Jepson HDC 8203E User manual

EN Operating instructions 03

DE Betriebsanleitung 17

FR Mode d’emploi 33

NL Handleiding 47

ES Instrucciones de servicio 61

PT Instruções de utilização 75

IT Istruzioni per l’uso 87

CORDLESS METAL CUTTING CIRCULAR SAW

HDC 8203E

EN CORDLESS METAL CUTTING CIRCULAR SAW

DE AKKUMETALLKREISSÄGE

FR SCIE CIRCULAIRE SANS FIL POUR LA COUPE DES MÉTAUX

NL DRAADLOZE METAAL CIRKELZAAG

ES SIERRA CIRCULAR PARA CORTE DE METALES INALÁMBRICA

PT SERRA CIRCULAR DE CORTE DE METAL SEM FIO

IT SEGA CIRCOLARE PER IL TAGLIO DEI METALLI A BATTERIA

2

6

10

3

7

11

4

8

5

9

1

1

3

5

6

2

89

10

11

4

7

2

EN

DE

FR

NL

ES

PT

IT

1. EC DECLARATION OF CONFORMITY 4

2. SPECIFICATIONS 5

3. USER INSTRUCTIONS 5

4. SAFETY INSTRUCTIONS 6

4.1. ILLUSTRATION OF SAFETY INSTRUCTIONS 6

4.2. DISCLAIMER 6

4.3. GENERAL POWER TOOL SAFETY WARNINGS 7

4.4. CIRCULAR SAW SAFETY WARNINGS 8

4.5. BATTERY SAFETY WARNINGS 10

5. APPLICATION 10

6. FUNCTIONAL DESCRIPTION 11

6.1. UNPACKING 11

6.2. CARTON CONTENTS 11

6.3. CHARGING THE RECHARGEABLE BATTERY 11

6.4. FITTING THE RECHARGEABLE BATTERY 11

6.5. REMOVING THE RECHARGEABLE BATTERY 12

6.6. INSTALLING THE BLADE 12

6.7. REMOVING THE BLADE 12

6.8. ADJUSTMENT DEPTH OF CUT 12

6.9. ADJUSTMENT OF BEVEL ANGLE 12

6.10. HOW TO USE THE SIGHTING NOTCH 12

6.11. STARTING AND STOPPING TOOL 12

6.12. REMOVING CHIPS 12

6.13. HOW TO USE THE RIP FENCE 13

6.14. LOWER RETRACTING BLADE GUARD 13

6.15. HOW TO USE THE TOOL 13

6.16. CLAMP THE WORK PIECE 13

7. MAINTENANCE 13

7.1. KEEP TOOL CLEAN 13

7.2. WARNING 13

7.3. TRANSPORT 14

7.4. DISPOSAL OF RECHARGEABLE BATTERIES/BATTERIES 14

8. QUOTATION 14

9. SPARE PARTS 14

10. WARRANTY 14

ENGLISH

3

1. EC DECLARATION OF CONFORMITY

(according to Appendix IIA of the machine Directive)

We, Jepson Power GmbH, Ernst – Abbe – Straße 5, 52249 Eschweiler, Germany, as the manufacturer

declare herewith under our responsibility that the product:

Name: Hand Dry Cutter HDC 8203E

Manufacturing date: See machine label

Serial number: See machine label

complies with the following standards, directives and referenced standard documents:

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

2011/65/EU RoHS Directive

EN 62841-1 :2015

EN 62841-2-5:2014

EN 55011

EN 12100

Pierre Michiels, Managing Director

Name, Position Eschweiler, 01.01.2023

CE symbol to document compliance

with the basic safety and health

requirements according to Appendix I

of the Machinery Directive.

For EU countries only

Do not dispose of electrical tools

together with domestic waste!

In accordance with the European

directive 2002/96/EC on waste electrical and

electronic equipment and transposition into

national law, obsolete electrical tools must be

collected separately and recycled in an environ-

mentally-compatible manner.

To reduce the risk of injury, please read

the operating instructions.

Protect the rechargeable battery from

heat, excessive solar radiation, re, frost,

water and humidity.

Protect rechargeable battery packs

from humidity!

Protect rechargeable battery packs

from re! There is danger of explosion!

Cordless Allicance System (=CAS) is a

cross-manufacturer battery pack

system. Further information is available

at www.cordless-alliance-system

ENGLISH

4

EN

DE

FR

NL

ES

PT

IT

2. SPECIFICATIONS

Nominal voltage 18V

Saw blade speed while idling 3.500 min-1

Saw blade diameter 203 mm | 8”

Bevel angle 0°~45°

Bore 25,4 mm | 1“

Max. cutting depth 90°: 67 mm | 2.63”

45°: 42 mm | 1.65”

Net weight 5,4 kg | 12 lbs

Sound pressure level 87,3 dB

Sound power level 98,1 dB

Vibration - main handle ah = 2,05 K = 0,07

Vibration - auxiliary handle ah = 2,39 K = 0,3

Information referred to 2.2 of Annex 1 of the E. G. Directive on vibrations)

3. USER INSTRUCTIONS

Notes for the customer

The instruction manual includes important

instructions as to how to operate the machine

safely, correctly and economically. Observing

these instructions helps to avoid risks, repair costs

and downtimes and to increase the reliability and

lifetime of the machine.

The instruction manual must be read and used

by each person who works with the electrical

equipment. This applies in particular to the

“Safety Instructions” chapter. It is too late to read

the manual and safety instructions when work is

actually being carried out at the machine.

Always keep one copy of this manual next to the

machine so that it is at hand ready to be consulted!

In case of any doubt or questions, always contact

the machine manufacturer.

In addition to the instruction manual, the accident

prevention regulations which apply in the country

of use and the user location must be adhered to. In

addition, the recognised technical rules regarding

accident prevention must be observed.

Liability and warranty

All the information contained in this instruction

manual has been drawn up to the best of our

knowledge and belief, taking our experience to date

into consideration.

The original version of this instruction manual was

drawn up in the German language and was checked

by us for accuracy of content. The translation into

the respective national/contractual language was

carried out by a recognised translation agency.

This instruction manual has been put together with

the greatest of care. However, if you should discover

any incomplete items or mistakes, please inform us

in writing. Your suggestions for improvement will

help us to create a user-friendly manual.

Subsequent Orders and Copyright

Further copies of this instruction manual can be

ordered from the address below. We ask for your

understanding that further copies are subject to

charge.

Jepson Power GmbH

Ernst-Abbe-Straße 5

D-52249 Eschweiler

Phone: +49 (0)2403 – 6455-0

Fax: +49 (0)2403 – 6455-15

Mail: [email protected]

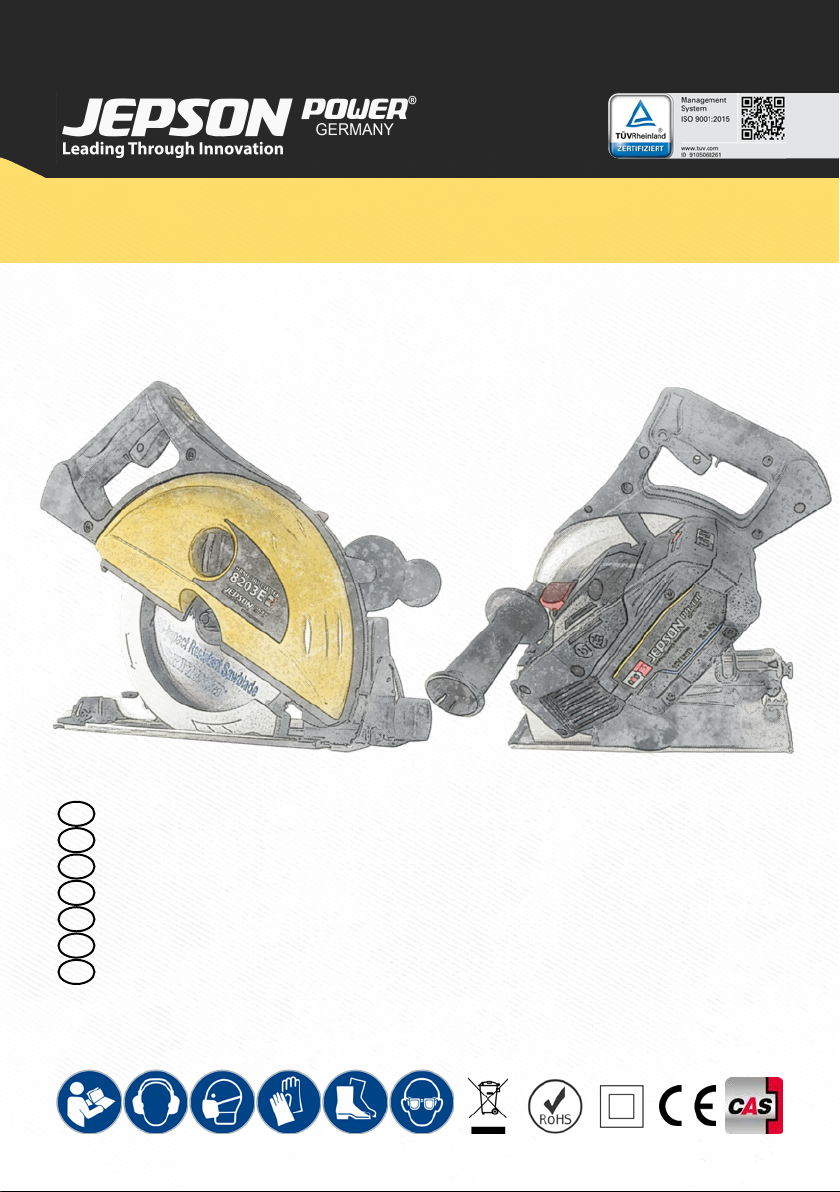

See page 2 - g. 1

1. Main handle

2. Side handle

3. Cover lock knob

4. Bevel lock

5. Base

6. Retracting blade guard

7. Sighting notch

8. Blade lock

9. Safety switch for unlocking

10. Depth lock lever

11. Battery lock

ENGLISH

5

All rights are expressly reserved. Duplication or

transfer on to third parties in any form whatsoever

is not allowed without our prior written permission.

Abbreviations

V Volt

A Ampere

Hz Hertz

W Watt

~ a.c.

/min Revolutions per minute rpm

N Newton

4. SAFETY INSTRUCTIONS

The basic prerequisite for safe handling and

disturbance-free operation of this electric tool

is knowledge of the basic safety instructions.

In addition, the accident prevention rules and

regulations which apply in the user location must

be adhered to, as well as the recognized rules of

the trade with regard to safety and correct working

methods.

It is not permitted to use the electric tool for other

purposes than those intended by the manufacturer.

Such use could give rise to unforeseeable risks.

Local working and safety rules and laws must always

be followed. The same applies to regulations which

apply to the environment.

Safety equipment must never by removed or

bridged over.

When using oils, greases and other chemical

substances, the safety regulations which apply to

the particular product must always be observed!

Contact with chemicals should be avoided as far

as possible. Before it is permissible to work with

these substances the instructions for use on the

packaging must be read and followed. This applies

for all chemicals, therefore also for cleaning media.

All notes and signs regarding safety and possible

risks must be kept in a fully legible condition.

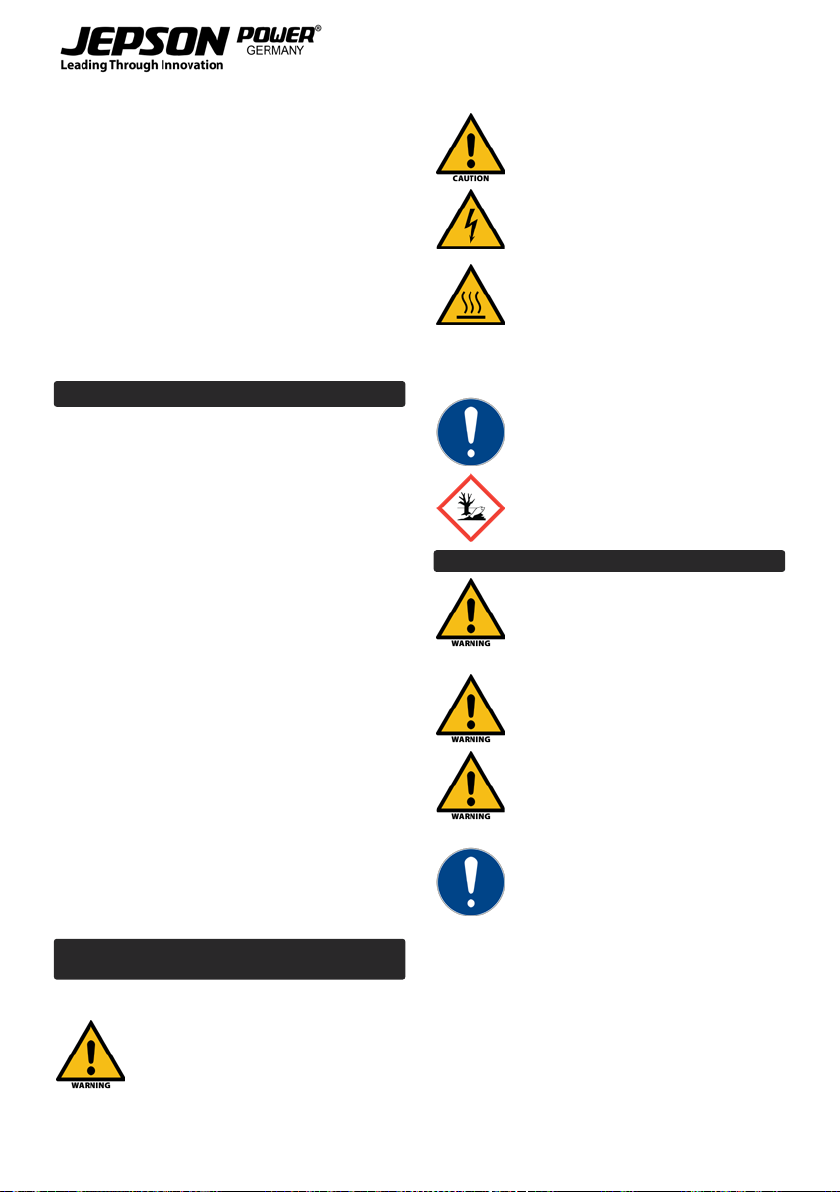

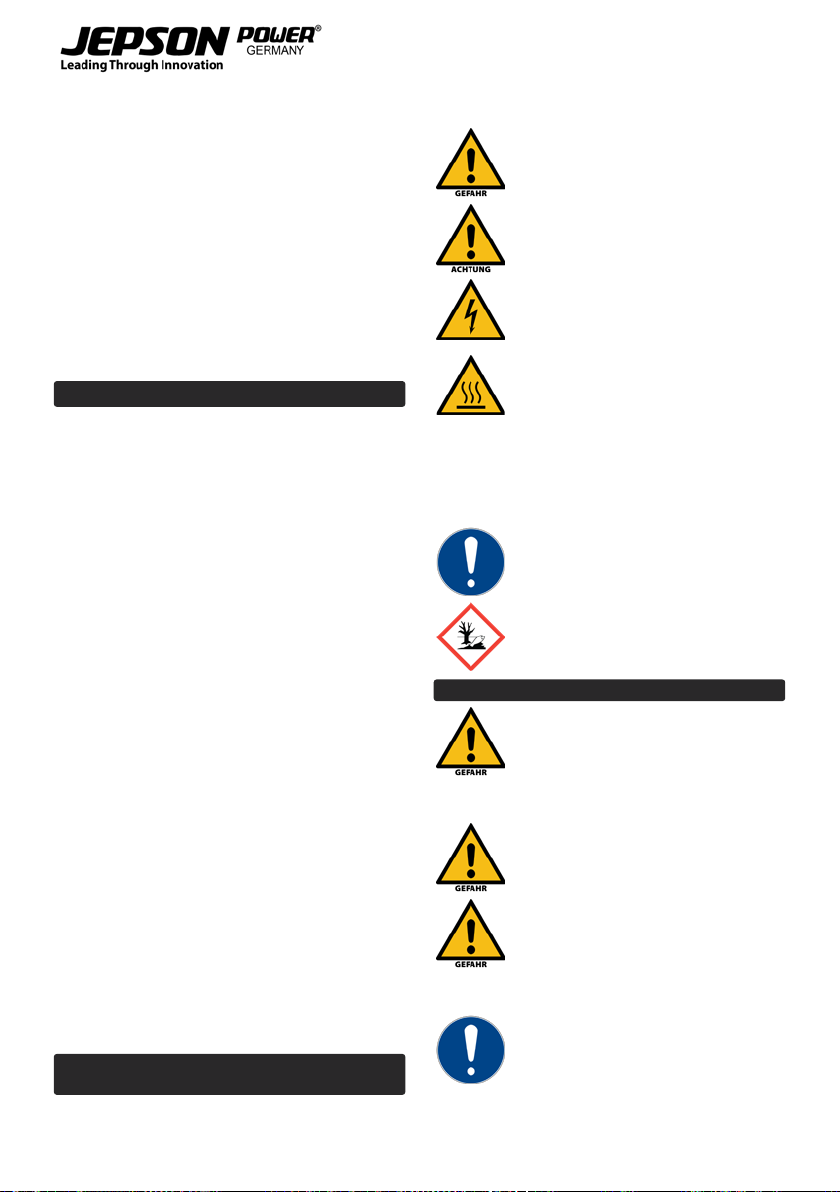

4.1. ILLUSTRATION OF SAFETY INSTRUC

TIONS

The following symbols are used in the instruction

manual:

Warning against possible danger of

injury or danger to life for persons

Warning against possible damage to

property or the environment

Warning against dangerous electrical

voltage

Warning against hot surfaces

Ignoring these instructions can lead to serious

damage to health, up to life-threatening injuries!

This symbol indicates important

information

Hazardous to the environment

4.2. DISCLAIMER

This power tool fulls the basic EC

safety and health regulations.

Nevertheless, dangerous situations

can arise.

All safety equipment must be

maintained in perfect condition.

Always pay attention to moving

parts. These can cause injury because

of their movement or by sudden

movement.

Only use the power tool when it is in

perfect condition from the technical

point of view, and only use it for

intended purpose while being aware

of safety issues and risks, and paying attention

to the instruction manual! In particular, have any

disturbances which could have a negative eect

on safety corrected immediately!

ENGLISH

6

EN

DE

FR

NL

ES

PT

IT

4.3. GENERAL POWER TOOL SAFETY

WARNINGS

WARNING!! Read all safety warnings,

instructions, illustrations and speci-

cations provided with this power

tool.

Failure to follow all instructions listed below may

result in electric shock, re and/or serious injury.

The following term “power tool”, refers to

mains-powered power tools (with mains cable) and

battery-powered power tools (without mains cable).

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE.

1. Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with grounded power

tools. Unmodied plugs and matching outlets

will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use

of a GFCI reduces the risk of electric shock.

3. Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the inuence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the o-position before

connecting to power source and/or BATTERY

pack, picking up or carrying the tool. Carrying

power tools with your nger on the switch or

energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ENGLISH

7

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

h) Do not let familiarity gained from

frequent use of tools allow you to become

complacent and ignore tool safety

principles. A careless action can cause

severe injury within a fraction of a second.

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch

does not turn it on and o. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or remove the BATTERY pack,

if detachable, from the power tool before

making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may aect the power tool’s operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations dierent from those

intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow

for safe handling and control of the tool in

unexpected situations.

5. Battery tool use and care

a) Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

b) Use power tools only with specically

designated battery packs. Use of any other

battery packs may create a risk of injury and re.

c) When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from

one terminal to another. Shorting the battery

terminals together may cause burns or a re.

d) Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If

contact accidentally occurs, ush with water.

If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery

may cause irritation or burns.

e) Do not use a battery pack or tool that is

damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour

resulting in re, explosion or risk of injury.

f) Do not expose a battery pack or tool to re

or excessive temperature. Exposure to re or

temperature above 130 °C may cause explosion.

g) Follow all charging instructions and do not

charge the battery pack or tool outside

the temperature range specied in the

instructions. Charging improperly or at

temperatures outside the specied range may

damage the battery and increase the risk of re.

6. Service

a) Have your power tool serviced by a

qualied repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained

b) Never service damaged battery packs. Service

of battery packs should only be performed

by the manufacturer or authorized service

providers.

4.4. CIRCULAR SAW SAFETY WARNINGS

Cutting procedures

1. DANGER!! Keep hands away from

cutting area and the blade. Keep

your second hand on auxiliary

handle, or motor housing. If both

hands are holding the saw, they cannot be cut

by the blade.

ENGLISH

8

EN

DE

FR

NL

ES

PT

IT

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below

the workpiece.

3. Adjust the cutting depth to the thickness

of the workpiece. Less than a full tooth of

the blade teeth should be visible below the

workpiece.

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to a

stable platform. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

5. Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring. Contact with a “live” wire will also make

exposed metal parts of the power tool “live” and

shock the operator.

6. When ripping always use a rip fence or

straight edge guide. This improves the

accuracy of cut and reduces the chance of blade

binding.

7. Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

8. Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw, for

optimum performance and safety of operation.

9. Kickback causes and related warnings

Kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator;

• When the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator;

• If the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward the operator.

• Kickback is the result of saw misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below.

10.Maintain a rm grip with both hands on

the saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line with

the blade. Kickback could cause the saw to

jump backwards, but kickback forces can be

controlled by the operator, if proper precautions

are taken.

11.When blade is binding, or when interrupting

a cut for any reason, release the trigger and

hold the saw motionless in the material until

the blade comes to a complete stop. Never

attempt to remove the saw from the work or

pull the saw backward while the blade is in

motion or kickback may occur. Investigate and

take corrective actions to eliminate the cause of

blade binding.

12.When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material. If saw blade is binding, it may walk

up or kickback from the workpiece as the saw is

restarted.

13.Support large panels to minimise the risk of

blade pinching and kickback. Large panels

tend to sag under their own weight. Supports

must be placed under the panel on both sides,

near the line of cut and near the edge of the

panel.

14.Do not use dull or damaged blades. Blunt

or improperly set blades produce narrow kerf

causing excessive friction, blade binding and

kickback.

15.Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut. If blade adjustment shifts while

cutting, it may cause binding and kickback.

16.Use extra caution when making a

“plunge cut” into existing walls or

other blind areas. The protruding blade

may cut objects that can cause kickback.

Lower guard function

17.Check the lower guard for proper closing

before each use. Do not operate the saw if

lower guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position. If saw is accidentally

dropped, lower guard may be bent. Raise the

lower guard with the retracting handle and

make sure it moves freely and does not touch

the blade or any other part, in all angles and

depths of cut.

18.Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

ENGLISH

9

before use. The lower guard may become

sluggish due to, gummy deposits, or a build-up

of debris.

19.Lower guard may be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard

by retracting handle and as soon as blade

enters the material, the lower guard must be

released. For all other sawing, the lower guard

should operate automatically.

20.Always observe that the lower guard is

covering the blade before placing saw down

on bench or oor. An unprotected, coasting

blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the

time it takes for the blade to stop after switch is

released.

21.This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

22.Never hold piece being cut in your hands or

across your leg. Secure the workpiece to a

stable platform. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

4.5. BATTERY SAFETY WARNINGS

1. Protect the machine and the rechargeable

batteries from humidity!

2. Do not throw the rechargeable batteries into

a re!

3. Do not use any defective or deformed

rechargeable batteries!

4. Do not open the rechargeable batteries!

5. Do not touch the contacts of the rechargeable

batteries and do not short-circuit them!

6. A slightly acidic, combustible liquid may leak

from defective li-ion rechargeable batteries! If

any battery liquid is leaking and comes in

contact with the skin, immediately rinse with

a copious amount of water. If any battery

liquid gets into your eyes, rinse with clean

water and immediately consult a doctor for

medical treatment!

7. Remove the rechargeable batteries from the

machine before carrying out any setting,

retooling, maintenance or cleaning tasks.

8. Ensure that the machine is switched o when

you push in the rechargeable battery.

9. Please remove the rechargeable battery

from the machine if the machine is put down,

transported or stored unattended.

5. APPLICATION

1. Do not use abrasive wheels with this

machine. Use only original Jepson Power saw

blades

2. Use only original Jepson Power or CAS

(Cordless Alliance System) battery packs

and accessories.

3. Battery packs marked with CAS are 100%

compatible with CAS devices (Cordless

Alliance System).

4. Tighten blade retaining bolt and all clamps

before operating.

5. Secure work piece properly. Work piece

should be straight and rmly clamped to avoid

possible movement and pinching as the cut

nears completion.

6. Allow the blade to come to a complete stop

before removing or securing workpiece, or

changing workpiece angle.

7. Check the inside surfaces of the arbor

anges as well as the sides of the blade for

freedom from any foreign matter.

8. Check the blade for cracks or other damage

before operation. Replace cracked or

damaged blade immediately.

9. Never start the tool with the work piece

against the blade.

10. Allow the motor to achieve full speed

before cutting.

11. After turning tool“ON”, gently push the tool

forward to engage work piece, then slowly

increase pressure as required to produce

the least amount of“sparking”.

12. Important: After completing the cut,

release power switch and wait for coasting

blade to stop completely before putting the

saw down.

13. Never operate the tool in an area with

ammable solids, liquids, or gases. Sparks or

hot fragments could cause a re or explosion.

14. This tool is designed for ferrous metals only.

Do not attempt to cut wood, masonry,

magnesium, or any other pyrophoric

materials with this tool.

15. Do not use cutting uids or lubricants on

the blade.

16. Some metals have coatings, which can be

toxic. Take extra care to prevent inhalation

ENGLISH

10

EN

DE

FR

NL

ES

PT

IT

and skin contact when working with these

materials. Request, and follow, any safety

information available from your material

supplier.

17. There are certain applications for which

this tool was designed. The manufacturer

strongly recommends that this tool NOT be

modied and/ or used for any application

other than for which it was designed. If

you have any questions relative to its

application DO NOT use the tool until you

have written the manufacturer and have

been advised.

Metal chips are often very sharp and hot. Never

touch them with bare hands. Clean up with a

magnetic chip collector and a chip hook or other

appropriate tool.

6. FUNCTIONAL DESCRIPTION

This machine is a dry cutting circular saw designed

to cut ferrous metals, which uses carbide tipped saw

blades. The saw should only be used with original

Jepson Power saw blades.

6.1. UNPACKING

Carefully remove the tool and all loose items from

the shipping container. Retain all packing materials

until after you have inspected and satisfactorily

operated the machine.

6.2. CARTON CONTENTS

1. Metal cutting saw HDC 8203E

2. Original Jepson Power carbide tipped LBS saw

blade 203/48T

3. 2x 18V LiHD 5.5A high-performance battery

4. Air-Cooled LiHD charging station

5. Rip fence cutting guide

6. Hex wrench

6.3. CHARGING THE RECHARGEABLE

BATTERY

Check whether the rated voltage of the

rechargeable battery agrees with the information

specied on the machine.

Rechargeable battery and charger are matched to

each other. Only use the Jepson Power Air-Cooled

LiHD chargers for recharging.

Before using a new machine, rst of all charge the

rechargeable battery.

A description of how to start up and charge the

Jepson Power Air-Cooled LiHD charger can be

found in the appended instructions “Jepson Power

Air-Cooled LiHD charging station”.

The rechargeable battery is equipped with a

temperature monitoring system. This guarantees

that the rechargeable battery is only charged in

the temperature range between 0°C and 50°C. This

achieves a long service life for the rechargeable

battery.

A considerably shortened operating time per

charging procedure indicates that the rechargeable

battery is spent and needs to be replaced.

WARNING!! Explosion hazard

Protect the rechargeable battery

from heat, re and moisture.

Do not place the rechargeable

battery onto heating appliances and do not

expose the rechargeable battery to strong

solar radiation for a longer period of time.

Temperatures above 50°C are detrimental to the

rechargeable battery. Allow a heated rechargeable

battery to cool down before charging it.

The optimum storage temperature ranges between

10°C and 30°C.

CAUTION!! Do not open the

rechargeable battery and protect it

from impacts. Keep the rechargeable

battery in a dry and frost-proof place.

WARNING!! Cover the rechargeable

battery’s contacts if it is stored

outside the charger. There is a re and

explosion hazard in case of a short

circuit caused by metallic bridging.

Follow the instructions for the

protection of the environment.

6.4. FITTING THE RECHARGEABLE BATTERY

Slide the charged rechargeable battery into the

battery guide next to the handle until it perceptibly

engages.

CAUTION!! Before using the machine,

convince yourself that the

rechargeable battery is rmly seated

in the machine.

ENGLISH

11

6.5. REMOVING THE RECHARGEABLE

BATTERY

Unlock the rechargeable battery by pressing the

locking lever (See g. 11) and pull it out of the

battery guide.

CAUTION!! Do not use force to do so.

6.6. INSTALLING THE BLADE

1. Unplug the rechargeable battery for all service

work.

2. Remove any accumulated debris in the guards

and around the spindle. Check the lower

retracting blade guard to ensure that it is in

working order.

3. Clean the inner spindle ange. Orient the

ange so that the correct bore size faces the

blade and place the new blade on the spindle,

making sure that the teeth point forwards. (If

in doubt of the orientation of the blade, refer

to the legend cast into the lower retracting

blade guard) Avoid contact with blade teeth

to prevent personal injury.

4. NOTE: Only use original Jepson Power saw

blades.

5. Place the outer spindle ange on the spindle

with the at side toward the blade. See g. 2.

6. Replace and nger- tighten the blade retaining

bolt by turning it clockwise.

7. Push in the blade lock lever and rotate the

spindle by hand until the lock engages the

spindle See g. 3. Tighten the blade retaining

bolt securely with the provided wrench and

release the spindle lock.

6.7. REMOVING THE BLADE

1. Unplug the rechargeable battery for all service

work.

2. See g. 3. It is not necessary to remove the

outer blade cover, just leave it in place. Push

in the spindle lock and using the supplied

hex wrench, rotate the blade until the lock

engages the blade spindle.

3. Avoid contact with the blade teeth to prevent

personal injury.

4. While holding the blade lock lever, use the

provided wrench to loosen the blade retaining

bolt. Then remove it and the outer spindle

ange.

5. The blade may now be carefully removed.

6.8. ADJUSTMENT DEPTH OF CUT

Adjust the depth of cut so that the saw blade

protrudes through the thickness of work piece. To

adjust the depth of cut:

1. Unplug the rechargeable battery for all service

work.

2. Lift the depth lock lever at the rear of the saw.

See g. 4.

3. Raise or lower the saw base until the blade

extends the desired depth below the base.

(See the scale and pointer cast into the main

body casting.)

4. Press the depth lock lever down rmly, locking

the saw in the selected position.

6.9. ADJUSTMENT OF BEVEL ANGLE

To adjust the bevel angle, refer to the bevel gauge

on the base. There are markings for dierent angles

from 0 to 45 degrees. To adjust the bevel angle:

Loosen the bevel lock knob

( See g. 5 ) and the smaller knob at the rear. Lift the

bevel lock knob out of the slot and rotate the base

to the desired angle. The most commonly used

angles each have an individual slot. Simply drop the

bevel lock into the slot and tighten. If other angles

are needed, tighten the bevel lock knob to hold at

the desired position. Then tighten the smaller knob

at the rear of the base.

6.10. HOW TO USE THE SIGHTING NOTCH

To aid in free- hand cutting, a sighting notch is

located at the front of the base. See g. 6. Align

the cutting line on the work piece with the sighting

notch. Make the cut. Use the right-hand notch

(between the two marking dots) for straight cuts

and the left- hand notch (located below the rivet)

for 45- degree bevel cuts.

6.11. STARTING AND STOPPING TOOL

Do not press the trigger switch before or while

inserting the rechargeable battery. To start the

machine, rst press the safety lock button then

squeeze the trigger switch to start the motor.

Release the trigger switch to stop the motor. See

g. 7.

6.12. REMOVING CHIPS

This dry-cut metal saw has an internal chip collector.

When the chip collector is full, the chips

ENGLISH

12

EN

DE

FR

NL

ES

PT

IT

must be cleared. To do this, rst shut down and

Unplug the rechargeable battery. The outer blade

cover lock knob has a bayonet lock thread. See g.

8. To remove cover, turn knob anticlockwise while

pushing in against the spring tension. Then lift

cover away. Recently- cut chips can be very hot.

Take care when removing the cover to keep the

chips or shavings away from your hands or other

body

parts. Do not throw hot debris where paper or other

ammable materials are located. To replace the

outer blade cover, line up tang with slot and push in

against the spring while turning clockwise. Ensure

that the cover is properly seated.

6.13. HOW TO USE THE RIP FENCE

Using the rip fence will provide more accurate

straight cuts than by cutting free- hand. For instal-

lation, Unplug the rechargeable battery. Then insert

the rip fence in the mounting slots in the base.

6.14. LOWER RETRACTING BLADE GUARD

The lower retracting blade guard is a safety device

important for your protection. Every

time you use the saw, make sure that the guard

rotates freely and returns quickly and completely

to its closed position. Before each use, remove

any accumulated chips, or shavings from the area

around the hub of the guard. DO NOT LUBRICATE

THIS AREA. The hub has a dry lm lubricated surface

that does not need oiling. NEVER block or wedge

the blade guard in the open position. NEVER use

your saw if the blade guard is not in working order.

If blade guard movement is sluggish or if binding

exists, return the saw to your nearest AUTHORIZED

SERVICE CENTER for repair.

6.15. HOW TO USE THE TOOL

Eective control of this powerful saw requires

two- handed operation for maximum protection.

Support the work properly and to hold the saw

rmly WITH BOTH HANDS to

prevent loss of control which could cause personal

injury. Always hold the side handle with the left

hand and the rear handle with the right hand for

proper hand support of the saw. Protect your eyes

from injury with safety glasses or goggles.

Do not use cutting uids or lubricants on the blade.

6.16. CLAMP THE WORK PIECE

Secure the work piece properly. The work piece

should be straight and rmly clamped to avoid

possible

movement and pinching as the cut nears

completion. Provide adequate support for long or

wide work pieces. Conrm that the blade has come

to a complete stop before removing or securing the

work piece, or changing the work piece angle. Press

the safety, then the trigger switch. Move the saw

forward to contact the work piece. Clamp the work

piece on a rigid support, such as a bench or saw

horses. Mark the line of cut on the work piece. Be

sure that the cuto line is far enough on the work

piece to allow proper operation of the telescoping

guard. Place the front edge of the saw squarely on

work piece before starting the motor. Sight the

cutting line with the sighting notch indicator or

use the rip fence. Be certain that the blade is not

contacting the work piece. Press the safety, then the

trigger switch, allow the motor to come up to full

speed and move the saw forward to begin the cut.

Do not force the cut. Let the saw do the cutting at

the rate of speed permitted by the type of cut and

work piece. Increase feed pressure as the blade

cuts through the thicker cross-sections (to maintain

minimum “sparking”). Decrease the feed pressure as

the blade cuts through the thinner cross sections

(to maintain motor speed and avoid overloading

the machine). After completing the cut, release the

power switch and wait for the coasting blade to

stop completely before putting the saw down.

7. MAINTENANCE

7.1. KEEP TOOL CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to

clean plastic parts. They could possibly dissolve or

otherwise damage the material. Wear safety glasses

while using compressed air.

7.2. WARNING

Make sure that the tool is turned o and not

connected to a power source before you perform

maintenance and/or examine the tool. For safety

reasons and in order to ensure proper functioning

of the device, repairs, maintenance and adjustment

of the tool must be performed by a certied service

center. Use only original spare parts.

ENGLISH

13

7.3. TRANSPORT

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

The user can transport the batteries by road without

further requirements.

When being transported by third parties (e.g.:

air transport or forwarding agency), special

requirements on packaging and labelling must

be observed. For preparation of the item being

shipped, consulting an expert for hazardous

material is required.

Dispatch batteries only when the housing is

undamaged. Tape or mask o open contacts and

pack up the battery in such a manner that it cannot

move around in the packaging.

Please also observe possibly more detailed national

regulations.

7.4. DISPOSAL OF RECHARGEABLE

BATTERIES/BATTERIES

The machine, rechargeable batteries,

accessories and packaging should be

sorted for environmental-friendly

recycling.

Do not dispose of power tools and batteries/

rechargeable batteries into household waste!

Only for EC countries:

According to the European Guideline

2002/96/EC, power tools that are no

longer usable, and according to the

European Guideline 2006/66/EC, defective or

used battery packs/batteries, must be collected

separately and disposed of in an environmentally

correct manner.

Li-Ion:

Please observe the instructions in

section „7.3 Transport“.

Subject to change without notice.

8. QUOTATION

When returning a defective machine for repair with

cost estimate. We charge a handling fee of 50€, but

does not apply if a repair order or purchase of a new

machine is given.

9. SPARE PARTS

For current spare parts list with order numbers

please visit our website:

www.drycutter.com

10. WARRANTY

The warranty time (warranty according to the

commercial code) is 12 months from the day of sale

to the end consumer.

It covers and is limited to the free replacement

of the defective parts or the free repair of defects

that are demonstrably due to the use of imperfect

materials during production or due to assembly

errors.

Incorrect use or start-up and unauthorized instal-

lations or repairs not specied in the operating

instructions void the warranty. Parts that are subject

to wear are also excluded from the warranty. We

expressly reserve the right to make decisions on

the warranty application. The warranty is void if

the device is opened by a third party. Transport

damages, maintenance work as well as damage and

malfunctions due to insucient maintenance are

not covered by the warranty.

For warranty claims, the proof of purchase of the

device must be given by presenting the delivery

note, bill, or cash receipt.

As far as it is legal, we assume no liability for any

personal, material or consequential damages, in

particular if the device is used dierently than for

the purpose indicated in the operating instructions,

not installed or repaired according to the operating

instructions, or repairs were executed by a

layperson.

We reserve the right to perform repairs or

maintenance over and above the ones specied in

these operating instructions at the factory.

The quality and safety of the JEPSON POWER

circular cold saw depends on the exclusive use of

original JEPSON POWER saw blades or saw blades

with the same cutting width, blade diameter and

recommended cutting speed. The use of other saw

blades may damage the machines.

The original JEPSON POWER saw blade fulls all

requirements of the TÜV examination (several

inspection oces) and is therefore certied by these

inspection oces. In case of use of saw blades with

dimensions that dier from the original JEPSON

POWER saw blades, the manufacturer assumes no

liability.

ENGLISH

14

EN

DE

FR

NL

ES

PT

IT

The warranty excludes:

• Wear parts such as switches, anges, carbon

brushes, supportings and cutting tools (saw

blades, carbide inserts, drills and abrasive) as

well as electronic units.

• Other parts that are subject to wear through

use or natural wear and tear.

• Tool failure due to non-compliance with the

instruction manual, unconventional use,

abnormal atmospheric conditions, improper

operating conditions, overload, or lack of

service or maintenance.

• Tool failure due to replacement parts or

additional parts that are not original Jepson

Power parts.

• Machines to which changes or additions have

been made.

ENGLISH

15

16

EN

DE

FR

NL

ES

PT

IT

1. EGKONFORMITÄTSERKLÄRUNG 18

2. TECHNISCHE DATEN 19

3. BENUTZERHINWEISE 19

4. SICHERHEITSHINWEISE 20

4.1. DARSTELLUNG VON SICHERHEITSHINWEISEN 20

4.2. ALLGEMEINE SICHERHEITSHINWEISE 20

4.3. SPEZIFISCHE SICHERHEITSVORSCHRIFTEN 23

5. BESCHREIBUNG 25

5.1. ANGABEN ZUR VERWENDUNG 25

6. FUNKTIONSBESCHREIBUNG 25

6.1. AUSPACKEN 25

6.2. PACKUNGSINHALT 25

6.3. AKKU LADEN 26

6.4. AKKU EINSETZEN 26

6.5. AKKU ENTNEHMEN 26

6.6. ANBRINGUNG DES SÄGEBLATTS 26

6.7. ENTFERNUNG DES SÄGEBLATTS 26

6.8. EINSTELLUNG DER SCHNITTTIEFE 27

6.9. EINSTELLUNG DES NEIGUNGSWINKELS 27

6.10. VERWENDUNG DER VISIERKIMME 27

6.11. EIN UND AUSSCHALTEN DES GERÄTS 27

6.12. ENTFERNUNG VON METALLSPÄNEN 27

6.13. VERWENDUNG DES PARALLELANSCHLAGS 27

6.14. UNTERE EINZIEHBARE SÄGEBLATTSCHUTZVORRICHTUNG 28

6.15. VERWENDUNG DES GERÄTS 28

6.16. BEFESTIGUNG DES ARBEITSSTÜCKS 28

7. INSTANDHALTUNG UND KUNDENDIENST 28

7.1. GERÄT SAUBER HALTEN 28

7.2. REINIGUNG 29

7.3. SCHMIEREN 29

7.4. TRANSPORT 29

7.5. ENTSORGUNG AKKUS/BATTERIEN 29

8. KOSTENVORANSCHLAG 29

9. ERSATZTEILE 29

10. GARANTIE 29

17

DEUTSCH

1. EGKONFORMITÄTSERKLÄRUNG

(nach Anhang IIA der Maschinenrichtlinie)

Wir, Jepson Power GmbH, Ernst – Abbe – Straße 5, 52249 Eschweiler, Germany, erklären in alleiniger

Verantwortung , dass das Produkt :

Maschinenbezeichnung: Hand Dry Cutter HDC 8203E

Baujahr: Siehe Maschinenetikett

Seriennummer: Siehe Maschinenetikett

Auf das sich diese Erklärung bezieht, mit den folgenden EG-Richtlinien und harmonisierten Normen oder

anderen normativen Dokumenten übereinstimmt:

2006/42/EC Machinery Directive

2014/30/EU EMC Directive

2011/65/EU RoHS Directive

EN 62841-1 :2015

EN 62841-2-5:2014

EN 55011

EN 12100

Pierre Michiels, GF

Name, Position Eschweiler, 01.01.2023

CE-Zeichen zur Dokumentation der

Übereinstimmung mit den

grundlegenden Sicherheits- und

Gesundheitsanforderungen gemäß

Anhang I der Maschinenrichtlinie

Nur für EU Länder

Werfen Sie Elektrowerkzeuge nicht in

den Hausmüll!

Gemäß Europäischer Richtlinie

2002/96/EG über Elektro- und Elektronik- Altgeräte

und Umsetzung in nationales Recht müssen

verbrauchte Elektrowerkzeuge getrennt gesammelt

und einer umweltgerechten Wiederverwertung

zugeführt werden.

Zur Verringerung eines Verletzungs-

risikos lesen Sie die Betriebsanleitung.

Schützen Sie den Akku vor Hitze,

übermäßiger Sonneneinstrahlung,

Feuer, Frost, Wasser und Feuchtigkeit.

Akkupacks vor Nässe schützen!

Akkupacks vor Feuer schützen!

Es besteht Explosionsgefahr!

Cordless Allicance System (=CAS) ist ein

herstellübergreifendes Akku-System.

Weitere Informationen erhalten Sie

unter

www.cordless-alliance-system.com

18

DEUTSCH

EN

DE

FR

NL

ES

PT

IT

2. TECHNISCHE DATEN

Nennspannung 18V

Leerlaufdrehzahl 3.500 min-1

Sägeblattdurchmesser 203 mm | 8”

Neigungswinkel 0°~45°

Aufnahmedurchmesser 25,4 mm | 1“

Max. Schnitttiefe 90°: 67 mm | 2.63”

45°: 42 mm | 1.65”

Nettogewicht 5,4 kg | 12 lbs

Schalldruckpegel 87,3 dB

Schallleistungspegel 98,1 dB

Vibration - Hauptgri ah = 2,05 K = 0,07

Vibration - Hilfsgri ah = 2,39 K = 0,3

Angaben nach 2.2 des Anhangs 1 der V.G. Richtlinie über Vibrationen

3. BENUTZERHINWEISE

Hinweise für den Kunden

Die Betriebsanleitung enthält wichtige Hinweise,

um die Maschine sicher, sachgerecht und

wirtschaftlich zu betreiben. Ihre Beachtung hilft

Gefahren zu vermeiden, Reparaturkosten und

Ausfallzeiten zu vermindern und die Zuverlässigkeit

und Lebensdauer der Maschine zu erhöhen.

Die Betriebsanleitung ist von jeder Person zu lesen

und anzuwenden, die mit dem Elektrowerkzeug

arbeitet. Dies gilt insbesondere für das Kapitel

Sicherheitshinweise. Während des Arbeitseinsatzes

ist es hierfür zu spät. Bewahren Sie ein Exemplar

dieser Betriebsanleitung ständig zusammen

mit dem Elektrowerkzeug auf, so dass sie stets

gribereit ist!

Im Zweifelsfall ist immer der Hersteller

anzusprechen.

Neben der Betriebsanleitung sind die im

Verwenderland und an der Einsatzstelle geltenden

verbindlichen Reglungen zur Unfallverhütung zu

beachten. Daneben sind auch die anerkannten

fachtechnischen Regeln für sicherheits- und

fachgerechtes Arbeiten einzuhalten.

Haftung und Gewährleistung

Alle die in dieser Anleitung enthaltenen Informa-

tionen wurden zu unserem besten Wissen und

Gewissen erstellt.

Diese Anleitung wurde mit größter Sorgfalt erstellt.

Allerdings, wenn Sie unvollständigen Elemente oder

Fehler entdecken sollten, informieren Sie uns bitte

schriftlich. Ihre Verbesserungsvorschläge helfen

uns, eine benutzerfreundlichere Betriebsanleitung

zu erstellen.

Nachfolgende Bestellungen und Urheberrecht

Weitere Exemplare dieser Anleitung können von der

unten angegebenen Adresse bestellt werden. Wir

bitten um Ihr Verständnis, dass weitere Exemplare

gebührenpichtig sind.

Jepson Power GmbH

Ernst-Abbe-Straße 5

D-52249

Eschweiler

Phone: + 49 (0)2403 – 6455-0

Fax: +49 (0)2403 – 6455-15

Mail: [email protected]

Siehe Seite 2 - Abb. 1.

1. Hauptgri

2. Seitengri

3. Einrastknopf für Abdeckung

4. Sperrvorrichtung für Neigungswinkel

5. Unterteil

6. Einziehbare Sägeblattschutzvorrichtung

7. Visierkimme

8. Sperrvorrichtung für Sägeblatt

9. Sicherheitsschalter für Entriegelung

10. Feststellhebel für Schnittstärke

11. Akku-Raste

19

DEUTSCH

Alle Rechte sind ausdrücklich vorbehalten. Die

Vervielfältigung oder Übertragung an Dritte in

welcher Form auch immer ist ohne unsere vorherige

schriftliche Genehmigung nicht gestattet.

Abkürzungen

V Volt

A Ampere

Hz Hertz

W Watt

~ AC

/min Umdrehungen/Minute

N Newton

4. SICHERHEITSHINWEISE

Die Grundvoraussetzung für eine sichere

Handhabung und störungsfreien Betrieb dieses

elektrischen Werkzeuges ist die Kenntnis der

grundlegenden Sicherheitshinweise. Darüber

hinaus sind die Unfallverhütungsvorschriften,

die am Standort des Nutzers gelten, sowie die

anerkannten Regeln der Technik im Hinblick auf die

Sicherheit und korrekte Arbeitsweise einzuhalten.

Es ist nicht gestattet, das elektrische Werkzeug für

andere Zwecke als die vom Hersteller vorgesehenen

verwenden. Eine solche Verwendung könnte zu

unvorhersehbaren Risiken führen.

Lokale Arbeits-und Sicherheitsvorschriften und

Gesetze müssen immer befolgt werden. Das gleiche

gilt für Regelungen, die für die Umwelt gelten.

Sicherheitseinrichtungen dürfen nie entfernt oder

überbrückt werden.

Bei der Verwendung von Ölen, Fetten und anderen

chemischen Substanzen, müssen die Sicherhe-

itsvorschriften, die zu dem jeweiligen Produkt

gelten immer beachtet werden! Kontakt mit

Chemikalien sollte, so weit wie möglich vermieden

werden. Bevor es zulässig ist, mit diesen Stoen

zu arbeiten, ist die Gebrauchsanweisung auf der

Verpackung zu lesen und zu befolgen. Dies gilt für

alle Chemikalien, also auch für die Reinigung von

Geräten oder Werkstücken.

Alle Notizen und Zeichen zur Sicherheit und

möglichen Risiken müssen in vollständig lesbarem

Zustand gehalten werden

4.1. DARSTELLUNG VON SICHERHEITSHIN

WEISEN

In der Betriebsanleitung werden folgende Symbole

verwendet:

Warnung vor möglicher Verletzungs-

oder Lebensgefahr von Personen

Warnung vor möglichen Sach- und/

oder Umweltschäden

Warnung vor gefährlicher

elektrischer Spannung

Warnung vor heißer Oberäche

Das Nichtbeachten dieser Hinweise kann

schwere gesundheitsschädliche Auswirkungen

zur Folge haben, bis hin zu lebensgefährlichen

Verletzungen!

Dieses Symbol deutet auf wichtige

Sachverhalte hin!

Umweltgefährlich

4.2. ALLGEMEINE SICHERHEITSHINWEISE

Dieses Elektrowerkzeug entspricht

den grundlegenden EG Sicherhe-

its-und Gesundheitsvorschriften.

Dennoch können gefährliche

Situationen entstehen.

Alle Sicherheitseinrichtungen

müssen in einwandfreiem Zustand

gehalten werden.

Achten Sie immer auf sich

bewegende Teile. Diese können

durch ihre Bewegung oder durch

plötzlich einsetzende Bewegung

Verletzungen verursachen.

Benutzen Sie das Elektrowerkzeug

nur in technisch einwandfreiem

Zustand sowie bestimmungsgemäß,

sicherheits- und gefahrenbewusst

unter Beachtung der Betriebsanleitung! Lassen

20

DEUTSCH

Table of contents

Languages:

Other Jepson Saw manuals