320.805.004 2 Date: 2022-02-09

The following symbols are used to identify important safety information on the product an in this manual:

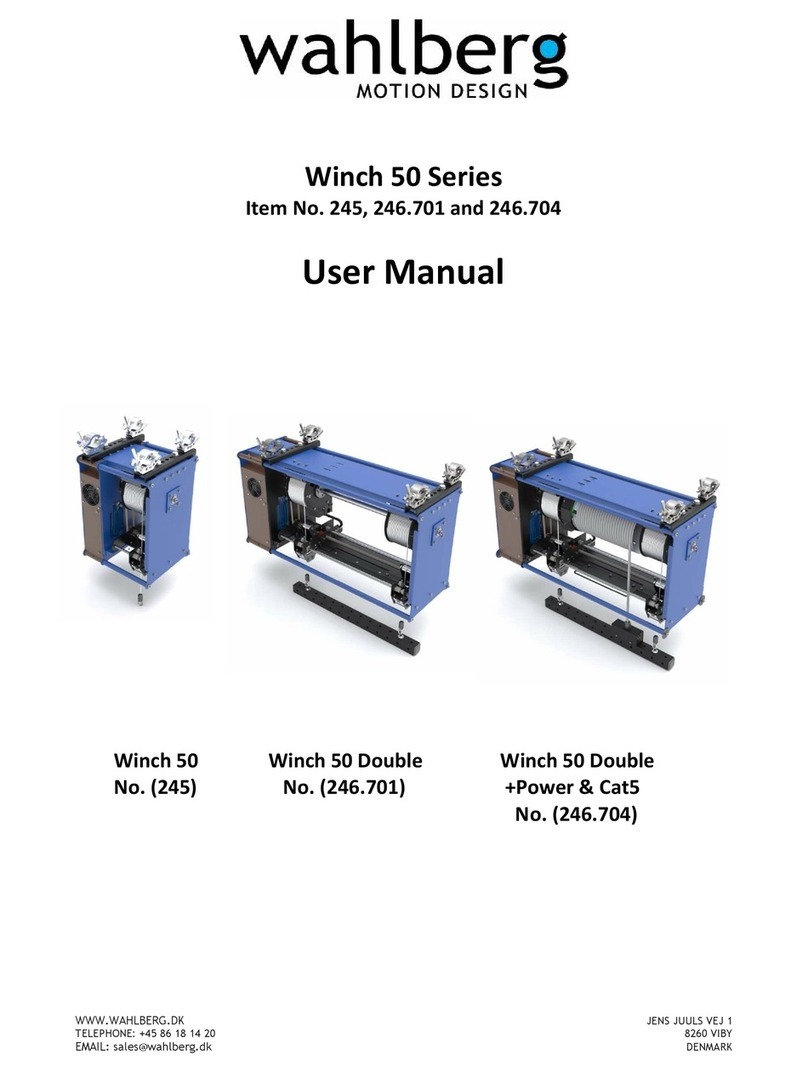

This product is for professional use only. It is not for household use.

This product presents risks for severe injury or death due to fire hazards, electric shock, and falls.

Read this manual before installing, powering or servicing the product; follow the safety precautions listed

below and observe all warnings in this manual and printed on the product. If you have questions about how

to operate the product safely, please contact you Wahlberg Motion Design supplier or Wahlberg Motion

Design. Use only genuine Wahlberg Motion Design parts or parts approved by Wahlberg Motion Design.

PROTECTION FROM ELECTRIC SHOCK

Before using the product, check that all power distribution equipment and cables are in perfect

condition and rated for the current requirements of all connected devices.

Select a suitable power plug converter supplied with the product.

Isolate the battery and charger from power immediately if any seal, cover, cable, or other

component is damaged, defective, deformed, wet, or showing signs of overheating. Do not reapply

power until repairs have been completed.

Refer any service operation not described in this manual to a qualified technician.

PROTECTION FROM BURNS AND FIRE

Do not operate the product if the ambient temperature (Ta) exceeds 40° C (104° F).

The exterior of the motors becomes warm during use. Avoid contact by persons and materials.

Do not modify the product in any way not described in this manual.

PROTECTION FROM INJURY

Always secure the load on the platform and make sure it is within the weight limit and centered.

Ensure that the surface is flat and clean before using the platform.

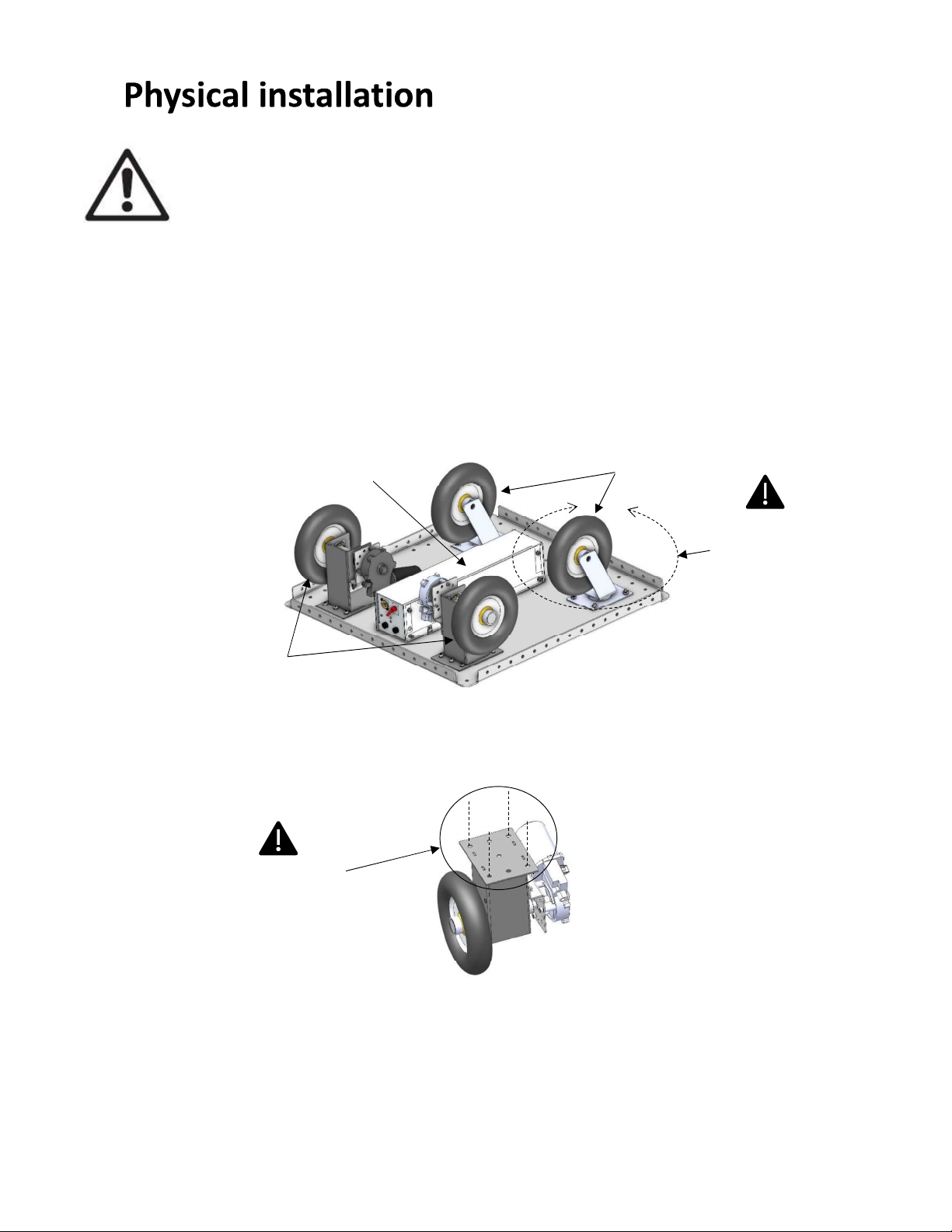

Always install the product as described in this manual.

Do not operate the product with missing or damaged covers, or shields.

Disposing of this product

Wahlberg Motion Design products are supplied in compliance with Directive

2012/19/EU of the European Parliament and of the Council of the European

Union on WEEE (Waste Electrical and Electronic Equipment), including

amendments where applicable.

Help preserve the environment! Ensure that this product is recycled at the

end of its life. Your supplier can give details of local arrangements for the

disposal of Wahlberg Motion Design products.