appropriate rung tube before climbing. Failure to do so may result in injury.

• Set up your ladder so the rungs are always level from front to back and from side to side.

Recommended use

• Never use a ladder while you are under the inuence of alcohol, drugs or medication, or when you are not physically t to use it.

• Use extreme caution when getting on or off ladder. When possible, have someone hold the ladder to stabilise it.

• Do not stand above the third rung from top when the ladder is fully extended.

• Over-reaching may cause you to lose your balance or tip the ladder. Do not lean too far over the side of the ladder and keep three points of

contact at all times.

• Never move the ladder while someone is on it.

• When using the ladder as a stepladder or extension ladder, always face the ladder and maintain a rm grip.

• Use extreme caution when pushing or pulling anything while standing on the ladder.

• Never use the ladder as a brace or use ladder jacks.

• Keep all ladder rungs, ladder feet, work platforms, and other standing and gripping surfaces clean and free from foreign materials.

• If a spill occurs, clean it up before continuing work.

• Use caution when using the ladder around electricity. Ensure that the ladder does not come in contact with electrical wires, circuits or

currents.

• If you have to work outdoors or in windy conditions, take extra caution.

• Keep clothing and body parts out of all moving mechanisms, including the hinge locks and lock tabs, to avoid pinching.

• Keep clothing and body parts away from rungs when telescoping the outer ladder over the inner ladder.

Using on uneven surface

• When using your ladder on a staircase, ensure that the rungs are level and that each foot is on a solid, secure surface.

Extention ladder tips

• Do not allow the full weight of the ladder to fall on the hinges as the ladder folds from the extension to the A-frame position.

• When releasing the lock tabs, make sure you support the inner ladder assembly with one hand to prevent it from sliding down rapidly.

• Failure to do so may result in injury.

• Use the proper angle for the extension ladder position. The distance from the base of the ladder to the bottom of the support wall should

be one quarter the working height of the extension ladder.

• The minimum distance between the ladder and the support wall must be at least one metre.

• When using your ladder as a tall extension ladder, stake the feet to the ground and tie down the top for extra security.

• Extend the ladder at least one metre above a supporting roof.

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com 3

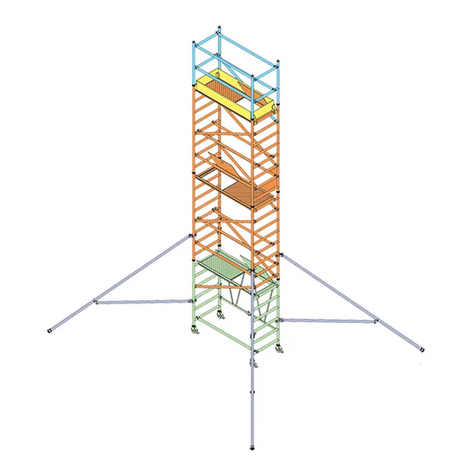

EQUIPMENT IDENTIFICATION

The Jefferson Multi-Purpose Ladder is made

up of 3 main components:

1 Inner Ladder Section and 2 Outer Ladder

Sections.

The inner and outer sections work together

using hinge locks and lock tabs which enable

you to adjust and extend the ladder into

different lengths and positions.

The 3 main working congurations are:

1. A-Frame Stepladder

2. Uneven A-Frame Stepladder

3. Extension Ladder

See Page 4 for further information on setting up

the ladder to work in each conguration.

Push knob

locking hinge

• Inner ladder

section

•Ladder

side rail

Spring loaded •

'J' lock

•Outer

ladder section

•Rung

•Anti-slip feet

•

OPERATION GUIDE

Push Knob Hinge Locks - Change your ladder’s shape

The ladders inner section allows the ladder to be folded into 3 set positions; extension ladder, twin stepladders, and storage.

Each of these congurations is made possible by the push knob locking hinge located on each side of the ladder.

To adjust the angle of the ladder:

1) With the center hinges in the closed position (Fig. 1) push the knobs with the palm of your hand directly onto the centre

of the ladder, they will stay in the open position.

2) In the open position (Fig. 2) the ladder angle can be adjusted.

Note: The open position can be verified by the exposed triple inner posts on the push knob.

3) When the ladder reaches any of the 3 set positions, the push knobs will automatically spring back into the closed position.

4) To close ladder to the folded position, repeat steps 1-3.

WARNING!

• Serious injury or death could result if supporting hinges are NOT LOCKED when ladder in use.

• Make certain supporting hinges are LOCKED before using ladder EACH TIME.

FIG.1 CLOSED

FIG.2 OPEN

(Triple Inner Posts)

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com

4

LADDER CONFIGURATIONS

1. A-Frame Stepladder

1) The A- Frame position is easiest completed with the ladder standing up as

excess pressure is not exerted on the hinge.

At this point the height of the ladder can be changed to the desired height using the Spring loaded “J” locks

• For every position all hinges are supporting hinges and must be locked

• Never straddle front and rear sections.

• Always face ladder and maintain rm grip while on it.

• DO NOT stand on or above second rung from top of ladder

2. Uneven A-Frame (Stair Ways)

1) Raise to desired height.

2) Lower one side of the inner section until the desired step height is reached.

3) Position ladder on stairway, ensuring all legs are on rm ground or steps.

3. Extension Ladder

Note: The extension ladder position is easiest completed with the ladder laying on the ground.

(1) Conguring the ladder into the extension ladder position, as with the stepladder position, the extension ladder

position starts with changing the angle.

Note: The push knob hinge will catch in each of the 3 positions. Continue to disengage and rotate the sections until

the fully open extension ladder position is reached.

(2) Unlock one set of “J” locks and extend outer section to desired length. If additional height is needed, repeat with

opposite side. Make sure “J” locks are properly re-engaged.

(3) With all locks properly engaged, lift ladder from one end and slowly walk ladder up until it rests against desired

surface. Watch for overhead wires.

(4) Adjust ladder to proper climbing position or approximately 75°.

CAUTION!

• Always face ladder and maintain

firm grip while on it.

• DO NOT stand on or above the

second rung from the top of ladder.

75°

Approx.

CAUTION!

• Hinges and “J” locks must be

secure before climbing.

• DO NOT stand on or above second

rung from top of ladder.

• Refer to set up caution label on

ladder for proper set up.

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com 5

SAFETY LABELS

When using the ladder in the

step-ladder position do not

stand on the upper two rungs

as this will cause the ladder

to be unstable.

When using the ladder in the

step-ladder position placed on

a staircase, do not stand on

the upper two rungs as

this will cause the ladder

to be unstable.

Always ensure the lock is facing the surface you are

placing the ladder against. Failure to do so may cause

the locks to fail whilst using the ladder.

Correct

Positioning

Incorrect

Positioning

When using the ladder in the fully

extended position do not stand on

the upper three rungs as this will

cause the ladder to be unstable.

Make sure to always keep at least

one hand securely gripping the ladder

while working in this position.

Locked

No triple inner

post showing

Unlocked

Triple inner

post showing

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com

6

EC DECLARATION OF CONFORMITY

We, Tundra Industrial, as the authorised European Community representative of the manufacturer, declare that the

following equipment conforms to the requirements of the following Directives:

Directive: Description:

EN 131-1:2015 Ladders - Part 1: Terms, types, functional

sizes

EN 131-2:2010+A1:2012 Ladders - Requirements, testing, marking

EN 131-3:2007 Ladders - User instructions

EN 131-4:2007 Ladders - Single or multiple hinge-joint

ladders

Equipment Category: Multi-Purpose Ladder

Product Name/Model: JEFLADMPAS03

JEFLADMPAS04

JEFLADMPAS05

JEFLADMPAS06

Notified Body: Beide (UK) Product Service Limited

Flat 107, 25 Indescon Square, London,

United Kingdom, E14 9DG

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 12 May 2017

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park, Chester, United

Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com 7

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

Jefferson Multi Purpose Ladders • JEFLADMPAS03 • JEFLADMPAS04 • JEFLADMPAS05 • JEFLADMPAS06

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the

remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the need to

provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred.

These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this

warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by

the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its

products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

USER MANUAL

MULTI-PURPOSE LADDER

V1.2

www.jeffersontools.com

8

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of

the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus return

carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to warranty@

jeffersontools.com

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

This manual suits for next models

3

Table of contents

Other Jefferson Ladder manuals

Popular Ladder manuals by other brands

Costway

Costway TJ10013 manual

Stockmaster

Stockmaster Navigator User instructions

W+W

W+W TRI-KLAPP 115 Mounting instruction

pisko

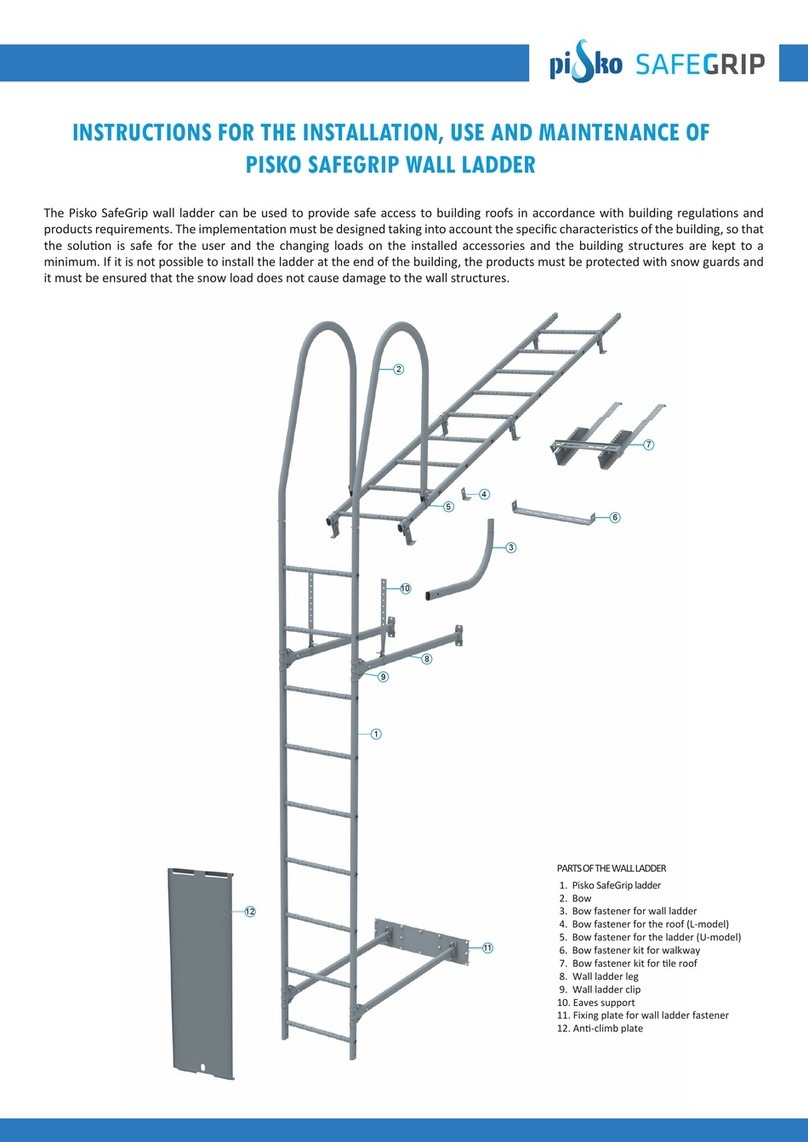

pisko SAFEGRIP INSTRUCTIONS FOR THE INSTALLATION, USE AND MAINTENANCE

PRIMAL TREESTANDS

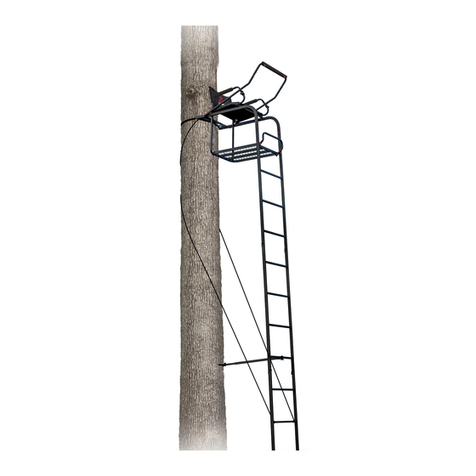

PRIMAL TREESTANDS PVLS-316 Instruction and safety manual

EXIT Toys

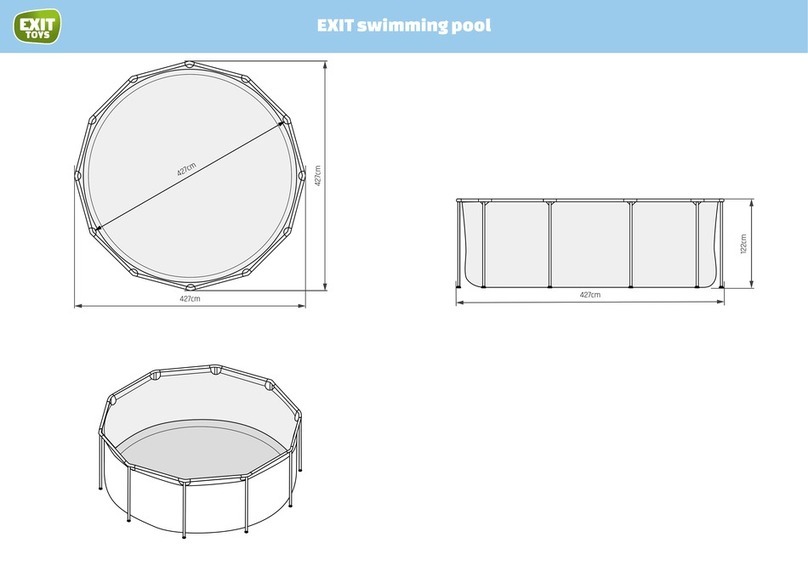

EXIT Toys 8633960640 user manual