3

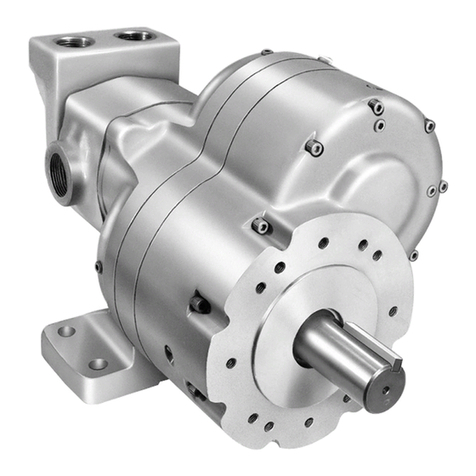

PLACING MOTOR IN SERVICE

Lubrication

Ingersoll--Rand No. 50 Ingersoll--Rand No. 28

Always use an air line lubricator with this motor. We

recommend the following Filter--Regulator--Lubricator

Unit (FRL):

F o r U S A -- N o . C 2 2 -- 0 4 -- G 0 0

For International -- No. C26--C4--A29

After each forty hours of operation, or as experience

indicates, inject 1.5 cc of Ingersoll--Rand No. 28 Grease

into the Grease Fitting (55). Do not grease excessively.

Too much grease in the Gear Case will cause heating.

Grease leakage from the spindle end is also an indication

that an excessive amount of grease has accumulated

within the Gear Case.

Installation

Always use clean dry air at 90 psig (6.2 bar/620 kPa)

maximum air pressure. Dust, corrosive fumes and/or

excessive moisture can ruin the motor of an air tool. An

air line filter can greatly increase the life of an air tool.

The filter removes the dust and moisture. Be sure all hoses

and fittings are the correct size and tightly secured. See

Drawing TPD905--2 for a typical piping arrangement.

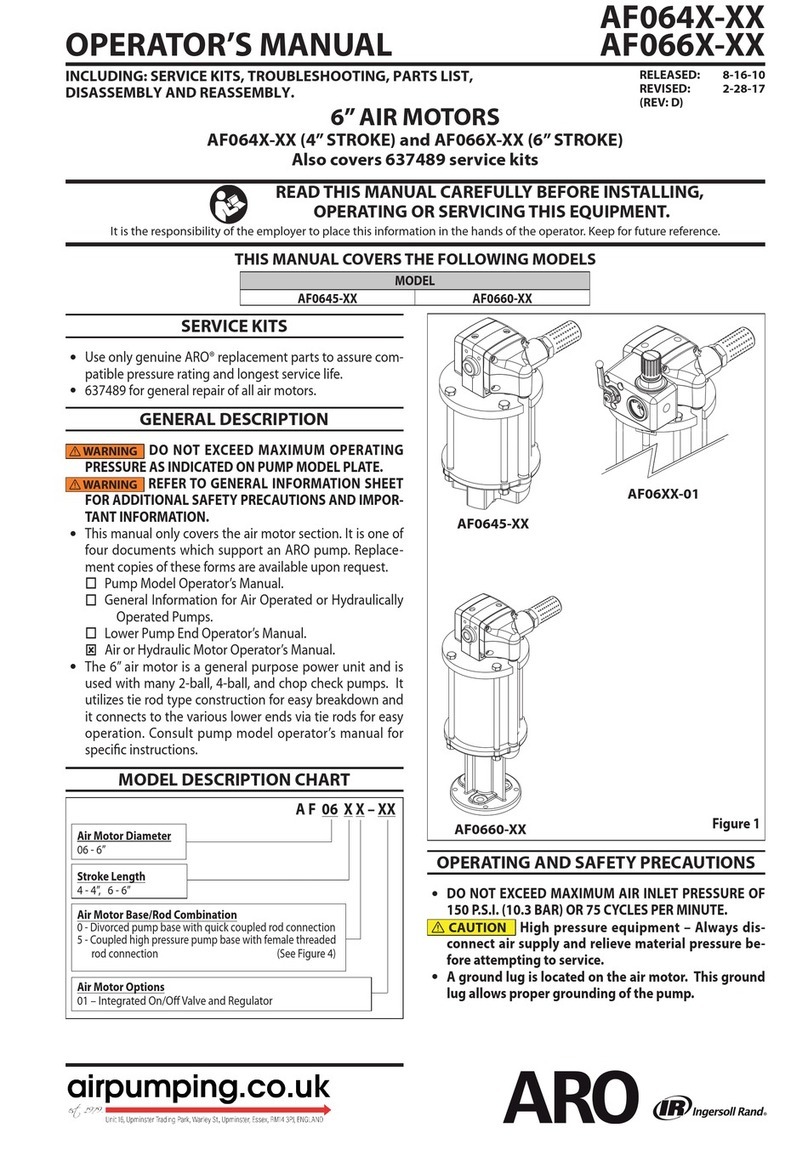

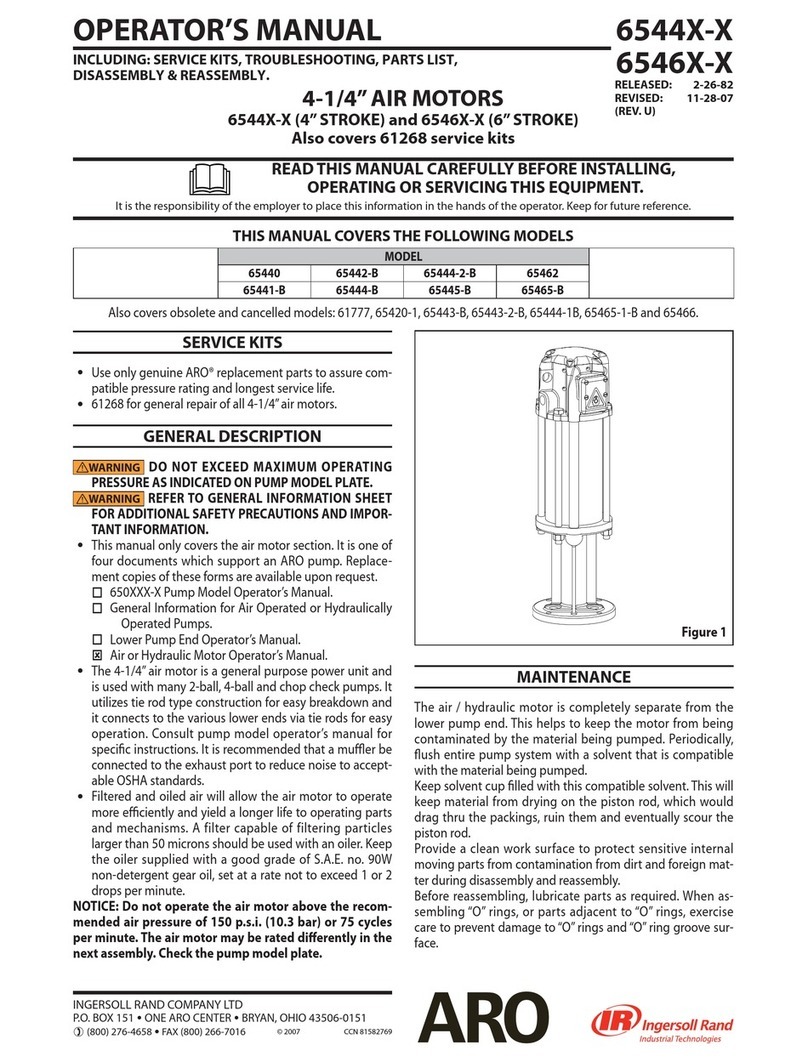

(Dwg. TPD905--2)

F

LR

Main

ine(s) Inner Ø

to be 3X Size of

Air Tool’s Inlet Ø

To Air

System

To Air

Tool

Lubricator

Emergency

Shut--Off

Valve

Regulator Filter

Compressor

FRL

Drain Regularly

Branch

ine(s) Inner Ø

to be 2X Size of

Air Tool’s Inlet Ø

It is important that the motor be serviced and inspected at

regular intervals to maintain safe, trouble--free operation

of the motor.

Tools, hose and fittings shall be replaced if unsuitable for

safe operation and responsibility should be assigned to

ensure that all tools requiring guards or other safety

devices are kept in operating condition. Maintenance and

repair records should be maintained on all tools.

Frequency of repair and the nature of the repairs can

reveal improper application or use. Scheduled

maintenance by competent authorized personnel should

detect any mistreatment or abuse of the motor and worn

parts. Corrective action should be taken before returning

the motor for use.

When replacement parts are necessary, consult

Maintenance Section for part identification.

Maintenance Instructions

When removing a Spindle Planet Gear Shaft (61) from the

Spindle (59), always press it out so that it is ejected at the

short hub end of these parts. Likewise, when installing a

Shaft, start it into the narrow flange at the short hub end.

This is important, as the shaft holes are slightly tapered, so

the Shaft fits much tighter in the front, or wide, flange of

the Spindle.

Spindle Planet Gear Bearings (63) must be installed with

care to avoid distorting or fracturing the thin shell

surrounding the needles. Use a bearing inserting tool, as

shown in Drawing TPD786, when installing a needle

bearing. Press only on the stamped end of the bearing.

Press one bearing from each end of the hole when two

bearings are used in one gear. Never use one bearing as an

anchor for installing the second bearing.

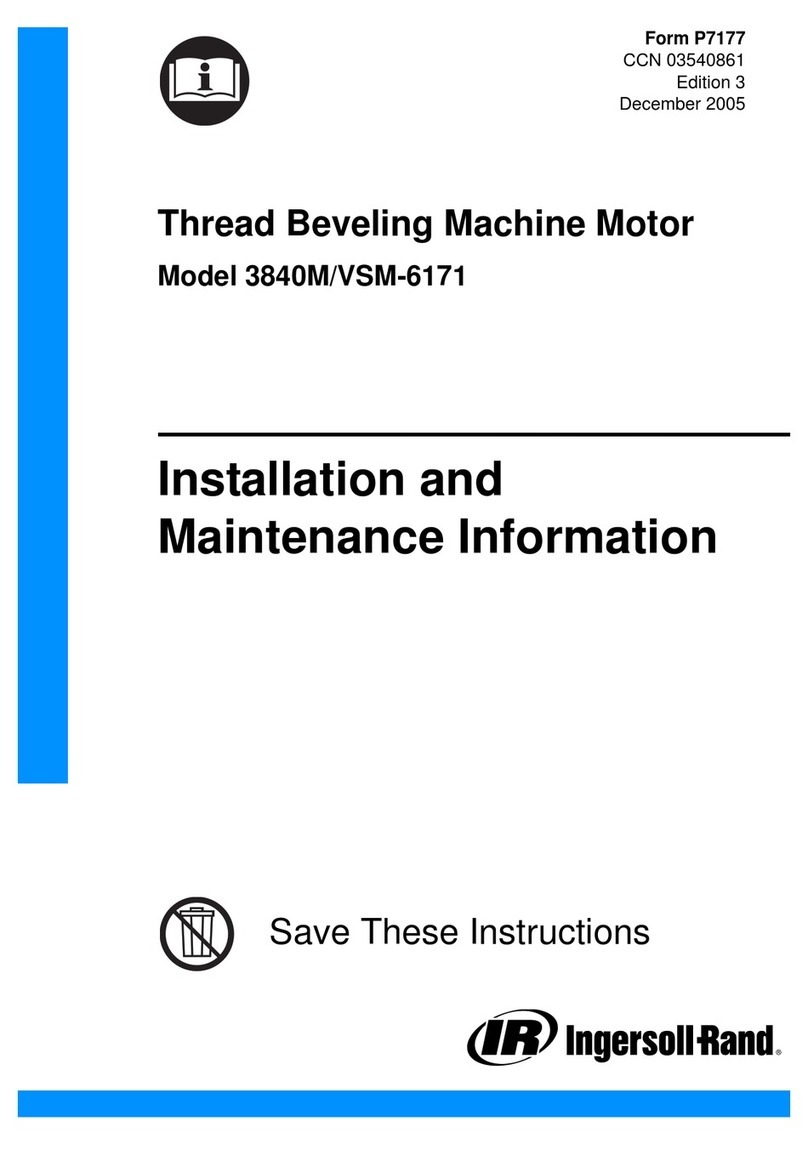

Needle Bearing Inserting Tool

(Dwg. TPD786)

SHOULDER TO

REGULATE DEPTH

PILOT TO FIT I.D. OF

BEARING.

LENGTH OF PILOT TO BE

APPROXIMATELY 1/8”

LESS THAN LENGTH OF

BEARING

Periodically check the Regulator Mounting Screws (40),

Gear Case Mounting Screws (57) and Adapter Mounting

Screws (66) for tightness.