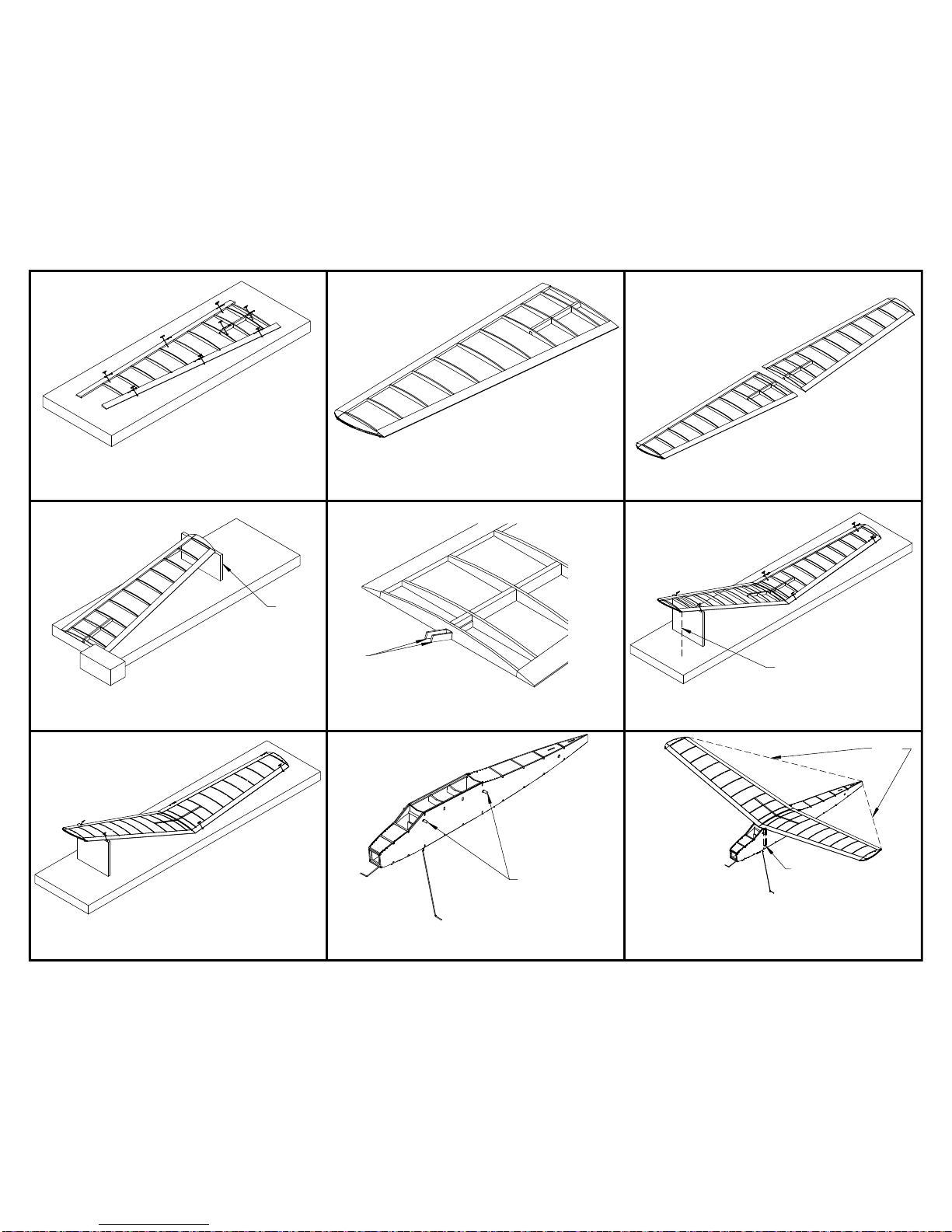

10.

Cut the six nose block laminations from 1/8" balsa. Also cut the two

nose block key pieces (part F1 on the plan). Note the grain direction

for each nose block piece. Glue all the pieces together. A piece of

1/8" dowel can be used to align the individual laminations. Remove

the dowel after gluing the laminations.

11. 12.

13. 14. 15.

16. 17. 18.

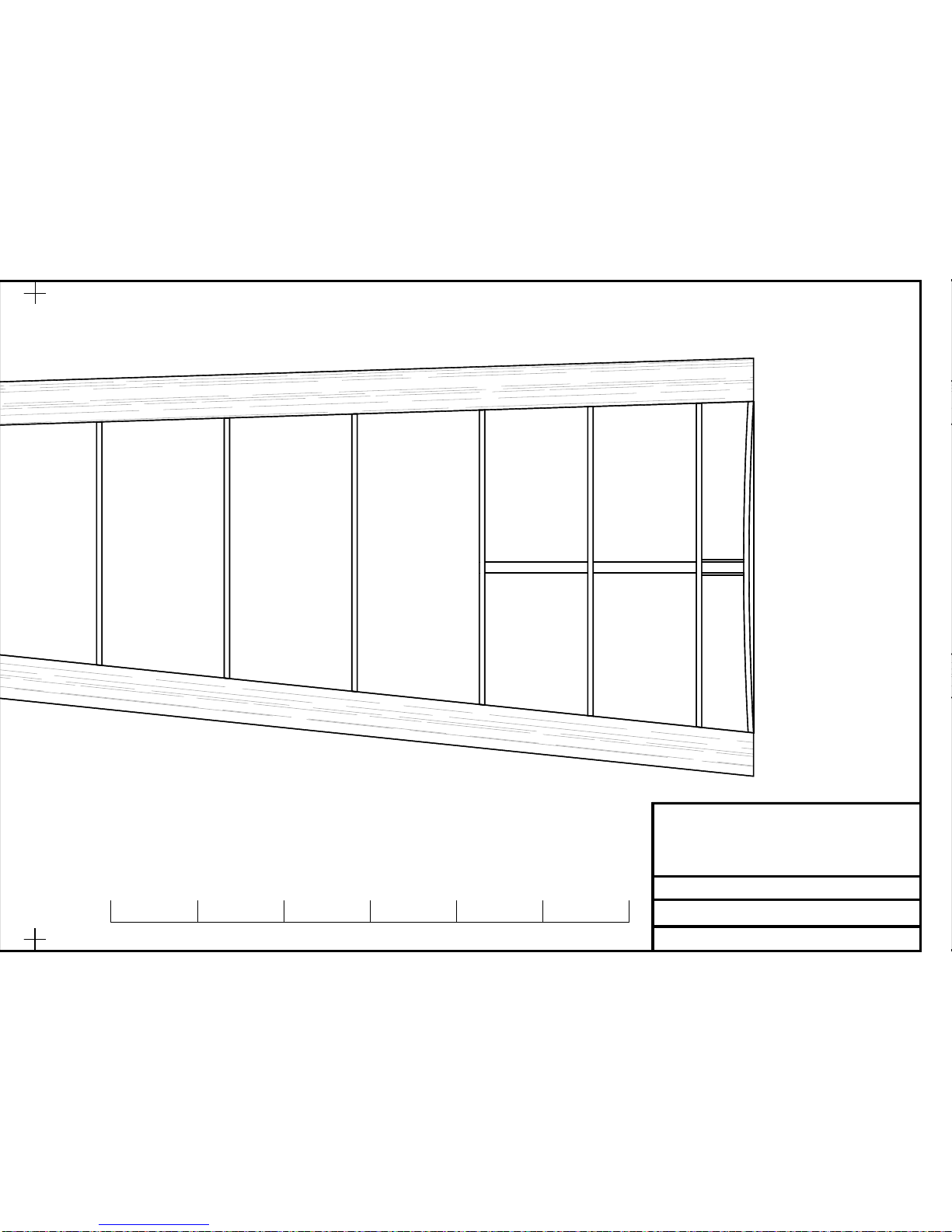

Cut the 1/2" x 1/8" tapered stock for the leading edge, and trailing

edge. Cut each piece a bit long for trimming after assembly. Lay

some plastic kithchen wrap over the plan. Glad Wrap works

especially well. Pin the LE and TE pieces to the building surface.

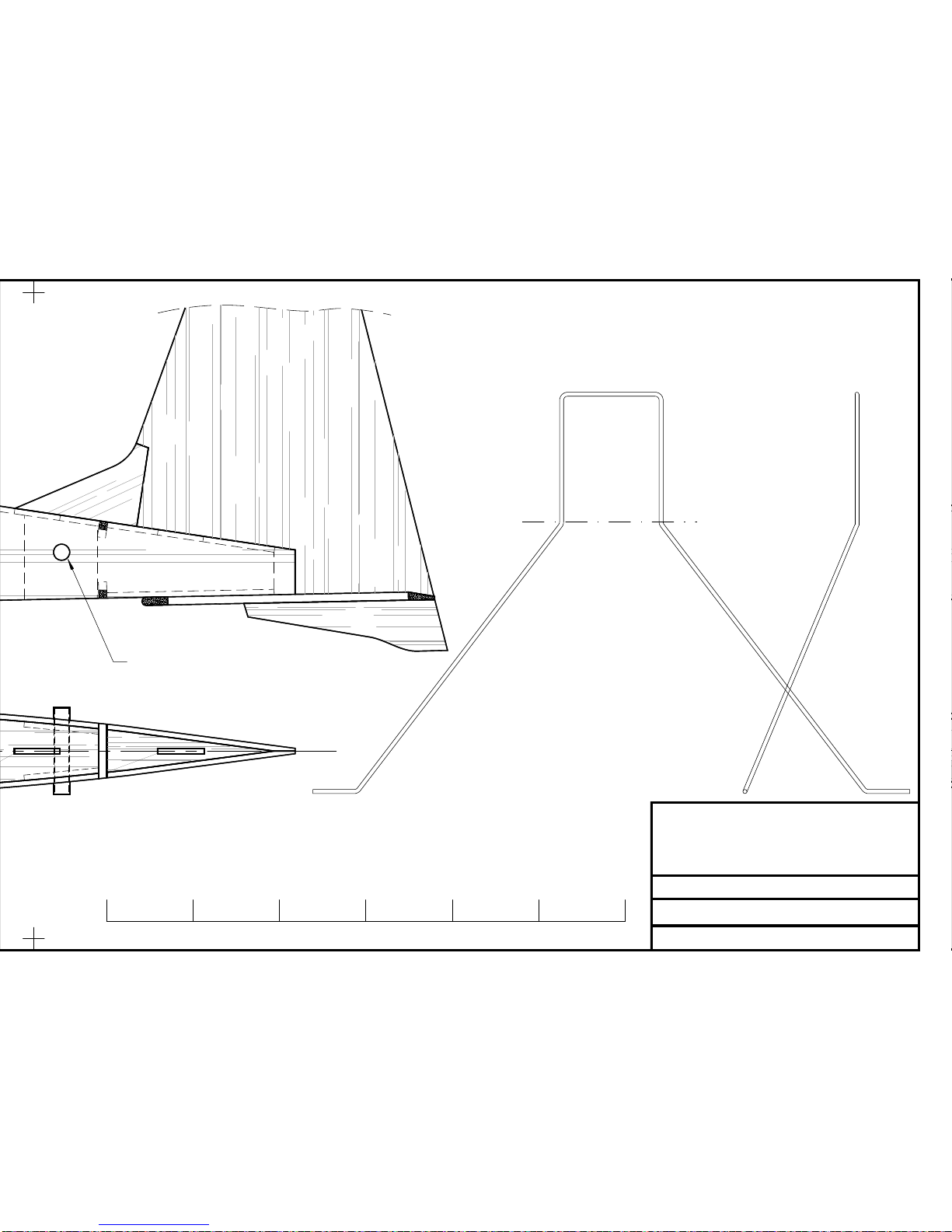

Bend the landing gear from .047" piano wire. Glue the landing gear

to part F2. Also glue part F2A to F2. When dry sand the face of

F2A so it is even with the landing gear wire.

Glue the landing gear assembly to the forward face of former F3.

Also glue in the gussets F4.

Rough shape the nose block using the plan as a guide. Place

the nose block on the fuselage and final sand the nose block

shape.

Build the stab and assemble the two fin parts.

F1 (2)

Sand the stab LE round and the TE to a taper on the top. Cover the

fuselage and stab. If you water shrink and dope the stab, be sure

they are pinned to a flat surface while drying. Two coats of 50-50

clear dope should be enough on the stab. Leave it pinned to a flat

surface for at least a week after doping before it is glued to the

fuselage.

Glue parts F13, F17, and F18 to the rear of the fuselage as shown.

Also add 3/32" balsa strips to the fuselage nose between cross

pieces 1 and 2.

F2 F2A

F4

F18

F17

F13

3/32" SQ

Use ribs R2 and R4 to locate the wing spar. Pin the spar to the

building board using a "X" pattern with the pins. Do not pin

through the spar. Glue the ribs to the LE, TE, and spar.