JetLegend T-45 Goshawk

Page 4 of 24

BEFORE YOU BEGIN

Keep this in mind as you proceed:

Look at EVERY assembly step you finish,

and ask yourself:

"Is this going to crash my airplane?"

A chain is only as strong as its weakest link,

and this is a high-performance aircraft that

will be very intolerant of sloppy assembly

techniques. Even the smallest component is

important and can cause the loss of your

airplane, so take the time to do things right.

Or REdo them if they are wrong. Careful work

will result in a long-lasting plane that gives

you years of pleasure, one loose component

could result in the complete loss of the

aircraft and all the components inside it, and

someone can even get hurt. So pause every

once in a while when building it and

double-check your workmanship.

TOOLS AND ADHESIVES

Some useful tools for assembly will

be a screw gun for drilling holes and a dremel

tool with a 90 degree attachment, and some

high quality screwdrivers. Not much else is

needed. Two allen wrenches are provided

with the kit that fit all the bolts.

As far as adhesives go, Loctite Hysol is the

strongest and best epoxy for installing the

components, but if you cannot get any, 30

minute epoxy will do. Avoid five minute

epoxy, it is not nearly as strong as the 30

minute kind, and it gives you much more time

to properly align things before it sets.

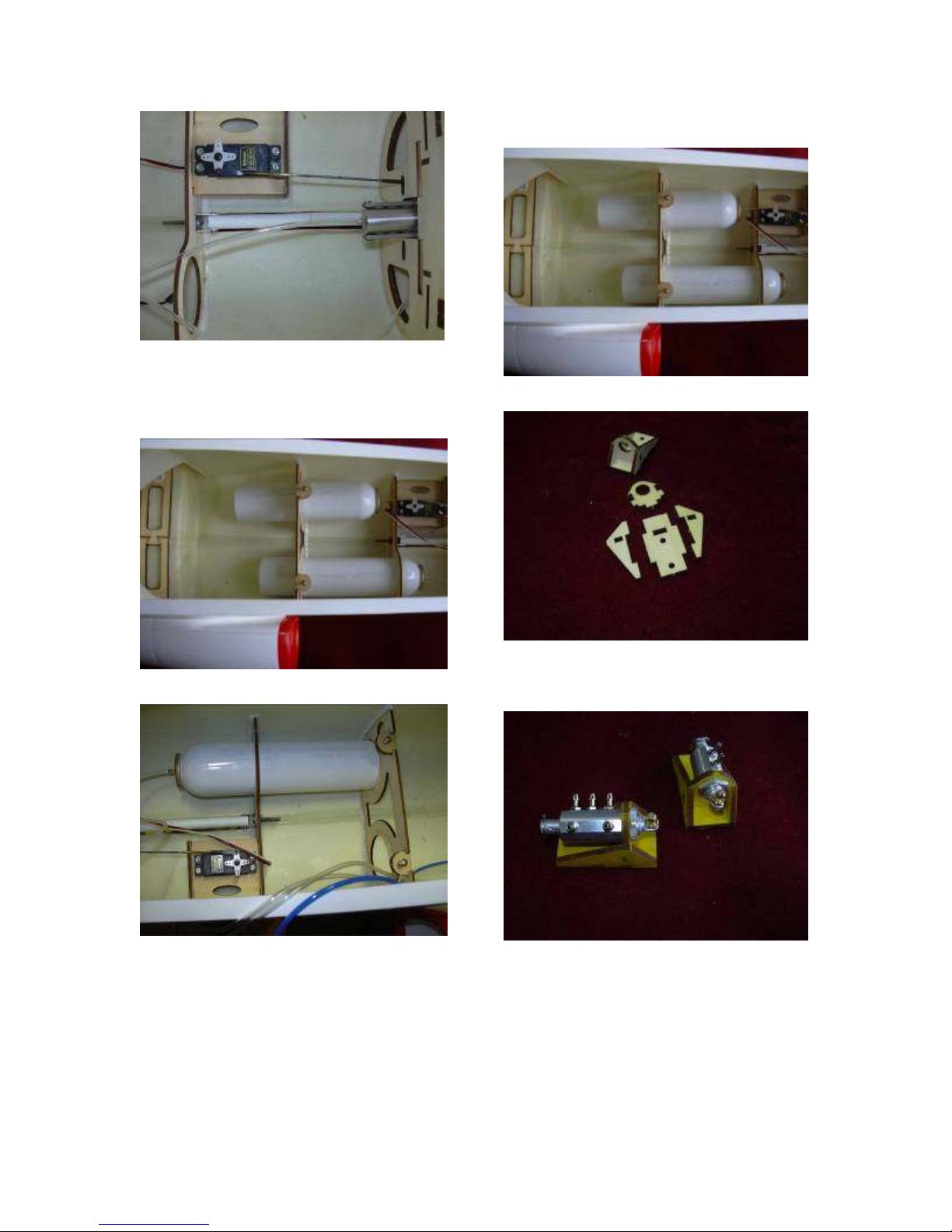

PNEUMATIC AND FUEL SYSTEMS

All tubing joints must be cut off very square to

avoid leaks. Do not clip them with scissors or

cutters or you will get an angled, leak-prone

end on the tubing. Use a very new razor and

cut all joints dead straight for best results.

When you are done, your air systems should

hold air overnight at the very least...for

months is even better. Any leaks are

unacceptable, it will be a matter of time

before you are damaging your aircraft with a

gear-up, or even worse, a one- or two- gear

landing, so take your time and track down

any leaks, no matter how slight, before flying.

RADIO INSTALLATION

There are enormous variations in

how you can set up your radio trays. You

may or may not use dual power switches, a

power distribution box for servos, battery

backers, smoke pumps, etc., according to

your personal tastes. If you like, you can cut a

new blank tray if the factory-made cutouts do

not suit your installation. What is shown here

is just some basic guidelines of how some of

the necessary systems are installed, but

where exactly you want to install them is up

to you. Just make sure all components are

well-secured with tie-wraps or Velcro, and

that the turbine ECU and fuel pump are kept

well away from the receiver so as not to get

any radio interference.

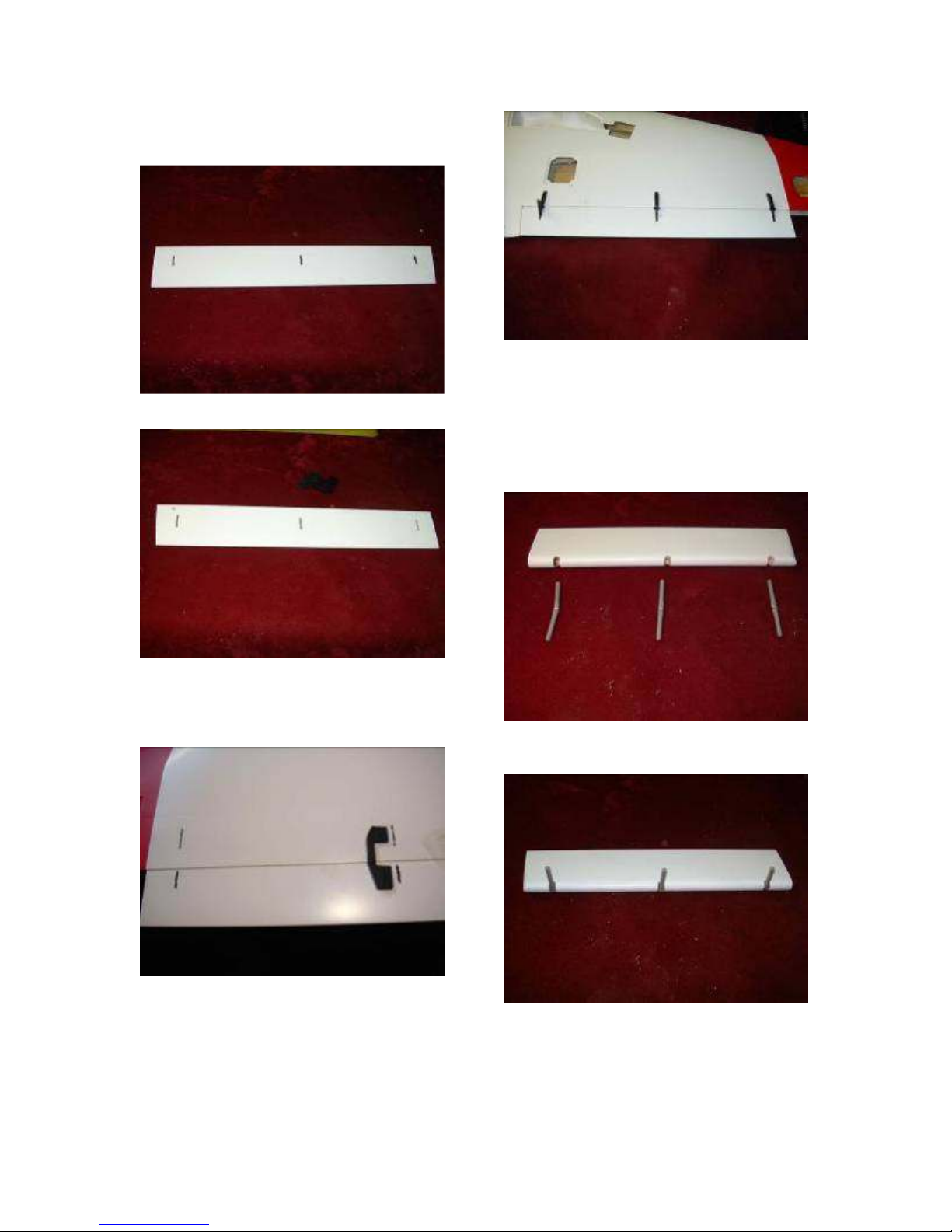

There are great variations in servo

choices and how the servos are mounted.

Some may come with flat mounts, feel free to

use them. Whatever way you mount your

servos, be sure to mount them SECURELY.

Any play may result in flutter and the loss of

your aircraft. The aluminum mounts and

plywood blocks provided in the kit can be

modified accordingly to suit the servos you

chose. Do not use rubber servo grommets,

they are to dampen the vibration of a glow

engine, turbine engines produce no vibration,

so all the grommets will do is allow the servo

to move and lead to potential flutter. Digital

servos are highly recommended on all flight

controls, as are servos with metal gears.

Plastic gears can chip a tooth if the control

surface is bumped while assembling the

aircraft at the field, and it's too easy for this

situation to go unnoticed until the servo fails

in the air. Metal servo arms are also good

insurance against flutter. The linkages and

fiberglass control horns provided in the kit are

extremely strong, there is no need to replace

them with aftermarket ones. Be sure to use

all the provided retention hardware, including

the tiny circlips. They are all there for a

reason. The horns on your servos and the

holes in the fiberglass control horns provided

in the kit may need to be drilled out to

accommodate the clevis pins. It's easier to

do this to all of the horns before any

assembly. Do this carefully, and discard

anything with an oversized hole, as any slop

here is unacceptable.

It is highly recommended that all

servos be "burned in" for an hour or so before

installation, using a servo driver to excercise