Jegs 92600 User manual

Installation Instructions for 92600

ATV Winch

3000 lb. Rated Pull

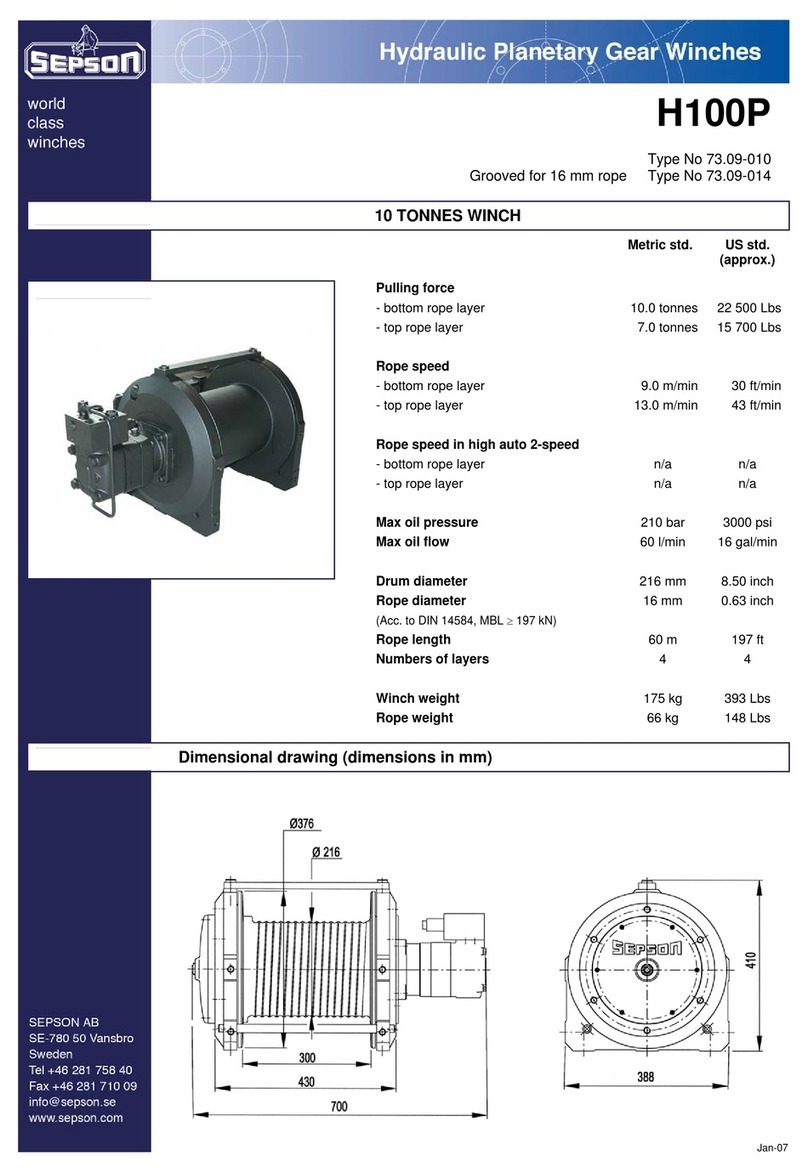

SPECIFICATIONS

Rated line pull: 3000 lbs. (1360kgs) single line

Motor: Permanent magnetic DC 12V with 1.2 hp. /0.9kw output

Gear: Differential planetary

Gear ratio: 153 : 1

Wire rope: 3/16”x 41’( 4.8mm x 11m)

Drum size: 1.25”x 2.86”( 31.75mm 72mm)

Dimensions: L x W x H ( 300mm 105mm 105mm)

N W.: 7.5 kg

G.W.: 11 kg

Line speed and motor current (first layer)

Line pull

Lbs.

0

1000

2000

3000

Kgs

0

454

907

1360

Line speed

FPM

9.5

6.6

3.6

2.3

MPM

2.8

2.0

1.1

0.7

Motor current

Amps

12

60

90

150

Line pull and cable capacity

Layer of cable

1

2

3

4

5

Rated line pull per layer

Lbs.

3000

2320

1890

1590

1380

Kgs

1360

1052

858

720

620

Cable capacity per layer

Ft.

4.9

11.5

19.3

28.5

32

M

1.5

3.5

5.9

8.7

10

INTRODUCTION

Congratulations on your purchase of a JEGS winch. Designed and built to strict specifications. With proper use and

maintenance your winch should bring you years of satisfying service.

WARNING - Read, study and follow all instructions before operating this device. Failure to heed these instructions may

result in personal injury and/or property damage.

Your winch can develop tremendous pulling forces and if used unsafely or improperly could result in property damage,

serious injury or death. Ultimately, safe operation of this device rests with you, the operator.

CAUTION Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. This

notation is also used to alert against unsafe practices.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

1-800-345-4545 jegs.com

INCLUDED WITH YOUR WINCH

DESCRIPTION QUANTITY

1. Winch Assembly with Wire Rope 1

2. Cap Bolt M8 x 30 2

3. Lock Washers 2

4. Flat Washers 2

5. M8 Nuts 2

6. Snatch Block/Pulley 1

7. Clevis Hook w/ Pin 1

8. Power cord/Switch Assembly 1

9. Strap 1

WINCH ACCESSORIES YOU WILL NEED

NOT INCLUDED WITH YOUR WINCH

Gloves –For handling the wire rope and hook strap.

Clevis/D-shackle - For connecting your snatch block and anchor strap.

Anchor Strap/Chain - Tree saver anchor straps are made of high quality nylon with high tensile strength from 5,000 to

10,000 lbs.

Heavy Blanket - place on the cable to absorb energy should the wire rope break.

WINCH ASSEMBLY AND MOUNTING

1. Your winch is designed with a bolt pattern that is standard in this class of winch. Many winch mounting kits are

available that utilize this bolt pattern for the most popular ATVs and mounting channels. If you cannot find a kit locally,

contact JEGS and we will provide you with the name of a dealer near you.

2. Regardless of the mounting kit you use, ensure that your winch is mounted on a flat surface so that the three major

sections (motor, drum and gear housing) are properly aligned. Proper alignment of the winch will allow even distribution

of the full rated load.

3. Utilize the M8 x 30 mounting bolts, washers and nuts included.

4. Connect the battery (4’1”) and motor (5’9”) leads. Connect the red (positive+) to the in-facing terminal (marked+) on

the motor and the black (Negative-) to out-facing terminal (marked-) on the motor. Then connect the red (positive+)

lead from the power switch to the positive ( + ) terminal of the vehicles 12 volt battery. Connect the black (negative -)

lead from the power switch to the negative ( - ) terminal of the battery. ( Fig 1 & Fig 2 & Fig 3 & Fig 4 )

CAUTION - Batteries contain gases which are flammable and explosive. Wear eye protection during installation and

remove all jewelry. Do not lean over battery while making connections.

5. Assemble the Clevis Hook to the cable. Pull and turn the clutch knob to the Off position (Free-spooling). Pull out

some cable from the drum. Take off the pin from the Clevis Hook, connect the Clevis Hook to the cable and mount the

pin back to the Clevis Hook.

6. Always use the Hand Saver when free-spooling and re-spooling the wire rope. ( Fig 5 ) Using the Hand Saver will

keeps your hands and fingers away from the rotating drum.

7. Check for proper drum rotation. Pull and turn the clutch knob to the off position (Free-spooling). Pull out some cable

from the drum, and then turn the clutch knob to the In position to engage the gears. Press the cable out button on the

power switch. If the drum is turning and releasing more cable then your connections are accurate. If the drum is turning

and collecting more cable then reverse the leads on the motor. Repeat and check rotation.

1-800-345-4545 jegs.com

1-800-345-4545 jegs.com

WINCH PARTS LIST

NO.

Part#

Qty.

Description

1

200100

1

Motor

2

200200

1

Stationary Gear Housing Assembly

3

200300

1

Gear Carrier Assembly

4

200001

1

T-Series Rotator Gear

5

200002

1

Drum Support Plata

6

200003

4

Spring Washer 4 & Pan Head Screw M4 12

7

200004

1

Drum Support Bushing

8

200400

1

Clutch Assembly

9

200005

1

Spring

10

200006

1

Drum Assembly

11

200007

1

Screw M5 5

12

200008

1

T-Series Bushing

13

200009

1-2

Thick Flat Washer

14

200010

2

Hex Flange Nut M5

15

200011

1

T-Series Base Plate Assembly

16

200012

1

Tension Plate

17

200500

1

T-Series F/W Knob Assembly

18

200013

1

Elastic Pin 2.5 14

19

200014

2

Cap Screw M6 16

20

200015

2

Screw M5 10

21

200016

2

Screw M8 30

22

200017

2

Flat Washer 8

23

200018

2

Lock Washer 8

24

200019

2

Nut M8

25

200700

1

Cable Assembly

26

200600

1

Switch Assembly

27

200800

1

Pulley Block

28

200900

1

Strap

1-800-345-4545 jegs.com

Winch Assembly Drawing

1-800-345-4545 jegs.com

Hand Bar Switch Assembly

When installing your ATV winch system, read and follow all mounting and safety instructions. Always use caution when

working with electricity and remember to verify that no exposed electrical connections exist before energizing your

winch circuit. To install the complete kit, you will need to mount the winch, contactor handlebar mounted mini-rocker

switch and remote socket (optional on the 2.5ci winch). Mounting locations may vary depending on make and model of

the ATV. Read and understand the following instructions to choose the appropriate mounting locations.

1-800-345-4545 jegs.com

Handlebar mount Mini-rocker switch assembly

Exact positioning may vary depending on ATV make and model.

It is recommended that the switch be installed on the left handlebar.

A piece of electrical tape around the handlebar will help prevent

rotation of mount on the handle bar. Do not tighten over any hoses or

cables. Once the handle bar switch is mounted, route the two bullet

terminal wires back to where the contactor will be mounted. Splice

the end of the red 20ga wire to key controlled electrical wire of the

ATV. Using a test light locate a suitable wire from the ATV key

switch. The wire should only have power when the key is in the "ON"

position.

Use a test light to locate a suitable wire.

1-800-345-4545 jegs.com

SAFETY PRECAUTIONS

WARNING - DO NOT EXCEED RATED CAPACITY.

WARNING - Intermittent use only.

WARNING - Do not use winch to lift or move people.

WARNING - A minimum of five wraps of cable around the drum barrel is necessary for pulling and holding the rated

load. The cable clamp is not designed to hold the load without 5 wraps of cable around the barrel.

WARNING - Keep yourself and others a safe distance to the side of the cable when under tension.

WARNING - The wire rope may break before the motor stalls. For heavy loads at or near rated capacity, use a pulley

block/snatch block to reduce the load on the wire rope.

WARNING - Never step over a cable, or near a cable under load.

WARNING –Do not move the vehicle to pull a load (towing) on the winch cable. This could result in cable breakage.

WARNING Disconnect the remote control and battery leads when not in use.

WARNING Do not exceed maximum pull rating. Avoid shock loads by using the control switch intermittently to take up

the slack in the wire rope. Shock loads can far exceed the rate capacity for the wire rope and drum.

WARNING - Do not exceed maximum line pull ratings. Shown on the tables.

WARNING - When re - spooling the cable, ensure that the cable spools in the under - wind position with the cable

entering the drum from the bottom, not the top. To re-spool correctly, and while wearing gloves, keep a slight load on

the cable while pushing the remote button to draw in the cable. Walk toward the winch not allowing the cable to slide

through your hands. Do not let your hands get within 12”of the winch while re-spooling. Turn off the winch and repeat

the procedure until a few feet of cable is left. Disconnect the remote control and finish spooling by hand by rotating the

drum by hand with the clutch disengaged. Keep hands clear of the fairlead and drum while the winch is under power.

Do not use as a hoist. Do not use for overhead lifting. Failure to heed these warnings may result in personal injury

and/or property damage.

CAUTION - Use gloves to protect hands when handling the cable. Never let the cable slide through your hands.

Apply blocks to the wheels of the vehicle when on an incline. No modifications, alterations, or deviation to the winch are

authorized by the manufacturer and should not be made. Duration of winching pulls should be kept as short as

possible. If the motor becomes uncomfortably hot to the touch, stop winching immediately and let is cool down for a few

minutes. Do not pull for more than one minute at or near the rated load.

CAUTION –If the motor stalls do not maintain power to the winch. Electric winches are designed and made of

intermittent use and should not be used in constant duty applications.

CAUTION- Never release the free-spool clutch when there is a load on the winch.

CAUTION - Use hand saver hook when handling the hook for spooling or un-spooling the wire rope.

GENERAL TIPS FOR SAFE OPERATION

The ATV3000 is rated at 3,000 lbs. capacity when spooling the first rope layer on the drum. Overloads can damage the

winch/motor/or wire rope. For loads over 50%. We recommend the use of the pulley block/snatch block to double the

wire rope line. This will aid in two ways, a) reduce the number or rope layers on the drum, as well as, b) reduce the load

on the wire rope by as much as 50%. When doubling the line back to the vehicle, attach to the frame or other load

bearing part.

The vehicle engine should be kept running during operation of the winch to minimize battery brain and maximize power

and speed of the winch. If the winch is used for a considerable time with the engine off the battery may be drained and

too weak to restart the engine.

Get to know your winch before you actually need to use it. We recommend that you set up a few test runs to familiarize

yourself with rigging techniques, the sounds your winch makes under various loads, the way the cable spools on the

drum, etc.

Inspect the wire rope and equipment before each use. A frayed or damaged rope shall be replaced immediately. Use

only manufacturer s identical replacement rope with the exact specifications.

Inspect the winch installation and bolts to ensure that all bolts are tight before each operation. Never connect the cable

back to itself. This will cause cable damage. Always use a snatch block, sling or chain of suitable strength as shown in

the illustrations.

Store the remote control inside your vehicle in a place that it will not be damaged.

Any winch that appears to be damaged in any way, is found to be worn, or operates abnormally SHALL BE REMOVED

FROM SERVICE UNTIL REPAIRED. It is recommended that the necessary repairs be made by a manufacturers’

authorized repair facility.

1-800-345-4545 jegs.com

Pull only on areas of the vehicle as specified by the vehicle manufacturer.

Only attachments and/or adapters supplied by the manufacturer shall be used.

RIGGING TECHNIQUES

Self-Recovery

Locate a suitable anchor such as a strong tree trunk or boulder.

Always use a sling as an anchor point.

CAUTION

Do not attach the clevis hook back onto cable as this could cause damage to

the cable. As shown in Fig 3.1

Do not winch from an acute angle as the wire rope will pole up on one side of

the drum causing damage to wire rope and the winch. Fig 3.2

Short pulls from an angle can be used to straighten the vehicle. Long pulls

should be done with the wire rope at a 90° angle to the winch/vehicle.

When pulling a heavy load, place a blanket or jacket over the wire rope five or six

feet from the hook. In the event of a broken cable it will dampen the snap back.

For additional protection open the hood of the vehicle as shown in Fig 3.3

For pulls over 1,000 lbs. we recommend the use of the snatch block/pulley block

to double line the wire rope. Fig 3.4 This reduces the load on the winch and the strain

on the rope by approximately 50%.

WARNING –Never use your winch for overhead hoisting or for lifting people or

moving people.

1-800-345-4545 jegs.com

INCHING TECHNIQUIES A-Z

a. Take time to assess your situation and plan your pull.

b. Put on gloves to protect your hands.

c. Disengage the clutch to allow free - spooling and also save battery power.

d. Attach the hand saver hook to the clevis hook.

e. Pull out the wire rope to your desired anchor point using the hand saver hook.

f. Secure the clevis hook to the anchor point sling, chain or snatch block. Do not attach the hook back onto the wire

rope.

g. Engage the clutch.

h. Connect the remote control to the winch.

i. Start your engine to ensure power is being replenished to the battery.

j. Power in the wire rope guiding the wire under tension to draw up the slack in the wire. Once the wire is under tension

stand well clear. Never step over the wire rope.

k. Double check your anchors and make sure all connections are secure.

l. Inspect the wire rope. Make sure there are at least 5 wraps of wire rope around the winch drum.

m. Drape a blanket or jacket over the wire rope approximately 5 to 6 feet from the hook. Open the hood for added

protection.

n. Clear the area. Make sure all spectators are well back and that no one is directly in front or behind the vehicle or

anchor point.

o. Begin winching. Be sure that the wire rope is winding evenly and tightly around the drum. The vehicle that is being

winched can be slowly driven to add assistance to the winching process. Avoid shock loads; keep the wire rope under

tension.

p. The vehicle to be winched should be placed in neutral and the emergency brake released. Only release the brake

pedal when under full tension. Avoid shock loads to the winch. This can damage the winch, rope and vehicle.

q. The winch is meant for intermittent use. Under full load with a single line rig do not power in for more than a minute

without letting the motor cool down for a few minutes and then resume the winching operation.

r. The winching operation is complete once the vehicle is on stable ground and is able to drive under its own power.

s. Secure the vehicle. Be sure to set the brakes and place the vehicle in park.

t. Release the tension on the wire rope. The winch is not meant to hold the vehicle for long periods of time.

u. Disconnect the wire rope from the anchor.

v. Rewind the wire rope. Make sure that any wire already on the drum has spooled tightly and neatly. If not, draw out

the wire and re-spool from the point where the rope is tight.

w. Keep your hands clear of the winch drum and fairlead as the wire rope is being drawn in.

x. Secure the hook and hook strap.

y. Disconnect the remote control and store in a clean, dry place.

z. Clean and inspect connections and mounting hardware for next winching operation.

1-800-345-4545 jegs.com

MAINTAINENCE

1. Periodically check the tightness of mounting bolts and electrical connections. Remove all dirt or corrosion and always

keep clean.

2. Do not attempt to disassemble the gear box. Repairs should be done by the manufacturer or an authorized repair

center.

3. The gear box has been lubricated using a high temperature lithium grease and is sealed at the factory. No internal

lubrication is required.

REPLACING THE WIRE ROPE

1. If the wire rope has become worn or is beginning to show signs of strands breaking it must be replaced before being

used again. To do this, remove the defective rope by free spooling. Remove the M5 x 5mm bolt on the drum and

release the rope.

2. Insert the end of new rope and secure the M5 x 5mm bolt tightly.

3. Engage the clutch and re-spool the new rope on the drum keeping tension on the rope as it spools. Ensure that the

rope is re-spooling in the under wind position.

WARNING - Only replace the wire rope with the identical replacement part recommended by the manufacturer.

SYMPTOM

POSSIBLE CAUSE

SUGGESTED ACTION

Motor does

not turn on

-Switch Assembly not

connected property

-Loose battery cable

connections

-Solenoid malfunctioning

-Defective Switch Assembly

-Defective motor

-Water has entered motor

-Insert Switch Assembly all the

way into the connector.

-Tighten nuts on all cable

connections.

-Tap solenoid to loosen contacts.

Apply 12volts to coil terminals

directly. A clicking indicates

proper activation.

-Replace Switch Assembly

-Check for voltage at armature

port with switch pressed. If

voltage is present replace motor.

-Allow to drain and dry. Run in

short bursts without load until

completely dry.

Motor runs but

cable drum

does not turn

-Cam Ring (clutch)

not engaged

-Move Cam Ring to the in

position. If problem persists, a

qualified technician needs to check

and repair.

Motor runs

slowly or

without normal

power

-Insufficient current or

voltage

-Battery weak, recharge. Run

winch with vehicle motor running.

-Loose or corroded battery cable

connections. Clean, tighten, or

replace

Motor

overheating

-Winch running time too

long

-Allow winch to cool down

periodically.

Motor runs in

one direction

only

-Defective or stuck

Solenoid

-Defective Switch

Assembly

-Tap solenoid to loosen contacts.

-Repair or replace solenoid.

-Replace Switch Assembly

TROUBLESHOOTING

1-800-345-4545 jegs.com

Table of contents

Popular Winch manuals by other brands

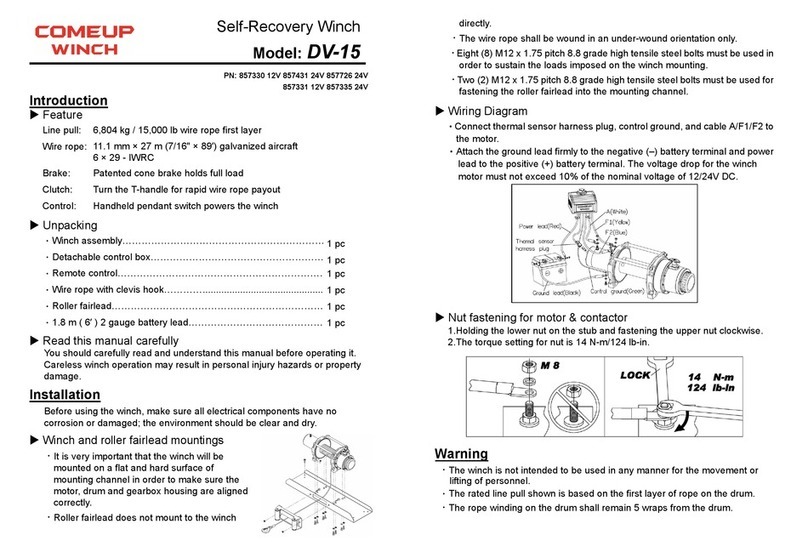

Come.up Winch

Come.up Winch GTD-800 manual

Come.up Winch

Come.up Winch GIO 80 manual

AWD

AWD AWD0907A instruction manual

Tuff-Built

Tuff-Built Best Hoist 60138 Operation & maintenance manual

Runva

Runva T-2000 Assembly & operating instructions

Warrior Winches

Warrior Winches 95SPS12 Assembly & operating instructions

Clas Ohlson

Clas Ohlson 30-6217 quick start guide

Harken

Harken Powered Performa Winch 70.2 STP EL Installation and maintenance manual

Comeup

Comeup CWL-200L quick start guide

Warrior Winches

Warrior Winches 20YPSHY-CAD owner's manual

Harken

Harken LokHead 500 KIT.US instruction manual

GEBUWIN

GEBUWIN WW2000 /D Series operating instructions