GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new JET-machine. This manual has been

prepared for the owner and operators of a JET JTS-315LA table saw to promote safety during installation, operation and

maintenance procedures. Please read and understand the information contained in these operating instructions and the

accompanying documents. To obtain maximum life and efficiency from your machine, and to use the machine safely, read this

manual thoroughly and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. Warranty

3. Safety

Authorized use

General safety notes

Remaining hazards

4. Machine specifications

Technical data

Noise emission

Contents of delivery

Description of machine

5. Transport and start up

Transport and installation

Assembly

Dust connection

Mains connection

Starting operation

6. Machine operation

7. Setup and adjustments

Changing saw blade

Mounting the raving knife

Mounting the saw guard

Rising and tilting sawblade

Rip fence setup

Adjusting 90°stop

Adjusting sawblade parallel

8. Maintenance and inspection

9. Troubleshooting

10. Environmental protection

11. “Safe operation”.........appendix A

1. Declaration of conformity

On our own responsibility we hereby

declare that this product complies

with the regulations* listed on page 2.

Designed in consideration with the

standards**. CE type examination***

performed by****.

2. Warranty

The Seller guarantees that the

supplied product is free from material

defects and manufacturing faults. This

warranty does not cover any defects

which are caused, either directly or

indirectly, by incorrect use,

carelessness, accidental damage,

repair, inadequate maintenance or

cleaning and normal wear and tear.

Guarantee and/or warranty claims

must be made within twelve months

from the date of purchase (date of

invoice). Any further claims shall be

excluded.

This warranty includes all guarantee

obligations of the Seller and replaces

all previous declarations and

agreements concerning warranties.

The warranty period is valid for eight

hours of daily use. If this is exceeded,

the warranty period shall be reduced

in proportion to the excess use, but to

no less than three months.

Returning rejected goods requires the

prior express consent of the Seller

and is at the Buyer’s risk and

expense.

Further warranty details can be found

in the General Terms and Conditions

(GTC). The GTC can be viewed at

www.jettools.com or can be

sent by post upon request.

The Seller reserves the right to make

changes to the product and

accessories at any time.

3. Safety

3.1 Authorized use

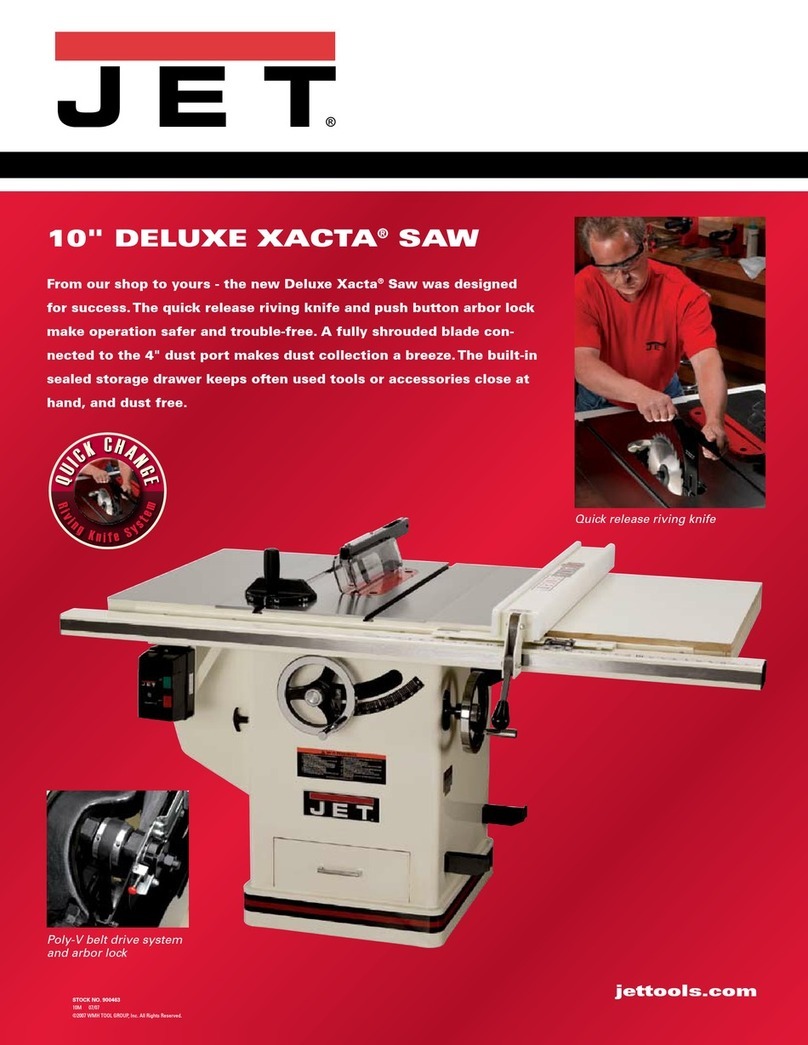

This machine is designed for sawing

wood, wood derived materials as well

as similar to be machined hard

plastics only.

Machining of other materials is not

permitted and may be carried out in

specific cases only after consulting

with the manufacturer.

No metal workpieces may be

machined.

The workpiece must allow to safely be

loaded, supported and guided.

Do not cut round stock without

suitable jigs or fixtures. The rotating

saw blade could turn the work-piece.

The proper use also includes

compliance with the operating and

maintenance instructions given in this

manual.

The machine must be operated only

by persons familiar with its operation,

maintenance and repair and who are

familiar with its hazards.

The required minimum age must be

observed

The machine must only be used in a

technically perfect condition

When working on the machine, all

safety mechanisms and covers must

be mounted.

In addition to the safety requirements

contained in this operating

instructions and your country’s

applicable regulations, you should

observe the generally recognized

technical rules concerning the

operation of woodworking machines.

Any other use exceeds authorization.

In the event of unauthorized use of

the machine, the manufacturer

renounces all liability and the

responsibility is transferred

exclusively to the operator.

3.2 General safety notes

Woodworking machines can be

dangerous if not used properly.

Therefore the appropriate general

technical rules as well as the following

notes must be observed.

Read and understand the entire

instruction manual before attempting

assembly or operation.

Keep this operating instruction close

by the machine, protected from dirt

and humidity, and pass it over to the

new owner if you part with the tool.

No changes to the machine may be

made.

Daily inspect the function and

existence of the safety appliances

before you start the machine.

Do not attempt operation in this case,

protect the machine by unplugging

the mains cord.

Remove all loose clothing and confine

long hair.

Before operating the machine,