Best Hoist Material Winch

Operation and Maintenance Manual

4

135062 rev01, 31AUG2020

2.0. INTRODUCTION to WINCH APPLICATIONS

Congratulations on your purchase of a Best Hoist Material Winch.

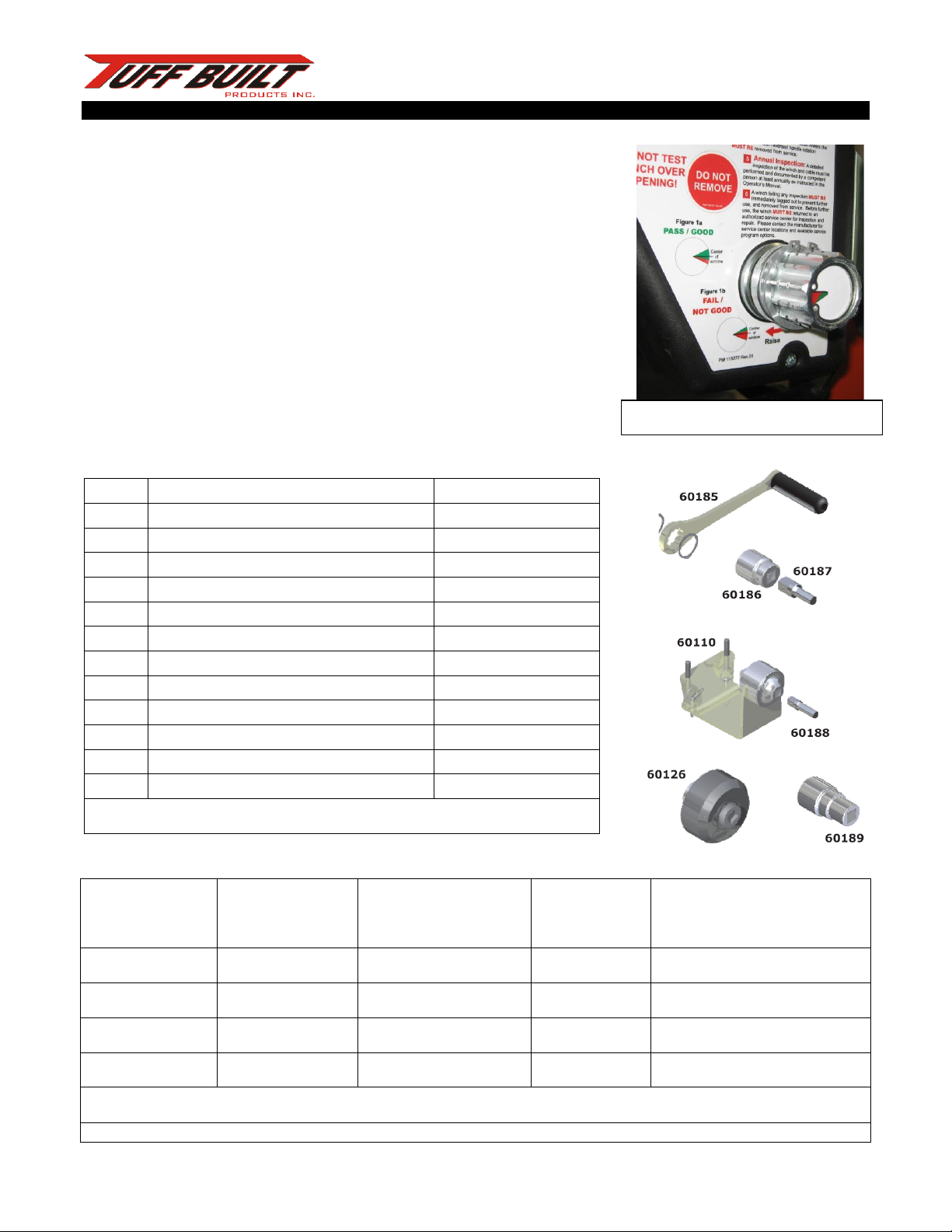

Pro-Series winches combine many advanced safety features, easy to read visual brake wear indicator, visual overload

indicator integral to the snap hook, and optional usage indicator.

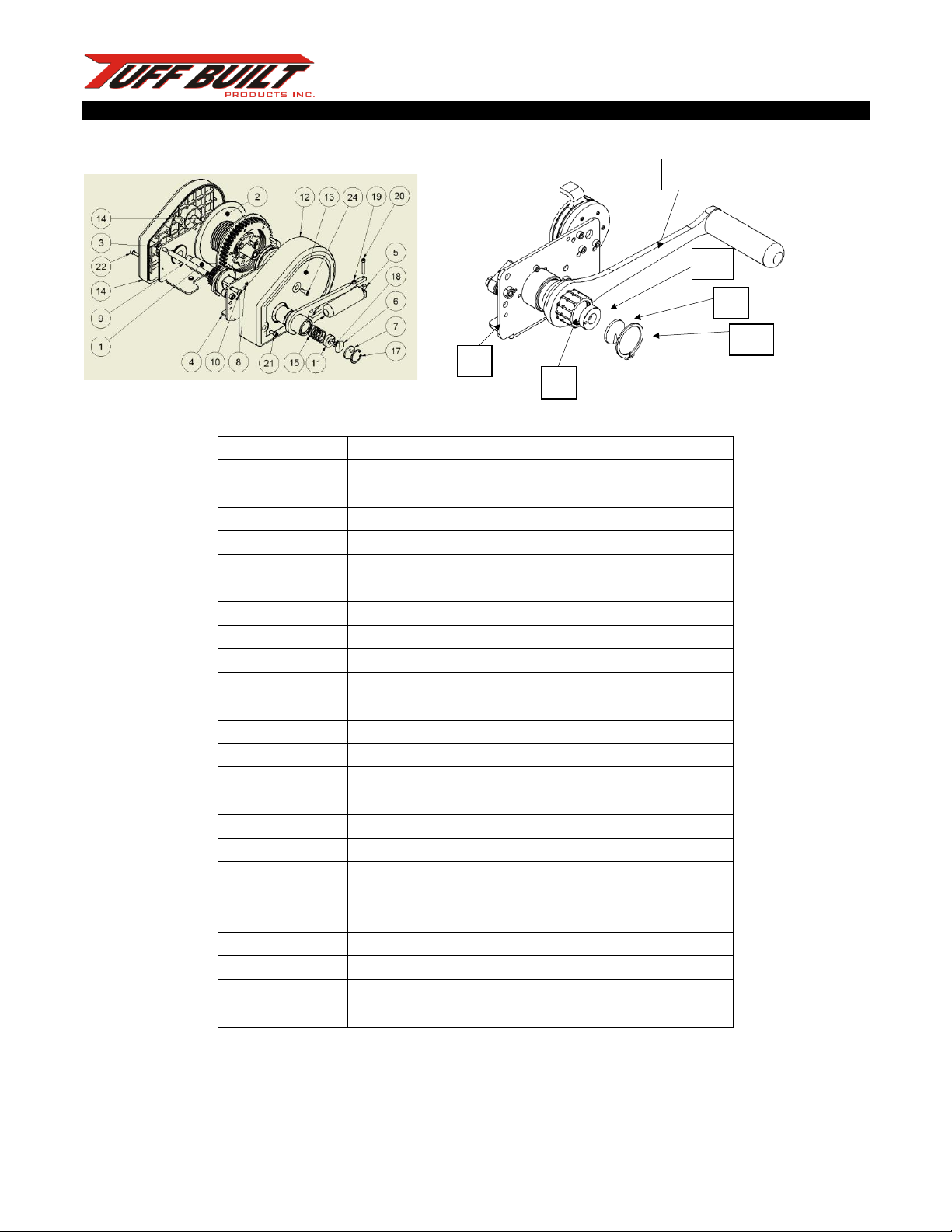

Some versions of these winches feature a unique drive input hub design which allows the winch to be easily switched from

a manual crank to various power drive options to allow the winch to be driven with different types of corded and cordless

power hand drills (See Section 6 for further information on Power Drive options).

The winch may be equipped with a variety of winch line options including, stainless or galvanized steel cable in various

diameters, and ropes in various diameters and constructions to meet your specific job requirements.

This product has been specifically designed and carefully manufactured to provide reliable operation in many different

safety-at-heights applications. These include, but are not limited to:

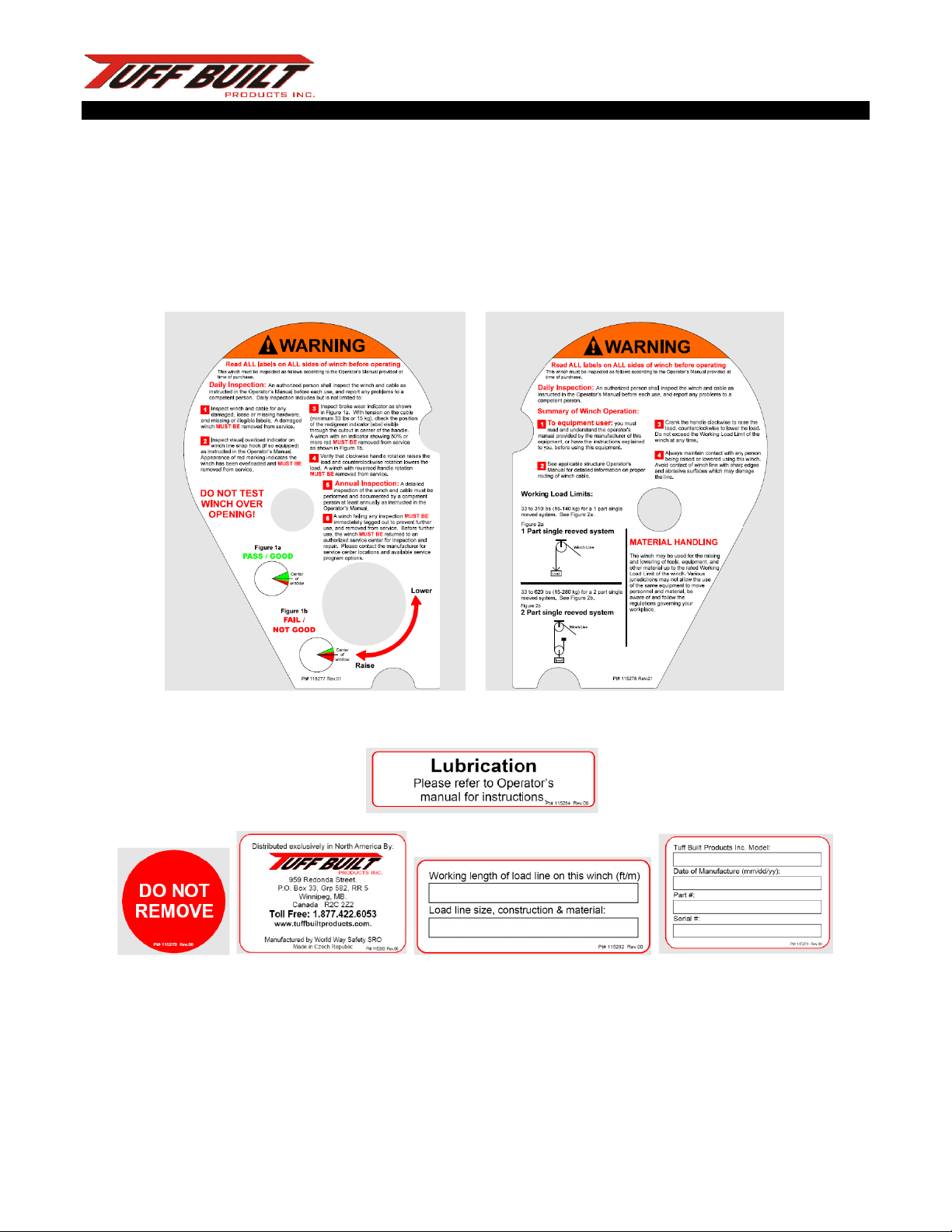

2.5 MATERIAL HANDLING

The winch may be used for the raising and lowering of tools, equipment, and other material not exceeding the rated

Working Load Limit of the winch. Be aware of and follow the regulations governing your workplace.

3. APPLICATION RESTRICTIONS

There are restrictions and limitations that must be carefully considered in the selection, installation, and operation of this

winch. Serious injury or death may result from failure to consider these factors.

3.1 WORKING LOAD LIMIT

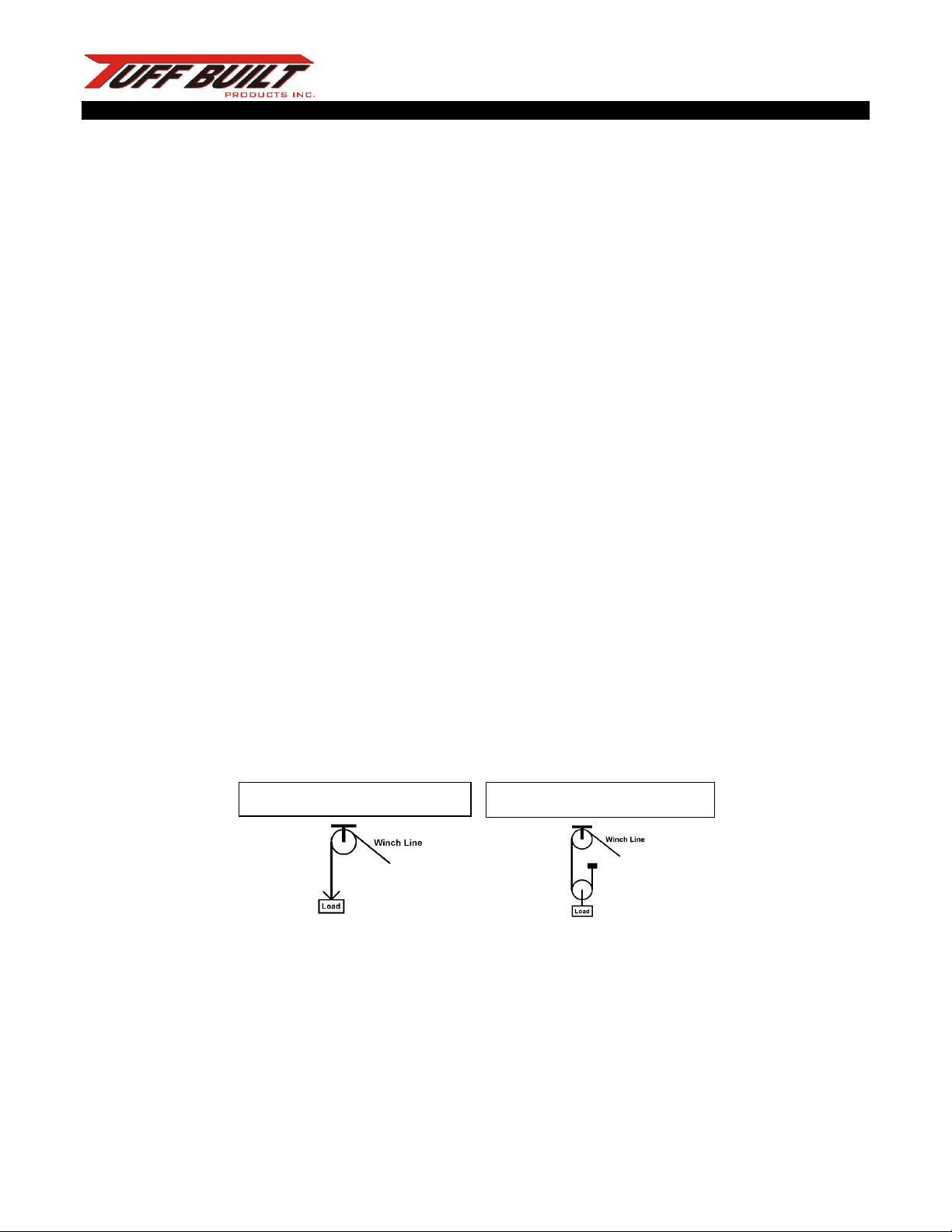

This winch is designed and rated to a working load of 400 lbs (181 kgs) when used in a 1 Pulley Single Reeved System, or a

maximum of 800 lbs (363 kgs) when used in a 2 Pulley Single Reeved System (see Figure 2).

Figure 2, 1 & 2Pulley Single Reeved Systems

Please refer to the Operator’s Manual(s) for all other accessories in the system to determine which reeving option(s) are

applicable to the system.

Note: Please be aware that a 2 Pulley Single Reeved System is rated for a higher working load limit, but that

raising/lowering speed is only half that of a 1 Pulley Single Reeved System.

Ensure that all other system components have a working load limit matching that of the winch. System rating is equal to

that of the lowest rated system component.