6

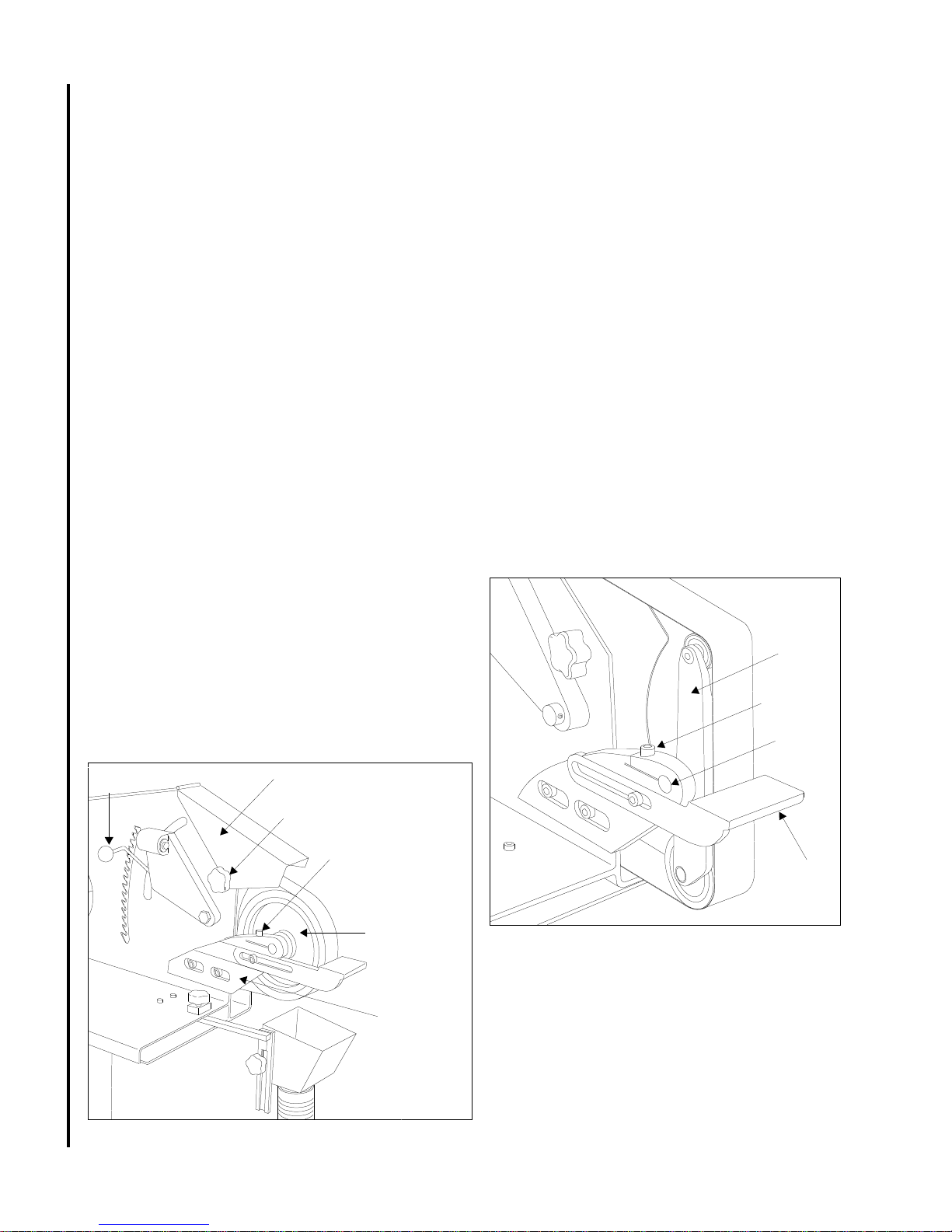

A B C D

17. Keep hands in sight and clear of all moving parts

and cutting surfaces.

18. All visitors should be kept at a safe distance

from the work area. Make workshop completely

safe by using padlocks, master switches, or by

removing starter keys.

19. Know the tool you are using—its application,

limitations, and potential hazards.

General Electrical Cautions

This machine should be grounded in accordance with

the National Electrical Code and local codes and

ordinances. This work should be done by a qualified

electrician. The machine should be grounded to

protect the user from electrical shock.

Wire sizes

Caution: for circuits which are far away from the

electrical service box, the wire size must be in-

creased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended:

AWG (American wire gauge) Number

Conductor Length 240 Volt Lines 120 Volt Lines

0 - 50 Feet No. 14 No. 14

50 - 100 Feet No. 14 No. 12

Over 100 Feet No. 14 No. 8

Abrasive grinding can be hazardous to operators and

bystanders. Grinding sparks, chips and dust par-

ticles thrown off by the grinding disc can cause

serious injury by contact or inhalation. To avoid

such injuries you must comply with the following

safety requirements:

1. Always wear protective eyewear when operating

machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields which

comply with ANSI Z87.1. Use of eye wear which

does not comply with ANSI Z87.1 specifications

could result in severe injury from breakage of

eye protection. See Figure A, below.

2. Wear leather safety gloves, arm guards, leather

aprons and safety shoes.

3. A dust collection system is recommended,

Operator shall also wear a dust mask at all

times. See Figure B, below.

4. Additional precautions may be necessary for

grinding materials which are flammable or have

other hazardous properties. You should always

consult the manufacturer of such materials for

instructions on grinding and handling.

5. Do not force or jamb the workpiece into the

grinding disc.

6. Before grinding, always allow the motor to come

up to operating speed, then check the grinding

disc for wobble, runout, or any unbalanced

Safety requirements for abrasive grinding machines

condition. If the disc is not operating accurately

and smoothly, immediately stop the motor and

make repairs before attempting any grinding

operations.

7. Abrasive discs must be stored in a controlled

environment area. Relative humidity should be

35% to 50% and the temperature should be

between 60 and 80 degrees Fahrenheit. Failure

to do so could cause premature disc failure.

8. Examine the face of the grinding disc carefully.

Excessive grinding which wears down to the

backing material can tear the disc. Never use a

disc which shows backing, nicks or cuts on the

surface or edge or damage due to creasing or

poor handling.

9. When installing a new disc, be certain the disc is

accurately centered on the drive wheel. Failure

to do so could cause a serious unbalanced

condition.

10. Always present the workpiece to the wheel while

resting the workpiece firmly on the table. Failure

to do so could result in damage to the workpiece

or throwing of the workpiece off the wheel.

11. Safety shoes which comply with ANSI Z41.1 shall

be worn. See Figure C.

12. Personal hearing protection such as ear plugs or

ear muffs shall be used to protect against the

effect of noise exposure. See Figure D: