Jefferson JEFLADTEL10 User manual

www.jeffersontools.com

FEATURES

User Manual

v.1.1

JEFLADTEL10

WARNING! Failure to adhere to the warnings and

instructions contained in this manual and on the

product could result in serious or fatal injury.

SPECIFICATIONS

Closed height: 80.5 cm

Opened height: 2.9 m

Safe working height: 1.7 m

Width: 47.6 cm

Maximum Load: 150 kg

Weight: 9.5 kg

MAX

150KG

• Strong, lightweight and portable aluminium alloy frame & safe closing system

• Compact telescopic frame design for storing in conned spaces

• Equipped with a locking mechanism for enhanced safety and peace of mind

while working

• Wide-base top bar and bottom rung provides added stability and sturdiness

• 10 x large slip resistant treads

• Hand grips for extra security and stability while climbing

• Anti-slip feet for added grip and durability.

• Supplied with secure fastening storage strap

• Manufactured and tested to EN 131-6: 2019

TELESCOPIC

LADDER

10 Rungs • EN 131-6: 2019

www.jeffersontools.com

User Manual

v.1.1

JEFLADTEL10

1. SAFETY

WARNING:

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND KEEP FOR FUTURE REFERENCE

1.1. Identify any electrical risks in the work area, such as overhead lines or other exposed electrical equipment.

1.2. This ladder does not offer insulation or protection from electrical hazards.

1.3. The ladder shall be only be positioned at on its feet, not the rungs or steps.

1.4. Never position or use the ladder on slippery surfaces (such as ice, shiny surfaces or signicantly contaminated solid surfaces)

unless additional effective measures are taken to prevent the ladder slipping or ensuring contaminated surfaces are sufciently clean.

1.5. The ladder shall be erected at the correct position, such as the correct angle for a leaning ladder (angle of inclination approximately 1:4)

with the rungs or treads level (e.g. 1m away from the base of a wall if extending to climb 4m up (see fig.A)).

1.6. Always position the ladder against a at, non-fragile surface and secure properly before use e.g. tied down or with the

use of a suitable stability device.

1.7. The locking mechanisms for all the extended rung sections shall be locked before using the ladder.

1.8. Never attempt to move or reposition the ladder from above.

1.9. The Jefferson 2.9M Telescopic Ladder is constructed from a lightweight aluminium alloy for a strong and portable

climbing solution for domestic use.

1.10. Extends and locks rung by rung to reach the perfect level with secure locking tabs for smooth and responsive adjustment.

BEFORE USE

1.11. Before using the ladder it shall be checked that all locking mechanisms are working properly.

If the mechanism is not working properly, do not use the ladder.

1.12. Wear tight-tting clothing, remove jewellery and tie long hair back when using the ladder.

1.13. Always wear suitable footwear when climbing a ladder; at, dry, treaded, shoes with securely tied laces are

considered appropriate footwear.

1.14. Ensure that the surface you will rest the ladder against is capable of supporting the combined weight of the ladder,

operator and any carried objects.

1.15. Doors (but not re doors or similar), windows and areas of entry/exit should be secured when using the ladder.

1.16. All distractions should be reasonably avoided. Always set up the Telescopic Ladder so that it is always freely accessible.

1.17. When transporting ladders on roof bars or in a truck, ensure they are suitably placed and secured to prevent damage.

1.18. The ladder shall be inspected after delivery and before every use to conrm condition and operation of all parts.

Use the checklist provided in the ‘Before Use: Risk Assessment’ section of this manual.

1.19. Visually check that the ladder is not damaged and is safe to use at the start of each working day when the ladder is to be used.

1.20. Remove any contamination from the ladder, such as wet paint, mud, oil or snow.

1.21. For professional users, regular periodic inspection is required.

1.22. Before using a ladder at work, a risk assessment should be carried out respecting the legislation in the country of use.

1.23. Ensure the ladder is suitable for the task. If unsure, contact a qualied person for guidance.

1.24. Do not use a damaged or otherwise unsuitable ladder.

USING THE LADDER

1.25. Do not exceed the maximum total load of 150kg/330lbs for this ladder.

1.26. Only allow one person to use the ladder at any time.

1.27. Ladders should only be used for light work of short duration.

1.28. Use non-conductive ladders for unavoidable live electrical work. This ladder is not suitable for live electrical work as it is

conductive and offers no protection from electrical hazards.

1.29. Never erect or use the ladder upside down. The base should always sit rmly on the ground.

1.30. Do not use the ladder outside in adverse weather conditions, such as strong wind or rain.

1.31. Do not leave an extended ladder unattended.

1.32. Take precautions against children playing on the ladder.

1.33. Do not place any tools or other objects on the rungs and do not hang anything on the ladder system.

1.34. Equipment carried while using a ladder should be light and easy to handle.

1.35. Face the ladder and keep a secure grip when ascending and descending.

1.36. Do not slide down the stiles of the ladder.

1.37. Climb and descend with deliberate movements.

1.38. Always maintain 3 points of contact with the ladder at all times e.g. two feet on the same rung and a hand on the stiles.

1.39. Use additional safety equipment if this is not possible.

1.40. Maintain a handhold whilst working from a ladder or take additional safety precautions if you cannot.

1.41. Do not overreach; always keep your belt buckle (navel) inside the stiles and both feet on the same step/rung throughout the task.

1.42. Avoid work that imposes a sideways load on ladders, such as side-on drilling through solid materials (e.g. brick or concrete).

1.43. In the leaning ladder position it is not allowed to climb higher than last metre of the ladder.

1.44. The user shall put the hands around the stile when bringing the ladder from extendedto storage position.

1.45. Do not stand on the top three rungs on the ladder; this can cause stability issues.

1.46. Do not use the ladder as a bridge.

1.47. Leaning ladders used for access to a higher level should be extended at least 1m above the landing point

1.48. Do not step off a leaning ladder at a higher level without additional security, such as tying off or use of a suitable stability device.

1.49. Do not step off the side of the ladder.

1m

4m

(Fig.A)

www.jeffersontools.com

User Manual

v.1.1

JEFLADTEL10

1. SAFETY

POSITIONING AND ERECTING THE LADDER

1.50. Do not spend long periods on a ladder without regular breaks (tiredness is a risk).

1.51. Take care when closing the ladder to not catch any ngers, clothing or hair in the mechanisms. Close one rung at a time.

1.52 Ensure the ladder is fully collapsed, all locks are secured and the ladder is free from contaminants before moving to the area of work.

1.53 Only erect and close in a safe work area.

1.54. Do not move the ladder when erect.

1.55. Only position and use the ladder on an even, level and unmoveable base.

1.56. When positioning the ladder, take into account risk of collision with the ladder e.g. from pedestrians, vehicles or doors.

1.57. Secure doors (not re exits) and windows where possible in the area.

1.58. Ensure that you are t enough to use a ladder. Certain medical conditions or medication, alcohol or drug abuse could make ladder use

unsafe.

2. REPAIR, MAINTENANCE AND STORAGE

REPAIR, MAINTENANCE AND STORAGE

2.1. Fully collapse the ladder, closing all rungs, and secure before storage or handling.

2.2. Clean with a suitable proprietary household cleaner and a soft dry cloth.

2.3. Dry all parts thoroughly before storing.

2.4. Do not submerge your ladder in water or any liquid for any reason.

2.5. Store your ladder indoors in a dry environment away from other contaminants. Do not rest other objects on the ladder.

2.6. Only store the ladder whenit is dry.

2.7. Do not subject your ladder system to humid or damp environments. These can damage the ladder.

2.8. Store the correct way up. The base should always sit on the ground.

2.9. Repairs and maintenance shall be carried out by a competent person with suitable replacement parts. Unapproved third party spares

are not recommended and will void your warranty.

2.10. For the angle indicator on the ladder, straight up parallel to wall and level parallel to ground.

2.11. To get the most out of your Telescopic Ladder, and for safety purposes, always clean the Ladder before and after use.

2.12. The Telescopic Tubes (5) must be kept clean; dirt, lings, paint, glue etc. must be cleaned away using a clean cloth after use

and before the Ladder is closed. Take care to also clean the rungs.

TIP:

For tougher stains, a small amount of non-abrasive cleaner can be added to a soft tissue or cloth. After cleaning, the Telescopic Tubes must be

treated with a silicon spray by opening all sections of the Ladder, spraying and wiping them clean with a paper towel or dry cloth. The Ladder must

always be dry. The end caps of the Ladder must always be sealed to prevent the ingress of dirt and other objects into the body which may cause

the Telescopic Tubes to become damaged. Any damage to your Telescopic Ladder should be repaired by a qualied person only.

WARNING!

Do not use your Ladder if damaged as this poses a severe risk of accident or injury and will void your warranty.

BEFORE USING THE 2.9M TELESCOPIC LADDER, PLEASE EXAMINE OUR ASSESSMENT FORM:

INSPECTION POINT YES NO

RUNGS: Are any rungs loose, cracked, bent, worn or missing?

RAILS: Are any rails loose, cracked, bent, split, frayed or worn?

LABELS: Are any labels missing or unreadable?

RUNG LOCKS: Are any rung locks loose, stuck, missing or broken?

HARDWARE: Is any hardware (screws/bolts/xings) missing,

loose or broken?

SHOES: Are the shoes worn, broken, unstable, loose or missing?

ADDITIONAL POINTS

CLEANLINESS: Is the ladder free from dirt/water/oil or other contaminants

which may impair safety or function?

Clean and dry the ladder before use.

SECURE AREA: Have all doors (excluding re doors or exits), windows and

distractions been secured and taken care of to prevent accident?

Secure all points before use.

FIT FOR PURPOSE: Are you condent that the ladder and any tools are t

for purpose and suitable for the task at hand?

Seek alternatives suitable for the task.

ADDITIONAL MEASURES: Have any additional safety measures necessary

for the task been taken? (i.e. securing of the ladder, well lit environment,

safety risk assessment been made?)

Do not proceed until all appropriate measures

have been taken.

www.jeffersontools.com

User Manual

v.1.1

JEFLADTEL10

3. TROUBLESHOOTING

PROBLEM SOLUTION

LOCKING MECHANISMS WILL NOT ENGAGE The rungs are not properly positioned. Extend to the maximum height

for the rung and attempt to secure again.

TELESCOPIC TUBES ARE STIFF The Ladder is dirty/contaminated and must be cleaned as instructed in

the ‘Care & Maintenance’ section above.

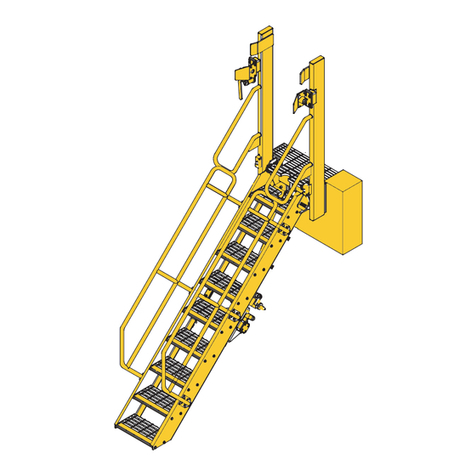

4. EQUIPMENT IDENTIFICATION

Top Bar

Storage Strap

Hand Grips

Locking

Mechanism

Telescopic Tubes

Bottom Rung

www.jeffersontools.com

User Manual

v.1.1

JEFLADTEL10

6. OPERATION

CLOSED INTERMEDIATE LENGTH FULL LENGTH

OPERATION

The Telescopic Ladder can be used at various heights for different tasks. Closed Intermediate length Full length

NOTE:

The Telescopic Ladder should be inclined using the 1-4 rule; for every 4 parts up, the Ladder should be placed 1 part out (e.g. 2m up, 50cm out).

The Telescopic Ladder can be used at various heights for different tasks.

5. LOCKING MECHANISM

The Locking Mechanisms (3) lock each rung with 2 steel locking pins that automatically spring into place when the Ladder is extended.

CAUTION:

Ensure all Locking Mechanisms are engaged before and after use.

To collapse the Telescopic Ladder down to its closed position, push the Locking Mechanisms (3) together simultaneously (FIG 1) and release.

Fig.1 Fig.2

www.jeffersontools.com

User Manual

v.1.1

JEFLADTEL10

Place the Telescopic Ladder on a

rm, level surface. Place your foot

on the Bottom Rung (6) to stabilise

the Ladder.

Starting with the second rung from

the bottom, use both hands to

grasp the Hand Grips (4) on either

side of the rung and pull upwards

to extend the step.

7. OPEN THE LADDER TO INTERMEDIATE LENGTH

8. OPEN THE LADDER TO FULL LENGTH

To close the ladder

When each step is fully extended, you should

hear a “click”, conrming that the Locking

Mechanisms (3) are engaged for that level.

Lock indicator lever displays when

each rung has successfully locked.

Hold the Telescopic Ladder in an upright

position. Place one foot on the Bottom Rung

(6) to stabilise the Ladder. Starting at the

lowest extended rung, use both hands to

grasp the Hand Grips (4) on either side of the

rung, then, with your thumbs, disengage the

Locking Mechanisms (3).

Fig A. Fig B. Fig C.

Bottom

Rung

2.

1.

C

l

i

c

k

C

l

i

c

k

Place the Telescopic Ladder on a rm, level

surface. Place your foot on the Bottom Rung

(6) to stabilise the Ladder.

Starting with the Top Bar (1), use both hands

to grasp the Hand Grips (4) on either side of

the rung and pull upwards to extend the step.

When each step is fully extended, you should

hear a “click”, conrming that the Locking

Mechanisms (3) are engaged for that level.

Fig A. Fig B. Fig C.

Top

Bar

C

l

i

c

k

Note: It is correct that the ladder will NOT lock until fully extended. As soon as upward pressure is released on the step it will self-retract.

This is normal and is a requirement of the EN131:6 standard, it is NOT a fault with the ladder.

C

l

i

c

k

User Manual

v.1.1

JEFLADTEL10

Jefferson Professional Tools & Equipment, or hereafter “Jefferson” warrants its customers that

its products will be free of defects in workmanship or material. Jefferson shall, upon suitable

notication, correct any defects, by repair or replacement, of any parts or components of

this product that are determined by Jefferson to be faulty or defective. This warranty is void

if the equipment has been subjected to improper installation, storage, alteration, abnormal

operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the

stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If

proof of purchase is unavailable from the end user, then the date of purchase will be deemed

to be 3 months after the initial sale to the distributor.

1 Year

• Jefferson 2.9M Safe Close Telescopic Ladder [JEFLADTEL10].

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be

subject to a minimum of 90 days cover or the remaining duration of the warranty period from

the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the

following address: www.jeffersontools.com/warranty and completing the online form.

Online warranty registration is recommended as it eliminates the need to provide proof of

purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will

be corrected by repair or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for

collection. Jefferson will arrange collection and transportation of any equipment returned under

warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour

and return transportation costs incurred. These costs will be agreed with the customer before

the machine is returned.

NOTE: * Jefferson reserve the right to void any warranty for damages identified as being

caused through misuse *

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians

or engineers. Jefferson’s liability under this warranty will not exceed the cost of correcting the

defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business

or hire of substitute equipment etc.) caused by the defect or the time involved to correct the

defect. This written warranty is the only express warranty provided by Jefferson with respect to

its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the

equipment involved.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment:

(Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where final

determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form.

You can complete the form online and submit it to us directly or download the form to print out

and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together

with details of your nearest authorised Jefferson repair centre. On receipt of this form Jefferson

will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer’s responsibility to ensure that the equipment is appropriately and securely

packaged for collection, together with a copy of the original proof of purchase. Please note

that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions

of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a copy of

the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will

be determined if the equipment is defective and in need of repair and any repairs needed are

covered by the warranty policy. In order to qualify for warranty cover all equipment presented

must have been used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return

delivery will be sent to the customer (normally within 7 working days). Note: If the repair

quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour

time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the

equipment is identified as the cause of the problem, a minimum of 1 hour labour at £30 per

hour plus carriage costs will be required before the equipment will be despatched back to the

customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to

the customer within 7 working days upon receipt of the equipment at an authorised Jefferson

Repair centre (subject to part availability). Where parts are not immediately available Jefferson

will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call:

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all

recommendations or suggestions are made without guarantee. Since the conditions of use are

beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from

the use of this data or suggestions. Furthermore, no liability is accepted if use of any product

in accordance with this data or suggestions infringes any patent. Jefferson Tools® reserve the

right to change product specifications and warranty statements without further notification. All

images are for illustration purposes only.

www.jeffersontools.com

LIMITED WARRANTY STATEMENT

EC DECLARATION OF CONFORMITYormity

We, Jefferson Professional Tools & Equipment, as the authorised European Community representative of

the manufacturer, declare that this equipment conforms to the requirements of the following Directives:

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park,

Chester, United Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048

Fax: +44 (0)1244 241 191

Email: [email protected]

www.jeffersontools.com

EN 131-6:2019 (as amended) Ladders. Telescopic ladders

TÜV Rheinland (Shanghai) Co., Ltd.

Signed By: Stephen McIntyre Date: 11 April 2020

Table of contents

Other Jefferson Ladder manuals