Page 2

A-10 Thunderbolt II

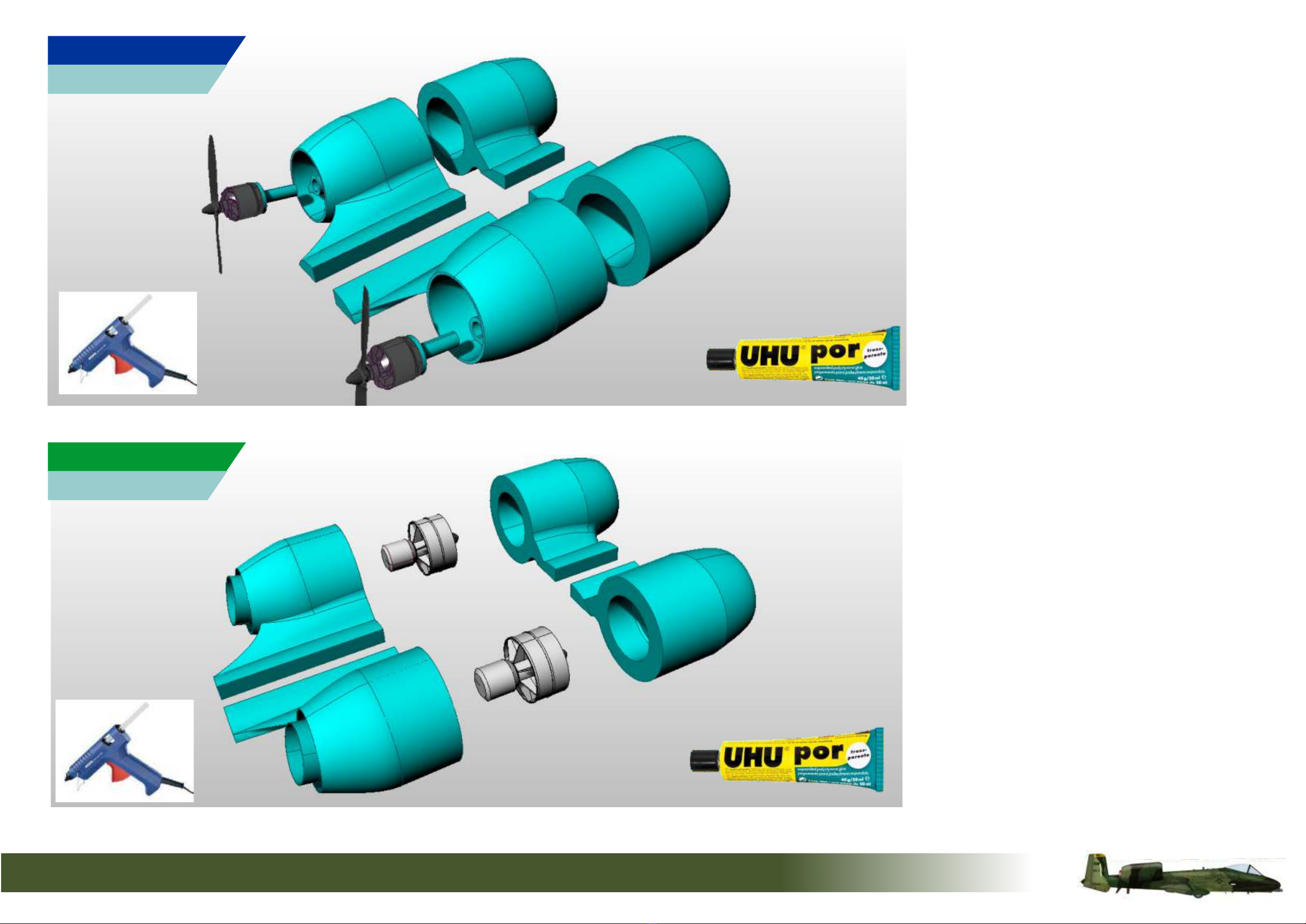

IMPORTANT. Designed for three different powerplant options, the twin

pushers / EDF option are perfectly fine taking off from undercarriage but

when hand launching, it is important to launch at 50% thrust levels and

increase steadily to avoid the downwards angled thrust from the high mounted

motors from overcoming the lift generated by the wing, forcing the plane to the

ground. The tail mounted single pusher is not affected by this affect.

‘Hog’ History Designers Notes

The first time I saw the ‘agricultural’ functional lines of the A-10, It was

unlike anything I had ever seen, and to be honest It took a bit of

warming up to.

It is probably the most brutal flying machine in the battleground,

tough, fearsome and packs a real punch with the gatling gun!

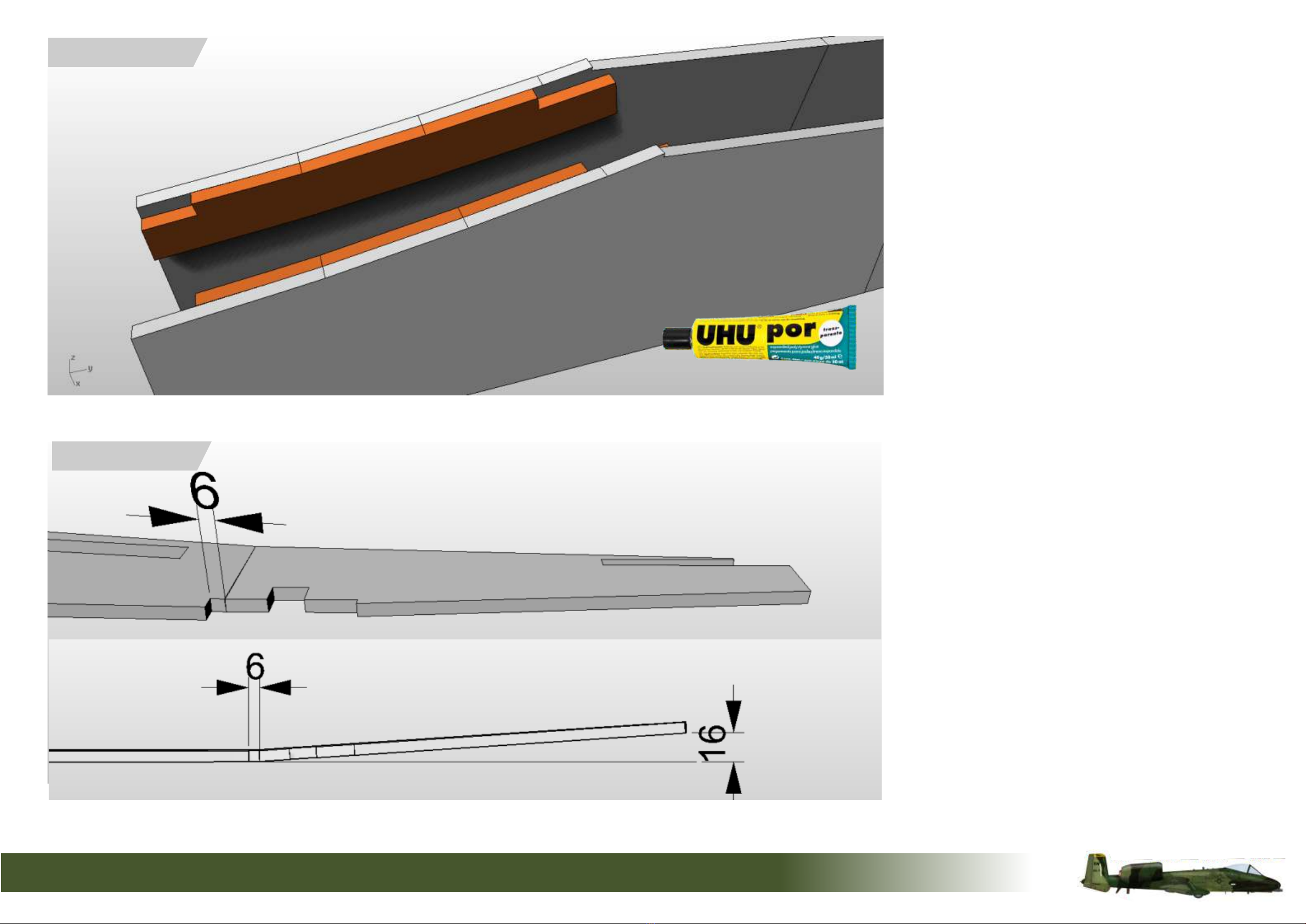

This model is at the limit of a depron sheet size, and introduces ‘crush

bending’ technique. It is also designed to house retracts and twin 5"

pushers or could be modified to take twin 64mm EDF units.

There are lots of camo patterns in existence for this bird, so you can

try the Arctic, Desert or simply grey... For me I love the Euro green

Camo scheme, as this is how I remember them in the 1980's flying

over my parents home in the UK.

Affectionately called the “Warthog” for its aggressive look and

often painted with teeth on the nose cone, the A-10 Thunderbolt

II is the U.S. Air Force’s primary low-altitude close air support

aircraft. The A-10 is perhaps best known for its fearsome GAU-8

Avenger 30mm gatling gun firing armor-piercing depleted

uranium and high explosive incendiary rounds.

The A-10 Thunderbolt II has excellent maneuverability at low air

speeds and altitude, and is a highly accurate and survivable

weapons-delivery platform. The aircraft can loiter near battle

areas for extended periods of time and operate in low ceiling

and visibility conditions. The wide combat radius and short

takeoff and landing capability permit operations in and out of

locations near front lines.

The pilots are protected by titanium armor that also protects

parts of the flight-control system. The aircraft can survive direct

hits from armor-piercing and high explosive projectiles up to

23mm. Their self-sealing fuel cells are protected by internal and

external foam. Manual systems back up their redundant

hydraulic flight-control systems helping pilots to fly and land

when hydraulic power is lost.

The first production A-10A was delivered to Davis-Monthan Air

Force Base, Ariz., in October 1975. The upgraded A-10C

reached initial operational capability in September 2007.

Specifically designed for close air support, its combination of

large and varied ordnance load, long loiter time, accurate

weapons delivery, austere field capability, and survivability has

proven invaluable to the United States and its allies. The aircraft

has participated in operations Desert Storm, Southern Watch,

Provide Comfort, Desert Fox, Noble Anvil, Deny Flight,

Deliberate Guard, Allied Force, Enduring Freedom and Iraqi

Freedom.