Jets Munt MERLIN M70XBL User manual

Merlin M70XBL-100XBL-140XBL-166TS-200XBL

Instruction Manual

(Version 1.4/2018)

Torrent d’en Puig, 31.08358, Arenys de Munt, BARCELONA,Spain

Tel/Fax: +34 93 7950113

www.jets-munt.com

E-mail: sales: [email protected]

service: service@jets-munt.com

©

Copyright 2018, Jets Munt SL. All Rights Reserved

Merlin Instruction manual V1.4 Pag: 2

Welcome!

Congratulations on the purchase of your new Jets Munt gas turbine engine. Jets Munt are

dedicated to the design and production of engines to the highest standards of quality and

reliability to bring you the customer the very latest next generation engine designs.

The MERLIN “XBL” and ”TS” models are the result of an intensive effort of design and tests by

the Jets-Munt staff. During the development period we made extensive use of the latest

Computational Flow Dynamics programs allowing us to optimize the engine performance

characteristics, and use the latest technology in electronics.

PLEASE READ!

The Jets Munt SL responsibility is limited exclusively to the repair of the engine and

accessories which are outlined in the conditions of warranty.

Before unpacking the engine, please read the manual, and agree to the conditions of

warranty.

Customer satisfaction is important to Jets Munt SL. Technical support is available trough your

local dealer and trough email.

Jets Munt S.L

Torrent d’en Puig 31

08358 Arenys de Munt

Barcelona. Spain

Web site: www.jets-munt.com

E-mail: service@jets-munt.com

Fax: +34 93 7950113

Legal and Disclaimer

The engine design and the contents of this manual are copyright by Jets Munt SL, Arenys de

Munt, Barcelona, Spain. All rights reserved.

This manual, the pictures and data are property of Jets-Munt and cannot be used or reproduced

in any way without written permission from Jets Munt SL.

Disclaimer

The MERLIN SERIES engines are a sophisticated piece of machinery. Care should be taken at all

times when using the engine. It should only be operated by those with the appropriate skills and

knowledge to do so. This engine is not a toy. Incorrect operation or misuse can cause damage to

property and bodily harm operators, spectators and animals. Jets Munt SL accepts no liability for

any kind of damage which may occur.

Jets Munt SL assumes no responsibility for any errors contained in this document and is not liable

for any damages resulting from such errors.

It is forbidden the use of this engine outside Radio Control applications,

especially those that power vehicles that carry people.

Merlin Instruction manual V1.4 Pag: 3

Warranty

The warranty period for the MERLIN engines is 2 years from the date of purchase, or 25 running

hours, whichever comes first. Warranty is valid solely for the original first owner and is non

transferable upon resale.

Warranty includes all supplied parts, and is limited to manufacturing and material defects only.

Shipment costs forth and back, including packing and customs fees are not covered by the

warranty and will be always at owner expense.

Damage or defective operation covered under the warranty terms will be repaired and tested at

no cost the original owner (other than shipping expenses). Repairs not covered under the terms

of warranty will be carried out by Jets Munt SL or their appointed agents after agreement of

costs.

Before returning the engine or ancillary equipment for service of repair, please contact first to

your local dealer or Jets Munt central office to agree action and costs. Do not ship before

contacting JetsMunt!! Shipping anything from outside the EU without appropriate dicuments

will introduce delay and costs at customs.

Please do not disassemble this engine or any other item supplied (ecu, pump, etc). You will

breach your warranty agreement and you will find it is a precision assembly which you will be

unlikely to re-assemble without considerable difficulty and specialist equipment. Simply

slackening the spinner nut of the rotor will immediately lose the delicate balance condition,

without which the engine may not run without damage to its rotating assembly.

This warranty is void if any one or more of the following conditions applies. In such a case Jets

Munt will accept no responsibility for any damage or any other consequence caused by the

engine operation.

1. The product has been subject to any form of operation whilst containing incorrect fuel, oil, or

fuel/oil mix.

2. The product is crash damaged, pump is blocked due dirt ingestion, electronics or pump are

flooded by fuel, connection leads are cut or lost its isolation and short-circuit, reverse polarity on

battery, etc.

3. Unauthorized maintenance or modifications have been made to any part of the product;

including the unlocking of the ecu and changing the manufacturer settings or any of the items

supplied has been disassembled.

4. Parts have been damaged by ingestion of foreign objects (e.g. wires, sand, water etc).

5. The engine has been operated incorrectly.

6. The product has been misused, neglected or inadequately maintained.

7. Damage to the engine where blockages in the fuel system have occurred by unfiltered or

contaminated fuel.

Merlin Instruction manual V1.4 Pag: 4

Jets-Munt Representatives:

Check the current dealer list on our web page, www.jets-munt.com

Safety Notes

Please remember the engine is not a toy and has the potential to cause bodily harm to you and

others if misused. The MERLIN engine is a sophisticated piece of machinery and should be

treated with a high level of safety when it is in operation. It is your responsibility as owner, to

ensure safe, careful and considerate operation of your engine at all times, and in accordance with

the manufacturer's instructions.

If you sell or give away this engine, please pass these instructions to the new owner.

The following guidelines should be read carefully and adhered to.

1. Always keep a CO2 or similar fire extinguisher of at least 2Kg of CO2 contents close when

starting and operating the engine. Don’t use a powder extinguisher.

2. Always protect eyes and ears during the starting procedure.

3. Be aware of the extreme intake suction hazard, we advise the use of a suitable commercial

wire mesh Foreign Object Damage guard to protect the engine intake. Ensure you have no loose

items of clothing (ties, etc.) or equipment which can readily be sucked into the engine intake,

even from adjacent to the engine.

4. Always operate your engine in open air away from confined spaces as the engine exhaust

contains gases which can cause asphyxiation and nuisance smells.

5. Do not touch the engine whilst it is running. Turbines rotate at a very high rpm and the engine

casing and exhaust can reach very high temperatures. Ensure anything affected by heat is kept

well clear of the engine and exhaust during operation.

6. Never use the engine near to sources of flammable gases, liquids or materials.

7. Keep unauthorized persons, spectators, children and animals well away from the starting area

(at least 30ft or 10 meters away).

8. Always handle turbine fuel and oil with care as they are highly flammable. Store them in

appropriate labeled containers. Never dispose inappropriately. We recommend the use of suitable

disposable protective gloves for the mixing of turbine oil/fuel. Turbine oil can be are hazardous to

health and must not be allowed to come into contact with skin, mouth, eyes or through

ingestion, accidental or otherwise. Take care when decanting and ensure any spillage is wiped

away immediately and clean any affected area with warm soapy water. Wash hands and any

affected part immediately after any contact.

9. Continual failed kerosene starting or excessive priming of the fuel system can cause excess

fuel to build up in the engine chamber which can cause flaming on eventual ignition. If fuel

excess is suspected the only way to drain the engine is to tip the engine forward and allow the

fuel to exit through the fod screen and mop up with a rag. It is no use tipping the engine with

Merlin Instruction manual V1.4 Pag: 5

the exhaust downwards as excess fuel will not be released due to the ngv being mounted

forward of the engine rear.

MERLIN SERIES Specifications

M70XBL

M100XBL

M166TS

M200XBL

Dimensions:

Diameter 75mm;

Length: 185mm

Diameter 90mm

Length: 204mm

Diameter102mm

Length: 240mm

Diameter 110mm;

Length: 265mm

Weight:

676g (engine)

832g total

installed

950g (engine).

1085gr total

installed

1.420g (engine).

1535gr total

installed

1.550g (engine).

1680gr total

installed

Nominal thrust

@ 15C and

sea level:

70N

100N

166N

200N

Max.RPM:

172,000 rpm

152,000 rpm

125.000

115.000

Idle RPM:

50,000 rpm

42,000 rpm

32.000

30.000

Idle thrust

2.8N

4N

5.5N

7N

EGT @ max

rpm

550-650 ºC

550-650 ºC

650-700ºC

650-725ºC

Fuel

consumption

0.2 kg/min

0.28 kg/min

0.46 kg/min

0.55 kg/min

Minimum

exhaust

diameter:

65mm

70mm

80mm

85mm

Battery:

Reccomended 2s

Lipo/>1500mAh

Optional 3s Life

Reccomended 2s

Lipo/>1800mAh

Optional 3s Life

Reccomended

3s

Lipo/>2000mAh

Optional 3s Life

Reccomended 2s

Lipo/>2200mAh

Optional 3s Life

Glow plug

voltage typ.

6.0V

6.0V

8.0V

5.5V

Pump RPM at

Ignition typ:

75 rpm

100 rpm

75 rpm

100 rpm

Minimum ecu

soft version:

7.41

7.39

7.41

7.39

Restart:

Yes

Yes

Yes

No

Fuel/ oil:

Kerosene/diesel + 4% Oil See page 17 for oil types and percentages

Engine Description

The engine is a turbojet of a single shaft design specifically designed to power RC aircraft. The

engine starts automatically thanks to an installed electric starter situated in the front. The

starting sequence is controlled by an electronic unit that initiates the starting sequence and

controls the parameters of the engine within the design limits.

The engine uses a system of direct liquid preheating, ignited by a long life ceramic glow plug

situated inside the engine. After the initial preheat the liquid fuel is gradually introduced. The fuel

should contain a small percentage of oil and uses part of this fuel to lubricate its two ceramic

high speed bearings.

The fuel for the engine is provided from an external fuel tank through a small electrical pump

that uses a three phase brushless motor. The engine speed between idle and maximum is

Merlin Instruction manual V1.4 Pag: 6

controlled by varying the speed of the fuel pump through an electronic controller called an ECU

(electronic control unit), that is connected to the engine trough a 3 wire digital data bus.

Installation Notes

1. The engine should be mounted using the strap mount supplied or an approved equivalent.

2. The connection cables from the engine to the ecu should be carefully routed away from the

engine intake so there is no possibility of accidental ingestion of the wire. Avoid placing the

cables close to the internal magnetic RPM sensor wich is located under the black cover at

approximately 2 o’clock when looking the engine from front with the electric connector at 12

o’clock. Cables too close can cause erratic RPM reading during startup.

3. Fuel pipe should be routed similarly clear of the intake.

4. The centre of the fuel tank should be mounted as near to the centre of gravity (CofG) of the

model as possible. This will minimize the CofG shift as the fuel is used during flight.

5. Any air ducting to the inlet of the engine must have sufficient diameter of at least twice of the

engine intake diameter.

6. If an extended exhaust duct is required, it should be of sufficient diameter and strength for

optimum engine performance. Leave a gap of 25mm between end of the engine exhaust to

exhaust tube (excluding bell mouth length)

7. Extreme care should be exercised to ensure that no foreign object, loose parts of the model or

debris are allowed to enter the compartment where the engine is installed.

We recommend testing the engine on a test stand prior airframe installation.

You should have a clear idea of how to arrange the components needed to run the engine inside

the model. The main issue is the fuel tank, you will need to arrange the CofG in the centre of the

tank and adjust the receiver and ECU batteries to achieve the correct location.

Electronic Control Unit (ECU)

The ECU is custom designed for the MERLIN engines and must not be

changed for any other, as this may result in improper control of the

engine. Your engine has been set up and run with this ECU at the

factory and the settings should be left as default. The ECU plugs into

your receiver throttle channel and is powered from the receiver

rechargeable battery. The ECU is pre-programmed and only requires

simply setting to your radio. The ecu is HV tolerant, accept voltages up to 10V in the throttle

connection.

ECU Data Terminal

The data terminal plugs into the ECU via the lead

supplied. The display can be used for starting and test

running. This socket also doubles as digital connection to

a computer. The display can be installed permanently on

board.

Merlin Instruction manual V1.4 Pag: 7

This Smart Data terminal includes dedicated screens for radio checking, last shutdown cause and

other special turbine operations. The most innovative and useful function is the internal

recorder/playback function. The terminal continuously stores all the data received from the ecu,

keeping in its permanent memory all the data of last 66 minutes of engine run, without the need

of the memory card. After the flight, the terminal can be pulled out of the plane and, without

connecting to the ecu, just using a 5-10V battery, the data stored can be played back in real

time, same presentation as if the engine was running. Playback mode can be still, forward or

reverse, speed x1, x 10 and x100 in both directions, so that would be easy to investigate any

issue at the field without the need of a computer or any other type of reader.

All the data, including all engine parameters, can be saved later to a memory card, where it can

be read using a text editor, or our viewer software. Also this data can be sent to engine

manufacturer to be studied. A detailed description can be found in last page of the present

manual.

The function of the buttons is described later in the “ECU setup”.

Engine installation: Electrical connections.

Connect the power lead of the battery to the

battery socket.

PLEASE: DOUBLE CHECK THE BATTERY

POLARITY BEFORE CONNECTING IT TO

THE ENGINE.

A reverse polarity connection will

immediately damage the electronic

components on both the ecu and the engine.

See the table on page 5 for the recommended

Lipo battery. Optionally is possible to use an LiFe battery of 9,9V /25C, although the engine run

better with the recommended Lipo battery. Other battery voltages are not supported. Battery

should be connected directly, DO NOT use switches (electronic or mechanical), electronic

regulators, diodes, voltage regulators, etc. Multiple battery operation using a “Y” lead is possible,

but at least one battery must be directly connected to the ecu.

Connect the throttle channel from your receiver to the socket in the ecu labeled “throttle” and

the data terminal to the socket “Terminal”. Maximum voltage at throttle input port is 10V.

Connect the fuel pump to the ecu. Check

the colors. If connector is placed reversed,

the pump will run backwards.

Merlin Instruction manual V1.4 Pag: 8

Connect the 3 wire powerbus to the engine

and to the ecu. This lead can be extended.

Although Data signal can be used with lead

lengths up to 10 meters, the power looses

on power wires (red and black) will increase

with length, so thicker cooper section must

be used on long lengths. Up to 1 meter,

1mm2 section is OK. If you make your

own extension lead, DOUBLE CHECK

THE POLARITY. You will damage the

electronics inside the engine if polarity is

reversed.

Engine installation: Fuel system

Install the fuel system components as seen in the above picture.

Pump: Note that the fuel pump has an arrow engraved in the front face

indicating the direction of the fuel flow. There are 2 types of pumps. Model

1304 are used on the engines up to 120N; model 1307 is used on engines

from 120 to 220N.

Fuel filter

The fuel filter must be installed close to the input port on the pump to prevent any particle to

enter in the pump and to damage it. Use a suitable length of the clear tubing supplied and keep

the tubing on the suction side as short as possible. Direction of flow inside the filter is not

important, but should be always the same after first use. Install the filter in vertical position with

the exit on top to not leave air trapped inside. Do not run the engine without the fuel filter.

Do not place anything (fuel filter, flowmeter, etc.) on the fuel line between the pump and the

engine. Check that the fuel line has the bends at suitable radius to prevent to the hose to be

pinched.

Finally connect the fuel pump and the battery to the ecu as shown.

The fuel pump is a delicate element, dropping it on the floor can

damage it, always handle with care. Never disassemble the fuel pump;

warranty from pump manufacturer will become void.

It is strongly recommended that, after a new installation or modification on the fuel system, to

disconnect the fuel hose from the engine, routing it to a appropriate container, and run the pump

few seconds using the “pump test function” on the ecu so that some fuel clean all the possible

dirt particles that could have entered in the system during installation.

Merlin Instruction manual V1.4 Pag: 9

ECU (Engine Control Unit) Set Up

The new ECU system of the XBL series is of modular design. All parameters concerning the

engine operation and run timers are stored in the engine and transferred to the ecu during power

up, enabling the replacement of the ecu without any adjustment, or, replacement of the engine

without readjusting the ecu, even with a different engine model. Check the table on page 5 to

check the minimum software version compatible with your engine model.

Parameters related to the installation, like radio setup, are stored in the ecu.

The ecu system supplied (ecu and engine) has been already tested and programmed at factory

for your engine. The engine has already been set up and tested using the same ECU and pump

supplied so there is very little to adjust in order to get the engine running, only the alignment to

your transmitter is necessary.

Confirm you have connected the ECU input to the throttle channel of your receiver,

DISCONNECT the ecu battery, and connect the Data Terminal into the ECU. Remove all rates,

mixes and throttle travel settings in the transmitter. Before doing any adjustment on the ecu,

check that your transmitter is sending the correct signal by checking the reading of “Pulse” in the

data terminal. It should be between 900-1050uS at STOP position, between 1100 and 1300uS at

IDLE position and between 1800 and 2200uS at Full Power position. Please note that these

readings on the ecu are measured directly from the signal received from your RC system, so you

should readjust your transmitter if the values read are outside that the ones suggested.

The setup assumes the use of a transmitter with manual trims.

If you use a TX with digital trims, is essential to use the switch in the TX programmed

for the function "Throttle cut", or “engine cut” which normally has the effect of

producing the “trim-down” function. Using a digital trim cause unstable idle, and

delay in shutting off the engine in emergency.

Check your radio manual for this before you start. Avoid using the digital trim if

possible.

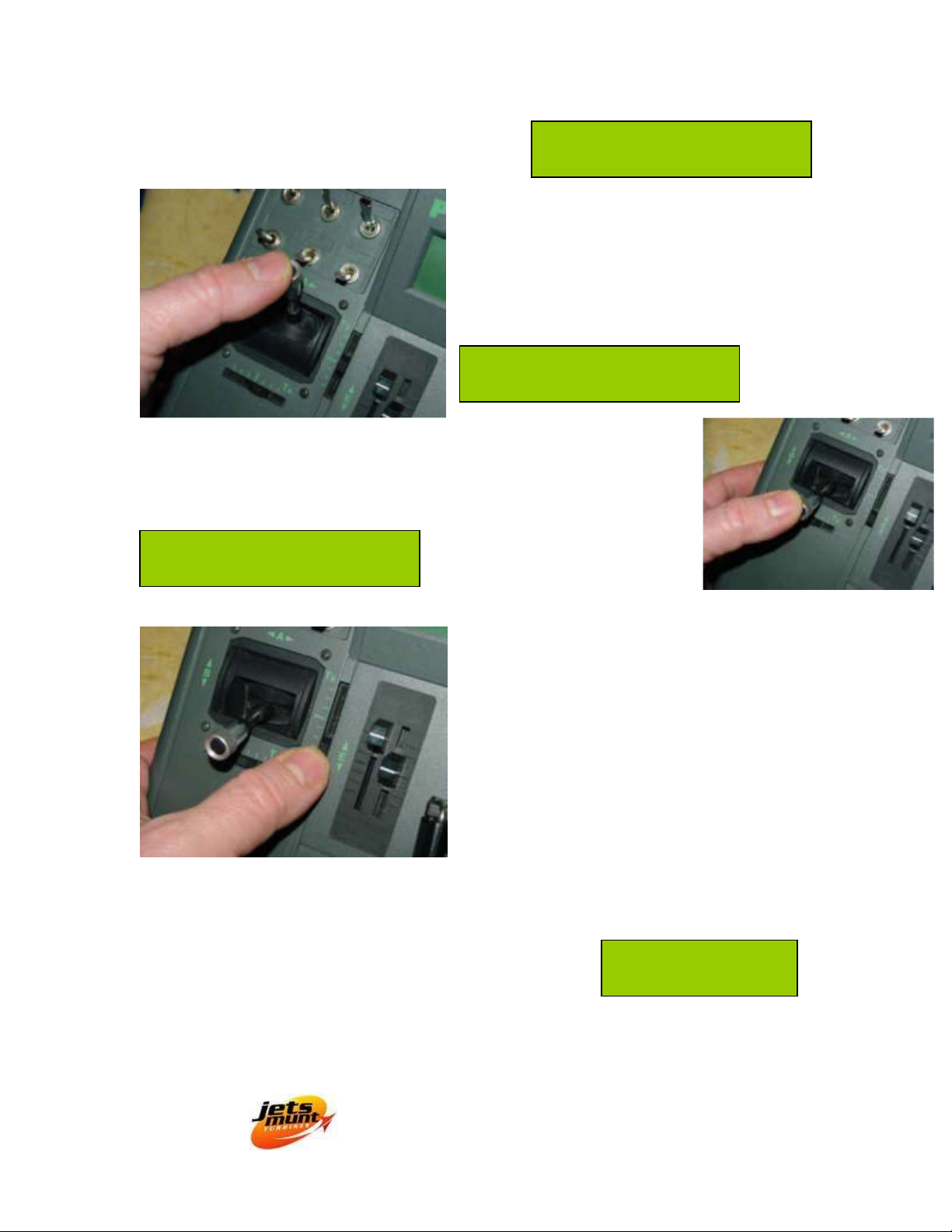

Aligning transmitter with ecu

As the display does not photograph well we have reproduced the display readings as a green

box. Turn on the transmitter and receiver. The

opening screen should show as below:

Note there are four buttons on the display, two on

the left and two on the right hand side. The left buttons move to the different screens and the

right buttons are used to change the values stored.

Press the second, left button and scroll through the

menus until you find the one showing:

Press the (-) button and the display will show the “Radio” parameters menus. First screen shows

graphically the current adjust on the radio. Press the (^) button to enter in the menus to adjust

the radio.

Trim Low T=020ºC

RPM 00000 PW 000

Info Run

Start Radio

RPM 00000 PW 000

Transmitter yes

adjust

RPM 00000 PW 000

Merlin Instruction manual V1.4 Pag: 10

Press the (right hand button (+)) to confirm that you

really want to program the radio. The screen will

change to:

On your transmitter, raise first the trim to full, and

next the throttle stick to full, in this order.

Ensure stick is firmly against the stop.

Now holding the stick against the stop, press the

right button (+) to store the signal from your TX

into the ECU.

The screen will now change to:

Move the trim to low (or switch the “engine cut” switch to On) and throttle stick

back to zero and again press the right hand button (+).

The display will now change to:

Leaving the throttle stick in the minimum position,

raise the throttle trim to the full up position or

switch “Engine Cut” switch to off, and again press

the “+” button to store the Idle position into the

ecu.

If you have done all steps correctly the blue LED

in the ecu will light up flashing 2 times in the ECU

when the “Idle” command is received, meaning

that trim and throttle stick are set to idle positions

on the transmitter. Lower your throttle trim and

the LED will change to a single flash sequence

indicating correct reading of the transmitter engine

shut off signal by the ecu.

On some Futaba transmitters, it has been found that the throttle channel the sense of movement

may require reversing (Servo reverse) and to repeat the transmitter alignment.

The correct adjustment of the throttle adjustment on the ecu

can be verified in the second screen of the data terminal, the

percentage of the throttle position should read 0% at the

position of engine stop (trim and stick down), 100% with

stick/trim full up and between 10% and 30% at idle.

This now completes your radio setup and should only need doing again if the radio settings are

changed.

Stick Up Trim Up

(Full power) Ok

RPM 00000 PW 000

Stick Down

Trim Down (Stop) Ok

T=020’C

RPM 00000 PW 000

Stick Down

Trim Up (Idle)

Pulse=1000uS 0%

Battery: 7,2V

Merlin Instruction manual V1.4 Pag: 11

Failsafe:

Never fly with the failsafe set to “hold”. It is strongly recommended that you setup your

radio system with the correct failsafe settings. In some countries is mandatory that the engine

stops in 2 seconds in the case of a failure of the radio link.

To program correctly the failsafe on your radio:

1) Adjust the travel of the throttle channel from -100% (stop position) to +100% (full

power)

2) Adjust the ecu to your radio as described above.

3) Adjust the failsafe position of the throttle channel in your radio to a -125%.

If all is correctly adjusted, the ecu will stop the engine immediately when receive the STOP

signal (-100%), but if the signal received is Failsafe (-125%) the ecu will set Idle power during 2

seconds, and, if after these 2 seconds the Failsafe condition persist, will shutdown the engine.

Once you have the radio programmed, you can check it by setting the throttle to the different

positions, and then switching off the transmitter; in this case the “failsafe” reading should be

displayed.

There are many more parameters that can be modified in the ECU, but we have specifically

programmed your ecu with the optimum settings, further adjustment should not be required and

can only be carried out by Jets Munt SL or your authorized dealer.

Preparing the engine for running.

A suitable platform/table/workbench is now required to clamp the test stand onto. Make sure this

can be easily transported outside and weight enough to ensure it cannot be blown over by the

thrust of the engine.

Select a clear area for running –keep clear of areas with loose leaves, sand or other debris that

could be picked up or drawn towards the intake. Ensure the fuel tank is position well clear of the

exhaust area and secured.

Important notes for kerostart engines. PLEASE READ

The kerostart system used on this engine is a reliable and well tested system that produces very

smooth and trouble free starts.

However, extra care and attention must be paid when starting a kerostart engine.

The main difference between gas and kerosene is that in the case of a failed ignition, the gas

dissipates quickly on the air and don't keep inside the engine. Kerosene is liquid and, if

unburned, will pool inside the engine and stay there forever. The engine can hold a big quantity

of kerosene inside. This kerosene will be ignited on next successful start up and will be pushed to

the exhaust as soon as the airflow inside the engine is sufficient, then it will be ignited in the

exhaust, causing a hot start (in extreme cases a big fireball) that surely will not hurt the engine,

but can destroy the model.

To prevent this:

Merlin Instruction manual V1.4 Pag: 12

-During the start-up listen to the engine sound to check for positive sound of ignition,

check looking from the exhaust that the kero is burning, or check for an increase in exhaust

temperature in the data terminal. A small plume of white smoke from the exhaust means that the

fuel is not burning. The fuel is pooling inside the engine. Abort immediately the start.

-Double check that the engine is not flooded. An extra security measure is to place a

manual valve between the last fuel tank and the pump intake line, to prevent that during the

process of filling the tanks or during storage, some fuel can arrive to the engine.

-After a failed start, or whatever condition that could cause that fuel be collected inside

the engine (i.e. extra priming), ALWAYS empty the engine of fuel by tilting the engine nose

down. Fuel will exit trough intake. Do not tilt upwards; due at the internal engine construction

the fuel cannot exit trough exhaust.

Another big difference between gas start and liquid start is that the kerosene can keep burning

slowly during long time inside the engine. This situation usually happen during an aborted start,

the start-up sequence is aborted by the user or automatically before the engine arrive to idle.

This can cause that the kerosene inside the engine keep burning for long time, and could destroy

the engine or the model. IF A STARTUP SEQUENCE IS NOT COMPLETED, ALWAYS CHECK FOR

FLAME INSIDE THE ENGINE. If there is flame, then set full throttle for over 3 seconds to engage

the starter and blow out the flame. USE SHORT BURSTS OF STARTER. Using the starter for long

time can destroy the starter motor. In the case that the start-up procedure has been aborted due

at starter failure, then it will be necessary to apply the CO2 fire extinguisher. A white smoke

plume from the engine is a good indication here; mean that there is no fire inside.

First engine runs.

Confirm your test stand is securely fixed to a bench or heavy table. Keep your ear

defenders within easy reach and a CO2 fire extinguisher handy. VERY IMPORTANT ON

KEROSTART ENGINES. Do not use a powder extinguisher, it will damage the engine.

Fill the fuel tank. Do not forget to filter the fuel, and to mix the oil.

Confirm all batteries are freshly charged and connected up.

Check there is a temperature reading on the data terminal.

Ensure the running area is clear of onlookers –especially the prohibited zone of a 10

metre radius 180° arc from engine centre around the rear

Verify that the fuel tube is full of fuel and purged of all air, if not; carry out the fuel prime

sequence as described here.

Priming the fuel system:

Fuel line need purging of all air after initial installation. Take extra care when priming the lines,

ensure fuel is primed only up 5cm before to reach the engine; too much fuel inside engine will

cause excessive flaming during start sequence.

Priming is achieved by a special menu on the ecu. Set the trim to low and go to “Info” menus

and next to “Pump test”. Click on “on” /”off” to start/stop the pump manually. Please observe

fuel line to engine very carefully and push the off button to shutoff as soon as fuel reaches close

to the engine. Best too short than to flood the engine.

IMPORTANT: The prime procedure should be done only to fill the fuel tube and filter

in the case of a first installation or in case of disassembling of the tubes. Do not run

Merlin Instruction manual V1.4 Pag: 13

the prime function so that the engine becomes flooded by fuel, as this will cause an

uncontrolled fire at next startup.

Starting the engine.

Set the throttle stick down and the trim up. “Idle” - Confirm that the LED in the ecu is blinking in

a sequence of 2 blinks and the screen shows

"Ready"

- !Ready to start!.

In the case that the exhaust temperature is over 100º, the ecu will power the starter to cool

down the engine. Wait until the cooling sequence finish.

Move the stick to full throttle and immediately back to idle again. The Ecu will begin the startup

sequence as described below:

First the internal glow plug will be energized. After 3 seconds, the starter will be powered up to

have the rotor turning at slow speed (3000- 5000 RPM).

Once the rotor is at correct speed, the pump and solenoid valves will be energized. Few seconds

later the kerosene will ignite and the exhaust temperature will begin to increase. The rpm and

pump power will increase automatically. During this phase the data terminal will display

“IGNITION”.

When the ignition is detected, the data terminal reading will change to “SwitchOver”, during this

phase the fuel will be routed to main injectors and the speed of the rotor will be progressively

increased to about 10,000 -15.000 RPM, depending on engine model.

Once this phase is finished, the reading will be “FUEL RAMP”. In this phase the ignition system is

switched off. The fuel flow and starter power will be increased automatically to increase the RPM

up to idle RPM. Before arriving to idle the Ecu will automatically disconnect power to the starter.

When the rotor speed reaches idle, the screen will change to “Run IDLE” and the engine speed is

adjusted to the IDLE RPM.

The engine is running!

Control of engine power/rpm is now handed back to the transmitter and controlled by the

position of the throttle stick. Increase/decrease the throttle slowly, verifying that the engine

accelerates/decelerates following the throttle command. Take special care around the engine

intake; keep your hands at a safe distance along with any other objects as they can

be easily ingested.

Engine shut down procedure:

To shut down the engine lower the trim and the stick. It is recommendable that before shutting

down the engine to restrain the model and then raise the throttle stick to approximately 25%,

allowing temperatures to stabilize for around 5 seconds before carrying out the shutdown

procedure. After the shutdown the ecu will keep the starting motor running to cool the engine

under 100ºc. A special feature on this ecu system is that the power of the receiver can be

switched off before the cooling procedure is complete. The ecu will shutdown itself when the

procedure is complete.

WHAT TO DO IN THE CASE OF AN EMERGENCY

During the start sequence the Ecu will be in charge of everything, controlling temperature and

RPM. The only thing the user can do is to abort the sequence by lowering the trim in the case

that something abnormal (excessive flames in the exhaust, etc).

Merlin Instruction manual V1.4 Pag: 14

If a problem is detected, first:

Move the trim to the low position to abort the sequence.

If there is a fire in the engine and the problem is because the starter has failed or the engine is

seized (not turning), IMMEDIATELY APPLY THE FIRE EXTINGUISHER through the intake

side of the engine, never trough the exhaust.

If there is a fire, but the rotor remains free to spin and the starter is OK, raise the trim and stick

to the full power position for 3 seconds, this will connect the starter manually to ventilate the

engine and extinguish the fire. The throttle channel acts as a starter switch.

Adjusting the engine maximum power.

The engine comes from factory adjusted for its maximum thrust. But it is possible to reduce the

maximum power if necessary. To do so, go to RUN menus and scroll the menus up to “Max

RPM”. Using the + and – buttons, you can change the rotor speed at full throttle. On engines

using ecus of version 7,42 or higher, on this screen is displayed, besides the full power RPM, the

equivalent thrust in Newton and in Lb. Please note that these figures are calculated supposing

an ambient temperature of 15ºC at sea level. Hotter ambient/higher altitude will reduce the

power output.

Autorestart function:

All JetsMunt engines except the M200 include the AUTORESTART function.

This function can quickly restart an engine automatically in Flight, but it should be understood

that such a system may cause damage to people and property.

By default this function is disabled in the ecu, the user should expressly enable it. By enabling

this function, the user agrees that he/she has understood the working principles and understands

its limitations.

Restart options and how to enable them

Within the “Radio” menu, a new choice has been added to define the restart operation.

The ecu offers 3 choices:

-Standard operation: After the shutdown the ecu should be reset (power cycled) to enable

another startup cycle. Engines are supplied in this mode from factory.

·Manual Start: user can normally shutdown the ecu trough the transmitter (by lowering the

stick and trim). The ecu will execute the normal shutdown and post run cooling. Once the cooling

is finished (temperature below 100ºC), the ecu will return to power-up state, allowing the engine

to be restarted through the normal procedure (Trim-up, cycle stick). The time to shut down and

later start is exactly the same as standard operation. This mode is useful for gliders, where the

engine is used to climb to height, shutdown, soaring, restart, climb, etc.

This mode does not pose any safety hazard besides the fact that the engine can be started

inadvertently if the start procedure is executed in the transmitter after the flight.

·Autorestart: In particular case of a fuel bubble that momentarily stops the combustion, the ecu

will detect this condition by monitoring the rpm, temperature and pump power, and then the ecu

triggers the auto restart sequence. This sequence is done with the engine hot, so the power is

restored quickly. This restarting function can help save the plane in few limited circumstances,

Merlin Instruction manual V1.4 Pag: 15

but it can also greatly increase the risk of fire, so before to enable this function, please read

and understand the following:

What does the auto-restart function does:

It automatically tries to restart the engine quickly and restore the power setting that is being

asked by the transmitter.

To trigger this function, the ecu checks:

-The radio signal is valid, no failsafe condition.

-The readings of the RPM are consistent with a flameout condition (the speed of the RPM

coasting down is between preset limits).

-The readings of the EGT are consistent with a flameout condition.

-The battery voltage is good.

-No other faults detected.

Once the ecu is satisfied that the shutdown/flameout was most likely caused by an interruption of

combustion, usually caused by an air bubble, the ecu triggers the quick restart function, where

the ignitor is energized to full voltage and the pump is started at a power dependent of the

current engine status (RPM and EGT). Once the ecu detects that the combustion has reassumed,

the starter power is set to full power to reach the idle rpm as quickly as possible, and the pump

power is increased accordingly to the real RPM increase, allowing for delays caused by bubbles

arriving to the engine. If after 10 seconds of restart the ecu doesn’t detect a stable combustion,

the procedure is aborted and the normal cooldown initiated.

What the autorestart function will not do:

-It will not restart the engine if the shutdown was caused by any fault other than a typical flame

out caused by air in the fuel system.

-It will not monitor and confirm flight conditions are optimum for a restart. Leaving the restart to

progress is the pilot responsibility and decision, depending on each particular case.

When should Re-Start function be enabled?

Restart takes an average time of 15s to establish restored level of pre-shutdown power. It is

highly recommended that Re-Start only be used on airframes capable of sustaining enough flight

for the re-start to be complete. Some aircraft examples include: lightly loaded planes, gliders, or

multiengine planes.

It is highly advised that a shutdown simulation be done before selecting Re-Start option in the

ECU Menu. Do it during a normal flight at a high altitude, then throttle down to idle then begin a

15sec count down. From this try to gauge if the aircraft can maintain controlled flight during this

time at idle setting.

If your plane cannot maintain flight for a minimum of 15sec without engine power, do not enable

the restart function.

-I’m flying my plane and the engine has shutdown with restart enabled, what should

I do:

1) Think that the chances of that the engine restart are slim. You don’t know

why it has shut down, so likely it will not restart, DO NOT RELY on it.

2) Fly your plane. Leave the throttle at mid setting and fly your plane keeping airspeed

in aft for a dead stick landing.

Merlin Instruction manual V1.4 Pag: 16

3) In case you see the plane begins to stall or an uncontrolled landing is most

likely, IMMEDIATELY set the trim and stick to STOP position to abort the restart function. A

crash with the engine running normally ends with a fireball; a crash with the engine off is not

likely to catch fire. Do not use the “digital trims” to shut down the engine, use a dedicated switch

to be operated quickly.

4) If the engine restart is initiated while on approach, evaluate if the

speed/position of the plane is still good for a safe landing, if so, land immediately, you don’t

know why the engine stopped and may stop again during a “go around” but this time the aircraft

may not be in an as favorable position. If the position/speed of the plane is not convenient, use

the engine power to go around and plan for a normal landing, BUT land as soon as possible.

5) Once the plane is on the ground, even in normal landing or crash landing, set the

transmitter in the STOP position. The engine could restart and go to full power on its own; the

ecu does not know when the plane is on the ground.

-Can I use the restart function many times?

NO!

Restart function is an emergency procedure and places a high stress on the engine

ancillary components. The starter and ignitor are fed with extra power that is not used in normal

startups, this places considerable more wear on them, also the engine is subjected to abrupt

temperature changes that could shorten its life.

Restart function is not the replacement of a poor fuel system. It can save a plane in

particular circumstances, but it can do much more harm than good. A belly landing or landing

gear damage due to a flameout induced heavy landing is more favorable than a similar landing

arrival with the engine in start phase that can possibly cause a fire and result in total destruction

of the model and or property.

Please Think twice before enabling the auto restart feature.

Disclaimer

There are no circumstances Jets Munt P/L or any of its Service Agents and employees will accept

or be held responsible for any losses or damages the Auto Restart feature causes should the

owner operator choose to enable this function.

Throttle curves.

By default the ecu control the RPM in linear way, i.e., at half stick position the engine turn at half of the

rotor RPM range. Jet engines develop the thrust in exponential mode, thus half RPM means approximately

¼ of thrust. On small engines with a high idle to full power rpm ratio, or in a high drag/low power planes,

often only the last 1/3 of the throttle stick produce significant thrust, with the low half stick travel being not

used. Although that with current digital TX the pilot can modify the throttle curve to suit his needs, three

throttle curves have been added to simplify the setup for most of the installations. These curves are

selected under the RADIO menus:

FULL EXPO: Mean linear RPM, it is the default setting and the mode used for all previous software

versions. Thrust develops exponentially, and it is the recommended curve for big engines or/and high

thrust/weight ratio planes, as it ease the control in low power used during taxi.

LINEAR: Mean that the thrust develop linearly with the throttle setting. Could cause difficult taxi, as it

would be difficult to fine adjust the power at low settings.

HALF EXPO: An intermediate setting between the other two modes.

Merlin Instruction manual V1.4 Pag: 17

Stick position

MODE

0% (Idle)

25%

50%

75%

100%

FULL EXPO

Idle thrust

6%

25%

56%

100%

% of total

thrust

HALF EXPO

Idle thrust

16%

38%

66%

100%

LINEAR

Idle thrust

25%

50%

75%

100%

Throttle curves can be changed while the engine running, so you can leave the throttle at a given position

and switch between the curves to see the difference.

Acceleration and deceleration settings.

Under the “RUN”menus is possible to change the acceleration and deceleration times. The engine is

supplied and tested from factory ready to use and usually these settings should be correct for normal use.

However the user can modify these default settings to allow the engine to run optimally in different

conditions.

Leave the acceleration and deceleration in “fast”mode when using the engine with kerosene and at ambient

temperatures below 25ºC and elevation below 500m.

If diesel fuel is used, or ambient temperature is over 25ºC or altitude is over 500m, then the engine could

experiment difficulties in accelerating. In these cases, try to set the acceleration to “normal”, “slow”or

“very slow”to find a setting where the engine operate normally. It is much better to have an engine than

respond slower to throttle changes than one that just stop when asked to accelerate faster than possible in

difficult ambient conditions!

Exhaust tubes.

The size and placement of the exhaust tube is not an exact science. The optimum tube diameter and the

gap between the engine exhaust and the tube intake is largely dependent of the airframe. An slow airframe

with big intakes will benefit of larger exhaust diameter and larger gap, to get the maximum static thrust

possible, while a fast airframe, with small intakes, bypass installation, will benefit of smaller exhaust

diameter and smaller gap, to get the maximum efflux speed.

As a general guideline, use an exhaust tube of a diameter equal or larger than the specified in page 5, with

a gap between the engine exhaust and beginning of exhaust tube (excluding the bell mouth) of 25mm. later

you can experiment moving the engine 5mm forward or aft to see if performance is better. Too larger gap

will cause hot gases to recirculate to the engine intake, decreasing performance and worsening the

acceleration. Too short gap will cause extra pipe noise and depression inside the pipe, in extreme cases the

exhaust tube can collapse due the low pressure inside (venture effect).

Use in gliders and in 3D planes.

If you plan to use your engine in a glider, please consider to de-rate your engine. The typical use that is

running at full power continuously for the entire flight in airframes that easily weight 4 times the engine

thrust is very hard for the engine, as the internal elements like combustion chamber are subjected to

maximum temperature and stress all the time, reducing the time between overhauls. We would

recommend using the engine at 80% of its maximum power in these conditions, or using the 100% for

takeoff, but later reducing to 80% during continuous climb.

We don’t recommend using our engines in 3D planes doing fast acrobatics. The gyroscopic forces that an

turbine rotor turning at +100.000RPM apply to the bearings doing a loop in less than 1s are extremely high

and can destroy the bearings or cause the compressor or turbine wheels to rub to the engine case.

Merlin Instruction manual V1.4 Pag: 18

List of ECU message codes

Here is a list of possible messages shown on the data terminal screen and their meaning.

TrimLow: Indicates that the signal received from the transmitter corresponds to the lowered

trim, that is to say, engine OFF.

Ready: Indicates that the engine is ready for starting, and that the transmitter signal

corresponds to IDLE, (LED lit twice)

StickLo!: This indicates that the throttle stick is in a position above IDLE, the engine will not

start with the stick in this position.

Glow Test: Verification of glow plug

StartOn: Test of the starter and rpm sensor

Ignition: Ignition phase.

SwitchOver: Phase of heating of the combustion chamber after detecting the ignition.

FuelRamp: Phase of acceleration until idle speed.

Run Idle: Engine working correctly, pilot have full control of engine power, command received

from transmitter is IDLE.

Running: Engine working correctly, pilot have full control of engine power, command received is

an intermediate setting between Idle and Full Power.

Run-Max: Engine working correctly, pilot have full control of engine power, command received

is Full Power

Stop: Engine off.

Cooling: Starter is operating to cool the engine.

GlowBad: Defective or disconnected glow plug.

StartBad: Defective starter, insufficient RPM reached during start, RPM sensor damaged, too

thick oil used on previous run, no cooling sequence done in previous run.

Low RPM: Engine had been shutdown because the speed has fallen below the minimum.

Usually lack of fuel (bubble)

HighTemp: Excessive temperature

Battery!: battery voltage out of limits.

No Engine data:Data bus disconnected from the engine.

Pump Overload:There is a restriction in the fuel pathe from the pump to the engine, or in the

engine itself.

Diagnoses:

During engine operation the Ecu measures and stores all the engine operating parameters

recorded during the last the 51 minutes of operation. These measures can be downloaded later

to a PC to study the behavior of the engine in flight and to diagnose any possible problems.

Also, after each cycle of operation, the Ecu stores the last cause of shut down and the values of

RPM, temperature and pump power. In order to access these measures, it is necessary to shut

down and power-up the Ecu. Set the trim down (trimLow) and push the left button on the

display. The Ecu will show the cause of last shutdown and the parameters value at the moment

of shut down. These are as follows:

Diagnosis messages:

UserOff: The engine has been shut down because it has received the shut down command from

the transmitter.

Merlin Instruction manual V1.4 Pag: 19

FailSafe: The engine has been shut down because of loss of the control signal from the

transmitter. After 0,5s of detecting a loss or invalid RC signal, the ecu sets engine power to idle,

and if after another 1,5seconds a valid signal is still not received the engine is shut down.

LowRPM: The engine has been shut down because the RPM has dropped below a minimum.

Cause could be lack of fuel, air bubbles, problem with the batteries, or defective RPM sensor.

RCPwFail: Lack of power from the radio receiver.

Other useful information and installation tips:

Fuel System

Always use appropriate containers to store fuel.

It is advisable to install an anti bubble system to the

fuel supply circuit. The simplest one is a felt filter

clunk installed into the fuel tank. This helps maintain

consistent fuel flow and greatly reduces the possibility

of air getting into the suction side of the pump circuit,

which could cause stoppages.

A BVM UAT is a best method of reducing the

possibility of air bubbles in the engine fuel

line. This is a very important aspect of the

operation of any turbine engine.

Use a appropriate adapter for the 6mm tube

output of the UAT to the 4mm in the inlet

side of the fuel pump, direction of fuel flow

is clearly shown at the top of the pump. The

clear 4mm tubing is used on the pressure

side of the pump. Clear tubing helps identify and locate any potential future problems with air

leaks.

The fuel pump and ECU can be mounted simply with a pair of tie wraps and/or Velcro.

When making any fuel line cuts use a sharp blade to make the cut squarely. The fuel filter

provided should be installed in an accessible place for regular inspection, close to the intake port

of the pump.

Fuel and Oil

1. Use CLEAN well filtered Jet A1 or kerosene fuel which is available from most airports, or

paraffin (K1) used for greenhouses available from most hardware stores. Diesel fuel can be used,

but startup time and acceleration could be worse than using kerosene. Diesel fuel vary

significantly between countries, you should test locally.

2. Ensure the fuel is clean and filtered at each stage of mixing and transfer to the model fuel

tank.

Please note the importance of using clean fuel. Failure to do so will result in blockages of the fine

fuel injectors in the engine or blockage of the engine lubrication system and subsequent bearing

damage

3. Ensure the fuel is free from moisture (water is heavier than fuel and will settle at the bottom

of the container).

Merlin Instruction manual V1.4 Pag: 20

4. Use good quality oil:

-> Aircraft turbine oils e.g. Exxon 2380, Mobil JetOil II. Mix at 4%. Do not use Aeroshell 500.

-> Mobil DTE Light turbine oil. Mix at 5%.

-> Recommended: 3% Mobil DTE Light/Shell Tellus 32/Igol Turbine 32 + 1% 2T Oil fully

synthetic (JASO FC)

DO NOT USE TCW-3 oil. Don’t use JetCat oil at 5% on VT80/M100 engines.

5. The fuel must be mixed with oil in the recommended ratio. Too little oil will shorten the

bearings life. You can use higher content of oil (5-6%) without any problem for the engine to

share the same fuel with other engines. 2T oils are not recommended because they tend to

become sticky after use, causing the starter to fail to reach enough rotor speed for a successful

start, ecu displays “Bad Start” Message.

Please remember to always handle fuel and oils with care! Avoid all direct contact with skin –in

case of contact wash all affected areas with soap and warm water immediately.

Feed Pipes

All the pipes must be Polyurethane or nylon as provided by Jets Munt or Tygon (like the ones

used by gasoline engines). Do not use Tygon on the pressure side of the fuel pump. Silicone

tubing must not be used anywhere in the installation as it is dissolved by fuel and oil. If in doubt,

take a small piece of tube and submerge it in kerosene for a few days and verify that its

characteristics have not changed.

Maintenance

1. Always keep the engine and its accessories clean and dry.

2. Regularly check wires for chafing or insulation breakdown etc.

3. Regularly check fuel pipelines for chafing and /or leaks at joints.

4. Check the engine and mounting for loose fittings and secure if required.

5. Ensure the fuel system is kept free from dust and dirt inclusion and that fuel is carefully

filtered.

Engine storage

1. Disconnect the ecu battery after the flight session. At “power off” there is a small current

taken from battery that can fully deplete a 2.000mAh battery in about 1 month.

2. In winter storage, it is recommended to store the engine inside a sealed plastic bag to prevent

moisture and dirt to collect inside the engine.

Running Time Counters.

Using the second left hand button, scroll through

the menu’s to the INFO menu.

This screen contains a timer which shows:

The total running time of the engine in minutes

(Tot),

The time in seconds of the last engine run (Last)

The total number of starts (cycles - CY).

Use this screen to keep track of your total running time and starts.

An extra timer is provided, called Service Timer, to keep track of the service intervals, it will be

reset when the engine is serviced in regular maintenance.

Timer: Tot:0000m

Last: 000s Cy:000

This manual suits for next models

4

Table of contents

Other Jets Munt Engine manuals

Popular Engine manuals by other brands

Oriental motor

Oriental motor PKP Series operating manual

Weston UK

Weston UK WEST EUROTECH 36 T2 instructions

Sorotec

Sorotec SFM 1650 PV-LO Translation of the original operating instructions

RADEMACHER

RADEMACHER RolloTube Basic 2160 20 90 installation instructions

R.A. Lister

R.A. Lister SR4 Instruction book & parts catalogue

Milwaukee

Milwaukee DCM2 350 C manual