Come.up Winch DV-15 User manual

Other Come.up Winch Winch manuals

Come.up Winch

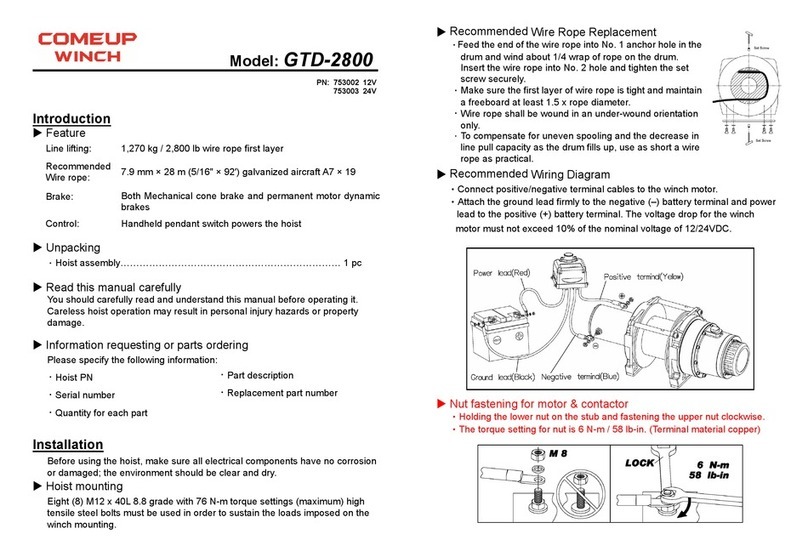

Come.up Winch GTD-2800 User manual

Come.up Winch

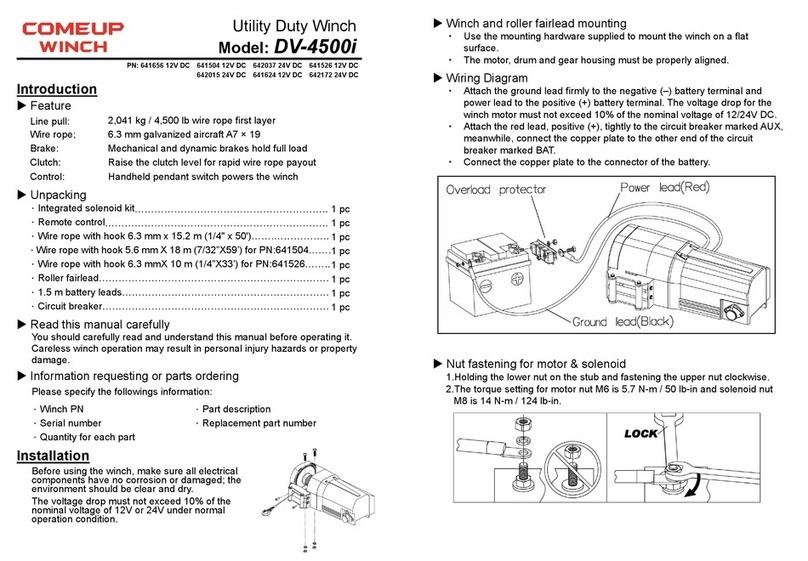

Come.up Winch DV-4500i User manual

Come.up Winch

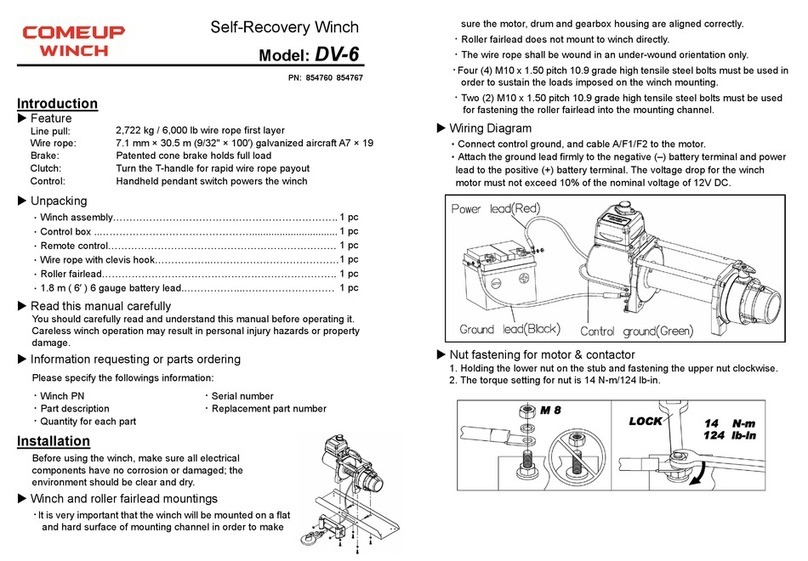

Come.up Winch DV-6 User manual

Come.up Winch

Come.up Winch Seal Slim 9.5rs User manual

Come.up Winch

Come.up Winch DV-2500i User manual

Come.up Winch

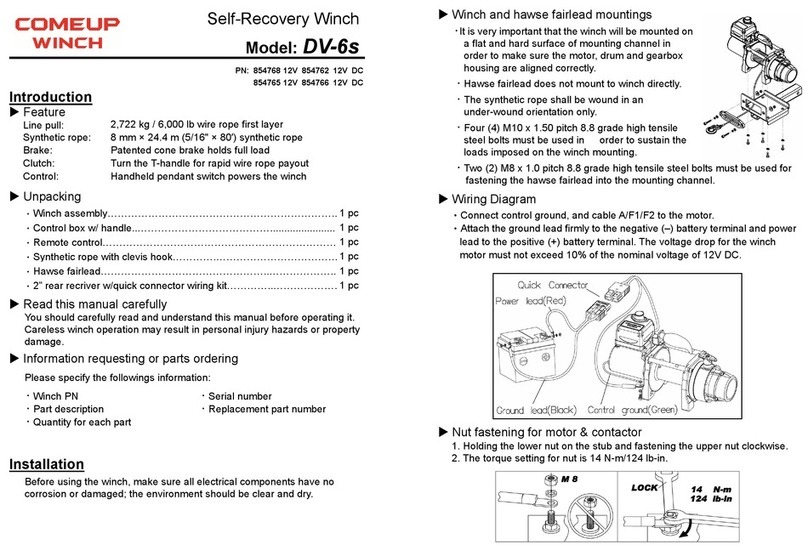

Come.up Winch DV-6s User manual

Come.up Winch

Come.up Winch GIO 100 User manual

Come.up Winch

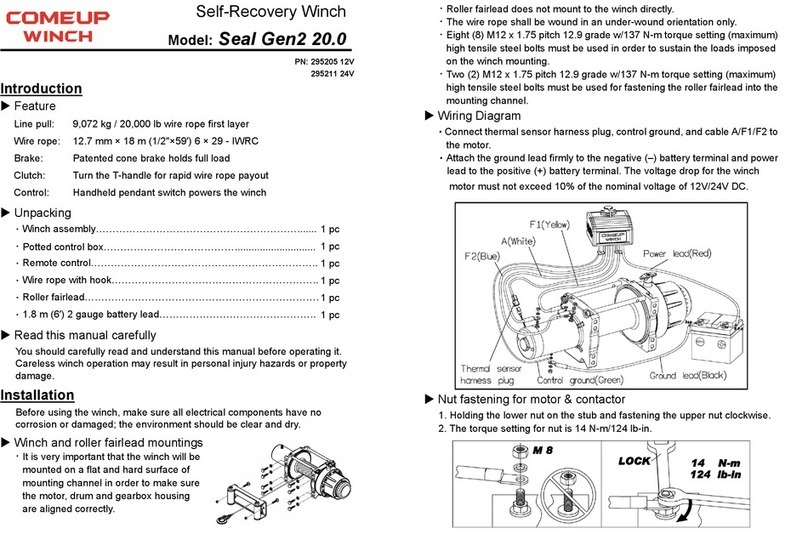

Come.up Winch Seal Gen2 20.0 User manual

Come.up Winch

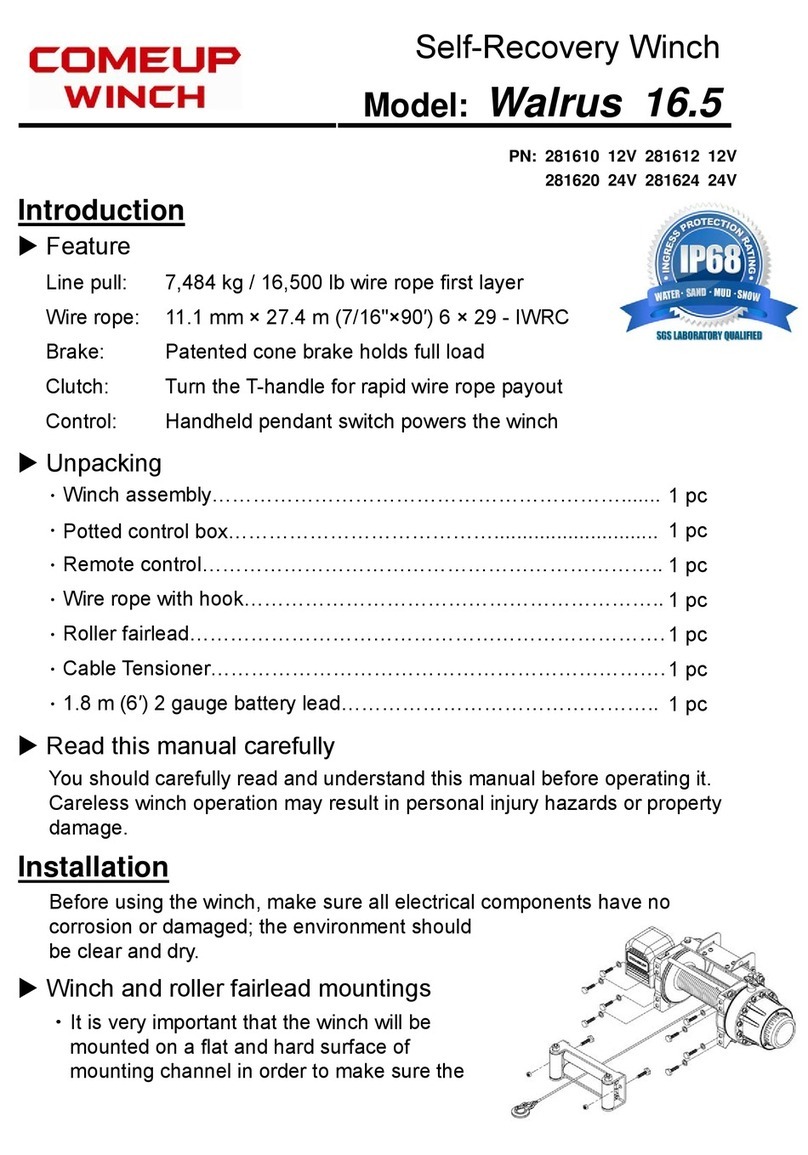

Come.up Winch Walrus 16.5 User manual

Come.up Winch

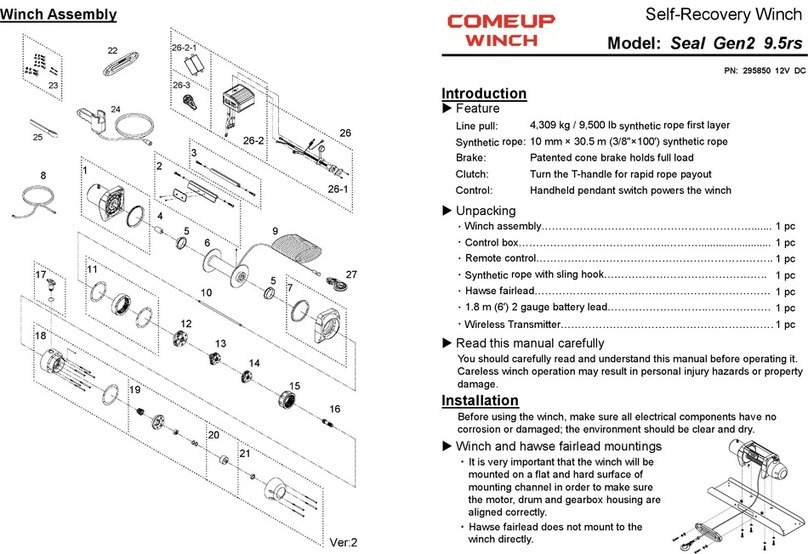

Come.up Winch Seal Gen2 16.5rs User manual

Come.up Winch

Come.up Winch 295750 12V User manual

Come.up Winch

Come.up Winch GTD-650 User manual

Come.up Winch

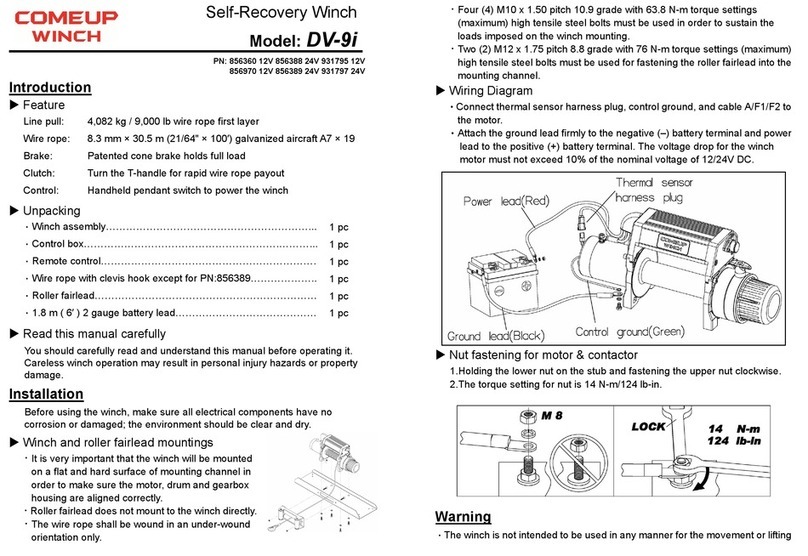

Come.up Winch DV-9i User manual

Come.up Winch

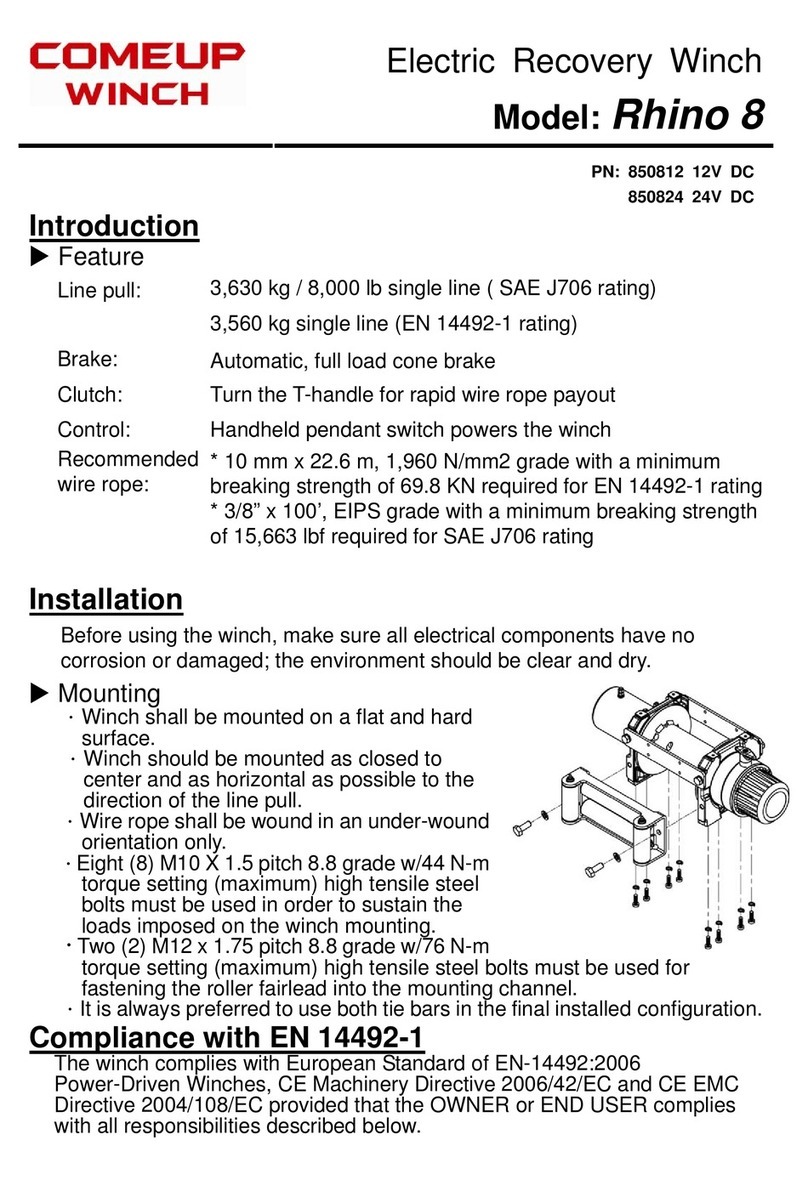

Come.up Winch Rhino 8 User manual

Come.up Winch

Come.up Winch GIO 80 User manual

Come.up Winch

Come.up Winch Seal Gen2 12.5rs User manual

Come.up Winch

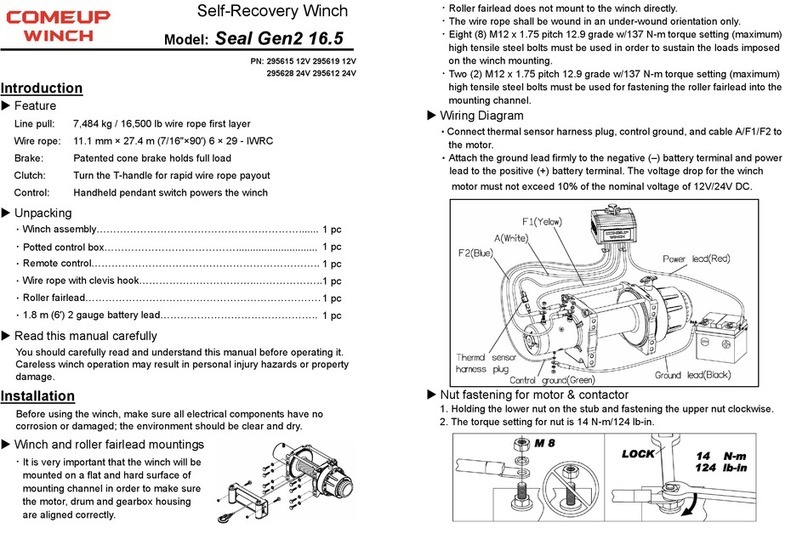

Come.up Winch Seal Gen2 16.5 User manual

Come.up Winch

Come.up Winch DV-9s User manual

Come.up Winch

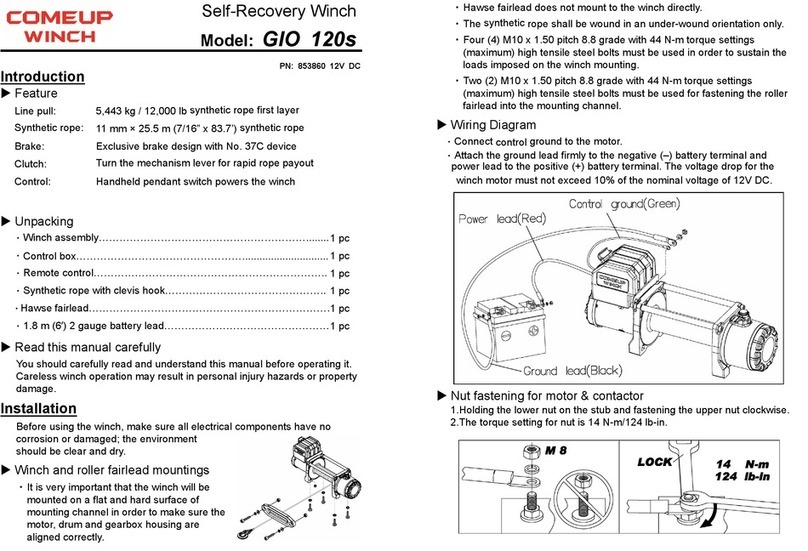

Come.up Winch GIO 120s User manual

Come.up Winch

Come.up Winch Rhino 8 Pro User manual

Popular Winch manuals by other brands

Comeup

Comeup DV-9 manual

Orvea

Orvea Italwinch 805 Installation and user manual

Prowinch

Prowinch PWJTHF300 user manual

Clas Ohlson

Clas Ohlson LD2000-A manual

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual