Jegs 81426 User manual

Installation Instructions for 81426

Hydraulic Lift Cart

500 lb. Capacity

Specifications

Capacity

500 lb.

Lift Range

9-1/4” to 28-1/2”

Table Size

27-3/4” x 17-3/4”

Important Safety Information

Assembly Precautions

1. Wear ANSI-approved safety goggles and heavy-duty gloves during assembly and use.

2. Keep assembly area clean and well lit.

3. Assemble only according to these instructions. Improper assembly can create hazards.

4. Keep bystanders out of the area during assembly.

5. Do not assemble when tired or when under the influence of drugs or medication.

Use Precautions

1. Do not exceed 500 lb. max weight capacity. Be aware of dynamic loading! Sudden load movement may briefly create

excess load causing product failure.

2. Use only on flat, level and hard surface capable of supporting the Lift Table and any item(s) placed on table. Evenly

distribute load on table to avoid tipping.

3. Use as intended only. Do not use Lift Table to lift or transport people.

4. Follow all hydraulic bleeding instructions specified in this manual.

5. This product is not a toy. Do not allow children to play with or near this item.

6. Use as intended only.

7. Do not adjust Safety Valve.

8. Keep clear of load while lifting and lowering.

9. Lower load slowly.

10. Do not use for aircraft purposes.

11. Inspect before every use; do not use if parts are loose or damaged.

12. Maintain product labels and nameplates. These carry important safety information.

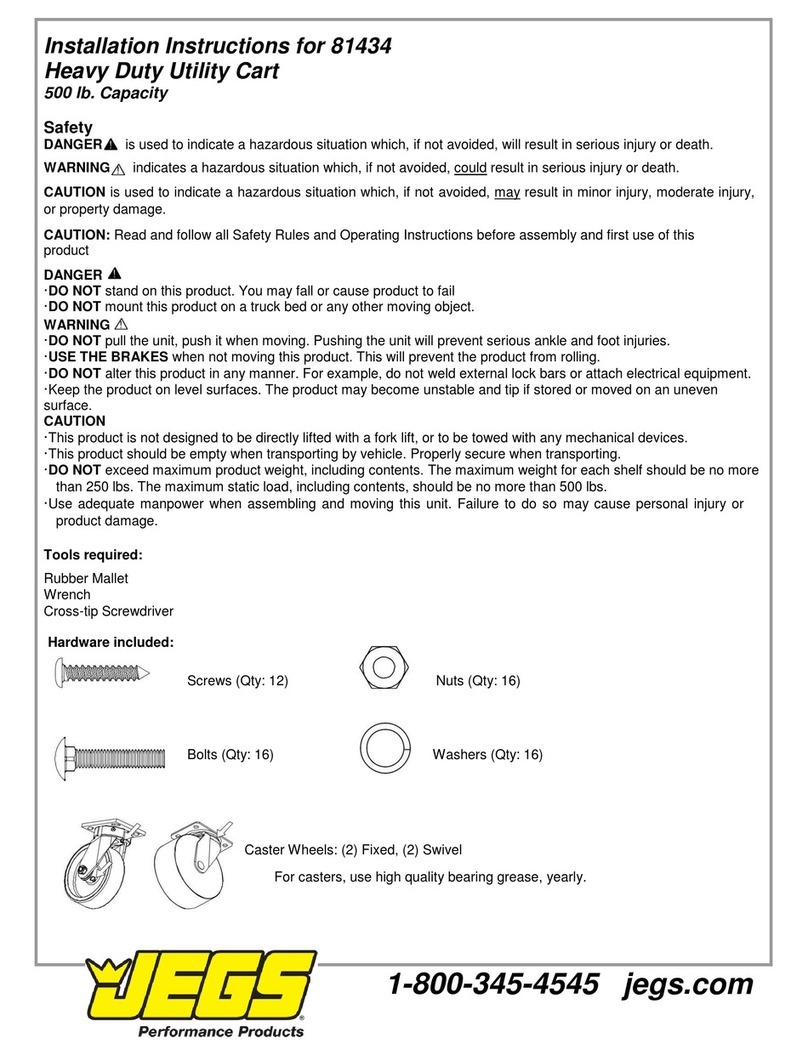

Assembly Instructions

Read the entire IMPORTANT SAFETY INFORMATION section at the

beginning of this document including all text subheadings therein

before setup or use of this product.

1. With assistance, grip the Base (9) of the Hydraulic Lift Table and

lift it from the box. Do not just grip the Table. Doing so will leave the

unit's frame in the packaging. Wheels (12)

2. Alternative: set the packaging sideways, grip the Base, and slide Lock Nuts (11)

the Lift Table out of the box

Washers (29)

3. Turn the Lift Table on its side.

Bushings (13)

Bolts (14)

Figure A

1-800-345-4545 jegs.com

4. Slide Bushing through center hole in front Wheel (12).

5. Set Wheel in the Wheel frame of the Base (9).

6. Slide the Bolt (14) through the Washer (29), Wheel Frame,

and Bushing (13).

Wrench

7. Use a wrench (sold separately) to fasten Lock Nut onto Bolt,

until the Front Wheel is secured in place.

8. Repeat steps 3-7 for other front Wheel.

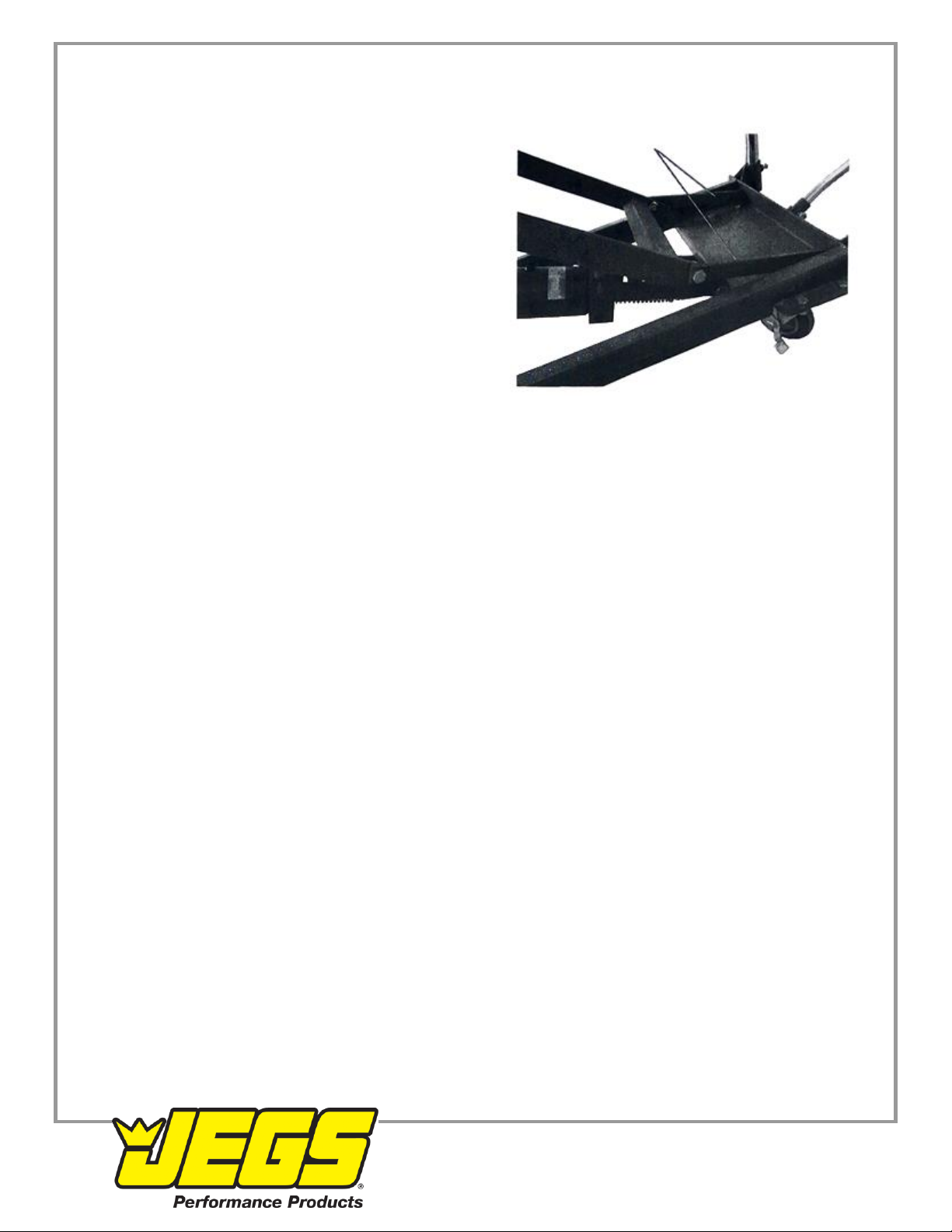

9. Slide Pump Lever (23) into Connecting Rod (22), aligning the Washer

installation holes.

10. Slide the Bolt (35) through the Washer (15) and through the

installation holes. Wheel Frame

11. Use the wrench to fasten the Lock Nut over the Bolt, securing

Pump Lever (23) in place. See Figure C.

12. Slide the ends of the Handle (31) into the handle slots on the Base.

13. Use the wrench to tighten the Bolts (20) until the Handle is Front Wheel

fastened in place. See Figure D.

14. Test the Lift Table to make sure it functions properly

before using it to lift a load. Lock Nut

Figure B

Connecting Rod (22)

Handle (31)

Bolt (35)

Wrench

Pump Lever

Wrench (23)

Figure C

Bolt (20)

Base (9)

Figure D

1-800-345-4545 jegs.com

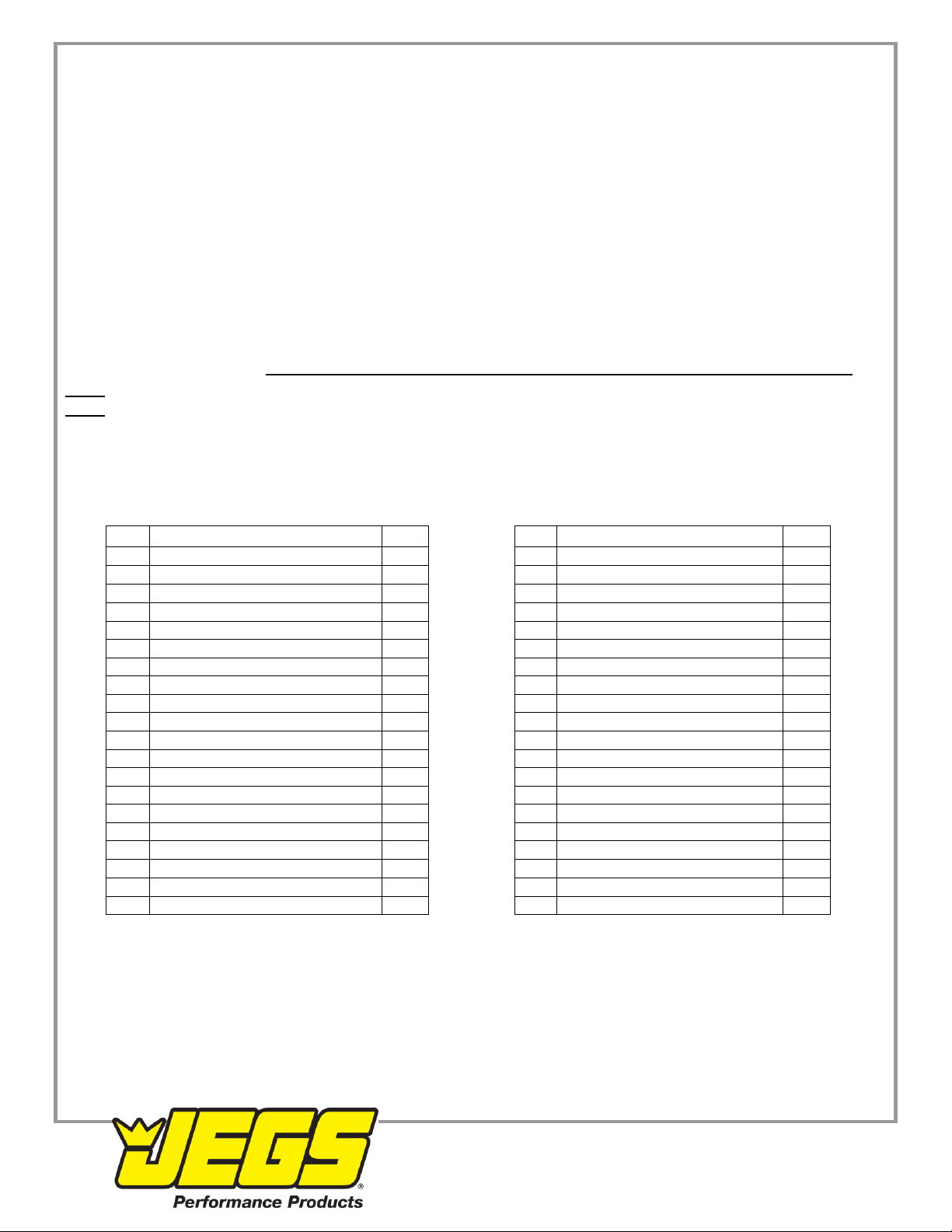

Operating Diagram Control Lever

Handle

Lift Table

Pump Lever

Safety Bar

Locking Caster

Base

1-800-345-4545 jegs.com

Operating Instructions

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all

text under subheadings therein before set up or use of this product.

1. Lock the back Casters to prevent the Lift Table from moving. Safety Bars

2. Raise the Lift Table by pumping the Pump Lever.

3. Once the desired height is reached, engage the Safety Bars

on sides of the Lift Frame by swinging them back towards the

handle. Lower the table slightly and make sure the bars lock

in place. See Figure E. This helps prevent uncontrolled Lift

Table drop.

4. To lower the Lift Table, pump the table up until the Safety

Bars can be disengaged.

5. Swing the Safety Bars up away from the Handle, towards

their original position.

6. Squeeze the Control Lever (33) to slowly lower the Lift Table.

Figure E

Maintenance

Procedures not specifically explained in this manual must be performed only by a qualified technician.

WARNING! TO PREVENT SERIOUS INJURY FROM TOOL FAILURE: Do not use damaged equipment. If

abnormal noise or vibration occurs, have the problem corrected before further use.

Cleaning, Maintenance, and Lubrication

1. BEFORE EACH USE, inspect the general condition of the tool.

Check for:

•loose hardware

•misalignment or binding of moving parts

•caster brake function

•hydraulic fluid leakage (hydraulic components not user-serviceable)

•cracked or broken parts

•any other condition that may affect its safe operation

2. AFTER USE, wipe external surfaces of the tool with clean cloth.

3. If the Control Lever does not lower the Lift Table easily, adjust the Pull Rod (32).

WARNING! Press the Control Lever only halfway down during adjustment. This will allow the Lift Table to lower slowly

for safety purposes.

a. With assistance, tip over Table Cart.

b. Loosen the Bolt (35) and Nut (25) and adjust the Pull Rod until it is tight.

c. Re-fasten the Nut and Bolt. Then test the Control Lever, making sure it is pressed halfway down.

Bleeding Instructions

If the Lift Table is not performing properly, it may be due to air in the hydraulic system. Follow these steps to bleed air

from the system.

1. Raise the Lift Table to its highest position.

2. Swing down the two Safety Bars so that they both rest on the top platform of the Base Assembly.

3. Carefully remove the rubber Fluid Plug (4a).

4. After the Fluid Plug is removed, swing the two Safety Bars back against their stops.

5. Squeeze the Control Lever to lower the Lift Table. This should purge the air out of the hydraulic system.

1-800-345-4545 jegs.com

6. Raise the Lift Table to its highest position and swing both Safety Bars down onto the Base Assembly (17).

7. Fill the Fluid Tank (5a) with new Hydraulic Fluid (not included).

8. Replace the Fluid Plug by firmly pressing it into the fluid hole while twisting it.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN

THIS DOCUMENT AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR MAKES

ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO

MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF

THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL

REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED

TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF

HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT

OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Record Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available individually as

replacement parts.

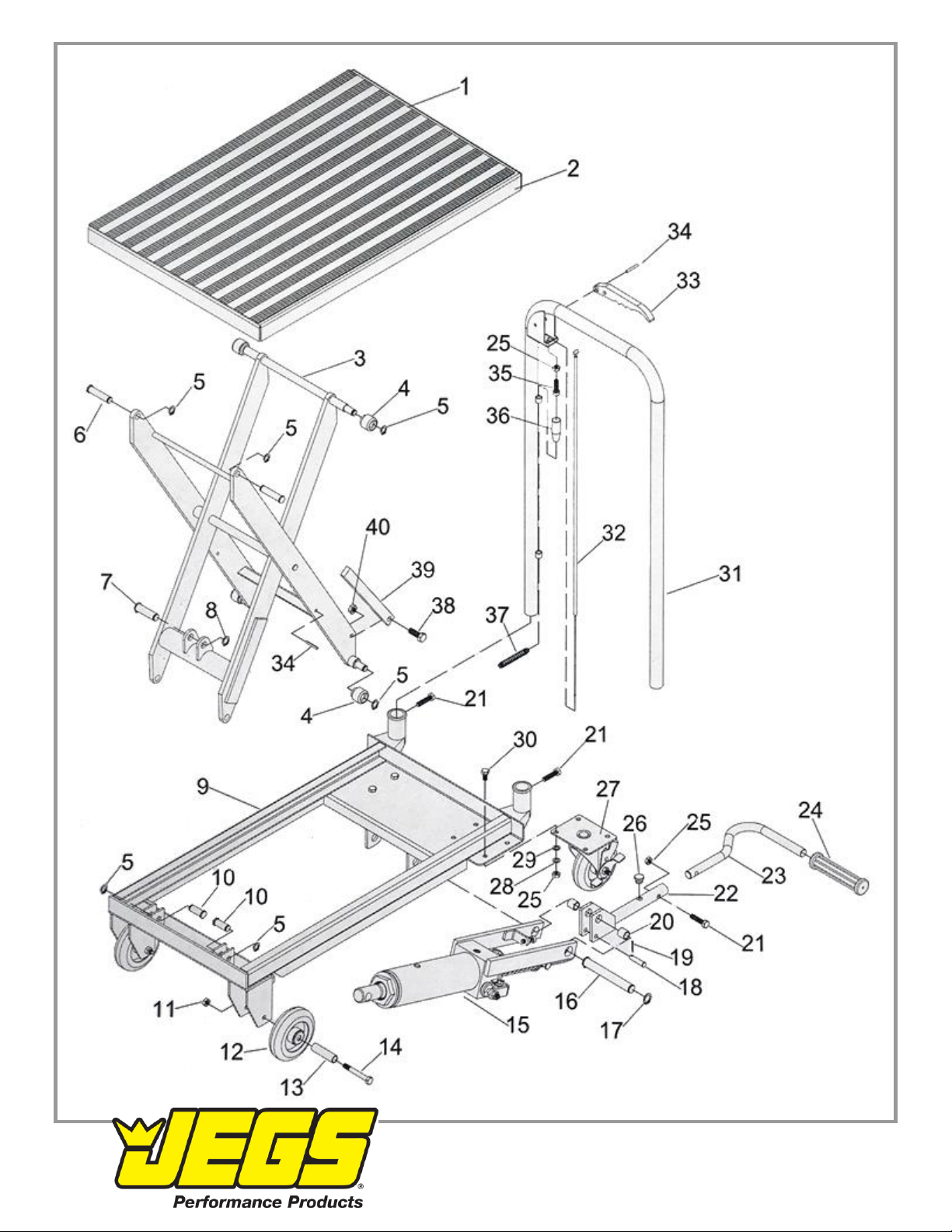

Parts Lists & Diagrams

Main Parts List

Part

Description

Qty.

Part

Description

Qty.

1

Protective Mat

1

21

Hex Bolt M8 x 35

3

2

Lift Table

1

22

Connecting Rod

1

3

Scissor Arm

1

23

Pump Lever

1

4

Roller

4

24

Foot Pedal

1

5

Retaining Ring 12

8

25

Hex Nut M8

10

6

Pin

2

26

Rubber Pad

1

7

Pin

1

27

Locking Swivel Caster 4”

2

8

Retaining Ring 14

2

28

Spring Washer 8

8

9

Base

1

29

Washer 8

8

10

Pin

2

30

Hex Bolt M8 x 16

8

11

Lock Nut M8

2

31

Handle

1

12

Wheel 4"

2

32

Pull Rod

1

13

Bushing

2

33

Control Lever

1

14

Hex Bolt M8 x 60

2

34

Roll Pin

3

15

Ram

1

35

Bolt M8 x 25

1

16

Pin

1

36

Jacket

1

17

Retaining Ring 16

2

37

Spring

1

18

Pin 8 x 40

1

38

Hex Bolt M10 x 30

2

19

Cotter Pin

1

39

Safety Bar

2

20

Bushing

2

40

Hex Nut M10

2

1-800-345-4545 jegs.com

Main Assembly Diagram

1-800-345-4545 jegs.com

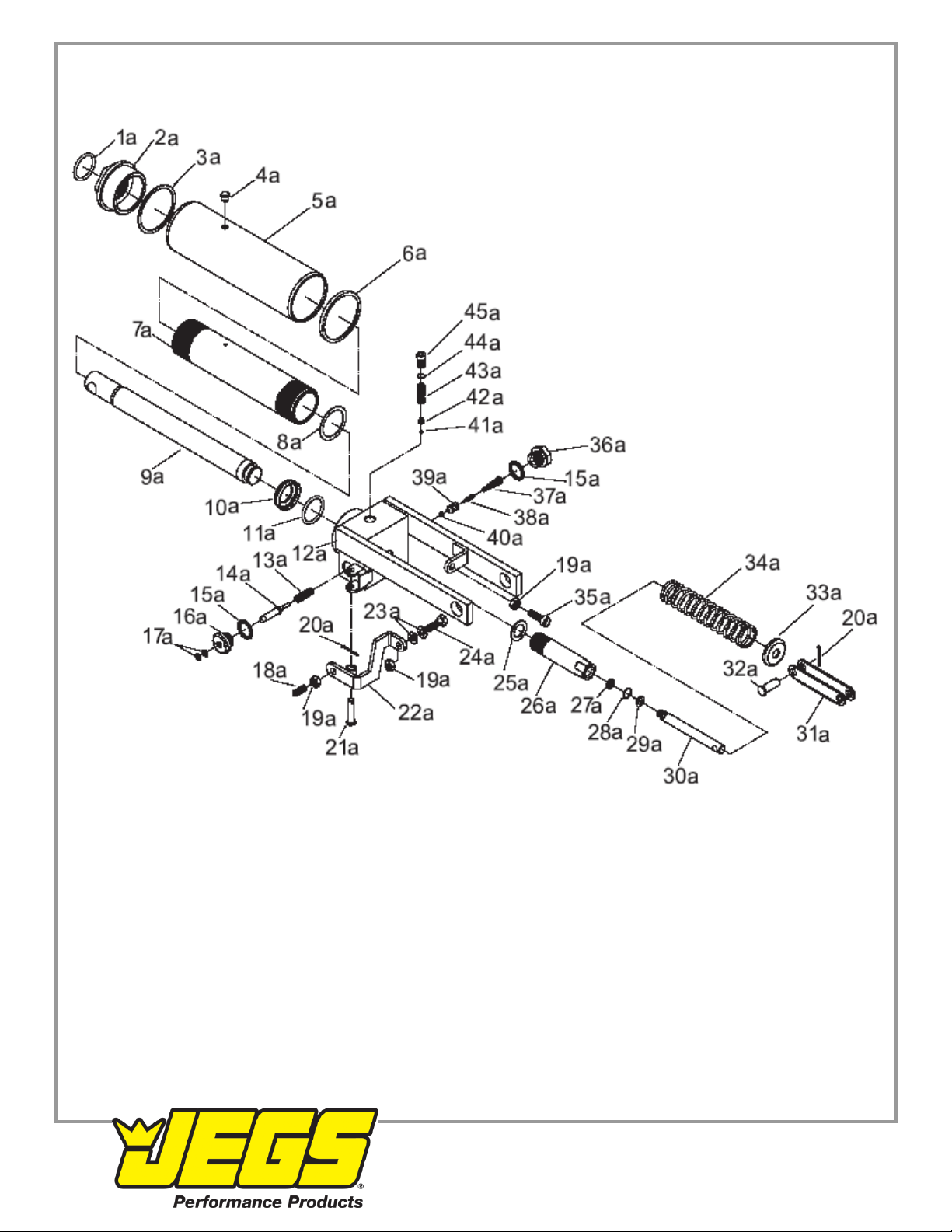

Parts List A –Ram

Part

Description

Qty.

Part

Description

Qty.

1a

O-Ring

1

24a

Bolt M8 x 25

1

2a

Top Nut

1

25a

Seal Washer

1

3a

Sealing Gasket

1

26a

Pump Cylinder

1

4a

Fluid Plug

1

27a

U-Cup

1

5a

Fluid Tank

1

28a

O-Ring

2

6a

T-Ring

1

29a

Retainer Ring

1

7a

Cylinder

1

30a

Pump Piston

1

8a

Copper Washer

1

31a

Linkage

1

9a

Ram

1

32a

Pin 8 x 24

1

10a

O-Ring Retainer

1

33a

Spring Cap

1

11 a

O-Ring

1

34a

Spring

1

12a

Base

1

35a

Bolt M8 x 25

1

13a

Spring

1

36a

Plug

1

14a

Release Valve

1

37a

Spring

1

15a

Seal Washer 20

2

38a

Pumping Valve Spindle

1

16a

Axle Sleeve

1

39a

Pumping Valve Seat

1

17a

O-Ring

2

40a

Steel Ball 6.35

1

18a

Screw M8 x 20

1

41a

Steel Ball 5

1

19a

Nut M8

3

42a

Ball Seat

1

20a

Cotter Pin 2.5 x 24

2

43a

Spring

1

21a

Pin

1

44a

O-Ring

1

22a

Release Valve Link

1

45a

Adjusting Bolt

1

23a

Washer 8

2

1-800-345-4545 jegs.com

Assembly Diagram A - Ram

1-800-345-4545 jegs.com

Other Jegs Outdoor Cart manuals