Jefferson JEFLUEXTM07 User manual

www.jeffersontools.com

7L MANUAL

EXTRACTOR

JEFLUEXTM07

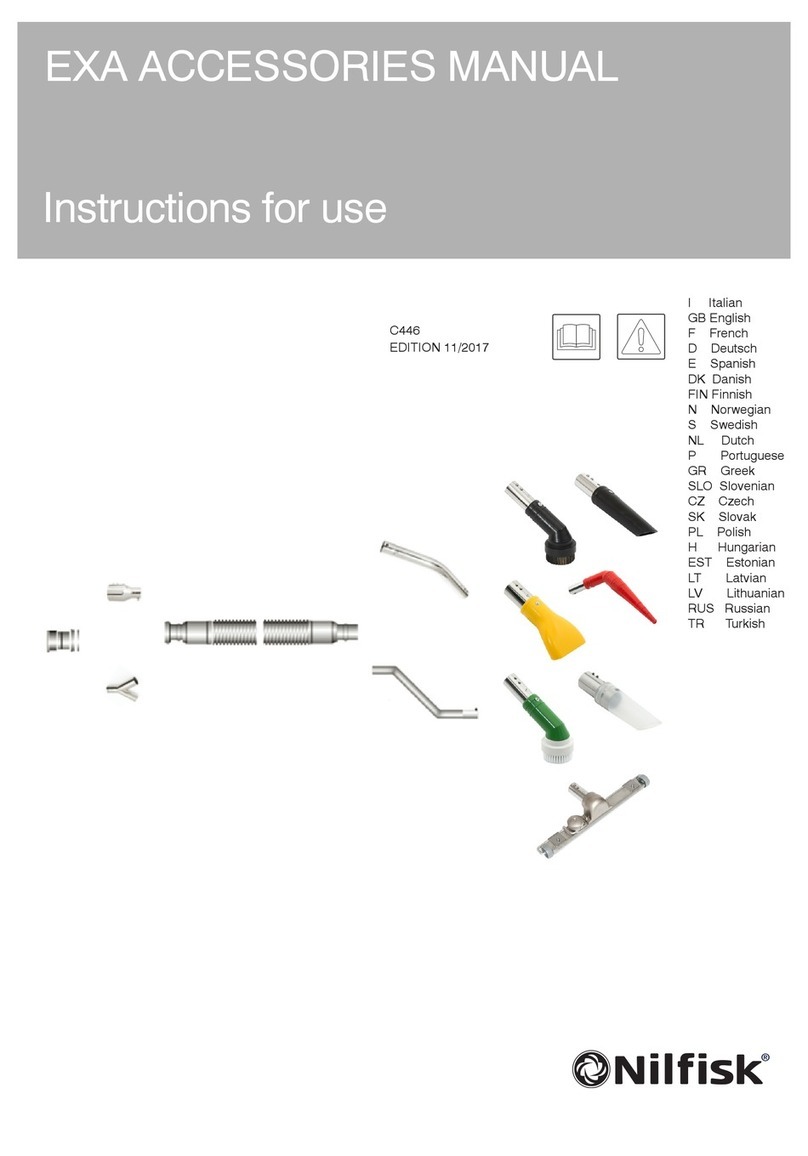

FEATURES 1. EQUIPMENT OVERVIEW

7ltr capacity

26mm suction port

4, 6, 8, 10mm x 1 Metre suction probes

Made from Acrylonitrile-Butadiene-Styrene thermoplastic polymer

material with Aluminium inator

Strong and durable with strong resistance to heat and chemicals.

Suitable for the extraction of all types of engine, transmission and

lubricating oils from cars, motorcycles, marine engines, stationary

engines and industrial machinery

Also suitable for low viscosity uids such as water, and

draining sh-tanks, basins, baths, cisterns, sinks etc

User Manual

v.1.1

JEFLUEXTM07

3. SAFETY

WARNING!

Ensure health & safety, local authority, and general workshop practice regulations are strictly adhered to when using this equipment.

Familiarise yourself with the extractors application and limitations, as well as the specic potential hazards relating to this product.

Ensure the extractor is maintained in good condition.

Replace or repair damaged parts using only genuine parts. Non authorised parts will invalidate the warranty.

Unit may be used only to extract engine or transmission oils, or similar NON-Corrosive uids. Unit may also be used for the transfer of water.

Ensure safety eye protection and protective clothing are worn when using this product.

Keep the work area clean, uncluttered and ensure there is adequate lighting.

Maintain correct balance and footing. Ensure the oor is not slippery and wear non slip shoes.

Keep children and unauthorised persons away from the working area.

Dispose of waste liquids in accordance with local authority regulations.

DO NOT store uids in the JEFLUEXTM07 container. Once used to extract uid, it must be emptied into an approved receptacle.

DO NOT use to extract hazardous or harmful chemicals, solvents, petrol, diesel, kerosene, alkaline or acids. If by chance such uids are

used in the unit, it must be immediately drained and thoroughly cleaned. Use with prohibited uids will invalidate your warranty.

DO NOT dismantle, tamper or adapt the extractor for any purpose other than for which it is designed.

DO NOT use the unit if it has been dropped or mishandled, check the unit to ensure there is no damage.

DO NOT store in areas of high temperature, direct sunlight, rain or snow.

Keep the extractor clean and store in a safe dry location.

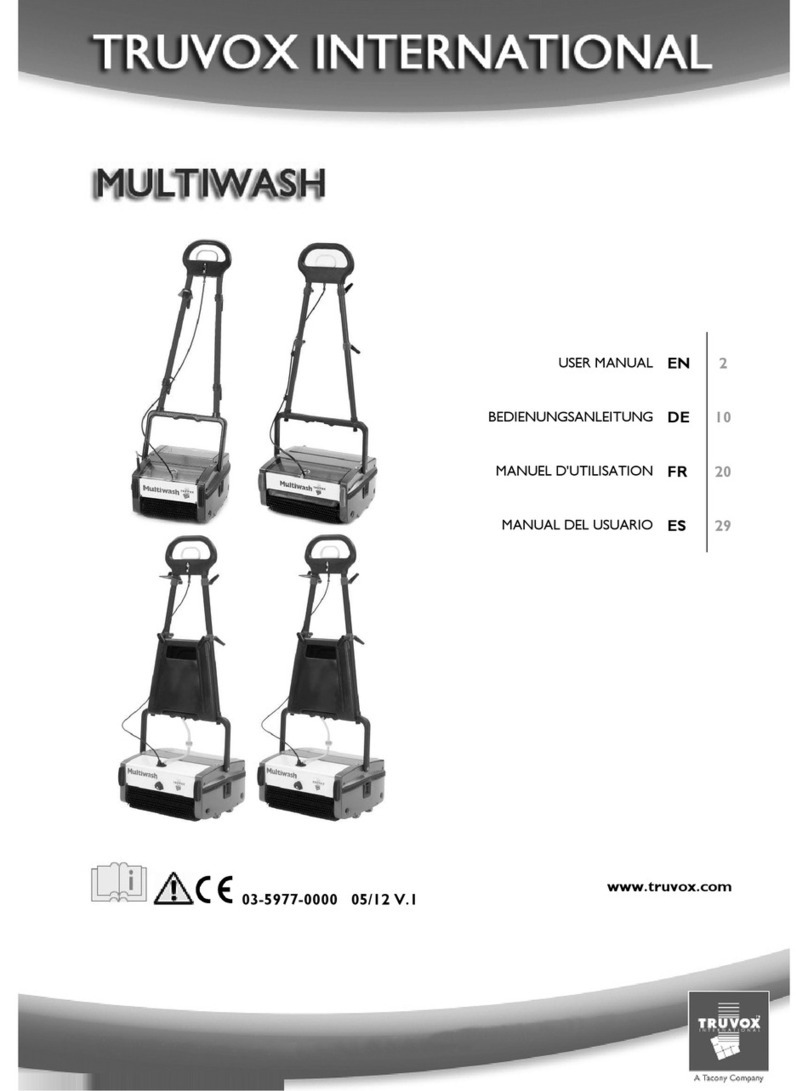

1

45

2

3

1Pump handle

2Pump inlet

3Vacuum release valve

4Probe storage holder

57 Litre capacity tank

2. OPERATING INSTRUCTIONS

2.1 Ensure the vehicle is on level ground and run the engine for approximately 5 minutes to warm the oil and allow any contaminants

within the oil to thoroughly mix and turn the engine off.

2.2 Remove the vehicle’s oil dipstick.

2.3 Select and insert the appropriate diameter probe into the dipstick hole until it reaches the bottom of the sump

2.4 Connect the extension tube to both the pump inlet and probe

2.5 Raise the handle to its highest limit and pump it fully several times to create a vacuum which will automatically begin to extract the oil/uid.

Observe the oil/uid as it rises up the chamber and stop pumping when the uid is 6”(150mmm) from the top. The unit will continue to ll

and will automatically shut off when the internal oat valve operates. DO NOT continue to pump after the unit has shut off as this may result

in liquid entering the inner pump chamber. If this should occur refer to section 4.8 on how to expel uid from the pump.

2.6 Once completed, remove the main suction tube from the pump, pour the oil/uid into a suitable container (the unit can be tipped upside

down to facilitate emptying) and dispose of it in accordance with local authority regulations.

2.7 Before using the pump again press the vacuum release valve for 5 seconds to release the vacuum within the pump. This valve is situated on

the top of the unit underneath the handle.

2.8 In the event of uid entering the inner pump chamber it can be expelled from the unit as follows. Firstly press the vacuum release valve for

5 seconds to release the vacuum within the pump. Seal off the uid entry/pouring hole by placing your hand over it, then pump the handle

up and down several times. Any uid that has entered the pump will be expelled from the air valve on the underside of the unit.

OTHER FLUIDS

2.9 Select and insert the appropriate diameter probe into the uid to be drained.

2.10 Connect the main suction tube to both the pump inlet and probe.

2.11 The operation of the extractor is the same as described in sections 2.6 to 2.8

User Manual

v.1.1

Jefferson Professional Tools & Equipment, or hereafter “Jefferson” warrants its customers that

its products will be free of defects in workmanship or material. Jefferson shall, upon suitable

notication, correct any defects, by repair or replacement, of any parts or components of this

product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage,

alteration, abnormal operations, improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the

stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If

proof of purchase is unavailable from the end user, then the date of purchase will be deemed

to be 3 months after the initial sale to the distributor.

1 Year

• Jefferson 7L Manual Extractor [JEFLUEXTM07].

90 Days

• All replacement parts purchased outside of the warranty period.

Important: All parts used in the repair or replacement of warranty covered equipment will be

subject to a minimum of 90 days cover or the remaining duration of the warranty period from

the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the

following address:

www.jeffersontools.com/warranty and completing the online form.

Online warranty registration is recommended as it eliminates the need to provide proof of

purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will

be corrected by repair or replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for

collection. Jefferson will arrange collection and transportation of any equipment returned under

warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour

and return transportation costs incurred. These costs will be agreed with the customer before

the machine is returned.

NOTE: * Jefferson reserve the right to void any warranty for damages identified as being

caused through misuse *

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians

or engineers. Jefferson’s liability under this warranty will not exceed the cost of correcting the

defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business

or hire of substitute equipment etc.) caused by the defect or the time involved to correct the

defect. This written warranty is the only express warranty provided by Jefferson with respect to

its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the

equipment involved.

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment:

(Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where final

determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form.

You can complete the form online and submit it to us directly or download the form to print out

and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together

with details of your nearest authorised Jefferson repair centre. On receipt of this form Jefferson

will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer’s responsibility to ensure that the equipment is appropriately and securely

packaged for collection, together with a copy of the original proof of purchase. Please note

that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions

of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a copy of

the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will

be determined if the equipment is defective and in need of repair and any repairs needed are

covered by the warranty policy. In order to qualify for warranty cover all equipment presented

must have been used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return

delivery will be sent to the customer (normally within 7 working days). Note: If the repair

quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour

time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the

equipment is identified as the cause of the problem, a minimum of 1 hour labour at £30 per

hour plus carriage costs will be required before the equipment will be despatched back to the

customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to

the customer within 7 working days upon receipt of the equipment at an authorised Jefferson

Repair centre (subject to part availability). Where parts are not immediately available Jefferson

will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call:

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all

recommendations or suggestions are made without guarantee. Since the conditions of use are

beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from

the use of this data or suggestions. Furthermore, no liability is accepted if use of any product

in accordance with this data or suggestions infringes any patent. Jefferson Tools® reserve the

right to change product specifications and warranty statements without further notification. All

images are for illustration purposes only.

www.jeffersontools.com

LIMITED WARRANTY STATEMENT

JEFLUEXTM07