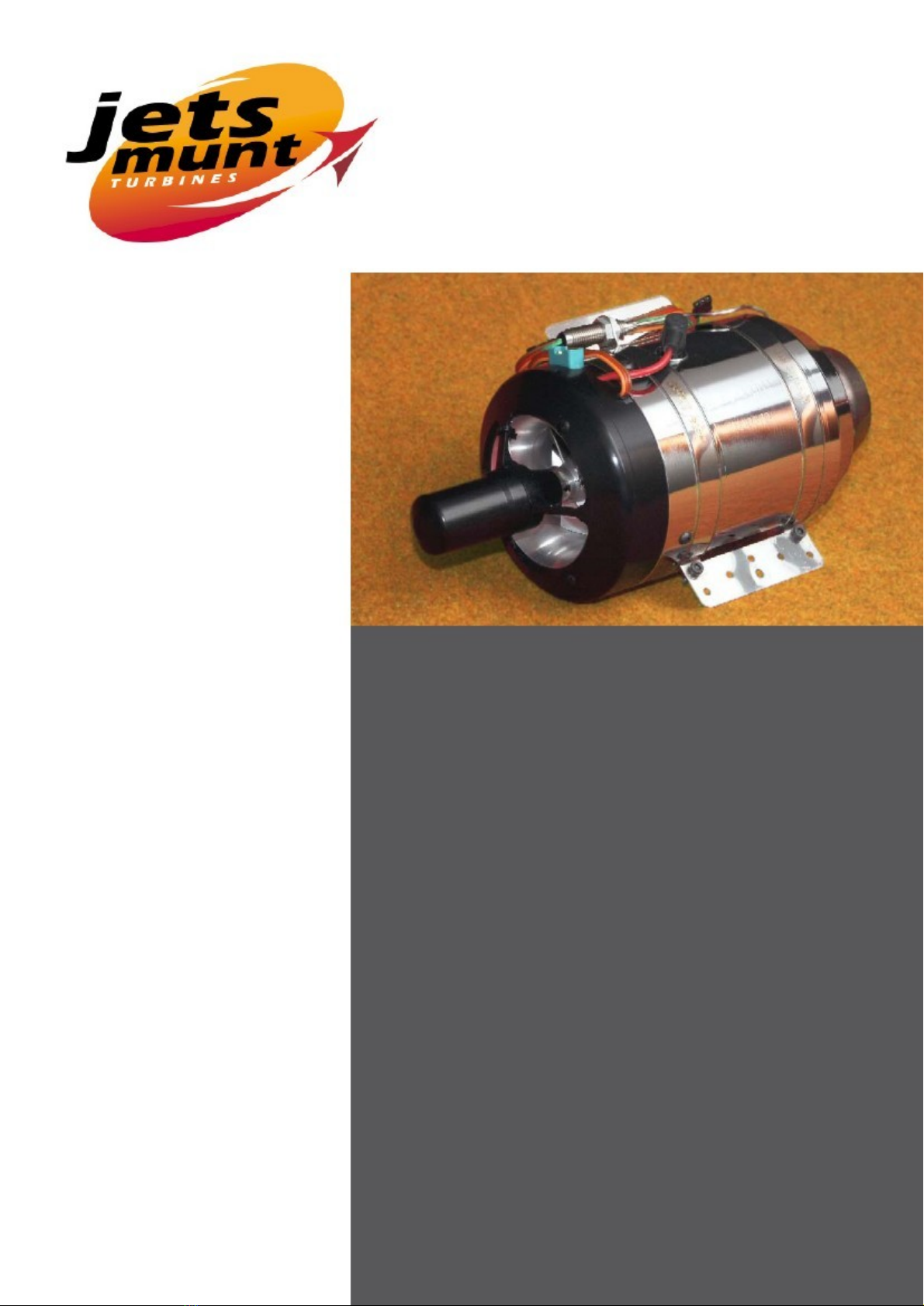

Jets Munt Merlin 90K User manual

Merlin 90K

Instruction Manual

Ve rs io n 1.0/2009

Index

4

4

4

5

5

6

6

7

7

8

8

Welcome!

Legal and Disclaimer

Disclaimer

Warranty

Jets Munt Representatives

Sa ety Notes

Merlin 90 Mk2 Specifications

Engine Description

Installation Notes

Electronic Control Unit (ECU)

ECU Data Terminal

Engine installation: Electrical connections

Temperature Probe (thermocouple)

RPM Sensor

Power cord

9

10

Engine installation: Start Gas system

Gas Valve

Engine installation: Fuel system

Fuel valve

Fuel filter

11

13

ECU (Engine Control Unit) Set Up

Aligning transmitter with ecu

Preparing the engine or running

First engine runs

Priming the uel system

13 Starting the engine

The engine is running!

Engine shut down procedure

List o ECU message codes

15

15

Diagnoses

Diagnosis messages

Other use ul in ormation and installation tips

Fuel System

Fuel and Oil

Feed Pipes

Maintenance

Battery charging and care

Running Time Counter

Extra ECU unctions

Engine Kill Switch

Merlin 90 Trouble Shooting

Welcome!

Congratulations on the purchase of your new Jets Munt Merlin 90K gas turbine engine. Jets Munt are dedicated to

the design and production of engines to the highest standards of quality and reliability to bring you the customer

the very latest next generation engine designs.

he Merlin 90 is the result of an intensive effort of design and tests by the Jets-Munt staff. During the

development period we made extensive use of the latest Computational Flow Dynamics programs allowing us to

optimize the engine performance characteristics.

Plea se Read!

The Jets Munt SL responsibilit is limited exclusivel to the repair of the engine and acce s s orie s

which are outlined in the conditions of warrant .

Before unpacking the engine please read the manual and agree to the conditions of warrant .

Customer satisfaction is important to Jets Munt SL. echnical support is available through your local dealer and

trough email.

Jets Munt S.L

orrent d’en Puig, 31

08358 Arenys de Munt

Barcelona. Spain

www.jets-munt.com

Fax: +34 93 7950113

Legal and Disclaimer

he engine design and the contents of this manual are copyright by Jets Munt SL, Barcelona, Spain.

All rights reserved.

his manual, the pictures and data are property of Jets-Munt and cannot be used or reproduced in any way with-

out written permission from Jets Munt SL.

Disclaimer

he Merlin 90K engine is a sophisticated piece of machinery. Care should be taken at all times when using the

engine. It should only be operated by those with the appropriate skills and knowledge to do so. his engine is not

a toy. Incorrect operation or misuse can cause damage to property and bodily harm to operators, spectators and

animals. Jets Munt SL accepts no liability for any kind of damage which may occur.

Jets Munt SL assumes no responsibility for any errors contained in this document and is not liable for any dam-

ages resulting from such errors.

It is forbidden the use of this engine outside Radio Control applications, speciall those that power

vehicles that carr people.

1

Warrant

he warranty period for the Merlin 90K is 2 years from the date of purchase, or 25 running hours, whichever

comes first. Warranty is valid solely for the original owner and is non transferable upon resale.

Warranty includes parts and labour and is limited to manufacturing and material defects only.

Damage or defective operation covered under the warranty terms will be repaired and tested at no cost the

original

owner (other than postage and packaging). Repairs not covered under the terms of warranty will be carried out by

Jets Munt SL, or their appointed agents after agreement of costs.

Before returning the engine or ancillary equipment for service of repair, please contact first to your local dealer or

Jets Munt central office to agree action and costs.

Please do not disasse mbl e this engine. You will breach our warrant agreement and ou will find it

is a precision asse mbl which ou will be unlikel to re-ass emble without considerable difficult and

specialist equipment. Simpl slackening the spinner nut of the rotor will immediatel lose the delicate

balance condition, without which the engine ma not run without dama ge to its rotating ass embl .

his warranty is void if any one or more of the following conditions applies. In such a case Jets Munt will accept

no responsibility for any damage or any other consequence caused by the Merlin 90 operation.

1. he engine is dissassembled.

2. he product has been subject to any form of operation whilst containing incorrect fuel, oil, or fuel/oil mix.

3. he product is crash damaged

4. Unauthorised maintenance or modifications have been made to any part of the product

5. Parts have been damaged by ingestion of foreign objects (e.g. wires, sand, water etc).

6. he engine has been operated incorrectly.

7. he product has been misused, neglected or inadequately maintained.

8. Damage to the engine where blockages in the fuel system have occurred by unfiltered or contaminated fuel.

Jets Munt Representatives

Check the current dealer list on our web page, www.jets-munt.com

2

Safet Notes

Please remember the engine is not a toy and has the potential to cause bodily harm to you and others if misused.

he Merlin 90K is a sophisticated piece of machinery and should be treated with a high level of safety when it is

in operation.

he following guidelines should be read carefully and adhered to.

1. Always keep a CO2 or similar fire extinguisher of at least 2Kg of CO2 contents close when starting and

operating the engine

2. Always protect eyes and ears during the starting procedure.

3. Be aware of the extreme intake suction hazard, we advise the use of a suitable commercial wire mesh Foreign

Object Damage guard to protect the engine intake. Ensure you have no loose items of clothing (ties, etc.) or

equipment which can readily be sucked into the engine intake, even from adjacent to the engine.

4. Always operate your engine in open air away from confined spaces as the engine exhaust contains gases which

can cause asphyxiation and nuisance smells.

5. Do not touch the engine whilst it is running. urbines rotate at a very high rpm and the engine casing and

exhaust can reach very high temperatures. Ensure anything affected by heat is kept well clear of the engine and

exhaust during operation.

6. Never use the engine near to sources of flammable gases, liquids or materials.

7. Keep unauthorized persons, spectators, children and animals well away from the starting area (at least 30 ft or

10 meters away).

8. Always handle turbine fuel and oil with care as they are highly flammable. Store them in appropriate labeled

containers. Never dispose inappropriately. We recommend the use of suitable disposable protective gloves for

the mixing of turbine oil/fuel.

Merlin 90 Mk2 Specific ation s

Dimension s:

Weight:

Nominal thrust

@ 15C and sea level:

Idle RPM:

Idle thrust @ 40,000:

EGT @ max rpm:

Fuel consumption:

Ma s s flow:

Pressure ratio:

Fuel/oil:

Outer Diameter 90 mm; Length: 230 mm

1.010 grams (engine only including starter). 1250 gr including pump, ecu and fuel valves

Guaranteed 90N (9,18Kg-20.2lbf), typical 95N (21,2lbf) @ 152,000 rpm

40,000

4N (0.8lbf)

550-650 ºC

0.33 l/min at 90N

180g/sec

3.2 to 1

Kerosene + 4% oil (3%-5% is OK) . Synthetic 2 motorcycle oil or turbine oil

3

Engine Description

he engine is a turbojet of a single shaft design specifically designed to power RC aircraft.

he engine starts automatically thanks to an installed electric starter situated in the front.

he starting sequence is controlled by an electronic unit that initiates the starting sequence and controls the

parameters of the engine within the design limits.

he engine uses a system of direct liquid preheating, ignited by a long life ceramic glow plug situated inside the

engine. After the initial preheat the liquid fuel is gradually introduced. he fuel should contain a small percentage

(4%) of oil and uses part of this fuel to lubricate its two ceramic high speed bearings.

he fuel for the engine is provided from a fuel tank through a small electrical pump. he engine speed between

idle and maximum are controlled by varying the speed of the fuel pump through an electronic controller called an

ECU (electronic control unit).

Installation Notes

1. he engine should be mounted using the strap mount supplied or an approved equivalent.

2. he temperature probe should be firmly fixed to the engine as supplied and not allowed to rattle against metal

parts as this could result in radio interference.

3. he signal cables from the engine must be carefully routed away from the engine intake so there is no

possibility of accidental ingestion of the wire.

4. Fuel and starting pipes should be routed similarly clear of the intake. The engine must not be run with

the starting pipe open to the atmosphere.

5. he fuel pump should be mounted at least 100 mm away from the front of the engine. he pump can emit

magnetic pulses that cause the speed sensor to transmit incorrect rpm information to the ECU. he fuel pump

should be preferably mounted with the spindle in the vertical position with the motor uppermost. In the event of

any fuel seeping from the pump this will not pass through the electric motor. Note the pump is supplied fitted

with built in suppres s ion to reduce radio frequenc noise.

6. he center of the fuel tank should be mounted laterally, as near to the center of gravity (CofG) of the model as

possible. his will minimize the C of G shift as the fuel is used during flight.

7. Any air ducting to the inlet of the engine must have a minimum area of 40cm2 equivalent to a 65 mm (2-1/2”)

square.

8. If an extended exhaust duct is required, it should be approved by Jets-Munt SL. We have found that an exhaust

of 65 mm diameter gives optimum engine performance.

9. Extreme care should be exercised to ensure that no foreign object, loose parts of the model, or debris are

allowed to enter the compartment where the engine is installed.

We recommend testing the engine on a test stand prior airframe installation.

You should have a clear idea of how to arrange the components needed to run the engine inside the model. he

main issue is the fuel tank, you will need to arrange the C of G in the centre of the tank and adjust the receiver

and ECU batteries to achieve the correct location.

Do not be tempted to move the fuel pump into the area between the tank and the engine as this can cause

interference with the rpm pickup and presents a potential hazard in event of fuel leaking from the pump.

In the event of the temperature probe wire being too short, it is correct to extend this with a good quality servo

extension lead – use a gold plated connector version. With this arrangement a error of around 10°C is

sometimes seen on the temperature display but this is of no consequence in normal starting and running.

4

Electronic Control Unit (ECU)

he Fadec ECU supplied with the engine is custom designed for the Merlin90K engine and must not be changed

for any other, as this may result in improper control of the engine. Your engine has been set up and run with this

ECU at the factory and the settings should be left as default. he ECU plugs into your receiver throttle channel

and is powered from the receiver rechargeable battery. he ECU is pre-programmed and only requires simply

setting to your radio. All ecu connections are color coded and easily identified.

ECU Data Terminal

he data terminal plugs into the ECU via the lead supplied.

he display should be used only for starting and test running.

his socket also doubles as the Computer connection socket.

Do not fly the plane with the display connected as there is a

potential for interference. he function of the buttons is de-

scribed later in the “ECU setup”.

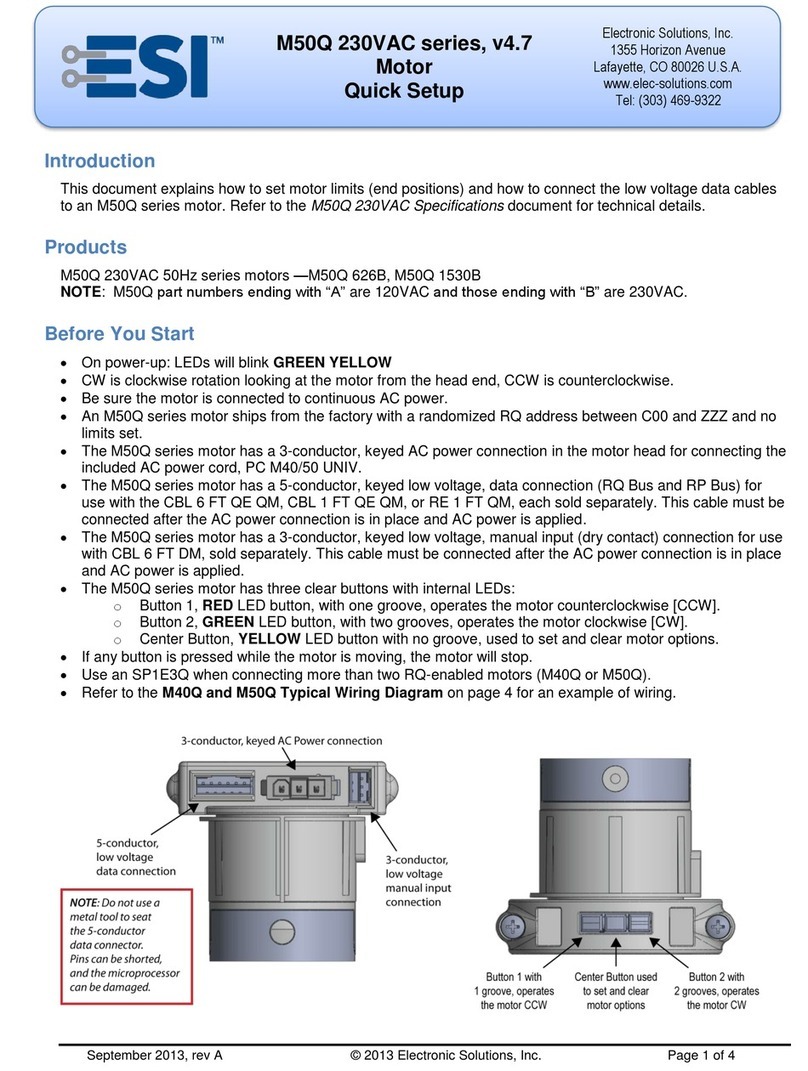

Engine installation: Electrical connections

Temperature Probe (thermocouple)

he engine mounting provides an attachment for the

temperature probe using the two nuts provided. he

temperature probe has been carefully shaped and installed at

the factory to align with the small hole in the exhaust cone.

When connecting the temperature probe plug, be sure to get

the plug in the correct orientation- one wire has a white sleeve

and this should be positioned as indicated on the ECU.

RP M Sensor

he RPM sensor used by the ECU to read the engine RPM

is mounted in the front of the engine, this is underneath the

black cover.

Because it receives the magnetic impulses of the rotor, it is

important to assure that other electrical devices that can

generate magnetic fields (e.g. servo, battery cables, pump etc),

mount at least 100 mm away from the engine.

Both the RPM pickup and thermocouple may need extending

to reach the ECU. A standard good-quality servo extension

can be used there- those for JR radios have the same colour

code and this helps avoid any errors when plugging in.

Power cord

he power for the starter and Glow plug is supplied through a 3 wire twisted lead with MPX connectors. Supplied

length is of 50 cm, if it is necessary to extend it, use 1mm² copper section lead.

5

6

Engine installation: Fuel s stem

Install the fuel system

components

as seen in the picture.

Fuel valve

he main fuel valve is of black color and must be connected to the “fuel valve”

ecu socket in any orientation, polarity will always be correct. Respect the

direction of flow as marked in the valve body.

Fuel filter

he fuel filter must be installed close to the input port on the pump to prevent

any particle to enter in the pump and to damage it. Use a suitable length of

the4 mm clear tubing supplied and keep the tubing on the suction side as

short as possible. Direction of flow inside the filter is not important, but should

be always the same after first use. Do not run the engine without the fuel filter.

Finally connect the fuel pump, the valves and the battery to the ecu as shown.

It is strongly recommended that, after a new installation or modification on the

fuel system, to disconnect the fuel hose from the engine, routing it to a

appropriate container, and run the pump few seconds using the “pump test

function” on the ecu so that some fuel clean all the possible dirt particles that

could have entered in the system.

he starting fuel valve is of gold color and must be connected to the “Gas

valve” ecu socket in any orientation, polarity will always be correct. Respect

the direction of flow as marked in the valve body.

Start/Gas valve

ECU (Engine Control Unit) Set Up

he ECU supplied is a special software version of the FADEC Autostart made by Xicoy Electronica SL. It is a

reliable unit and is supplied programmed for the Merlin 90. he engine has already been set up and tested using

the ECU and pump supplied so there is very little to adjust in order to get the engine running. Confirm you have

connected the ECU input to the throttle channel of your receiver, the ecu battery is fully charged and connected

and the Data erminal is plugged into the ECU. Remove all rates, mixes and throttle travel settings in the

transmitter. he setup assumes the use of a transmitter with manual trims.

If ou use a TX with digital trims, is essential to use the switch in the TX program med for the function

“Throttle cut”, or “engine cut” which normall has the effect of producing the “trim-down” function.

Check our radio manual for this before ou start. DO NOT use the digital trim in an case.

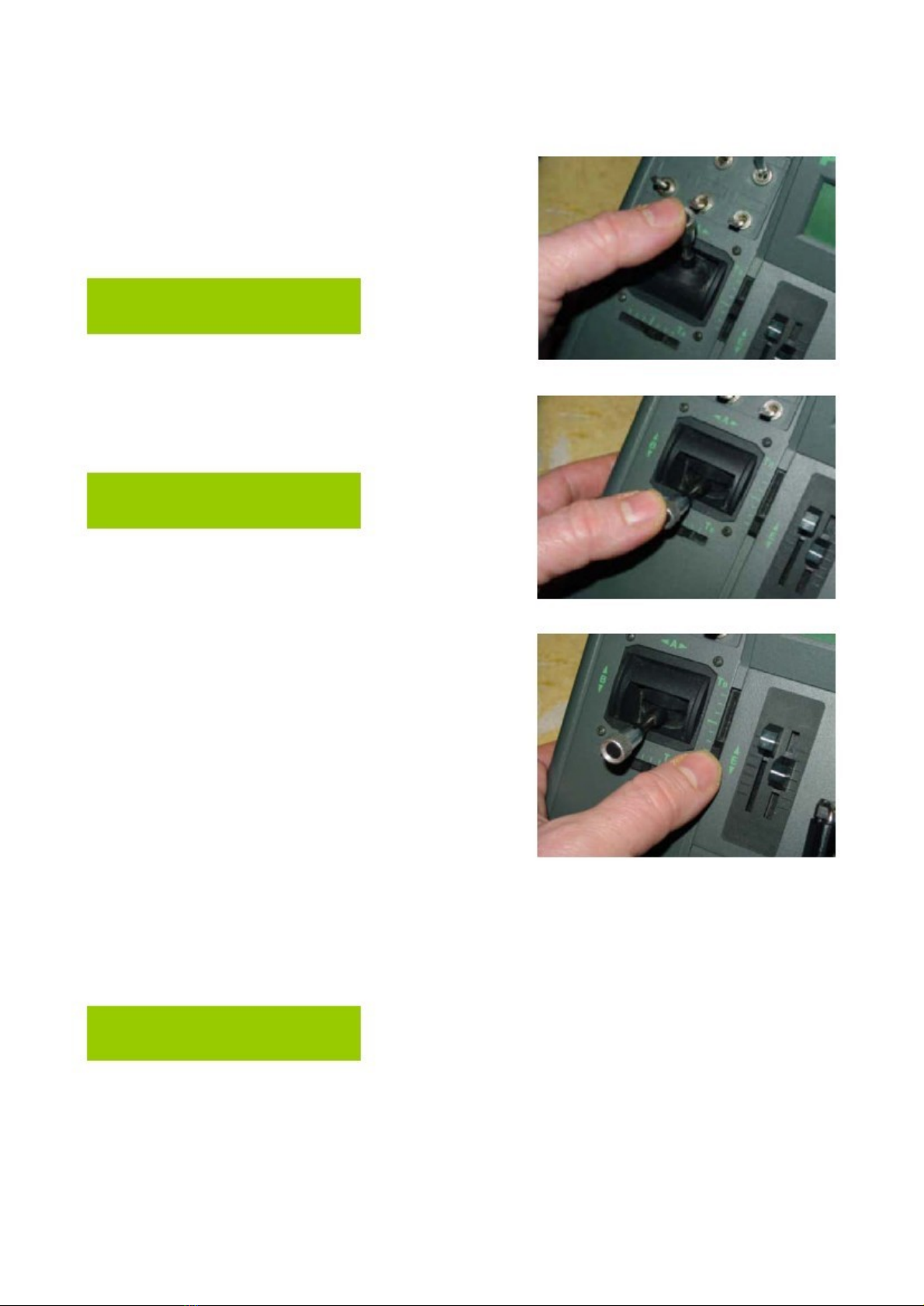

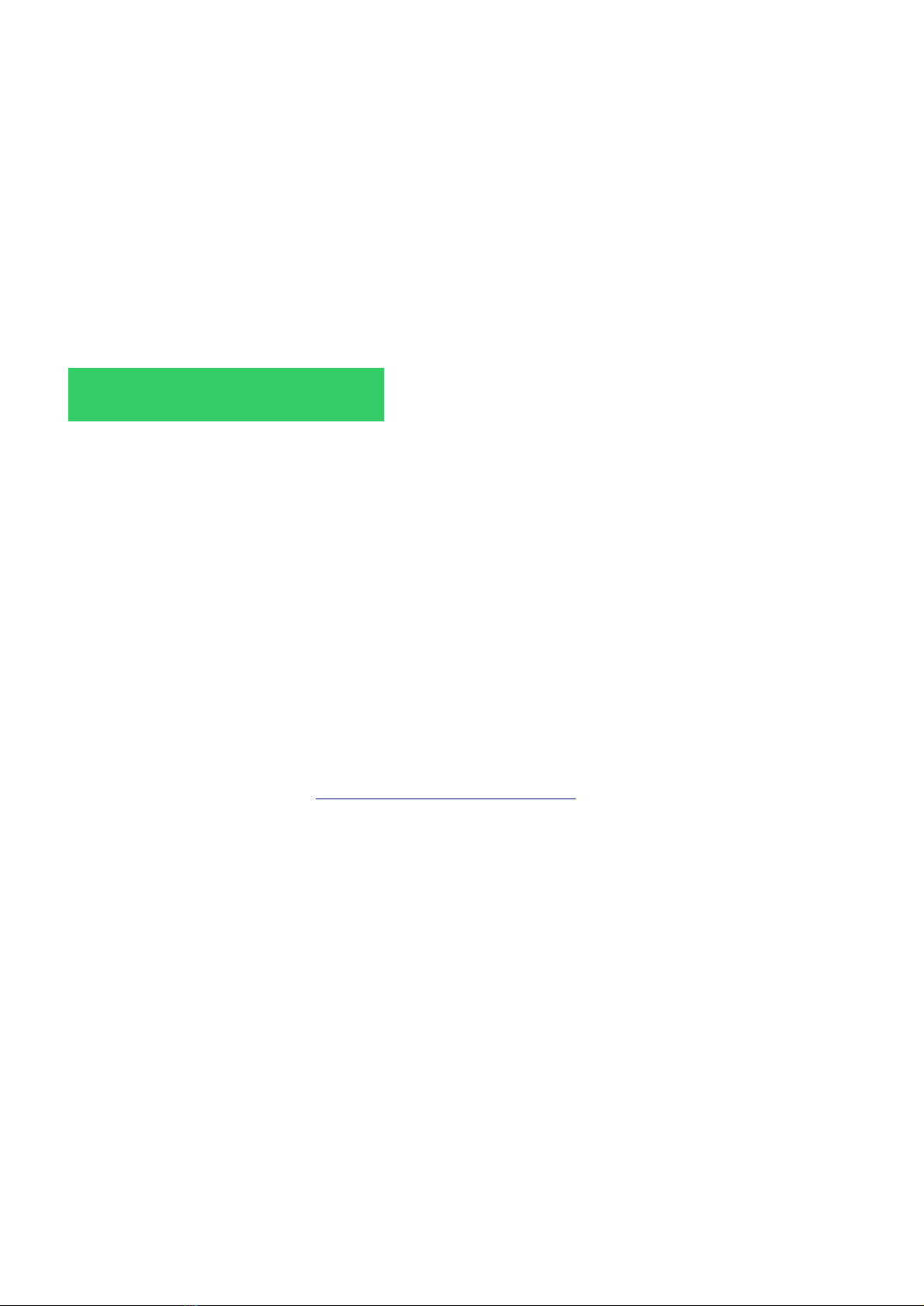

Aligning transmitter with ecu

As the display does not photograph well we have reproduced the display readings as a green box. urn on the

transmitter and receiver. he opening screen should show as below: (If the temp’’ probe is not connected it will

show as 0ºC). “ ” = ambient temp’.

Trim Low

RPM 00000

T=020ºC

PW 000

Note there are four buttons on the display, two on the left and two on the right hand side. he left buttons move

to the different screens and the right buttons are used to change the values stored. Press the second, left button

and scroll through the menus until you find the one showing:

Info Run

Start Radio

Press the (-) button and the ecu will show the “Radio” parameters menus.

Transmitter

adjust

yes

Press the (right hand button (+) to confirm that you really want to program the radio.

he screen will change to:

Stick p Trim p

(Full power)

7

On your transmitter, raise the throttle stick and trim to full.

Ensure stick is firmly against the stop.

Now holding the stick against the stop, press the right button

(+) to store the signal from your X into the ECU.

he screen will now change to:

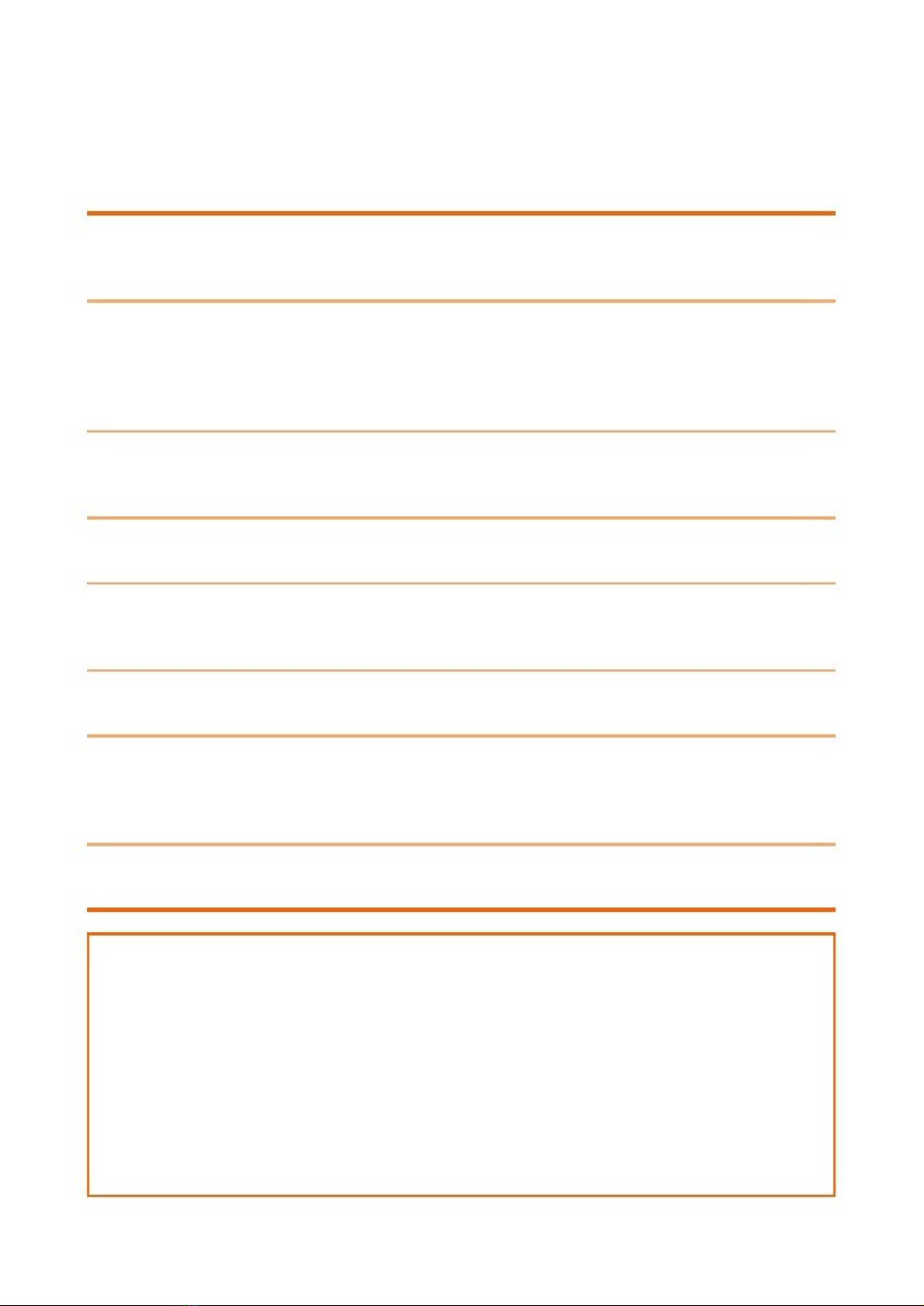

Stick Down

Trim Down (Stop)

Move the trim (or switch the “engine cut” switch to on) and

throttle

stick back to zero and again press the right hand button (+).

he display will now change to:

Stick Down

Trim p (Idle)

Leaving the throttle stick in the minimum position, raise the

throttle trim to the full up position or switch “Engine Cut”

switch to off, and again press the “+” button to store the value

into the ecu.

If you have done all steps correctly the green LED located

directly

above the data terminal socket in the ecu will light up in the ECU

when the “Idle” command is received, meaning that trim and

throttle stick are set to idle position on the transmitter.

Lower your throttle trim and the green LED will go out indicat-

ing correct reading of the transmitter engine shut off signal by

the Fadec ecu.

When using a Futaba transmitter, the throttle channel sense of movement may require reversing (Servo reverse)

and if so reverse and repeat the transmitter alignment. Correct reading of throttle % by the ecu can be verified in

the second screen of the HD , percentage of the throttle position is shown on, 0% in the position of engine stop

(trim and stick down), 100% with stick/trim full up and between 10% and 30% at idle.

Pulse=1000uS 0%

Battery: 7,2V

his now completes your radio setup and should only need doing again if the radio settings are changed

significantly.

here are many more parameters that can be modified in the ECU, but we have specifically programmed your

Merlin 90 ecu with the optimum settings, further adjustment should not be required and can only be carried out

by Jets Munt SL or your authorized dealer.

8

Preparing the engine for running

Always test the engine in a test bench before installing it into the plane, this will confirm that all system work as

they should, and you will be able to learn its operation and the emergency procedures. A suitable

platform/table/workbench is now required to clamp the test stand onto. Make sure this can be easily

transported outside and weight enough to ensure it cannot be blown over by the thrust of the engine.

Select a clear area for running – keep clear of areas with loose leaves, sand or other debris that could be picked

up or drawn towards the intake. Ensure the fuel tank is position well clear of the exhaust area and secured.

First engine runs

•Confirm your test stand is securely fixed to a bench or heavy table. Keep your ear defenders within easy reach

and a CO2 fire extinguisher handy. VERY IMPOR AN ON KEROS AR ENGINES.

•Fill the fuel tank. Do not forget to filter the fuel, and to mix the oil.

•Confirm all batteries are freshly charged and connected up. USE ONLY 7,4V Batteries.

•Check there is a temperature reading on the data terminal.

•Ensure the running area is clear of onlookers – especially the prohibited zone of a 10 metre radius 180° arc from

engine centre around the rear.

•Verify that the fuel tubes are full of fuel and purged of all air, if not, carry out the fuel prime sequence as

described here.

13

he kerostart system used on this is a reliable and well tested that produce very smooth and trouble free starts.

However, extra care and attention must be paid when starting a kerostart engine.

he main difference between gas and kerosene is that in the case of a failed ignition, the gas dissipates quickly

on the air and don't keep inside the engine. Kerosene is liquid and, if unburned, will pool inside the engine and

stay there forever. he engine can hold a big quantity of kerosene inside. his kerosene will be ignited on next

successful start up and will be pushed to the exhaust as soon as the airflow inside the engine is sufficient, and will

be ignited in the exhaust, causing a hot start (in extreme cases a big fireball) that will not hurt the engine, but can

destroy the model.

o prevent this:

-During the start-up listen to the engine sound to check for positive sound of ignition, check looking from

the exhaust that the kero is burning, or check for a increase in exhaust temperature in the data terminal. A small

plume of white smoke from the exhaust mean that the kero is not burning, so the kero is pooling inside the

engine. Abort immediately the start.

-Double check that solenoid valves are installed in the correct sense. A extra security measure is to place

a manual valve between the last fuel tank and the pump intake line, to prevent that during the process of filling

the tanks or during storage, some fuel can arrive to the engine.

-After a failed start, or whatever condition that could cause that fuel be collected inside the engine (i.e.

extra priming), ALWAYS empty the engine of fuel by tilting the engine nose down. Fuel will exit trough intake. Do

not tilt upwards, due at the internal engine construction, the fuel cannot exit trough exhaust.

Another big difference between gas start and kero start is that the kerosene can keep burning during long time

inside the engine. his situation usually happen during a aborted start, the start-up sequence is aborted by the

user or automatically before the engine arrive to idle. his can cause that the kerosene inside the engine keep

burning for long time, and could destroy the engine or the model. IF A S AR UP SEQUENCE IS NO COMPLE ED,

ALWAYS CHECK FOR FLAME INSIDE HE ENGINE. If there is flame, then set full throttle to engage the starter and

blow out the flame. USE SHOR BURS S OF S AR ER. Using the starter for long time can destroy the starter

motor. In the case that the start-up procedure has been aborted due at starter failure, then it will be necessary to

apply the CO2 fire extinguisher. A white smoke from the engine is a good indication here, mean that there is no

fire inside.

Important notes for kerostart engines. PLEA S E REA D

Priming the fuel s stem

Priming is achieved by a special menu on the ecu. Set the trim to low and go to “Info” menus and next to “Pump

test”. Click on “on” / ”off” to start/stop the pump manually. Please observe fuel line to engine very carefully and

push the off button to shutoff as soon as fuel reaches engine. Repeat the same operation on the burner line by

the appropriate menu.

IMP O RTA N T: The prime procedure should be done onl to fill the fuel tubes and filters in the case of

a first installation or in case of disas s e mbling of the tubes. Do not run the prime function so that the

engine becom es flooded b fuel, as this will caus e an uncontrolled fire at next startup.

Starting the engine

Set the throttle stick down and the trim up. “Idle” - Confirm that the green LED in the ecu is illuminated and the

screen shows “Ready” - !Read to start!

Move the stick to 50% and then back to idle again. he Ecu will begin the startup sequence as described below:

First the internal glow plug will be energized. After 6-10 seconds, depending on the engine temperature and

battery charge, the starter will be powered up to have the rotor turning at 3000 RPM.

Once the rotor is at speed, the pump and solenoid valves will be energized in pulsating mode. Few seconds later

the kerosene will ignite and the exhaust temperature will begin to increase. he rpm and pump power will

increase automatically. During this phase the data terminal will display “IGNI ION”.

When the exhaust temperature is of around 70ºC, the data terminal reading will change to “SWI CHOVER”, during

this phase the fuel will be routed to main injectors and the speed of the rotor will be progressively increased to

10,000 RPM.

Once this phase is finished, the reading will be “FUEL RAMP”. In this phase the engine receive fuel only trough its

normal fuel input, and internal glow plug iwill be disconnected . he fuel flow and starter power will be increased

automatically to increase the RPM up to idle RPM. When 25.000 RPM is reached the Ecu will automatically

disconnect power to the starter.

When the rotor speed reaches idle, the screen will change to “running” and the engine speed is stabilized.

The engine is running!

Control of engine power/rpm is now handed back to the transmitter and controlled by the position of the throttle

stick.

Increase/decrease the throttle slowly, verifying that the engine accelerates/decelerates. Take special care

around the engine intake, keep our hands at a safe distan ce along with an other objects as the can

be easil ingested.

Engine shut down procedure:

o shut down the engine lower the trim and the stick. Is recommendable that before shutting down the engine

please restrain the model then raise the throttle stick to approximately 25%, allowing temperatures to stabilise

for around 5 seconds before carrying out the shutdown procedure.

Both main fuel and starting fuel lines need purging of all air after initial installation. ake extra care when priming

the lines, ensure that NO fuel is pumped inside the engine. o do so, disconnect the fuel lines from the engine

wile priming.

WHAT TO DO IN THE CA S E OF AN EME R G E N C Y

During the start sequence the Ecu will be in charge of everything, controlling temperature and RPM. he only

thing the user can do, is to abort the sequence by lowering the trim in the case that something abnormal

(excessive flames in the exhaust, etc).

If a problem is detected, first:

MOV E THE TRIM TO THE LOW POS IT I ON TO AB OR T THE SE QUE N C E.

If there is a fire in the engine and the problem is because the starter has failed or the engine is seized (not

turning),

IM M E D I A T E L Y APPLY THE FIRE EXTI N G U I S H E R through the intake side of the engine, never trough the

exhaust.

If there is a fire, but the rotor remains free to spin and the starter is OK, raise the trim and stick to the full

power position this will connect the starter manually to ventilate the engine and extinguish the fire. he throttle

channel acts as a starter switch if the temperature is over 100ºC after an aborted start.

USE SHOR BURS S OF S AR ER. Using the starter for long time can destroy the starter motor.

List of ECU messa ge codes:

Here is a list of possible messages shown on the data terminal screen and their meaning.

TrimLo w: Indicates that the signal received from the transmitter corresponds to the lowered trim, that is to

say,engine OFF.

Read : Indicates that the engine is ready for starting, and that the transmitter signal corresponds to IDLE,

(green LED lit).

StickLo!: his indicates that the throttle stick is in a position above IDLE, the engine will not start with the

stick in this position, so the stick must set Low.

Glow Test: Verification of glow plug and heating up.

StartOn: est of the starter.

Ignition: Kerosene ignition phase and heating of the combustion chamber.

Switchover: Phase of switching the kerosene feed from igniter to normal injectors.

FuelRam p: Phase of acceleration until idle speed

Running: Engine working correctly, pilot have full control of engine power.

Stop: Engine off.

Cooling: Starter operating to cool the engine.

GlowBa d: Defective or disconnected glow plug.

StartB ad: Defective starter, insufficient RPM reached during start.

Low RPM: Engine speed below the minimum.

HighTe mp: Excessive temperature.

FlameOut: Exhaust GAS emperature below the minimum.

14

Dia gn os e s

During engine operation the Ecu measures and stores all the engine operating parameters recorded during the

last the 51 minutes of operation. hese measures can be downloaded later to a PC to study the behaviour of the

engine in flight and to diagnose any possible problems.

Also, after each cycle of operation, the Ecu stores the last cause of shut down and the values of RPM, temperature

and pump power. In order to access these measures, it is necessary to shut down and power-up the Ecu. Set the

trim down (trim Low) and push the left button on the display. he Ecu will show the cause of shutdown and the

parameter values at the moment of shut down. hese are as follows:

Diagnosi s mes s a ge s

UserOff:

FailSafe:

he engine has been shut down because it has received the shut down command from the

transmitter.

he engine has been shut down because of loss of the control signal from the transmitter. After

0,5sof detecting a loss or invalid RC signal, the ecu sets engine power to idle, and if after another

1,5 seconds a valid signal is still not received the engine is shut down.

he engine has been shut down because the RPM has dropped below a minimum. Cause could

be lack of fuel, air bubbles, problem with the batteries, or defective RPM sensor.

he engine has been shutdown because the temperature has dropped below the minimum of

(100ºC).(Usually a thermocouple failure).

Lack of power from the radio receiver.

Low RP M:

FlameOut:

RC PwF ail:

Other useful information and installation tips

Fuel S stem

Always use appropriate containers to store fuel.

It is advisable to install an antibubble system to the fuel supply

circuit.

he simplest one is a felt filter clunk installed into the fuel tank.

his helps maintain consistent fuel flow and greatly reduces the

possibility of air getting into the suction side of the pump circuit,

which could cause stoppages.

o prevent the felt element sliding out of position a washer is fitted

between it and the feed tube – as seen.

A BVM UA is another contemporary method

of reducing the possibility of air bubbles in the

engine fuel line. his is a very important as-

pect of the operation of any turbine engine.

Use a appropriate adapter for the 6 mm tube

output of the UA to the 4 mm in the inlet

side of the fuel pump, direction of fuel flow

is clearly shown at the top of the pump. he

clear 4 mm tubing is used on the pressure

side of the pump. Clear tubing helps identify

and locate any potential future problems with

air leaks.

15

he fuel pump and ECU can be mounted simply with a pair of tie wraps and/or Velcro. he best orientation for

the fuel pump is vertical. It is important to ensure any fuel seepage does not reach the motor brushes. he fuel

feed from the pump to the engine should have sufficient length of the clear tubing fitted to allow the fitment of

the electronic fuel shutoff valve and the valve should always go on the pressure side.

When making any fuel line cuts use a sharp blade to make and cut squarely. he fuel filter provided should

be installed in an accessible place for regular inspection, in line between the tank and the pump.

Fuel and Oil

1. Use CLE AN well filtered Jet A1 or kerosene fuel which is available from most airports, or paraffin (K1) used for

greenhouses available from most hardware stores.

2. Ensure the fuel is clean and filtered at each stage of mixing and transfer to the model fuel tank.

Pleas e note the importance of using clean fuel. Failure to do so will result in blocka ge s of the fine fuel

injectors in the engine or blocka ge of the engine lubrication s ste m and subsequent bearing damage.

3. Ensure the fuel is free from moisture (water is heavier than fuel and will settle at the bottom of the

container).

4. Use good quality aircraft turbine oils e.g. Aeroshell 500, Exxon 2380, Mobil JetOil II, Mobil D E Light turbine oil

or 2 synthetic oil with a specification JASO FC or better.

5. he fuel must be mixed with turbo oil in the ratio of 4% oil to 96% fuel (ratio 1:24). oo little oil will shorten the

bearings life. You can use higher content of oil (5-6%) without any problem for the engine to share the same

fuel with other engines.

Pleas e remember to alw a s handle fuel and oils with care! Avoid all direct contact with skin – in case

of conta ct wash all affected areas with soap and warm water immediatel .

Feed Pipes

All the pipes must be Polyurethane or nylon as provided by Jets Munt or ygon (like the ones used by gasoline

engines). Do not use ygon on the pressure side of the fuel pump.

Silicone tubing must not be used anywhere in the installation as it is dissolved by fuel and oil. If in doubt, take

a small piece of tube and submerge it in kerosene for a few days and verify that it’s characteristics have not

changed.

16

Maintenance

1.

Always

keep the

engine

and its

accessories clean

and dry.

2.

Regularly

check wires for

chafing

or

insulation

breakdown, etc.

3.

Regularly

check

fuel

and gas

pipelines

for

chafing

and /or

leaks

at joints.

4. Check the

temperature

probe is correctly positioned.

5. Check the

engine

and mounting for loose fittings and

secure

if required.

6.

Ensure

the

fuel

system is kept

free

from dust and dirt

inclusion

and that

fuel

is

carefully

filtered.

Batter charging and care:

he engine come with a LiPo (2 cell) batteries. You can use any type and capacity of battery, but only of 7,2 - 7,4V

nominal voltage, minimum recommended capacity is 2000mAh 20C type. Never use a 3s (11,1V) battery. Special

care should be taken with LiPo technology and they should be charged with a LiPo charger, using a regular NiCad

charger could cause the battery exploding or taking fire. Always follow the charger manufacturer

recommendations.

he ecu will not start the engine if the batteries show low voltage, but once the engine is running, the ecu will

keep it running until the batteries are completely empty, so this can cause the battery to discharge below it’s

safe voltage.

Always disconnect the batteries from the ecu after a flying session. Always there is a small amount of current

drawn from the ecu that can cause that a fully charged battery of 2000mAh be empty after 2 month.

Running Time Counter

Using the second left hand button, scroll through the menu’s to the INFO menu.

his screen contains a timer which shows:

he total running time of the engine in minutes ( ot).

he time in seconds of the last engine run (Last).

he total number of starts (cycles - CY) .

Use this screen to keep track of your total running time and starts.

Extra ECU functions

he

ecu provide

several menus

that

allow

to do some tests and

personalize

some

settings,

like:

•

Adjust the thrust/throttle curve

(Linear,

Expo,

Intermediate). Usual seting is EXPO that provides linear RPM

•

Check the capacity of battery used.

•

est the

starter,

Glow Plug,

valves

and Pump.

•

Check the

failsafe

counter

(time

and

pulses

of wrong RC signal).

•

Check and set the

maximum airspeed (if

pitot tube and

sensor installed).

•

Adjust

maximum engine

power.

Please refer to the FADEC manual http://ww w .espiell.com/ F AD06.pdf) for further information.

1718

Timer: Tot:0000m

Last: 000s Cy:000

Merlin 90 Trouble Shooting

PR OB L E M S

There is no reading on the screen

SOL U TI O N S

1. Disconnected receiver or the ecu/receiver batteries are empty

2. he display is badly connected

3. Problem in the ecu or display

1. he Battery is weak.

2. he start solenoid valve is not connected properly or fuel line not

primed.

3. oo long and thin leads from the battery to the fadec or from the fadec

to the engine

1. he manual fuel valve is partially

open

2. here is air in the line of fuel

3. he filters are blocked

1. he ecu has detected temperatures over 800ºC due to too slow starting

2. here is low battery or air in the tubes- herefore let it cool and retry

1. here is insufficient fuel or air bubble entering the engine during the

initial start up.

2. Low battery capacity

1. he ECU battery is empty: recharge

2. he filters are dirty

1. he fuel level is low and/or there is air in the pipes

2. here is a poor connection between the battery and pump

3. Interference

4. Check the “last power down” cause on the ecu

1. he engine is unbalanced by the ingestion of a foreign object.

Do not use the engine and send it in for service.

The kerosene does not ignite

There is little increas e of RP M

when the fuel ignites

The engine reduces the power

of it is stopped during starting

Engine does not accelerate

to maximum set rpm

The engine loses power in flight

The engine stops in flight

There is excessive vibration

and unusual noise

Merlin 90 Log

Owner ................................................................. Serial Number .................................................................Purchase Date ................................................

Start

No. Date Model Place Engine

Time

Flight

Time

Remarks

19

Jets Munt SL

Torr e nt d’en Pui g, 31

08358 A ren y s de M u nt

Bar c e o na (Spain)

Te /Fax: +34 93 79501 1 3

w w w . j e ts- m u nt .c o m

in f o @ j e t s- m u nt .c o m

© Cop yri g h t 2009, Jets Mu nt SL

A Rig h ts Reserv e d

Table of contents

Other Jets Munt Engine manuals

Popular Engine manuals by other brands

RADEMACHER

RADEMACHER RolloTube S-line DuoFern Brief instructions for installation and initial commissioning

ESI

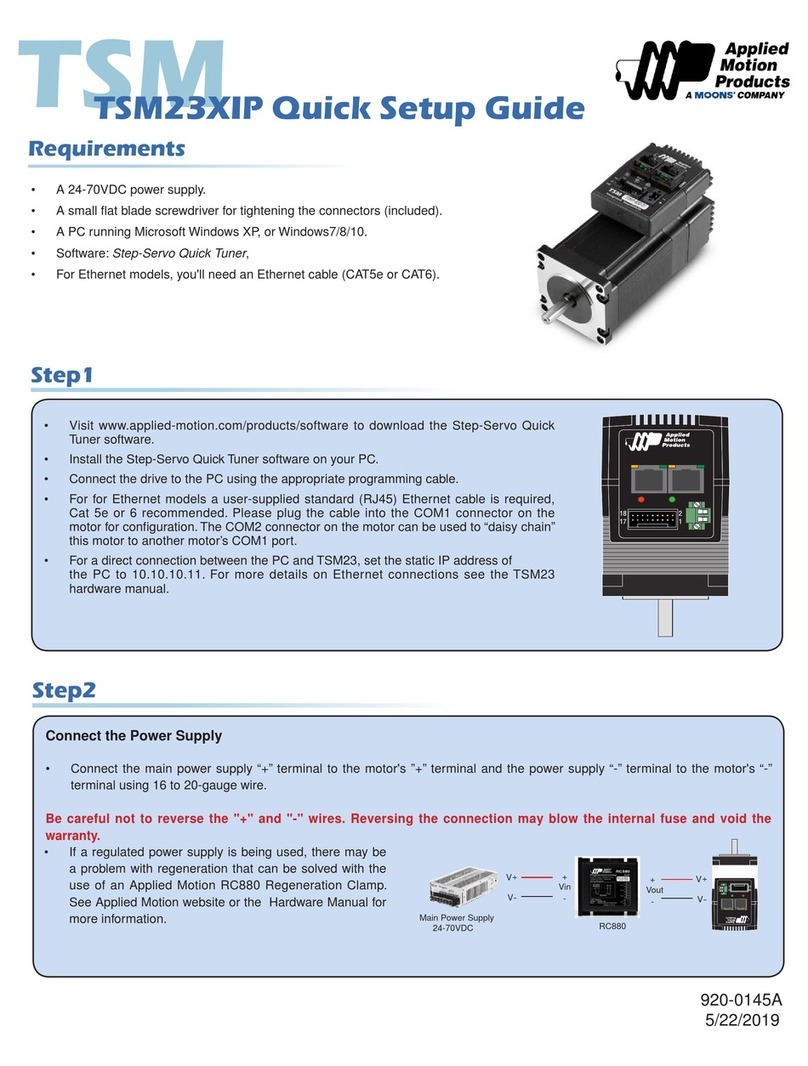

ESI M50Q Series Quick setup

Moons'

Moons' Applied Motion Products TSM23XIP Quick setup guide

Perkins

Perkins 4016-61TRS1 Operation and maintenance manual

Omec

Omec OMT2 Mounting & Maintenance Instructions

Aerotech

Aerotech BM Series Hardware manual