Spectre Module 14 Spectre Module 3

Installation

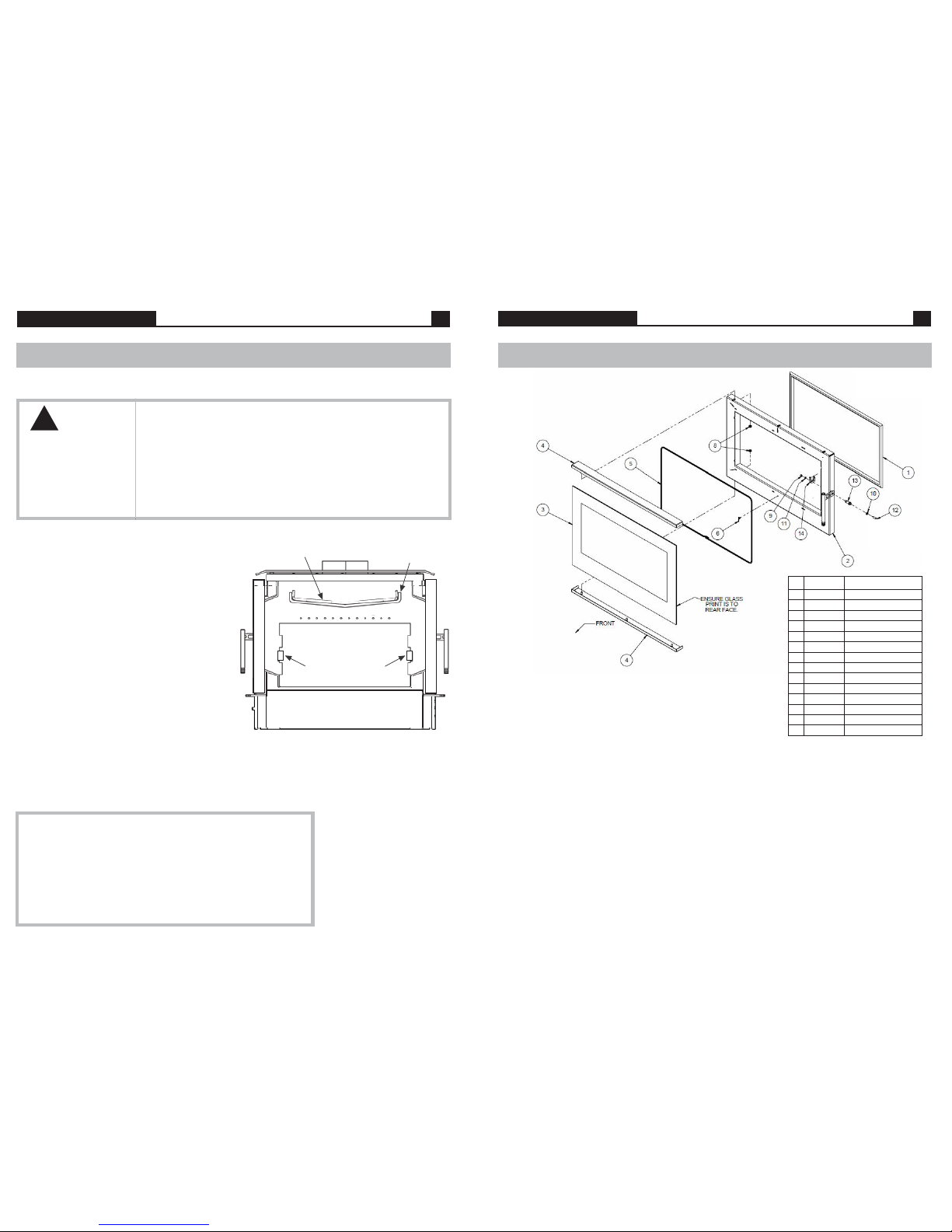

WARNING

!

Installation

THE INSTALLATION OF THIS APPLIANCE MUST BE CARRIED OUT AS PER THIS

MANUAL AND THE FLUE MANUFACTURER’S SPECIFICATIONS.

WE RECOMMEND THAT YOU USE A QUALIFIED INSTALLER TO CARRY OUT

THE INSTALLATION.

If you have any other enquiries, please contact the dealer from whom you

purchased your heater.

THIS APPLIANCE WEIGHS IN EXCESS OF 220 KILOGRAMS. EXTREME CARE

SHOULD BE TAKEN WHEN HANDLING THE APPLIANCE.

AF Gason Pty. Ltd. accepts no liability whatsoever for any interpretation of AS/NZS 2918:2001.

It is important you understand these installation instructions and minimum clearances to combustible materials before

selecting a position for your Jindara Spectre to ensure safe and correct installation is achieved.

Installation permit

Depending on your local authority requirements, a permit may be required for the installation of your heater. It is your

responsibility to arrange the same.

Flue requirements

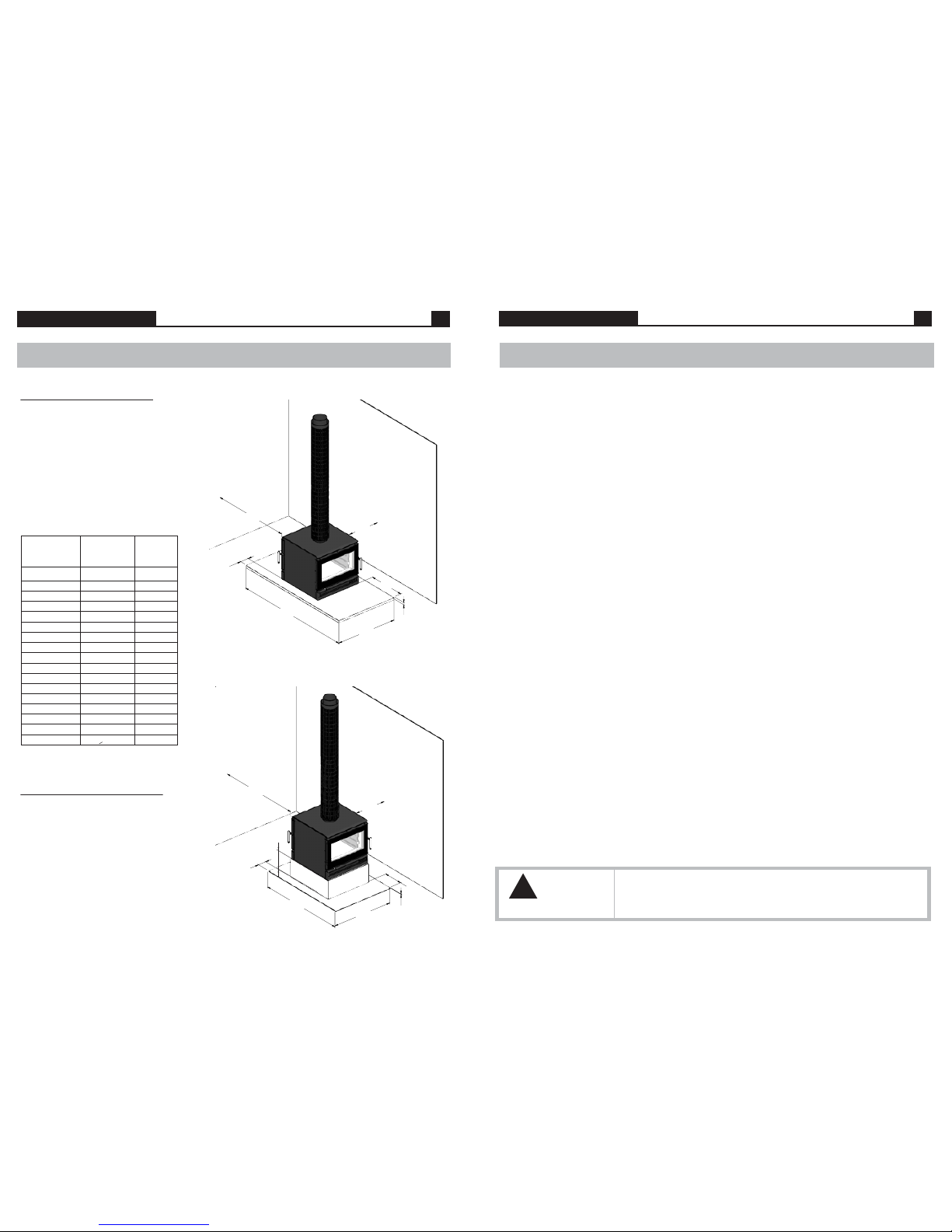

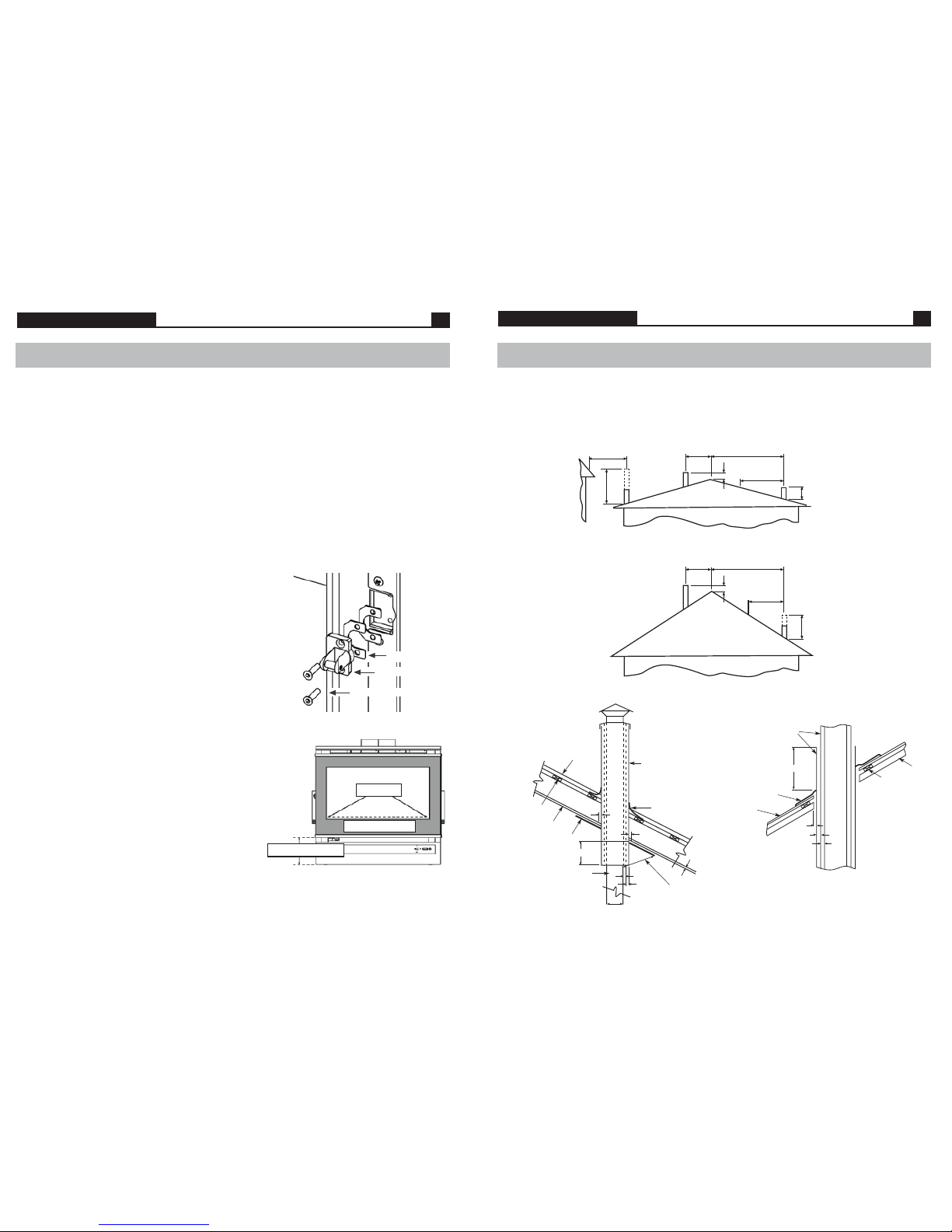

As per the dimensions in Figure 1, the Jindara Spectre can be installed with a Perforated 7” Default Flue Kit, or Figure 2,

a Solid 7” Default Flue Kit. In both instances, an additional 8” solid ue must be tted between the inner ue and outer

ue, to the height of the ceiling if any part of the unit is to be installed less than 1200mm from a heat sensitive surface.

The ue system installed with the Jindara Spectre must comply with Australian and New Zealand installation

standards AS/NZS 2918:2001, and be installed to the ue manufacturer’s instructions.

The performance of your Jindara Spectre is highly reliant on an eective ue system. In many cases poor start-up, dirty glass,

down draft which causes smoking when the door is open, and a reduction in heat outupt can all be related to the ue system

being too short, or incorrect installation. Too tall a ue can result in excess draft and short burn times along with excessive

heat output.

Clearance to combustibles

The Jindara Spectre module heater conforms to AS/NZS 2918:2001 when positioned in relation to combustible surfaces

as shown in Figures 1 & 2 on the following page. All dimensions used in this document are in millimetres and are minimum

unless otherwise stated.

These dimensions in Figures 1 & 2 state the minimum distance the Jindara Spectre can be placed in relation to any

combustible materials - plaster, wallpaper, timber, MDF, etc.

In the instance your Jindara Spectre is surrounded by non-combustible materials - brick, stone, concrete, cement sheet,

villaboard or similar, wall clearances can be reduced to 50mm. A 50mm clearance is required to ensure room air can

circulate around the wood heater during operation.

For additional clearance details, or to access the Jindara Spectre Freestanding Conformance Certicate, please contact the

Jindara Dealer from whom you purchased your heater.

Hearth & oor requirements

If the Jindara Spectre will be installed onto a non-combustible oor such as a brick, stone or concrete slab with tiles, etc.

which is at least 32mm thick, and extends at least 570mm in front of the appliance base at each door, a hearth or oor

protector may not be required.

If the Jindara Spectre is to be installed onto a combustible oor, a minimum 32mm Bellis Board, or similar non-combustible

hearth or oor protector must be placed in between the appliance and the combustible oor. At a minimum, the oor

protector must extend570mm in front of the appliance base in both directions, with a minimum overall depth of 1890mm.

The protector must be at least 940mm wide.

Firewood

Getting the most out of your rewood

Firewood is a sustainable source of energy and when used correctly can provide a cost eective form of heating in your

home. Too often poor heating results and operational issues are attributed to using unseasoned wood which leads to

excess smoking, causing creosote buildup and dirty glass. Wood should be stored in a dry place where good ventalition is

available. Freshly cut wood should be stored for between 12-24 months before burning.

Use only hardwood with your Jindara Spectre.

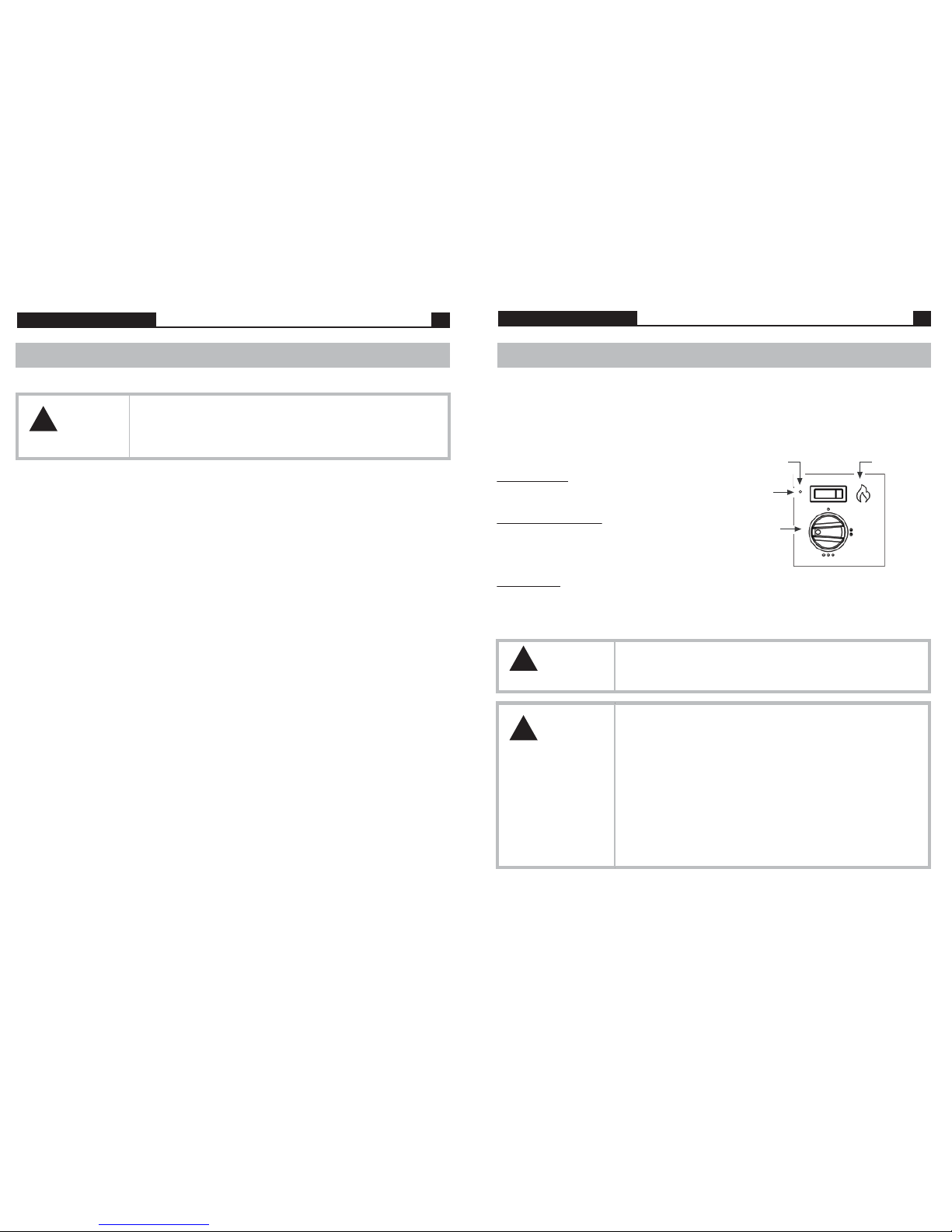

Thermal eciency

A wood’s eciency does not depend only on its type, but also on its moisture content as well as the temperature of the

combustion chamber. To achieve a greater eciency and longer burn cycle out of your Jindara Spectre, without the emissions

of hazardous particulates, your wood must be well seasoned.

Ideally, wood should not be burnt when its moisture content is above 20%. A moisture meter to measure moisture content

is a handy addition.

0% moisture

100% thermal eciency

10% moisture

88% thermal eciency

30% moisture

63% thermal eciency

50% moisture

39% thermal eciency

An example of available thermal eciency for a piece of wood as a fuel source at varying moisture levels.

The combustion process of burning wood

When wood is heated up to approximately 100 degrees celsius, moisture begins to evaporate from the fuel. There is no

heating value from the wood at this point. As moisture releases from the wood, it reduces the eciency of the combustion

process robbing heat energy from the wood. This demonstrates the importance of dry and well seasoned wood.

As rebox temperatures reach 250-300 degrees celsius, wood solids begin to break down and release volatile gases which

ignite and produce heat.

From 300+ degrees celsius, the main energy available from wood is released when fuel vapors containing up to 60% of

the wood’s potential heat is released.

Understanding combustion principles and learning how to manipulate various conditions surrounding the operation of

your Jindara Spectre enables you to achieve maximum comfort and eciency from your Australian made wood heater.

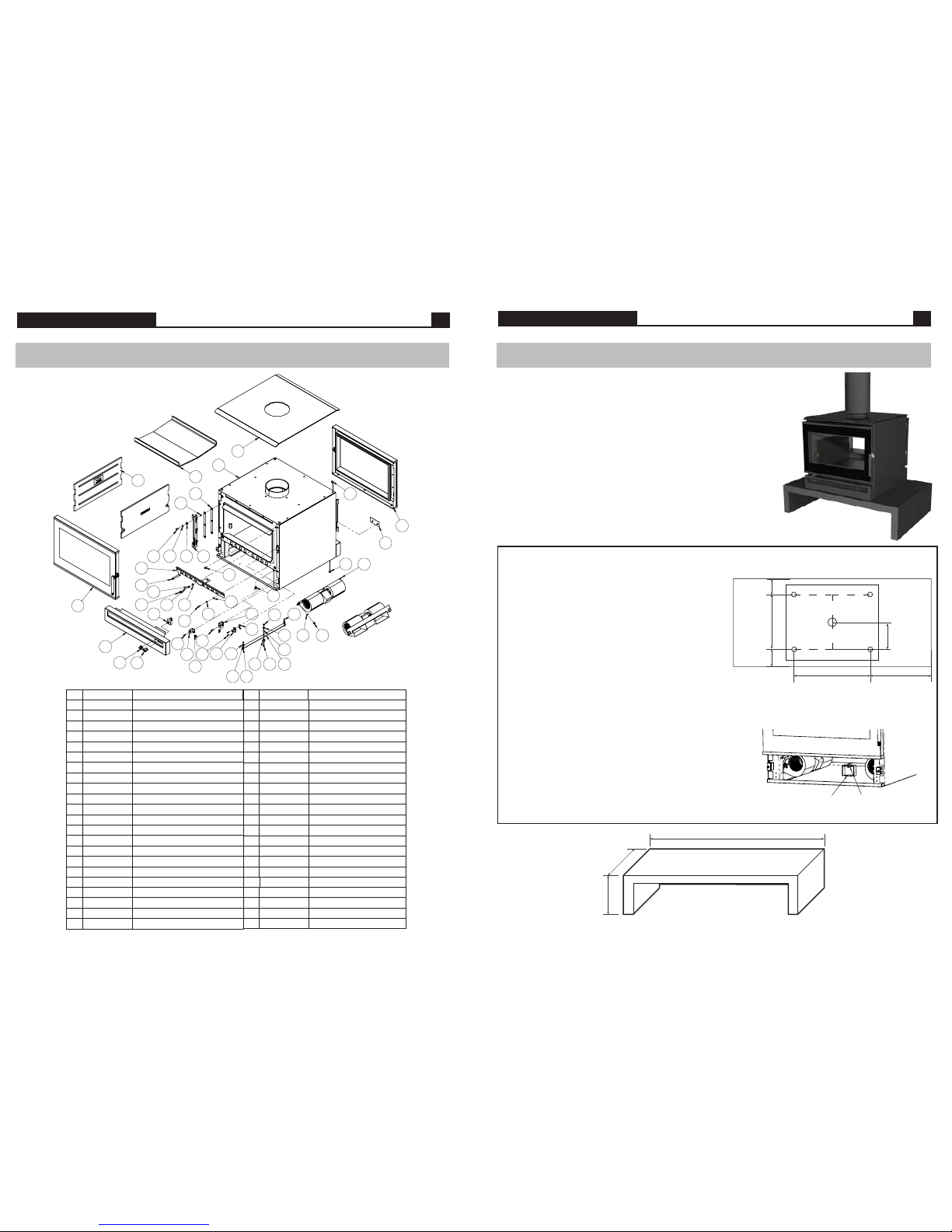

Figure 13