Page | 5

should not less than 85% of airflow when mechanical exhausting.) Mechanical

can be combined with the natural exhaust.

3. Debugging the cooler when the first running. Ensure that the operating current

at the rated current range.

4. Keep away any source of fire when assembling or operating the cooler.

5. Ensure the supply voltage is within the rated +/-10V range, otherwise it will

break the cooler such as cannot start the cooler or start and stop frequently.

6. Keep the wall controller and the control lines away from strongly EMI (such as

the equipment with frequency speed controller, SCR temperature and speed

controller, high frequency heating circuit or super high power motor etc). It is

better not to keep them at the same line of power lines, if you have to, then make

sure the distance between them is more than 30cm.

7. Please power OFF the cooler while it is raining or thundering. otherwise the air

compressor will absorb moisture.

8. The appliance must be fitted with means for disconnection from the supply

mains having a contact separation in all poles that provide full disconnection

under over voltage category III conditions, and these means must be

incorporated in the fixed wiring in accordance with the wiring rules.

9. Please make sure that the unit and power connection have good earthing,

otherwise may cause electrical shock.

10. This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

11. If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualified persons in order to avoid a hazard.

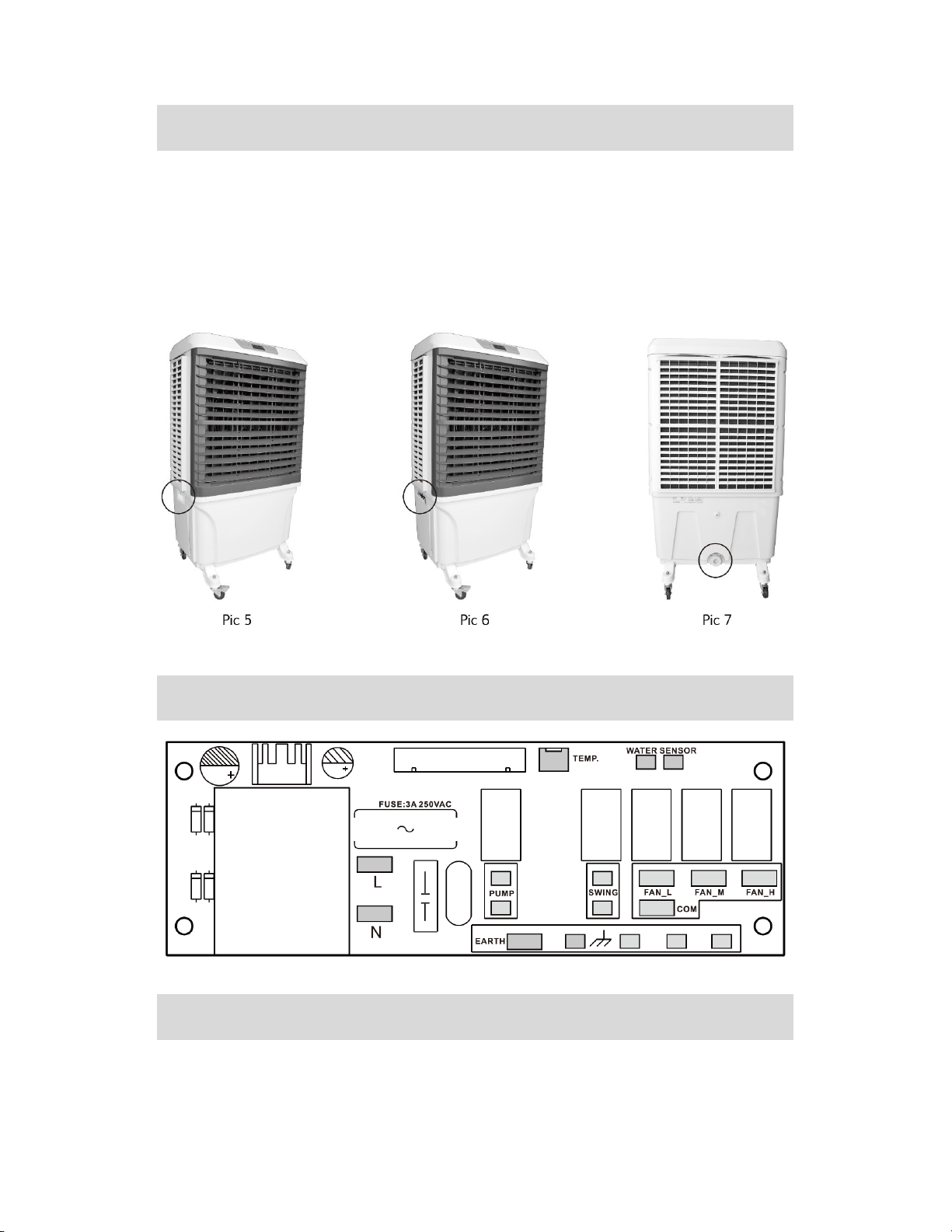

5. INSPECTION AND PREPARATION BEFORE ASSEMBLING

1. Please open the side panel to check the parts and the technical

parameters(the manual), if the parts are incomplete or breakage, Leave it as it is

.and inform us or the distributor.

2. Check if the supply voltage is same as the rated one and the supply frequency

same as rated one. Make the voltage is 230+/- 10V.

3. Make sure the water is clean with a steady hydraulic pressure,

0.2~0.6MPa(1.5~6kgf/cm2)