2

TABLE OF CONTENTS

INTRODUCTION...................................................................................................................................... 1

SPECIFICATIONS..................................................................................................................................... 1

1 Purchase Agreement, Full Assumption of Liability and Indemnity Agreement .......... 4

2 Safety Information............................................................................................................................. 6

2.1 Safety Rules......................................................................................................................................................................7

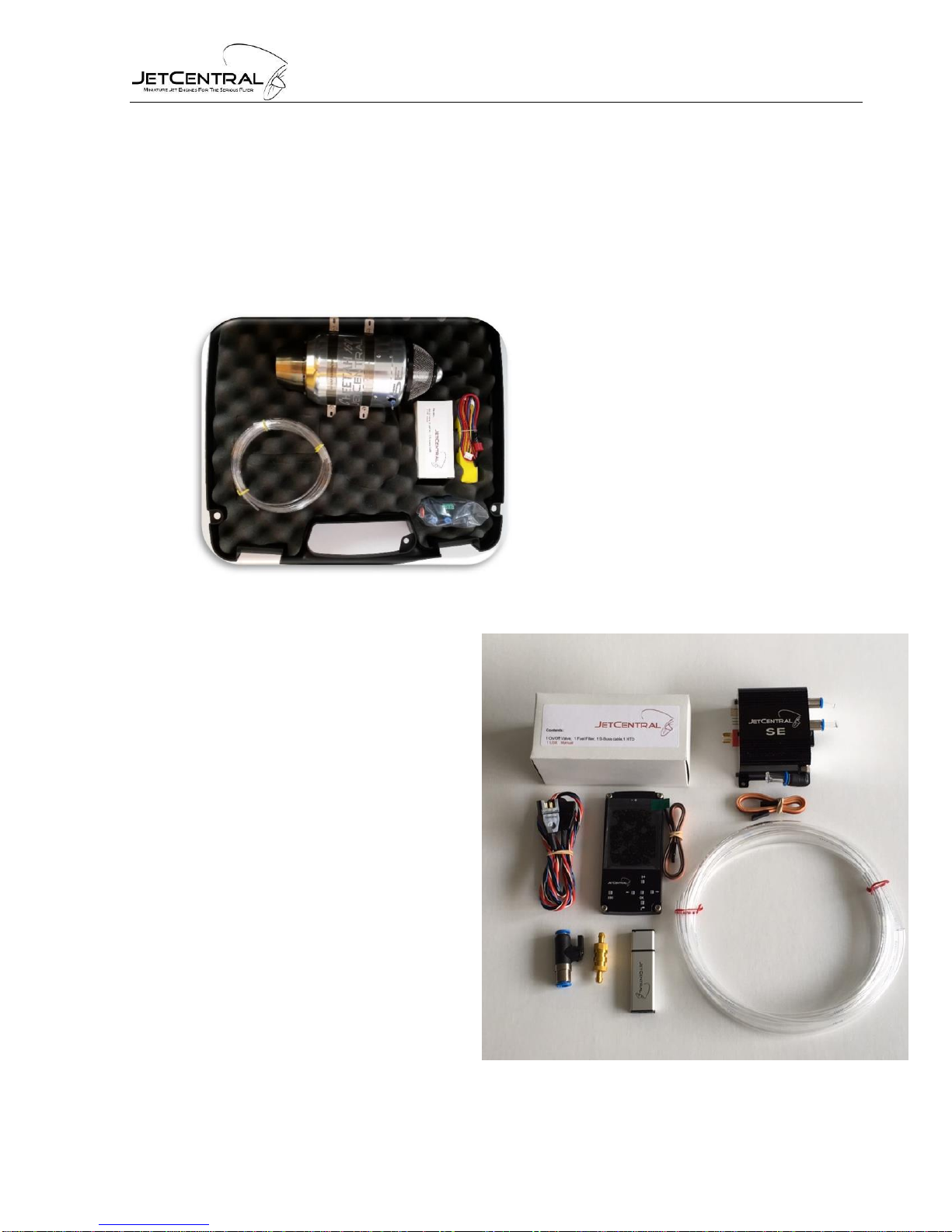

3 Turbine System Components Description ................................................................................ 8

3.1 Parts List ...........................................................................................................................................................................8

3.2 Turbine..............................................................................................................................................................................9

3.3 Fuel / Oil System ............................................................................................................................................................9

3.4 Kero Start System ..........................................................................................................................................................9

3.5 Hand Data Terminal (HDT).....................................................................................................................................10

3.6 SE POWERPACK / ECU...............................................................................................................................................11

3.6.1 Overview..................................................................................................................................................................................... 11

3.6.2 Features....................................................................................................................................................................................... 11

3.6.3 Measurements.......................................................................................................................................................................... 11

3.6.4 Other functions ........................................................................................................................................................................ 12

3.6.5 Micro SD memory slot location ........................................................................................................................................ 12

3.7 Optional Telemetry Interface ................................................................................................................................12

4 Turbine System.................................................................................................................................13

4.1 Connections to SE POWERPACK / ECU ................................................................................................................14

4.2 System Batteries .........................................................................................................................................................15

4.3 Receiver battery..........................................................................................................................................................15

4.4 Radio Receiver.............................................................................................................................................................15

4.5 Fuel System Connections .........................................................................................................................................16

4.6 Mounting Turbine and POWERPACK ..................................................................................................................16

5 Programming the SE POWERPACK / ECU................................................................................17

5.1 Welcome Screens........................................................................................................................................................17

5.2 Main Screen...................................................................................................................................................................17

5.3 Menu Screen .................................................................................................................................................................18

5.4 Starting Parameters Sub-menu .............................................................................................................................18

5.5 Running Parameters Sub-menu ............................................................................................................................19

5.5.1 Air Speed Limit / Turboprop RPM Limit...................................................................................................................... 20

5.6 Radio Adjustment Sub-menu..................................................................................................................................20

5.6.1 Transmitter Setup .................................................................................................................................................................. 20

5.6.2 Throttle Curves........................................................................................................................................................................ 21

5.6.3 Types of Throttle Curves ..................................................................................................................................................... 22

5.7 Info Menu.......................................................................................................................................................................22

5.8 Battery Menu................................................................................................................................................................23

5.9 Alarm Display...............................................................................................................................................................23

5.9.1 Stop Alarms ............................................................................................................................................................................... 23

5.9.2 Info Alarms ................................................................................................................................................................................ 24

5.9.3 Turbine Status Messages..................................................................................................................................................... 24

5.9.4 Turbine Alarm Messages..................................................................................................................................................... 25

5.10 World Menu................................................................................................................................................................26

5.11 Memory Menu............................................................................................................................................................26

5.11.1 Using the micro SD Card ................................................................................................................................................... 26

5.12 Test Menu....................................................................................................................................................................27