Jepson SHDC 8320 User manual

EN Operating instructions 03 - 20

DE Betriebsanleitung 21 - 40

FR Mode d’emploi 41 - 60

NL Handleiding 61 - 80

ES Instrucciones de servicio 81 - 100

PT Instruções de utilização 101 - 118

IT Istruzioni per l’uso 119 - 137

Certicates 138 - 139

METAL CUTTING CIRCULAR SAW

SHDC 8320 | HDC 8230N | HDC 8200

EN METAL CUTTING CIRCULAR SAW

DE METALLKREISSÄGE

FR SCIE CIRCULAIRE A COUPE DE MÉTAL

NL METAAL CIRKELZAAG

ES SIERRA CIRCULAR PARA CORTE DE METALES

PT SERRA CIRCULAR DE CORTE DE METAL

IT SEGA CIRCOLARE PER IL TAGLIO DEI METALLI

2

EN

DE

FR

NL

ES

PT

IT

GENERAL 4

1. EC DECLARATION OF CONFORMITY SHDC 8320 4

2. EC DECLARATION OF CONFORMITY HDC 8230 & HDC 8200 4

3. SPECIFICATIONS 5

4. USER INSTRUCTIONS 5

5. SAFETY INSTRUCTIONS 6

5.1. ILLUSTRATION OF SAFETY INSTRUCTIONS 6

5.2. GENERAL SAFETY INSTRUCTIONS 6

5.3. SPECIFIC SAFETY RULES 8

SUPER HAND DRY CUTTER 8320 10

6. DESCRIPTION 10

7. FUNCTIONAL DESCRIPTION 11

7.1. INTENDED USE 11

7.2. ELECTRICAL CONNECTION 11

7.3. EXTENSION CABLE 11

7.4. SAW BLADE 11

7.5. UNPACKING 11

7.6. INSTALLING THE SAW BLADE 11

7.7. REMOVING THE BLADE 12

7.8. ADJUST CUTTING DEPTH 12

7.9. USE OF SIGHTING NOTCH 12

7.10. BLADE GUARD 12

7.11. DUST COLLECTION SYSTEM 12

8. START AND STOP OFTHE MACHINE 13

8.1. SWITCHING THE MACHINE ON AND OFF 13

8.2. ELECTRONIC OVERLOAD PROTECTION AND LOAD INDICATOR LIGHT 13

8.3. USE OF THE MACHINE 13

8.4. CUTTING GUIDE 14

9. MAINTENANCE AND REPAIR 14

9.1. KEEP TOOL CLEAN 14

9.2. REPLACEMENT OF CARBON BRUSHES 14

9.3. STANDARD ACCESSORIES 14

HAND DRY CUTTER 8230N | 8200 15

10. DESCRIPTION 15

11. APPLICATION 16

12. FUNCTIONAL DESCRIPTION 16

12.1. UNPACKING 16

12.2. CARTON CONTENTS 16

12.3. INSTALLING THE BLADE 16

12.4. REMOVING THE BLADE 17

12.5. ADJUSTMENT DEPTH OF CUT 17

12.6. ADJUSTMENT OF BEVEL ANGLE 17

12.7. HOW TO USE THE SIGHTING NOTCH 17

12.8. STARTING AND STOPPING TOOL 17

12.9. REMOVING CHIPS 17

12.10. HOW TO USE THE RIP FENCE 17

12.11. LOWER RETRACTING BLADE GUARD 17

12.12. HOW TO USE THE TOOL 18

12.13. CLAMP THE WORK PIECE 18

13. MAINTENANCE 18

13.1. KEEP TOOL CLEAN 18

13.2. THE CARBON BRUSHES 18

13.3. WARNING 18

13.4. STANDARD ACCESSORIES 18

GENERAL 19

14. QUOTATION 19

15. SPARE PARTS 19

16. WARRANTY 19

TABLE OF CONTENTS

3

GENERAL

1. EC DECLARATION OF CONFORMITY SHDC 8320

(according to Appendix IIA of the machine Directive)

We, Jepson Power GmbH, Ernst – Abbe – Straße 5, 52249 Eschweiler, Germany, as the manufacturer

declare herewith under our responsibility that the product:

Name: Super Hand Dry Cutter SHDC 8320

Manufacturing date: See machine label

Serial number: See machine label

complies with the following standards, directives and referenced standard documents:

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

2014/65/EU RoHS Directive

EN 62841-1 :2015 EN 61000-3-2:2014

EN 62841-2-5:2014 EN 61000-3-3:2013

EN 55014-1 :2017

EN 55014-2:2015

Pierre Michiels, Managing Director

Name, Position Eschweiler, 01.08.2021

2. EC DECLARATION OF CONFORMITY HDC 8230 & HDC 8200

(according to Appendix IIA of the machine Directive)

We, Jepson Power GmbH, Ernst – Abbe – Straße 5, 52249 Eschweiler, Germany, as the manufacturer

declare herewith under our responsibility that the product:

Name: Hand Dry Cutter HDC 8230N | Hand Dry Cutter HDC 8200

Manufacturing date: See machine label

Serial number: See machine label

complies with the following standards, directives and referenced standard documents:

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

EN 60745-1 :2009+A11 :2010 EN 55014-2 :1997+A1 :2001+A2 :2008

EN 60745-2-5 :2010 EN 61000-3-2 :2006+A1 :2009+A2 :2009

EN 62233 :2008 EN 61000-3-3 :2008

EN 55014-1 :2006+A1 :2009+A2 :2011

Pierre Michiels, Managing Director

Name, Position Eschweiler, 01.08.2021

GENERAL

4

EN

DE

FR

NL

ES

PT

IT

3. SPECIFICATIONS

Machine SHDC 8320 HDC 8230N HDC 8200

Voltage (see machine label) 230 V / 50 Hz

110 V / 60 Hz

230 V / 50 Hz

110 V / 60 Hz

230 V / 50 Hz

No load speed 1.700 rpm 2.200 rpm 3.700 rpm

Power input 1.800 W 1.700 W 1.700 W

Max. saw blade diameter 320 mm | 12 5/8” 230 mm | 9” 203 mm | 8”

Bevel capability 0° 0°~45° 0°~45°

Arbor hole diameter 25,4 mm | 1“ 25,4 mm | 1“ 25,4 mm | 1“

Max. cutting depth 120 mm | 4.72”

(on guide rail)

90°: 82 mm | 3.22”

45°: 56 mm | 2.20”

90°: 67 mm | 2.63”

45°: 42 mm | 1.65”

Net weight 8,4 kg | 18,5 lbs 7,1 kg | 15,7 lbs 6,3 kg | 13,9 lbs

Noise level ISO1999 DIN45635 99,0 dB (A) 88,5 dB (A) 88,5 dB (A)

Sound pressure level 110,0 db(A) 99,5 db(A) 99,5 db(A)

Hand-arm vibration 1,4 m/s21,0 m/s21,0 m/s2

Information referred to 2.2 of Annex 1 of the E. G. Directive on vibrations)

4. USER INSTRUCTIONS

Notes for the customer

The instruction manual includes important

instructions as to how to operate the machine

safely, correctly and economically. Observing

these instructions helps to avoid risks, repair costs

and downtimes and to increase the reliability and

lifetime of the machine.

The instruction manual must be read and used

by each person who works with the electrical

equipment. This applies in particular to the

“Safety Instructions” chapter. It is too late to read

the manual and safety instructions when work is

actually being carried out at the machine.

Always keep one copy of this manual next to the

machine so that it is at hand ready to be consulted!

In case of any doubt or questions, always contact

the machine manufacturer.

In addition to the instruction manual, the accident

prevention regulations which apply in the country

of use and the user location must be adhered to. In

addition, the recognised technical rules regarding

accident prevention must be observed.

Liability and warranty

All the information contained in this instruction

manual has been drawn up to the best of our

knowledge and belief, taking our experience to date

into consideration.

The original version of this instruction manual was

drawn up in the German language and was checked

by us for accuracy of content. The translation into

the respective national/contractual language was

carried out by a recognised translation agency.

This instruction manual has been put together with

the greatest of care. However, if you should discover

any incomplete items or mistakes, please inform us

in writing. Your suggestions for improvement will

help us to create a user-friendly manual.

Subsequent Orders and Copyright

Further copies of this instruction manual can be

ordered from the address below. We ask for your

understanding that further copies are subject to

charge.

Jepson Power GmbH

Ernst-Abbe-Straße 5

D-52249 Eschweiler

Phone: +49 (0)2403 – 6455-0

Fax: +49 (0)2403 – 6455-15

Mail: [email protected]

All rights are expressly reserved. Duplication or

transfer on to third parties in any form whatsoever

is not allowed without our prior written permission.

GENERAL

5

Abbreviations

V Volt

A Ampere

Hz Hertz

W Watt

~ AC

/min Revolutions per minute rpm

N Newton

5. SAFETY INSTRUCTIONS

The basic prerequisite for safe handling and

disturbance-free operation of this electric tool

is knowledge of the basic safety instructions.

In addition, the accident prevention rules and

regulations which apply in the user location must

be adhered to, as well as the recognized rules of

the trade with regard to safety and correct working

methods.

It is not permitted to use the electric tool for other

purposes than those intended by the manufacturer.

Such use could give rise to unforeseeable risks.

Local working and safety rules and laws must always

be followed. The same applies to regulations which

apply to the environment.

Safety equipment must never by removed or

bridged over.

When using oils, greases and other chemical

substances, the safety regulations which apply to

the particular product must always be observed!

Contact with chemicals should be avoided as far

as possible. Before it is permissible to work with

these substances the instructions for use on the

packaging must be read and followed. This applies

for all chemicals, therefore also for cleaning media.

All notes and signs regarding safety and possible

risks must be kept in a fully legible condition.

5.1. ILLUSTRATION OF SAFETY INSTRUC

TIONS

The following symbols are used in the instruction

manual:

Warning against possible danger of

injury or danger to life for persons

Warning against possible damage to

property or the environment

Warning against dangerous electrical

voltage

Warning against hot surfaces

Ignoring these instructions can lead to serious

damage to health, up to life-threatening injuries!

This symbol indicates important

information

Hazardous to the environment

5.2. GENERAL SAFETY INSTRUCTIONS

This electric tool fulls the basic EC

safety and health regulations.

Nevertheless, dangerous situations

can arise.

All safety equipment must be

maintained in perfect condition.

Always pay attention to moving

parts. These can cause injury because

of their movement or by sudden

movement.

Only use the electric tool when it is in

perfect condition from the technical

point of view, and only use it for

intended purpose while being aware

of safety issues and risks, and paying attention

to the instruction manual! In particular, have any

disturbances which could have a negative eect

on safety corrected immediately!

WARNING! It is essential to read all the

instructions. Mistakes which are made while

attempting to follow the below instructions can

cause electric shock, re and/or serious injury.

The following term “Electric tool”, refers to

mains-powered electric tools (with mains cable)

and battery-powered electric tools (without

mains cable).

GENERAL

6

EN

DE

FR

NL

ES

PT

IT

KEEP THESE INSTRUCTIONS IN A

SAFE PLACE.

Work Area Safety

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquid, gases, or dust. Power tools create sparks,

which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you

to lose control.

Electrical Safety

Earthed tools must be plugged into an outlet

properly installed and earthed in accordance

with all codes and ordinances. Never remove the

earthing prong or modify the plug in any way. Do

not use any adaptor plugs. Check with a qualied

electrician if you are in doubt as to whether the

outlet is properly earthed. If the tools should

electrically malfunction or break down, earthing

provides a low resistance path to carry electricity

away from the user.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and refrig-

erators. There is an increased risk of electric shock if

your body is earthed or grounded.

Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Don’t abuse the cord. Never use the cord to carry

the tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged or

entangled cords increase the risk of electric shock.

When operating a power tool outside, only use

authorized cords for outdoor work. These cords are

rated for outdoor use and reduce the risk of electric

shock.

If operating a power tool in a damp location is

unavoidable, use an earth leakage circuit breaker.

Use of an earth leakage circuit breaker reduces the

risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the inuence

of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result

in serious personal injury.

Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid

safety shoes, hardhat, or hearing protection used for

appropriate conditions will reduce personal injuries.

Avoid accidental starting. Be sure switch is o-po-

sition before connecting to power source, picking

up or carrying the tool. Carrying tools with your

nger on the switch or plugging in tools that have

the switch on invites accidents

Remove any adjusting key or wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

Do not overreach. Keep a proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

Tool use and care

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

Do not use tool if switch does not turn it on and o.

Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and do not

allow persons unfamiliar with the power tool or

GENERAL

7

these instructions to operate the power tool. Tools

are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp

cutting edges are less likely to bind and are easier

to control.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts, and any

other condition that may aect the tools operation.

If damaged, have the tool serviced before using.

Poorly maintained tools cause many accidents.

Use the power tool, accessories and blades etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Use of the power

tool for operations dierent from those intended

could result in a hazardous situation.

Use clamps or other practical way to secure and

support the work piece to a stable platform. Holding

the work by hand against your body is unstable and

may lead to loss of control.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous

when used on another tool.

Service

Only qualied repair personnel must perform

tool service. Service or maintenance performed

by unqualied personnel could result in a risk of

injury.

When servicing tool, use only identical

replacement parts. Follow instructions in

the maintenance section of this manual. Use

of unauthorized parts or failure to follow

maintenance Instructions may create a risk of

electric shock or injury.

5.3. SPECIFIC SAFETY RULES

DANGER: Keep hands away from cutting area and

blade. Keep your second hand on auxiliary handle. If

both hands are holding the saw, they cannot be cut

by the blade.

WARNING! Do not reach underneath

the work. The guard cannot protect

you from the blade below the work.

Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

NEVER hold piece being cut in your hands or

across your leg. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

WARNING! Hold tool by insulated

gripping surfaces when performing

an operation where the cutting tools

may contact hidden wiring or its own

cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock

the operator.

When ripping, always use a rip fence or straight

edge guide. This improves the accuracy of cut and

reduces the chance of blade binding. Always use

blades with correct size and shape of arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of

control.

WARNING! Never use damaged or

incorrect arbor anges or bolts. The

arbor anges and bolt were specially

designed for your saw, for best

performance and safety of operation

Important: Kickback causes and related

warnings

Kick back is a sudden reaction to a

pinched, bound or misaligned saw

blade, causing an uncontrolled saw to lift up and

out of the workpiece toward the operator;

When the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the

operator;

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be

avoided by taking proper precautions as given

below.

Maintain a rm grip with both hands on the saw

and position your arms to resist kickback forces.

Position your body to either side of the blade, but

not in line with the blade.

Kickback could cause the saw to jump backwards,

but kickback forces can be controlled by the

operator, if proper precautions are taken.

GENERAL

8

EN

DE

FR

NL

ES

PT

IT

When blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the saw

motionless in the material until the

blade comes to a complete stop. Never attempt

to remove the saw from the work or pull the saw

backward while the blade is in motion or

KICKBACK may occur. Investigate and take

corrective actions to eliminate the cause of blade

binding.

When restarting a saw in the workpiece,

center the saw blade in the kerf and

check that teeth are not engaged into

the material.

If saw blade is binding, it may walk up or KICKBACK

from the workpiece as the saw is restarted.

Support large panels to minimize the risk of blade

pinching and KICKBACK. Large panels tend to sag

under their own weight. Supports must be placed

under the panel on both sides, near the line of

cut and near the edge of the panel. Do not use dull

or damaged blade. Dull blades produce a narrow

kerf causing excessive friction, blade binding, and

KICKBACK.

Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

blade adjustment shifts while cutting, it may cause

binding and kickback.

Use only recommended blades, rated

at the machine’s maximum rated RPM

or higher with correct arbor hole.

Guard function

Check guard for proper closing before each use. Do

not operate the saw if guard does not move freely

and enclose the blade instantly. Never clamp or

tie the guard so that the blade is exposed. If saw is

accidentally dropped, guard may be bent. Check

to make sure that guard moves freely and does not

touch the blade or any other part, in all angles and

depths of cut.

Check the operation and condition of

the guard return spring. If the guard

and the spring are not operating

properly, they must be serviced before

use. Guard may operate sluggishly due to damaged

parts, gummy deposits, or a build-up of debris.

Lower guard may be retracted manually only

for special cuts such as “plunge cuts”. Raise

lower guard by projecting portion and as soon

as blade enters the material, the lower guard

must be released. For all other sawing, the lower

guard should operate automatically.

Always observe that the guard is

covering the blade before placing

saw down on bench or oor.

An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade

to stop after switch is released.

Tighten blade retaining bolt and all clamps before

operating.

Secure workpiece properly. Workpiece should

be straight and rmly clamped to avoid possible

movement and pinching as the cut nears

completion.

Allow the blade to come to a

complete stop before removing or

securing workpiece, or changing

workpiece angle.

Check the inside surfaces of the arbor anges as

well as the sides of the blade for freedom from any

foreign matter.

Check the blade for cracks or other damage before

operation. Replace cracked or damaged blade

immediately.

Never start the tool with the workpiece against the

blade.

Allow the motor to achieve full speed before

cutting.

Important: After completing the cut, release

power switch and wait for coasting blade to stop

completely before putting the saw down.

Never operate the tool in an area with ammable

solids, liquids, or gases. Sparks from the

commutator/carbon brushes could cause a re or

explosion.

There are certain applications for which this

tool was designed. The manufacturer strongly

recommends that this tool NOT be modied and/

or used for any application other than for which it

was designed. If you have any questions relative to

its application DO NOT use the tool until you have

written the manufacturer and have been advised

WARNING: Always wear hearing protection with

this tool.

GENERAL

9

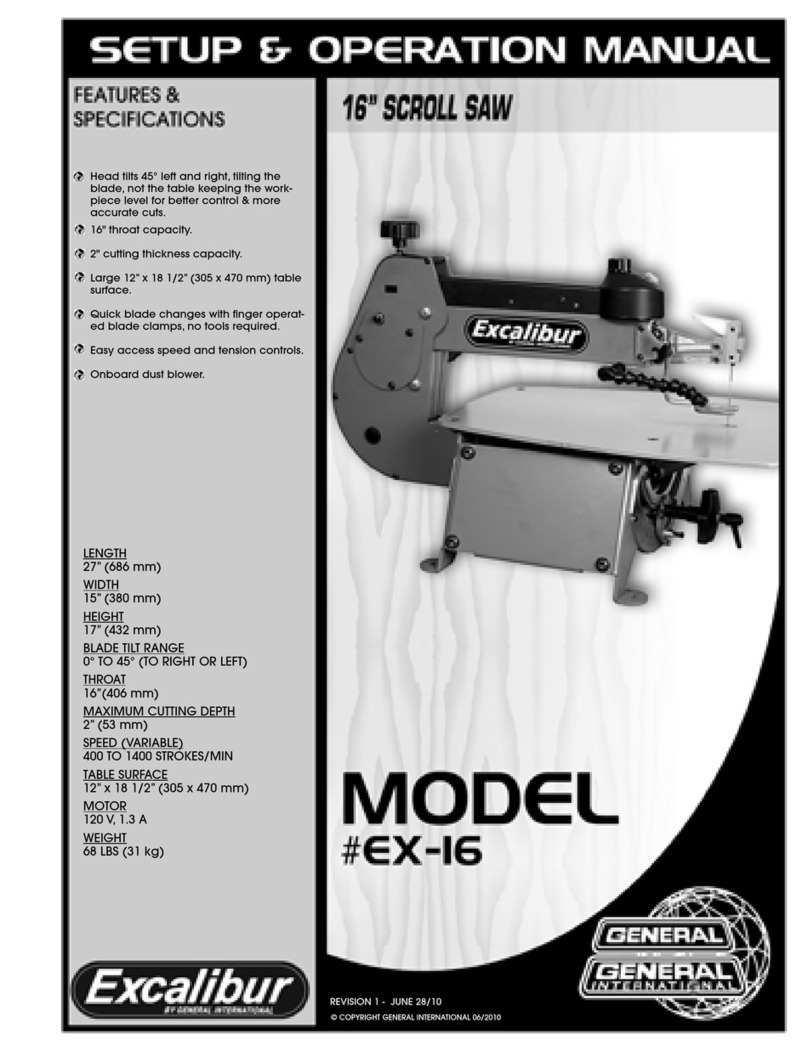

SUPER HAND DRY CUTTER 8320

6. DESCRIPTION

Arbor lock lever

Dust extractor port

Dust chamber cover

Guide clearance adjustor

L - hex key

stored in main handle

Load indicator light

Lock release button

Clip

Dust port cap

Lower blade guard

Depth lock lever

Depth lock scale

Motor unit

Base plate

Upper blade guard

Main handle

Power supply cable

Kick lever

Side handle

SUPER HAND DRY CUTTER 8320

10

EN

DE

FR

NL

ES

PT

IT

7. FUNCTIONAL DESCRIPTION

7.1. INTENDED USE

This saw is designed exclusively for the

sawing of rigid insulation panel,

sandwich panel, aluminum, steel and

plastics. This machine should not be

used for cutting other materials. Do not use this saw

to cut wood. The machine should not be converted

or modied, e.g. for any other form of use, other

than as specied in these operating instructions.

The user shall be liable for damages and accidents

due to incorrect use.

CAUTION: Do not overheat the blade

tips. Use of undue force will not

speed up the cutting operation.

Allow the tool to determine the best

feed rate.

CAUTION: When sawing plastics, avoid melting

the plastic.

7.2. ELECTRICAL CONNECTION

The network voltage must conform to

the voltage indicated on the tool name

plate. Under no circumstances should

the tool be used when the power

supply cable is damaged. A damaged cable must be

replaced immediately by an authorized Customer

Service Center. Do not try to repair the damaged

cable yourself. The use of damaged power cables

can lead to an electric shock.

7.3. EXTENSION CABLE

If an extension cable is required, it must

have a sucient cross-section so as to

prevent an excessive drop in voltage or

over-heating. An excessive drop in

voltage reduces the output and can lead to failure

of the motor. The following table shows you the

correct cable diameter as a function of the cable

length for this machine. Use only U.L. and CSA listed

extension cables. Never use two extension cables

together. Instead, use one long one

Total Extension Cord

Length (feet) Cord Size (AWG)

25 16

50 12

100 10

150 8

200 6

7.4. SAW BLADE

Only use original saw blades with a

diameter in accordance with the

markings on the tool name plate:

Only use saw blades with blade set

(cutting width) of 2.2 mm and blade thickness 1.8

mm.

Saw blades must be suitable for speeds of up to

1700 min -1or faster. Do not use any abrasive wheel

with this machine.

7.5. UNPACKING

Carefully remove the tool and all loose items from

the shipping container. Retain all packing materials

until after you have inspected and satisfactorily

operated the machine.

NOTE: An appropriate blade must be mounted

to the machine before operating. Refer to the

section of this manual: “INSTALLING THE SAW

BLADE”

Carton contents:

• SUPER Hand Dry Cutter 8320

• Original Jepson carbide tipped saw blade

320x2.2x25.4x84T

• M5 L-hex key

WARNING! DO NOT OPERATE THIS

TOOL UNTIL YOU READ AND

UNDERSTAND THE ENTIRE

INSTRUCTION MANUAL

7.6. INSTALLING THE SAW BLADE

Inner arbor ange ENSURE THAT THE MACHINE IS

DISCONNECTED FROM POWER

SOURCE

To install the blade:

Remove any accumulated debris in

the guards and around the arbor.

Clean the inner arbor ange. Orient the ange so

that the correct side faces the blade and place the

new blade on the arbor,

making sure that the teeth point forwards.

Place the outer arbor ange on the arbor with the

correct side toward the blade.

NOTE: Use blades that have an arbor bore which

can t, and that are rated for the machine’s

SUPER HAND DRY CUTTER 8320

11

maximum rated speed or higher. Avoid contact

with blade teeth to prevent personal injury.

NOTE: Take care to ensure that the blade is

centered (it is possible to tighten the blade

crooked between the anges).

Replace and nger-tighten the blade retaining bolt

by turning it clockwise.

Arbor lock lever Push in the arbor lock lever and

rotate the arbor by hand until the

lock engages the arbor. Tighten

the blade retaining bolt securely.

Rock the arbor with the wrench to

ensure that the arbor lock has

released and release the arbor lock.

7.7. REMOVING THE BLADE

DISCONNECT THE MACHINE FROM POWER

SOURCE.

Removal is the opposite of installing the blade, but

special care must be taken to avoid injury from the

blade.

Push in the blade lock lever and rotate the arbor

with the wrench on the retaining bolt until the lock

engages the arbor. Loosen the blade retaining bolt

with the provided wrench and release the arbor

lock.

Completely unscrew the blade retaining bolt and lift

it and the outer ange away, taking care not to drop

the blade.

Carefully rotate the lower blade guard out of the

way. The blade may now be removed.

7.8. ADJUST CUTTING DEPTH

DISCONNECT THE MACHINE FROM POWER

SOURCE.

Depth lock lever

Adjust the cutting depth as

desired. A depth scale is provided.

Loosen the depth lock lever and

set the depth to the desired level.

Then tighten the lever.

Depth lock scale

WARNING: Depth adjusting locking

lever must be tight and secure

before making cut. If blade

adjustment shifts while cutting, it may cause

binding and kickback.

7.9. USE OF SIGHTING NOTCH

Sighting notch To aid in free-hand cutting, a

sighting notch is located at the

front of the base.

Align the cutting line on the

work-piece with the sighting

notch. Additionally, the blade is

visible through small gaps in the cover for aligning

the blade perfectly with the intended line of cut.

7.10. BLADE GUARD

To test the function of the lower blade guard, rotate

the guard through the full stroke of its travel and

ensure that the guard is able to fully return back to

the closed position under its own spring tension.

If the guard is found to be sluggish or if it sticks in

any position, the problem will need to be remedied

before the machine is used again. It usually just

needs to be cleaned. To clean, rst remove the

sawblade and then clean all around the rotating

joint of the guard. All other repairs should be

performed by an authorized service center.

Kick lever Kicker Lever: When cutting

materials with bigger dimension/

cutting depth , such as sandwich

panel, often the lower blade guard

will not be able to bump open

automatically. In this case the

Lower blade guard kicker lever may be used to allow

the lower blade guard to open just

enough to get started. Simply

push the lever with the thumb of

the left hand without removing

one’s hand from the side handle.

After it begins, allow the guard to function automat-

ically as usual.

7.11. DUST COLLECTION SYSTEM

Dust collection should always be used to minimise

dust. Attach an appropriate hose and vacuum

cleaner system to the dust extractor port on the

machine.

Dust chamber If a vacuum cleaner is not available,

close the cap of the dust port.

There is a dust chamber which can

collect a small amount of dust or

chips which is built into the upper

blade guard. Clear the dust

chamber frequently to avoid it being overlled. To

SUPER HAND DRY CUTTER 8320

12

EN

DE

FR

NL

ES

PT

IT

clear the dust chamber, push up on the clip and

rotate the dust chamber cover to the open position

and dump out the dust. Once nished clip the cover

back to the closed position.

8. START AND STOP OF THE

MACHINE

Make sure that the power circuit voltage is the

same as that shown on the specication plate of the

machine and that switch is “OFF” before connecting

the tool to the power circuit.

8.1. SWITCHINGTHE MACHINE ON AND OFF

Keep the machine steady during switching and

during use by holding the main handle and the side

handles with both hands.

Lock release button To switch on: rst push the lock

release button , and then press the

trigger switch.

Trigger switch To switch o:

Release the trigger switch. After the machine has

been switched o, the sawblade will still rotate for a

time. Take care that parts of your body do not come

in contact the saw blade while it is still rotating!

As soon as you remove the machine from the

work-piece, always allow the lower blade guard to

close completely. In this way the sawblade is again

completely covered by the outer protective cover

8.2. ELECTRONIC OVERLOAD PROTECTION

AND LOAD INDICATOR LIGHT

Load indicator light This machine is equipped with a

load indicator light that will inform

the operator of load conditions.

Whenever the switch is turned on

and load conditions are normal,

the indicator light will be a solid

green color. If load is approaching overload

conditions, the indicator light will ash red. I f the

operator continues to run the machine in overload

conditions for a sustained period of time, the

electronic overload protection unit will shut the

machine o. The higher the level of overload, the

more quickly the machine will shut down.

When this happens, always remove the machine

from the work-piece and run the machine at no load

for a few minutes to allow the motor to cool down

before continuing to avoid a burn out of the motor.

8.3. USE OF THE MACHINE

Eective control of this powerful saw requires

two-handed operation for maximum protection.

Do not use this tool continuously over 30 minutes.

Support the work properly and hold the saw rmly

WITH BOTH HANDS to prevent loss of control which

could cause personal injury. Always hold the side

handle with the left hand and the rear handle with

the right hand for proper hand support of the saw.

Protect your eyes from injury with safety glasses or

goggles. Do not use cutting uids or lubricants on

the blade.

Sawing

The machine must reach full speed before cutting

begins and should only be switched o once cutting

has nished. Only operate the saw away from you

(pushing the circular saw forwards) and never

towards you (pulling the circular saw backwards). If

you saw towards you, there is the danger that the

circular saw might be accelerated out of the cutting

groove (recoil) and cause serious injury.

The lower blade guard should open automat-

ically when it hits the edge of the work-piece. If it

doesn’t open automatically, give it a little help at

the beginning of the cut by pushing the kicker lever

with the thumb of the left hand. This will open the

lower blade guard by about 20 degrees.

Sawing sections:

Make sure the cutting depth is set as desired. Place

the front part of the saw bench on the work-piece.

Switch the machine on. Push the machine in the

direction of cut. Take care that the saw base remains

rmly on the work-piece. Switch the machine o

and allow the lower blade guard to close completely

when cutting is completed. The depth is there to

adapt the position of the saw blade on the material.

Clamping the workpiece

Secure the work-piece properly. The work-piece

should be straight and rmly clamped to avoid

possible movement and pinching as the cut nears

completion. Provide adequate support for long

or wide work-pieces. Never position large or long

work-pieces so that they bend in the middle or

at the cutting face. This can lead to the saw blade

jamming and kicking back. Instead, support the

work-piece with several wooden battens, close to

the cutting face. Conrm that the blade has come

to a complete stop before removing or securing the

work-piece, or changing the work-piece angle.

SUPER HAND DRY CUTTER 8320

13

CAUTION: Keep the cord away from

cutting area to prevent it from

becoming entangled in the

work-piece.

Do not force the cut. Let the saw do the cutting at

the rate of speed permitted by the type of cut and

work-piece.

8.4. CUTTING GUIDE

Guide clearance adjustor

Guide rails are available to assist in

making precise straight cuts and

enhance safety. (These are an

optional accessory) The guide rail

may be secured with C-clamps if

desired. There are 2 guide

clearance adjustors for optimum t and safety.

Adjust these equally so that there is no looseness,

yet the base still slides freely.

The rubber sighting strip:

The sighting / anti-splinter strip must be cut to size

along its full length before the rst use. The rubber

strip must be backed by a work-piece when it is cut

for the rst time.

CAUTION: Failure to use a backing work-piece on

the rst cut may result in the rubber strip being

torn or damaged by the blade

Once it is cut to size, it will perfectly correspond

to the cutting edge and will also help to protect

the material from splintering. Once it is sized, the

operator can know at a glance exactly where the

line of cut will be. This saves a lot of time and eort

in making precise cuts.

9. MAINTENANCE AND REPAIR

9.1. KEEP TOOL CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to

clean plastic parts. They could possibly dissolve or

otherwise damage the material.

Wear safety glasses while using compressed air.

Clean all parts of the lower blade guard mechanism

to ensure smooth operation.

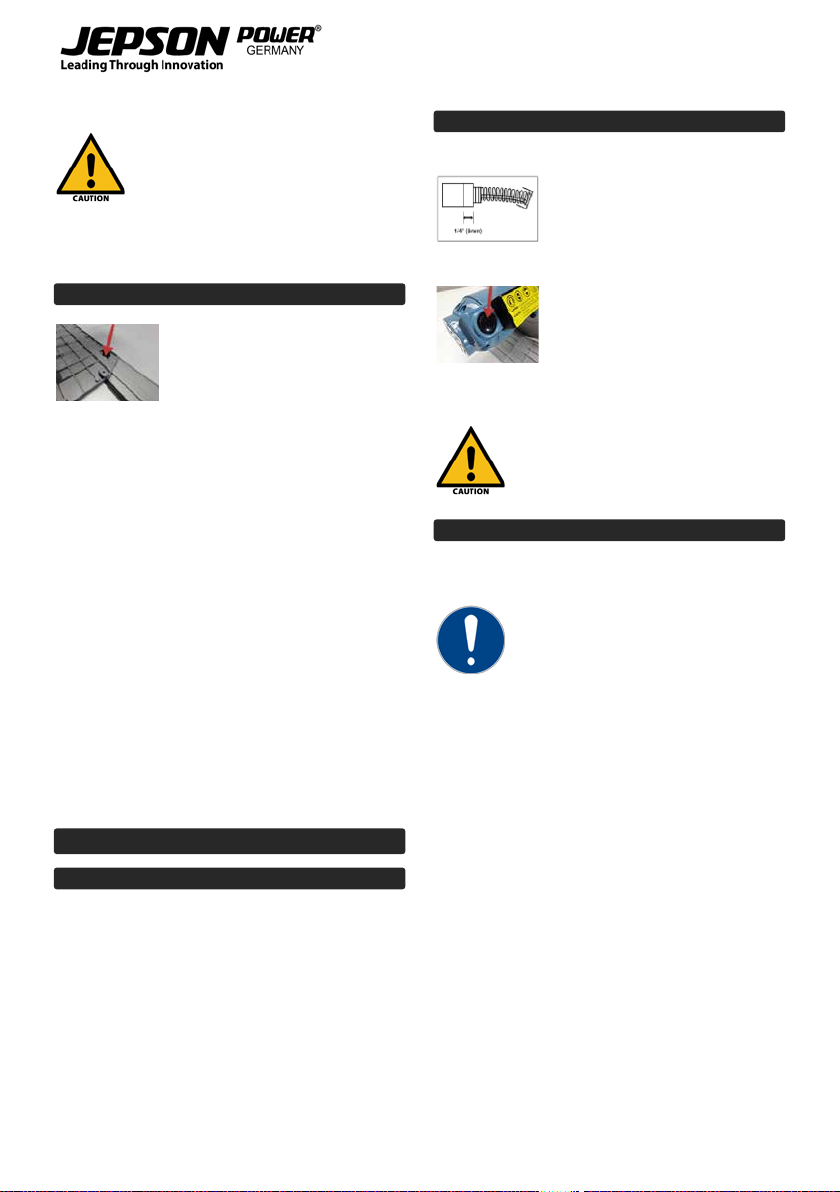

9.2. REPLACEMENT OF CARBON BRUSHES

The carbon brushes are a normal

wearing par t and must be

replaced when they reach their

wear limit.

To replace:

Kohlebürstenhalter Remove the brush caps and

withdraw the old brushes. Replace

with new brushes (always replace

as a pair) ensuring that they align

properly and slide freely. Instal-

lation is the reverse of removal.

Then replace the brush caps.

CAUTION: Always replace the brushes

as a pair.

9.3. STANDARD ACCESSORIES

• Carbide tipped saw blade 320x84T

• 5 mm L-hex key

If the replacement of the power supply

cord is necessary, this has to be done by

the manufacturer or their agent in

order to avoid a safety hazard

SUPER HAND DRY CUTTER 8320

14

EN

DE

FR

NL

ES

PT

IT

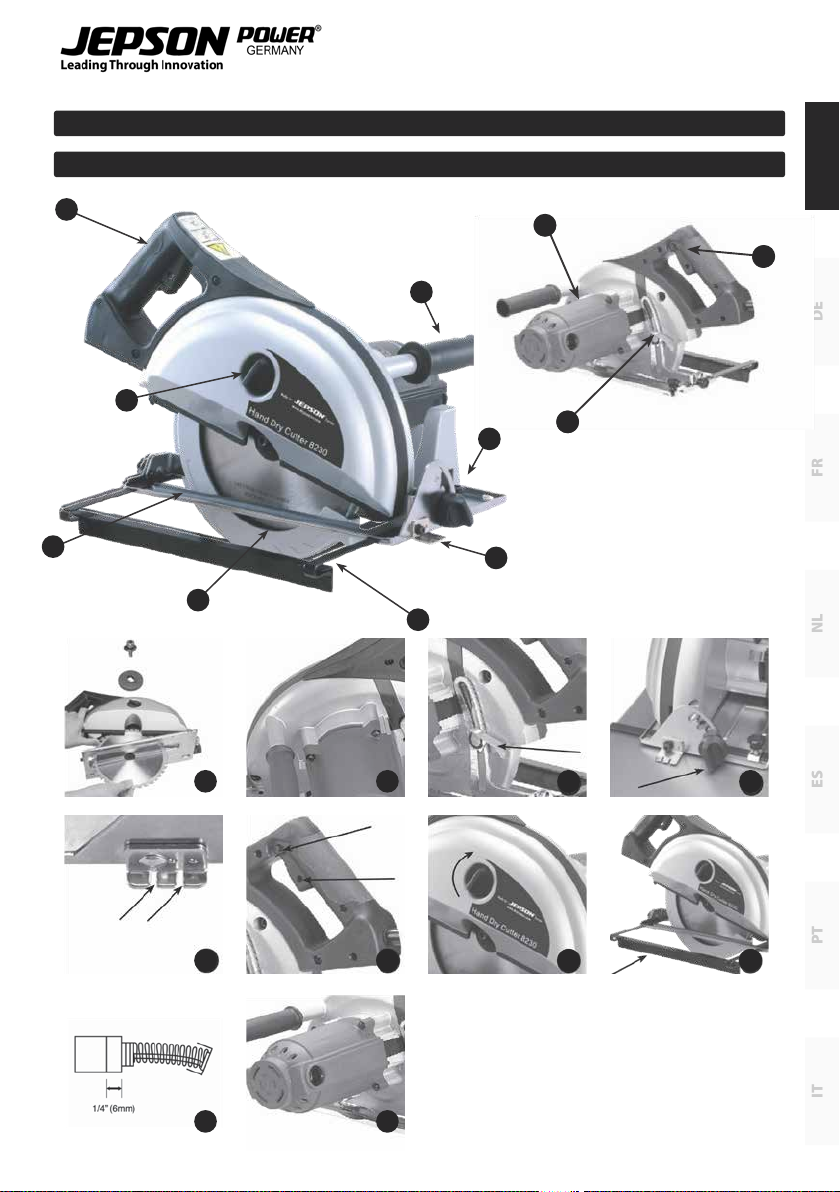

HAND DRY CUTTER 8230N | 8200

10. DESCRIPTION

2

2

6

10

45° 90°

3

7

11

4

8

5

9

1

3

4

5

6

7

8

9

10

11

HAND DRY CUTTER 8230N | 8200

15

11. APPLICATION

1. Do not use abrasive wheels with this machine.

Use only original Jepson Power saw blades

2. Tighten blade retaining bolt and all clamps

before operating.

3. Secure work piece properly. Work piece should

be straight and rmly clamped to avoid

possible movement and pinching as the cut

nears completion.

4. Allow the blade to come to a complete stop

before removing or securing workpiece, or

changing workpiece angle.

5. Check the inside surfaces of the arbor anges

as well as the sides of the blade for freedom

from any foreign matter.

6. Check the blade for cracks or other damage

before operation. Replace cracked or damaged

blade immediately.

7. Never start the tool with the work piece

against the blade.

8. Allow the motor to achieve full speed before

cutting.

9. After turning tool “ON”, gently push the tool

forward to engage work piece, then slowly

increase pressure as required to produce the

least amount of“sparking”.

10. Important: After completing the cut, release

power switch and wait for coasting blade to

stop completely before putting the saw down.

11. Never operate the tool in an area with

ammable solids, liquids, or gases. Sparks or

hot fragments could cause a re or explosion.

12. This tool is designed for ferrous metals

only. Do not attempt to cut wood, masonry,

magnesium, or any other pyrophoric materials

with this tool.

13. Do not use cutting uids or lubricants on the

blade.

14. Some metals have coatings, which can be

toxic. Take extra care to prevent inhalation

and skin contact when working with these

materials. Request, and follow, any safety

information available from your material

supplier.

15. There are certain applications for which this

tool was designed. The manufacturer strongly

recommends that this tool NOT be modied

and/ or used for any application other than

for which it was designed. If you have any

questions relative to its application DO

NOT use the tool until you have written the

manufacturer and have been advised.

Metal chips are often very sharp and hot. Never

touch them with bare hands. Clean up with a

magnetic chip collector and a chip hook or other

appropriate tool.

12. FUNCTIONAL DESCRIPTION

This machine is a dry cutting circular saw designed

to cut ferrous metals, which uses carbide tipped saw

blades. The saw should only be used with original

Jepson Power saw blades.

12.1. UNPACKING

Carefully remove the tool and all loose items from

the shipping container. Retain all packing materials

until after you have inspected and satisfactorily

operated the machine.

12.2. CARTON CONTENTS

1. Metal cutting saw

2. Original Jepson Power carbide tipped saw

blade

3. Rip fence cutting guide

4. Hex wrench

12.3. INSTALLING THE BLADE

1. Disconnect tool from power source.

2. Remove any accumulated debris in the guards

and around the spindle. Check the lower

retracting blade guard to ensure that it is in

working order.

3. Clean the inner spindle ange. Orient the

ange so that the correct bore size faces the

blade and place the new blade on the spindle,

making sure that the teeth point forwards. (If

in doubt of the orientation of the blade, refer

to the legend cast into the lower retracting

blade guard) Avoid contact with blade teeth

to prevent personal injury.

4. NOTE: Only use original Jepson Power saw

blades.

5. Place the outer spindle ange on the spindle

with the at side toward the blade. See g. 2.

6. Replace and nger- tighten the blade retaining

bolt by turning it clockwise.

7. Push in the blade lock lever and rotate the

spindle by hand until the lock engages the

spindle See g. 3. Tighten the blade retaining

bolt securely with the provided wrench and

release the spindle lock.

HAND DRY CUTTER 8230N | 8200

16

EN

DE

FR

NL

ES

PT

IT

12.4. REMOVING THE BLADE

1. Disconnect tool from power source.

2. See g. 3. It is not necessary to remove the

outer blade cover, just leave it in place. Push

in the spindle lock and using the supplied

hex wrench, rotate the blade until the lock

engages the blade spindle.

3. Avoid contact with the blade teeth to prevent

personal injury.

4. While holding the blade lock lever, use the

provided wrench to loosen the blade retaining

bolt. Then remove it and the outer spindle

ange.

5. The blade may now be carefully removed.

12.5. ADJUSTMENT DEPTH OF CUT

Adjust the depth of cut so that the saw blade

protrudes through the thickness of work piece. To

adjust the depth of cut:

1. Disconnect tool from power source.

2. Lift the depth lock lever at the rear of the saw.

See g. 4.

3. Raise or lower the saw base until the blade

extends the desired depth below the base.

(See the scale and pointer cast into the main

body casting.)

4. Press the depth lock lever down rmly, locking

the saw in the selected position.

12.6. ADJUSTMENT OF BEVEL ANGLE

To adjust the bevel angle, refer to the bevel gauge

on the base. There are markings for dierent angles

from 0 to 45 degrees. To adjust the bevel angle:

Loosen the bevel lock knob

( See g. 5 ) and the smaller knob at the rear. Lift the

bevel lock knob out of the slot and rotate the base

to the desired angle. The most commonly used

angles each have an individual slot. Simply drop the

bevel lock into the slot and tighten. If other angles

are needed, tighten the bevel lock knob to hold at

the desired position. Then tighten the smaller knob

at the rear of the base.

12.7. HOW TO USE THE SIGHTING NOTCH

To aid in free- hand cutting, a sighting notch is

located at the front of the base. See g. 6. Align

the cutting line on the work piece with the sighting

notch. Make the cut. Use the right-

hand notch (between the two marking dots) for

straight cuts and the left- hand notch (located

below the rivet) for 45- degree bevel cuts.

12.8. STARTING AND STOPPING TOOL

Make sure that the power circuit voltage is the same

as that shown on the specication plate

of the machine and that switch is “OFF” before

connecting the tool to the power circuit. To start

the machine, rst press the safety lock button

then squeeze the trigger switch to start the motor.

Release the trigger switch to stop the motor. See

g. 7.

12.9. REMOVING CHIPS

This dry- cut metal saw has an internal chip

collector. When the chip collector is full, the chips

must be cleared. To do this, rst shut down and

DISCONNECT TOOL FROM POWER SOURCE. The

outer blade cover lock knob has a bayonet lock

thread. See g. 8. To remove cover, turn knob

anticlockwise while pushing in against the spring

tension. Then lift cover away. Recently- cut chips can

be very hot. Take care when removing the cover to

keep the chips or shavings away from your hands or

other body

parts. Do not throw hot debris where paper or other

ammable materials are located. To replace the

outer blade cover, line up tang with slot and push in

against the spring while turning clockwise. Ensure

that the cover is properly seated.

12.10. HOW TO USE THE RIP FENCE

Using the rip fence will provide more accurate

straight cuts than by cutting free- hand. For instal-

lation, DISCONNECT TOOL FROM POWER SOURCE

then insert the rip fence in the mounting slots. In

the base.

12.11. LOWER RETRACTING BLADE GUARD

The lower retracting blade guard is a safety device

important for your protection. Every

time you use the saw, make sure that the guard

rotates freely and returns quickly and completely

to its closed position. Before each use, remove

any accumulated chips, or shavings from the area

around the hub of the guard. DO NOT LUBRICATE

THIS AREA. The hub has a dry lm lubricated surface

that does not need oiling. NEVER block or wedge

the blade guard in the open position. NEVER use

your saw if the blade guard is not in working order.

If blade guard movement is sluggish or if binding

exists, return the saw to your nearest AUTHORIZED

SERVICE CENTER for repair.

HAND DRY CUTTER 8230N | 8200

17

12.12. HOW TO USE THE TOOL

Eective control of this powerful saw requires

two- handed operation for maximum protection.

Support the work properly and to hold the saw

rmly WITH BOTH HANDS to

prevent loss of control which could cause personal

injury. Always hold the side handle with the left

hand and the rear handle with the right hand for

proper hand support of the saw. Protect your eyes

from injury with safety glasses or goggles.

Do not use cutting uids or lubricants on the blade.

12.13. CLAMP THE WORK PIECE

Secure the work piece properly. The work piece

should be straight and rmly clamped to avoid

possible

movement and pinching as the cut nears

completion. Provide adequate support for long or

wide work pieces. Conrm that the blade has come

to a complete stop before removing or securing the

work piece, or changing the work piece angle. Press

the safety, then the trigger switch. Move the saw

forward to contact the work piece. Clamp the work

piece on a rigid support, such as a bench or saw

horses. Mark the line of cut on the work piece. Be

sure that the cuto line is far enough on the work

piece to allow proper operation of the telescoping

guard. Place the front edge of the saw squarely on

work piece before starting the motor. Sight the

cutting line with the sighting notch indicator or

use the rip fence. Be certain that the blade is not

contacting the work piece. Press the safety, then the

trigger switch, allow the motor to come up to full

speed and move the saw forward to begin the cut.

CAUTION: Keep the cord away from cutting area to

prevent it from becoming entangled in the work

piece.

Do not force the cut. Let the saw do the cutting at

the rate of speed permitted by the type of cut and

work piece. Increase feed pressure as the blade

cuts through the thicker cross-sections (to maintain

minimum “sparking”). Decrease the feed pressure as

the blade cuts through the thinner cross sections

(to maintain motor speed and avoid overloading

the machine). After completing the cut, release the

power switch and wait for the coasting blade to

stop completely before putting the saw down.

13. MAINTENANCE

13.1. KEEP TOOL CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to

clean plastic parts. They could possibly dissolve or

otherwise damage the material. Wear safety glasses

while using compressed air.

13.2. THE CARBON BRUSHES

The carbon brushes are a normal wearing part and

must be replaced when they reach their wear limit.

See g. 10.

To replace: simply remove the brush caps and

withdraw the old brushes. Replace with new

brushes (always replace as a pair) ensuring that

they align properly and slide freely. Then replace the

brush caps. See g. 11.

13.3. WARNING

Make sure that the tool is turned o and not

connected to a power source before you perform

maintenance and/or examine the tool. For safety

reasons and in order to ensure proper functioning

of the device, repairs, maintenance and adjustment

of the tool must be performed by a certied service

center. Use only original spare parts.

If the replacement of the power supply cord is

necessary, this has to be done by the manufacturer

or their agent in order to avoid a safety hazard.

13.4. STANDARD ACCESSORIES

• Original Jepson Power carbide tipped saw

blade 203/42T (HDC 8200)

• Original Jepson Power carbide tipped saw

blade 230/48T (HDC 8230N)

• 6mm Hex wrench

• Rip fence

HAND DRY CUTTER 8230N | 8200

18

EN

DE

FR

NL

ES

PT

IT

GENERAL

14. QUOTATION

When returning a defective machine for repair with

cost estimate. We charge a handling fee of 50€, but

does not apply if a repair order or purchase of a new

machine is given.

15. SPARE PARTS

For current spare parts list with order numbers

please visit our website:

www.drycutter.com

16. WARRANTY

The warranty time (warranty according to the

commercial code) is 12 months from the day of sale

to the end consumer.

It covers and is limited to the free replacement

of the defective parts or the free repair of defects

that are demonstrably due to the use of imperfect

materials during production or due to assembly

errors.

Incorrect use or start-up and unauthorized instal-

lations or repairs not specied in the operating

instructions void the warranty. Parts that are subject

to wear are also excluded from the warranty. We

expressly reserve the right to make decisions on

the war- ranty application. The warranty is void if

the device is opened by a third party. Transport

damages, maintenance work as well as damage and

malfunctions due to insucient maintenance are

not covered by the warranty.

For warranty claims, the proof of purchase of the

device must be given by presenting the delivery

note, bill, or cash receipt.

As far as it is legal, we assume no liability for any

personal, material or consequential damages, in

particular if the device is used dierently than for

the purpose indicated in the operating instructions,

not installed or repaired according to the opera-

ting instructions, or repairs were executed by a

layperson.

We reserve the right to perform repairs or

maintenance over and above the ones specied in

these operating instructions at the factory.

The warranty excludes wear parts such as:

Switches, anges, carbon brushes, supportings and

Cutting tools (saw blades, carbide inserts, drills and

abrasive).

The quality and safety of the JEPSON circular

cold saw depends on the exclusive use of original

JEPSON saw blades. The use of other saw blades

may damage the machines.

The original JEPSON saw blade fulls all

requirements of the TÜV examination (several

inspection oces) and is therefore certied by

these inspection oces. In case of use of saw blades

of foreign makes, the manufacturer assumes no

liability.

Exclusion of the JEPSON POWER warranty

The warranty excludes:

• Parts that are subject to wear through use or

natural wear and tear, as well as tool defects due

to wear and tear due to normal conditions of use

or due to natural wear and tear.

• Tool failure due to non-compliance with the

instruction manual, unconventional use,

abnormal atmospheric conditions, improper

operating conditions, overload, or lack of service

or maintenance.

• Tool failure due to replacement parts or

additional parts that are not genuine Jepson

Power parts.

• Machines to which changes or additions have

been made.

• The minor dierences from the intended use of

the device that are not material to the value and

suitability of the tool.

GENERAL

19

20

This manual suits for next models

2

Table of contents

Languages:

Other Jepson Saw manuals

Popular Saw manuals by other brands

Black & Decker

Black & Decker 489051-00 instruction manual

Weber mt

Weber mt SM 82-3 Operating and maintenance manual

Ryobi

Ryobi TS1355LA user manual

Evolution

Evolution EVO230 Xtreme Original instructions

Ryobi

Ryobi RJ150V-01 Operator's manual

CH Hanson

CH Hanson Palmgren 9683337 Operating instructions & parts manual

Makita

Makita LS1030N technical information

Bosch

Bosch GCO 2000 Professional Original instructions

Jet EQUIPMENT & TOOLS

Jet EQUIPMENT & TOOLS JWBS-18 owner's manual

Parkside

Parkside SABRE SAW PFS 710 A1 Operation and safety notes

Black & Decker

Black & Decker CS1024 instruction manual

Wacker Neuson

Wacker Neuson BFS 1345 Operator's manual