1. Introduction

1.1 Purpose

This document provides detailed instructions and valuable safety information regarding the ins-

tallation, electrical connection and maintenance of the following JINNENG CLEAN ENERGY

TECHNOLOGY Crystalline Photovoltaic modules, involved module series are as follow Table 1:

All instructions and mechanical and electrical requirements should be read and understood be-

fore attempting installation.

The installer should conform to all safety precautions in this guide when installing the module.

Keep this guide in a safe place for further reference.

1.2 Limitation of Liability

Because the use of this manual and the conditions or methods of installation, operation, use and

maintenance of photovoltaic (PV) products are beyond JINNENG CLEAN ENERGY control,

JINNENG CLEAN ENERGY does not accept responsibility and expressly disclaims liability for

loss, damage, or expense arising out of or in any way connected with such installation,

operation, use or maintenance. JINNENG CLEAN ENERGY reserves the right to change the

manual without prior notice.

1.3 Others

1.3.1 Modules rated for use in this application class may be used in systems operating at grea-

ter than 50V DC or 240W, where general contact access is anticipated. Modules qualified for

safety through IEC 61730-1 and this part of IEC 61730 within this application class are consi-

dered to meet the requirements for safety class II.

1.3.2 Where common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers, flat

washers and the like) is used to attach a listed grounding/bonding device, the attachment must

be made in conformance with the grounding device manufacturer’s instructions.

2. Safety

2.1 General Safety

2.1.1 Consult and follow local codes and other applicable laws concerning required permitting as

well as installation & inspection requirements, rules, and regulations.

2.1.2 PV modules should be installed and maintained by qualified personnel.

2.1.3 Use the same performance modules within a given series.

JNMP60–XXX JNMP72–XXX

JNMP60(5BB)–XXX JNMP72(5BB)–XXX

JNMM60–XXX JNMM72–XXX

2.1.4 Follow all safety precautions of all components used in the system.

2.1.5 Do not shade portions of the PV module surface from the sun for a long period of time.

The shaded cell may become hot (hot spot phenomenon), which can result in solder joints

peeling off.

2.1.6 Do not clean the glass surface with chemicals.

2.1.7 Do not drop the PV module or drop objects onto the PV module.

2.1.8 Do not concentrate sunlight on the modules or panels.

2.1.9 Do not attempt to disassemble the modules, and do not remove any attached compon-

ents from the modules.

2.1.10 Do not scratch or hit at the back sheet, the glass, the terminal box. Do not pull the ca-

bles or touch them with bare hands.

2.1.11 Do not drill holes in the frame or scratch the insulating coating of the frame.

2.1.12 Keep the PV module packed in the carton until installation.

2.1.13 Do not use modules near equipment or in places where flammable gases may be

generated.

2.2 Installation Safety

2.2.1 Wear protective head gear, insulating gloves, safety shoes, and insulated tools when

installing the modules.

2.2.2 Do not install the modules in rain, snow, or otherwise wet or windy conditions.

2.2.3 Completely cover the PV module surface with an opaque material during PV module

installation and wiring to prevent accidental charge buildup.

2.2.4 Plug in connectors tightly when working on wiring.

2.2.5 Due to the risk of electrical shock, do not perform any work if the terminals of PV mod-

ule are wet.

2.2.6 Do not touch the terminal box and the end of output cables (connectors) with bare ha-

nds.

2.2.7 Do not unplug the connector under load.

2.2.8 Do not work alone.

2.2.9 Wear a safety belt if working far above the ground.

2.2.10 Do not wear metallic jewelry, which can cause electric shock, while installing or troub-

leshooting the PV system.

2.2.11 Follow the safety regulations for any and all other system components, including wir-

es, connectors, charging regulators, batteries, inverters, etc.

2.2.12 Do not expose wires to direct sunlight. Use UV-resistant cabling.

2.2.13 Do not damage the surrounding PV modules or mounting structure when replacing a

PV module.

2.2.14 Do not change any PV module components (diode, junction box, plug connectors, etc.

2.2.15 Maximum reverse current is 20.25A for module with 6 inch cells. Use a blocking diode

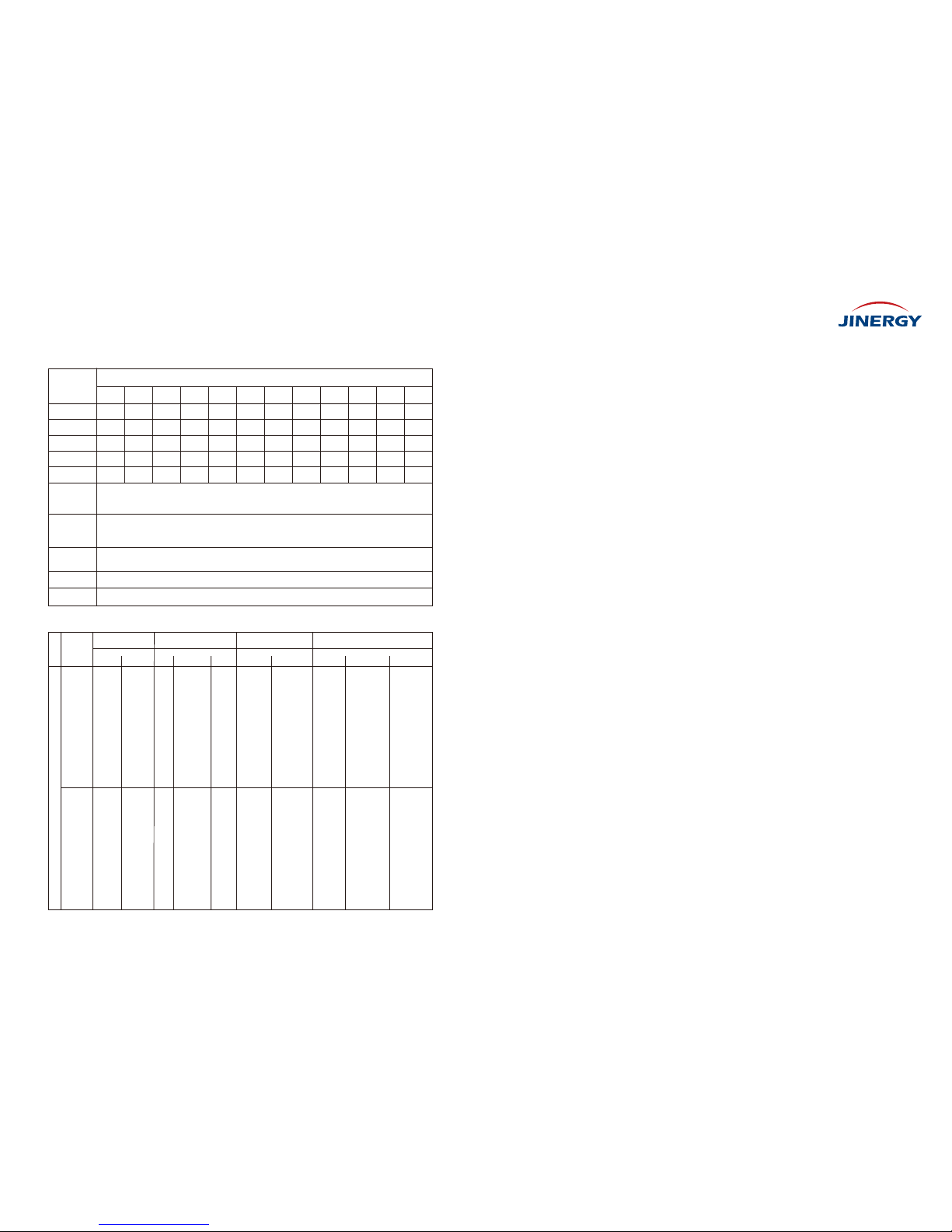

Table 1

3 4