Salford Farm Machinery Ltd. 05-2011

AC2000 Assembly Manual 2011

Table of Contents

General Information

Salford Recommended Torque Values .........................................................................................................5

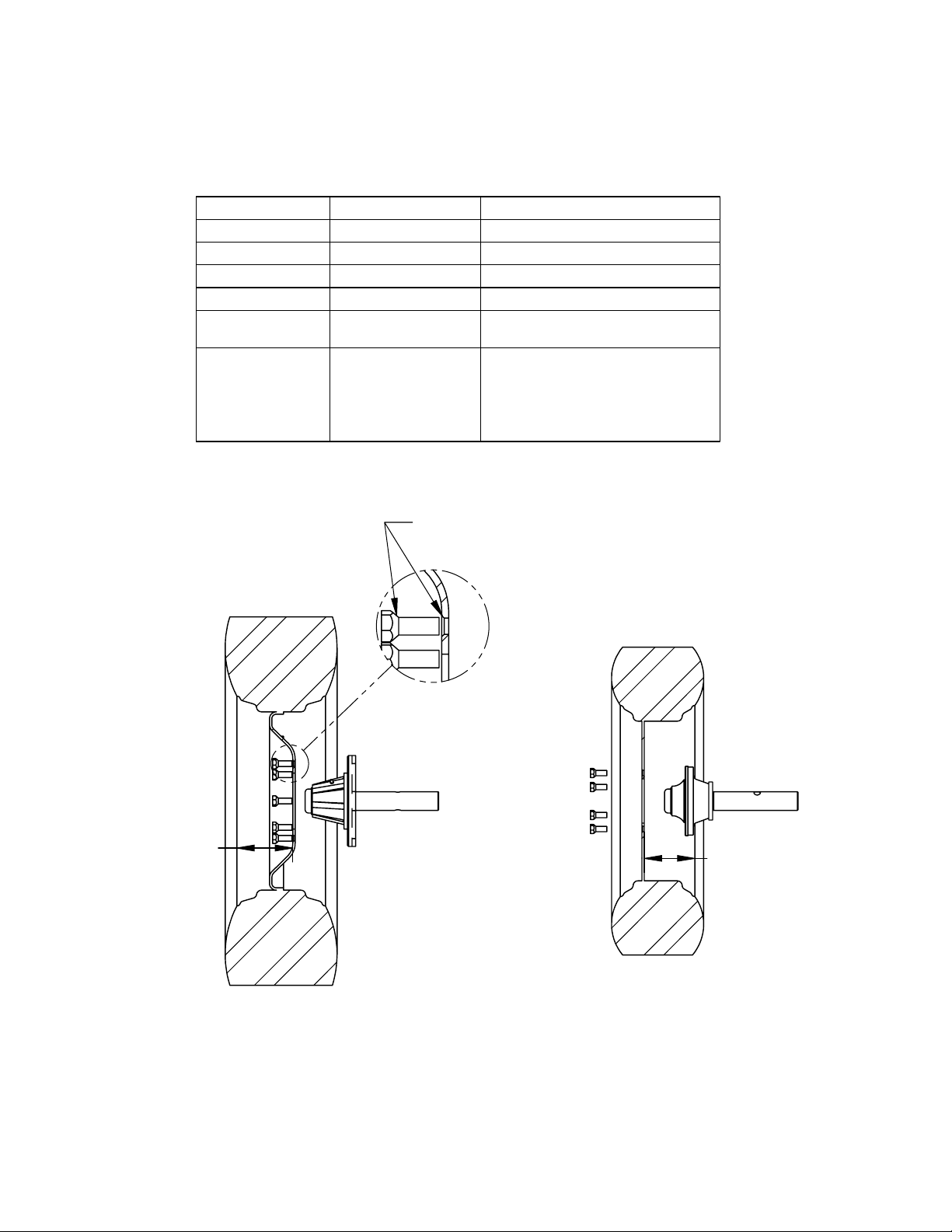

Wheel Torque Specications .......................................................................................................................6

Tire Pressure Ratings ...................................................................................................................................7

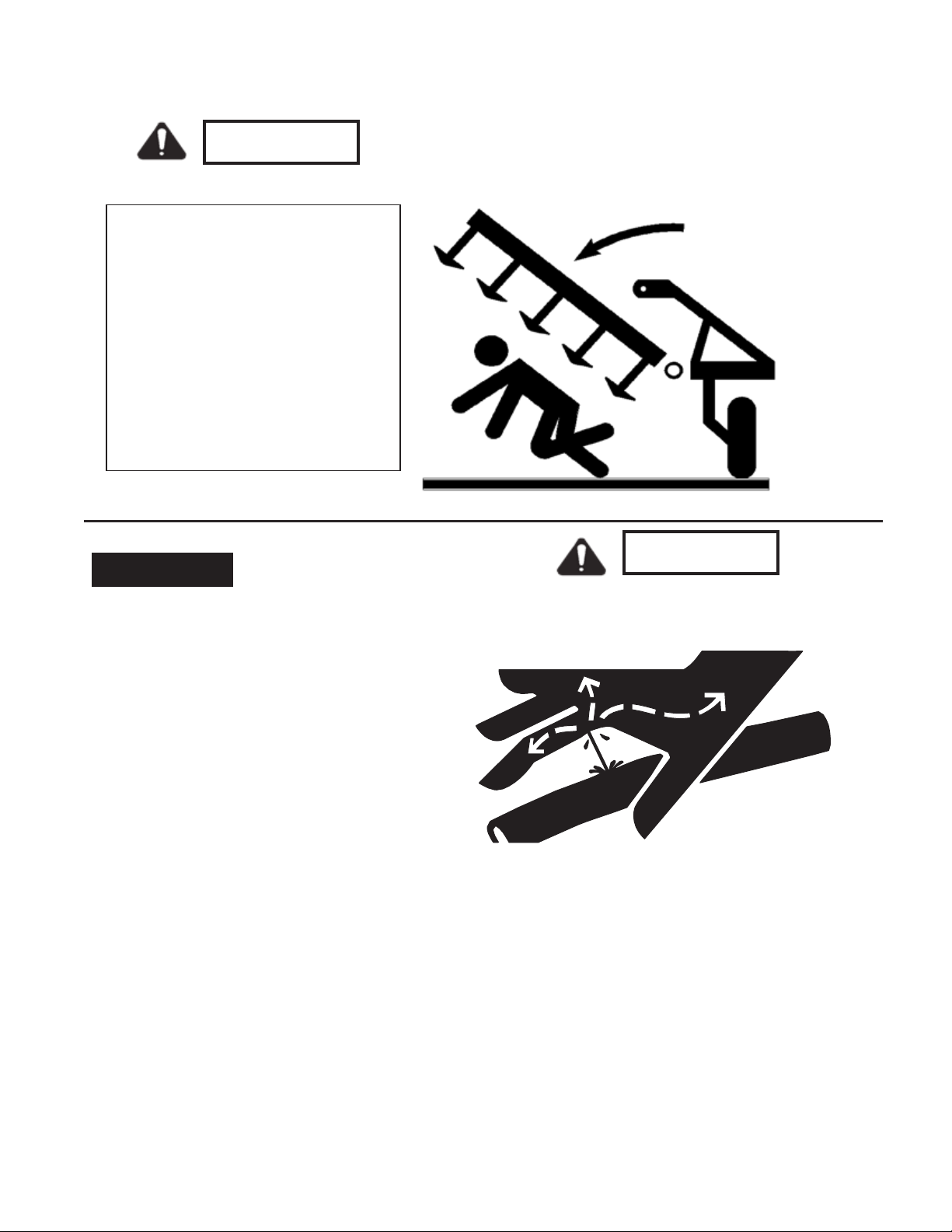

General Safety Precautions ..........................................................................................................................8

Frame Assembly and Wheels

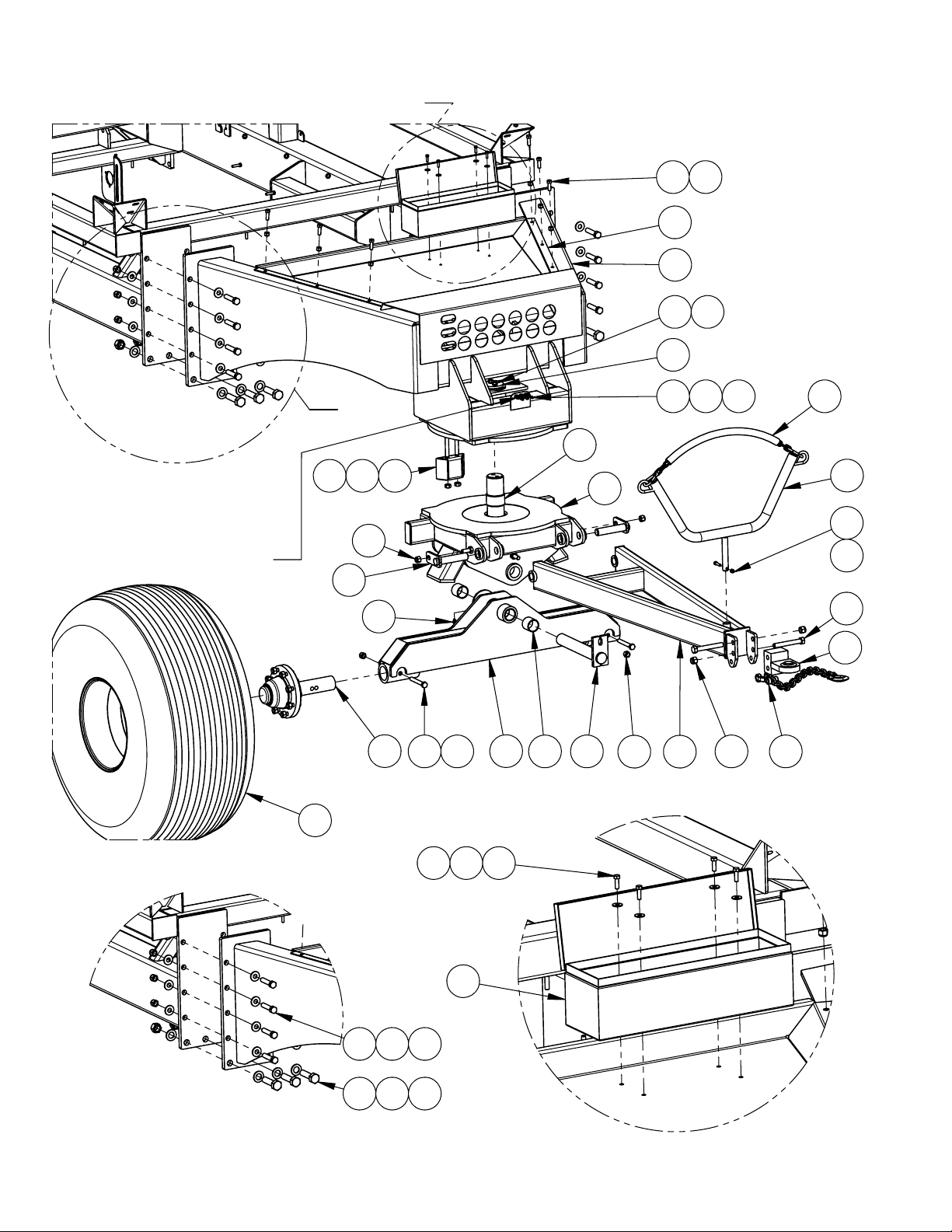

Tow Behind Front End Assembly ..............................................................................................................10

Tow Between Tongue Assembly................................................................................................................12

Hose Holder Assembly ..............................................................................................................................14

Tow Between Toolbox Installation ............................................................................................................15

Tow Behind Rear Tow Hitch......................................................................................................................16

Tow Between Rear Tow Hitch ...................................................................................................................18

Wheels and Axles

16,000 LB Axle Assembly .........................................................................................................................19

20,000 LB Axle Assembly .........................................................................................................................20

8,000 LB Hub and Spindle Assembly........................................................................................................22

16,000 LB Hub and Spindle Assembly......................................................................................................24

20,000 LB Hub and Spindle Assembly......................................................................................................26

Tanks and Platforms

Platform and Ladder ..................................................................................................................................28

Plastic Tank Cradle Assembly....................................................................................................................30

Plastic Tank Inner Ladder Parts .................................................................................................................32

Steel Lid Assembly ....................................................................................................................................34

Meterbox and Drive Installation

Meterbox Installation.................................................................................................................................36

Meterbox Assembly ...................................................................................................................................37

Transmission Mounting .............................................................................................................................40

Zero-Max Handle Installation....................................................................................................................42

Locking Collar Procedures ........................................................................................................................43

Ground Drive Installation ..........................................................................................................................44

Ground Drive Chain Routing.....................................................................................................................47

Hydraulic Drive Installation ......................................................................................................................48

Air Distribution

Tow Between 13” Fan Mounting...............................................................................................................50

Tow Between 17” Fan Mounting...............................................................................................................51

Tow Behind 13” Fan Mounting .................................................................................................................52

Tow Behind 17” Fan Mounting .................................................................................................................53

Tow Behind Air Distribution .....................................................................................................................54

Tow Between Air Distribution ...................................................................................................................56

Loading Augers

8” Auger Installation ..................................................................................................................................58

10” Auger Installation ................................................................................................................................60

8” Auger Parts ............................................................................................................................................62

Sensor Installation

Sensor Installation......................................................................................................................................64