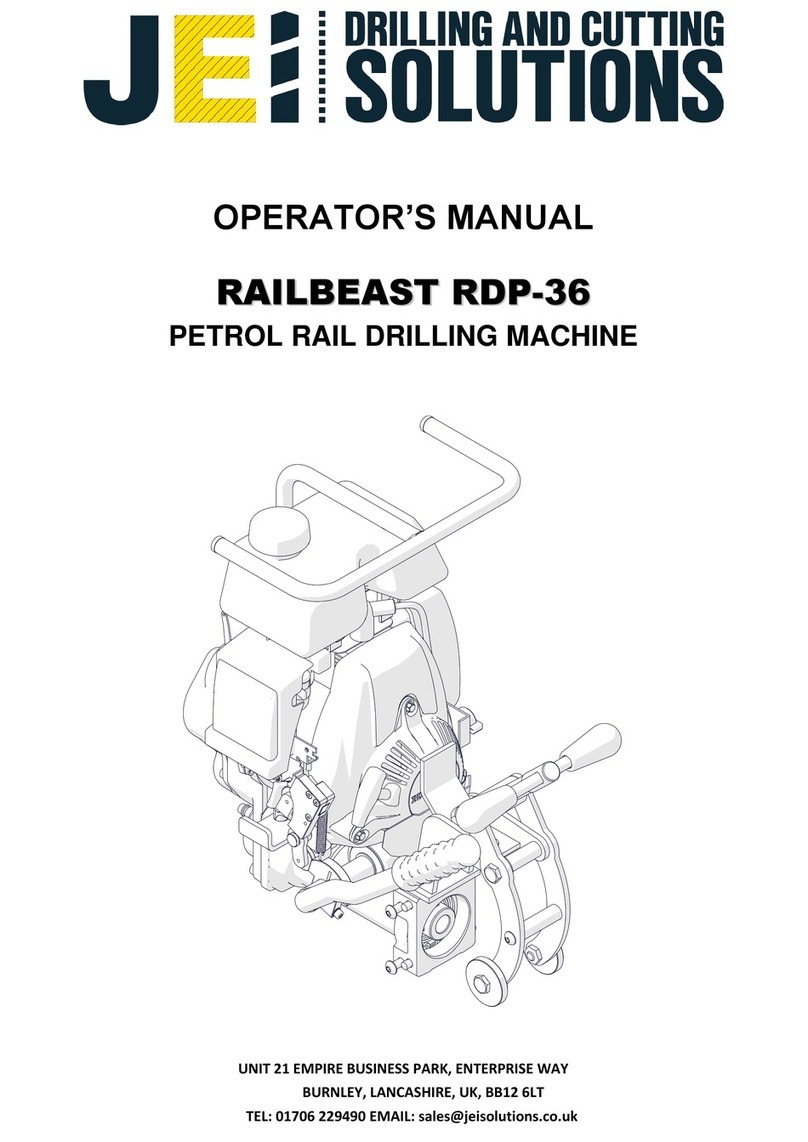

JEI DRILLING & CUTTING SOLUTIONS RAILBEAST RDE-36 User manual

UNIT 21 EMPIRE BUSINESS PARK, ENTERPRISE WAY

BURNLEY, LANCASHIRE, UK, BB12 6LT

TEL: 01706 229490 EMAIL: sales@jeisolutions.co.uk

OPERATOR’S MANUAL

ELECTRIC RAIL DRILLING MACHINE

R

RA

AI

IL

LB

BE

EA

AS

ST

T

R

RD

DE

E-

-3

36

6

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

1.4. Dimensions................................................................................................................ 5

1.5. Design ....................................................................................................................... 5

2. SAFETY PRECAUTIONS.................................................................................................. 6

3. STARTUP AND OPERATION........................................................................................... 8

3.1. Installing and removing the annular cutter.................................................................. 8

3.2. Installing and removing the rail profile templates........................................................ 9

3.3. Installing and removing the hole center positioner.....................................................10

3.4. Clamping the machine onto the rail and unclamping.................................................11

3.5. Connecting and disconnecting the cooling system....................................................12

3.6. Drilling.......................................................................................................................13

3.7. Replacing the motor brushes ....................................................................................15

4. ACCESSORIES...............................................................................................................16

4.1. Pressure cooling system with adapter.......................................................................16

4.2. Rail profile templates.................................................................................................18

4.3. Hole center positioners .............................................................................................19

5. DECLARATION OF CONFORMITY.................................................................................20

6. WARRANTY CARD..........................................................................................................21

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

3

1. GENERAL INFORMATION

1.1. Application

The RAILBEAST RDE-36 is a drilling machine designed to drill holes in rails of

UIC54, UIC60, P50, P65, S49, or any other standard. The machine can drill holes

with diameters of 36 mm (1.42″) by using annular cutters.

Ordered separately rail profile templates allow the machine to be clamped onto a

rail. Hole center positioners allow you to get the correct span between holes.

1.2. Technical data

Voltage

1~ 220–240 V, 50–60 Hz

1~ 110–120 V, 50–60 Hz

Power

1020 W

Tool holder

19 mm (3/4″) Weldon

Maximum drilling diameter

36 mm (1.42″)

Maximum drilling depth

30 mm (1.18″)

Stroke

40 mm (1.57″)

Rotational speed with no load

520 rpm

Rotational speed with load

350 rpm

Protection level

IP 20

Protection class

I

Noise level

More than 70 dB

Vibration level

1.55 m/s2(5.1 ft/s2)

Required ambient temperature

0–40°C (32–104°F)

Weight

14.5 kg (32 lbs)

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

4

1.3. Equipment included

1

RAILBEAST RDE-36 drilling machine

1 unit

2

Plastic box

1 unit

3

Handle

3 units

4

Cooling system

1 unit

5

4 mm hex wrench with a handle

1 unit

6

5 mm hex wrench with a handle

1 unit

–

Operator’s Manual

1 unit

6

1

2

5

4

3

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

5

1.4. Dimensions

1.5. Design

Pressing screw

MOTOR start

Carrying handle

POWER switch

Feed shaft

MOTOR stop

Arbor

558 mm (22″)

213 mm (8.4″)

361 mm (14.2″)

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

6

2. SAFETY PRECAUTIONS

1. Before use read this Operator’s, Manual and complete a training in occupational

safety and health.

2. Use only in applications specified in this Operator’s Manual.

3. Make sure that the machine has all parts and they are genuine and not damaged.

4. Make sure that the specifications of the power source are the same as those

specified on the rating plate.

5. Do not carry the machine by the power cord and do not pull the cord. This can

cause damage and electric shock.

6. Transport and position the machine by using the carrying handle.

7. Keep untrained bystanders away from the machine.

8. Before each use, make sure the correct condition of the machine, power source,

power cord, plug, control panel, and tools.

9. Before each use, make sure that no part is cracked or loose. Make sure to main-

tain correct conditions that can have an effect on the operation of the machine.

10. Before starting, make sure that the rail profile templates installed agree with the

rail standard.

11. Use the correct coolant for the ambient temperature.

12. Keep the machine dry. Do not expose the machine to rain, snow, or frost.

13. Keep the work area well lit, clean, and free of obstacles.

14. Make sure that the tool is correctly attached. Remove wrenches from the work

area before you connect the machine to the power source.

15. Do not use tools that are dull or damaged.

16. Unplug the power cord before you install and remove tools. Use protective gloves

to install and remove tools.

17. Do not make holes whose diameter or depth differ from those specified in the

technical data.

18. Do not use near flammable materials or in explosive environments.

19. Use eye and ear protection and protective clothing. Do not use loose clothing.

20. Do not touch chips or moving parts. Do not let anything catch in moving parts.

21. After each use, remove chips and coolant from the machine and the tool. Do not

remove chips with bare hands.

22. Unplug the power cord before you do maintenance or install/remove parts.

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

7

23. Repair only in a service center appointed by the seller.

24. If the machine falls, is wet, or has any damage, stop the work and immediately

send the machine to the service center for check and repair.

25. Do not leave the machine when it operates.

26. If you are not going to use the machine, remove the tool from the holder. Then,

remove the machine from the work area and keep it in a safe and dry place.

27. If you are not going to use the machine for an extended period, put anti-corrosion

material on the steel parts.

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

8

3. STARTUP AND OPERATION

3.1. Installing and removing the annular cutter

With the motor stopped, turn the handles (1) to move out the arbor. Install the arbor

as described before. Use gloves to put the correct pilot pin into the annular cutter (2).

Use a dry cloth to clean the cutter. Put the cutter into the arbor (3) to align the flat

surfaces (4) with the screws (5). Use the 4 mm hex wrench to tighten the screws.

To remove the cutter, loosen the screws (5) with the 4 mm hex wrench.

3

5

4

1

2

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

9

3.2. Installing and removing the rail profile templates

Select rail profile templates (not included) that agree with the rail standard. Put the

templates on the pins. Use the 6 mm hex wrench to tighten the screws.

To remove the templates, use the 6 mm hex wrench.

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

10

3.3. Installing and removing the hole center positioner

Select a hole center positioner (not included) that agrees with the rail standard, and

loosen the levers (1). Put the positioner onto the rail (2) so that the positioner face

aligns with the rail face (3). Lock the levers in this position. Next, use the 6 mm hex

wrench to tighten the screws (4) so that the positioner clamps onto the rail (5).

To remove the positioner, loosen the screws (4)and levers (1).

2

4

5

1

Clamped

Unclamped

3

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

11

3.4. Clamping the machine onto the rail and unclamping

Put the machine onto the rail (1). Make sure that the locating pin is in the first groove

of the hole center positioner (2) and the pressing screw is in the resisting socket (3).

Then, tighten the screw (4) to clamp the machine onto the rail.

To unclamp the machine, loosen the pressing screw.

1

4

2

3

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

12

3.5. Connecting and disconnecting the cooling system

Make sure that the bar of the frame is between the pin and the fitting (1). Next, attach

the cooling system to the fitting (2), and then fill the bottle with a coolant. Do not use

only water as the coolant. But you can mix water and drilling oil. Before you drill,

press the lever (3) several times. Press and release the lever during work to supply

the coolant.

To disconnect, pull out the hose from the fitting.

2

3

1

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

13

3.6. Drilling

Set the power switch to ‘I’. Then, press the green MOTOR button to start the motor.

Slowly turn the handles (1) to move out the cutter and start drilling.

When the annular cutter goes through the workpiece, the slug core is

pushed out with a large force.

1

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

14

After you drill the first hole, turn the handles opposite to (1), to retract the cutter.

Unclamp the machine as described before. Next, clamp the machine onto the rail in

the next groove of the hole center positioner, and make a next hole.

Continue as described until all holes are made. After the work is finished, press

the red MOTOR button to turn off the motor. Then, set the power switch to ‘O’ to turn

off the power.

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

15

3.7. Replacing the motor brushes

Every 100 work hours, check the condition of the brushes. To do this, unplug the

power cord and remove the motor cover (1). Next, remove the pressing plate (2), and

then remove the brush holder (3) and the brush (4). If the brush is shorter than 5 mm

(0.2″), replace the two brushes with new ones.

Install in reverse sequence. Then, let the motor operate with no load for

20 minutes.

1

2

3

4

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

16

4. ACCESSORIES

4.1. Pressure cooling system with adapter

Capacity of 5 liters.

Part number:

PJM-0676-10-00-00-0

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

17

Make sure that the bar of the frame is between the pin and the fitting (1). Connect the

cooling system with the adapter to the fitting (2, 3). Open the valve (4). Next, turn the

handle (5). Move the handle up-down several times to increase the pressure in the

bottle.

To remove, close the valve (4). Pull up the release valve (6) to release excess

pressure, and then pull out the adapter from the fitting.

6

3

2

4

5

1

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

18

4.2. Rail profile templates

Other templates available on request.

UIC54 templates:

RAIL-TEMPUIC54

UIC60 templates:

RAIL-TEMPUIC60

P50 templates:

RAIL-TEMPP50

P65 templates:

TAIL-TEMPP65

S49 templates:

RAIL-TEMPS49

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

19

4.3. Hole center positioners

Other positioners available on request.

UIC54 positioner:

RAIL-POSUIC54

UIC60 positioner:

RAIL-POSUIC60

P50 positioner:

RAIL-POSP50

P65 positioner:

RAIL-POSP65

S49 positioner:

RAIL-POSS49

WWW.JEIUK.COM RAILBEAST ELECTRIC RDE-36

This document is protected by copyrights.

Copying, using, or distributing without permission of Ansa Group Ltd is prohibited.

20

5. DECLARATION OF CONFORMITY

Declaration of Conformity

JEI DRILLING & CUTTING SOLUTIONS LTD

UNIT 21 EMPIRE BUSINESS

ENTERPRISE WAY

BURNLEY, LANCASHIRE, BB12 6LT

We declare with full responsibility that:

RAILBEAST RDE-36 ELECTRIC RAIL DRILLING MACHINE

is manufactured in accordance with the following standards:

•EN 60745-1

•EN 55014

•EN ISO 12100

and satisfies regulations of the guidelines: 2014/30/UE, 2014/35/UE, 2006/42/UE,

2011/65/UE, 2012/19/UE.

Person authorized to compile the technical file:

David McFadden, Unit 21 Empire Business Park,

Burnley

Burnley, 3 September 2019 ___________________________

David McFadden

Managing Director

Table of contents

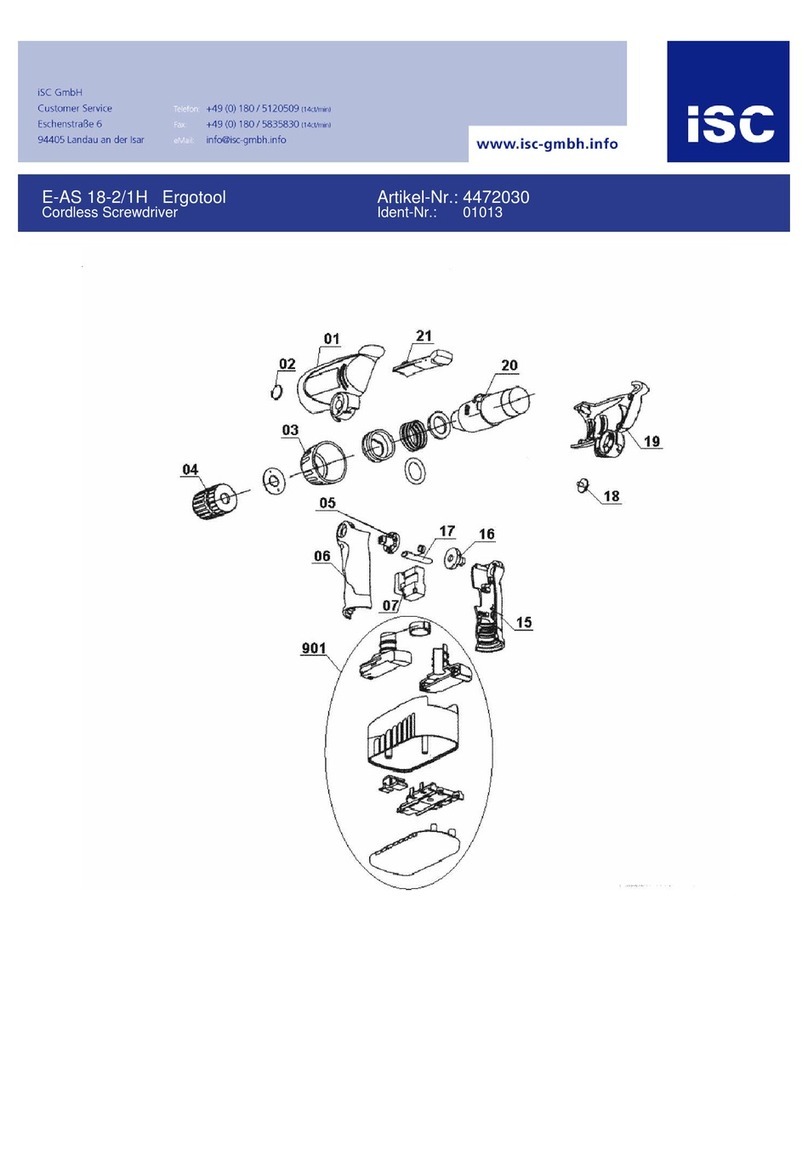

Other JEI DRILLING & CUTTING SOLUTIONS Drill manuals

Popular Drill manuals by other brands

Hilti

Hilti TE 3-ML operating instructions

EINHELL

EINHELL TE-RH 38 E Original operating instructions

Black & Decker

Black & Decker 1941 owner's manual

DeWalt

DeWalt D21570 Original instructions

EINHELL

EINHELL TC-RH 800 E Original operating instructions

101 Sampling Solutions

101 Sampling Solutions 2100R Operation & maintenance manual